High refractoriness under load and thermal shock resistant fireproof brick

A thermal shock-resistant and refractory brick technology, applied in the field of refractory materials, can solve the problems of spalling, low temperature, and less thermal shock stability, and achieve the effects of prolonging life, increasing the number of thermal shocks, and increasing the softening temperature under load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

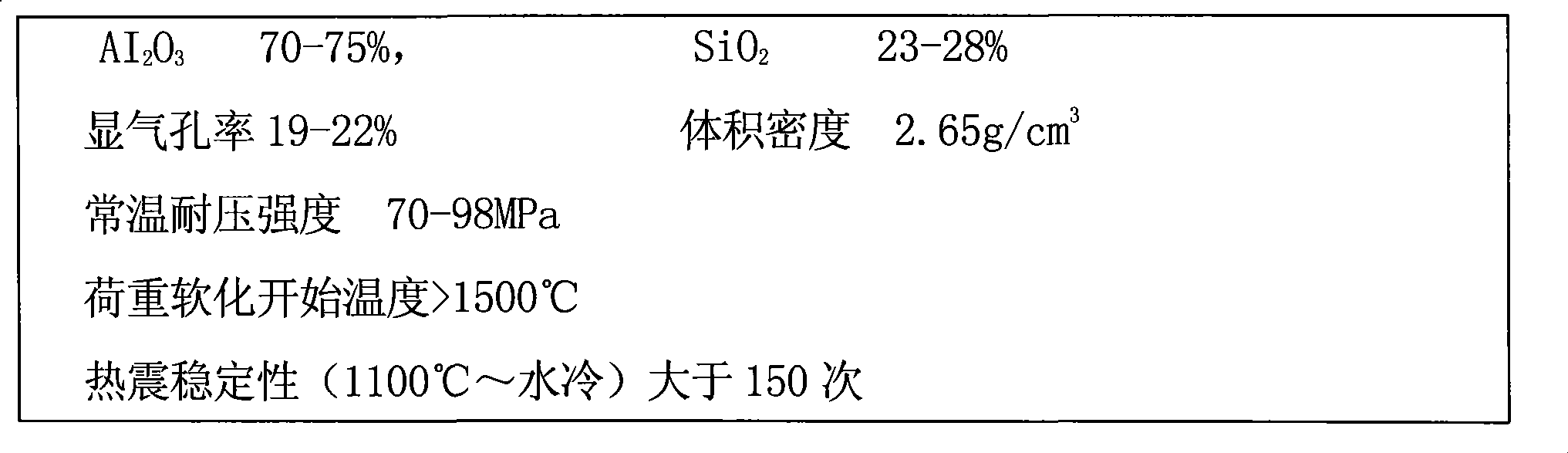

Embodiment 1

[0019] The high-load soft thermal shock-resistant refractory brick of the present invention is composed of 10% of high-alumina bauxite particles with a particle size of less than 3mm, 10% of fused corundum particles with a particle size of less than 3mm, and synthetic mullite with a particle size of less than 3mm 45% of the granular material is aggregate, add 15% of sillimanite powder with a particle size of 200 mesh, 10% of bonded clay with a particle size of 200 mesh, and add 30% of quartz sand powder with a particle size of less than 200 mesh and spodumene powder with a particle size of less than 200 mesh 10% cordierite powder with particle size less than 200 mesh 40% α-AI with particle size less than 500 mesh 2 o 3 Additive 10% compounded by powder 20% and appropriate amount of water are prepared according to the following method:

[0020] Weigh the above-mentioned high-alumina bauxite, fused corundum, and synthetic mullite granules in proportion and mix them evenly in a ...

Embodiment 2

[0022] The high-load soft thermal shock-resistant refractory brick of the present invention is composed of 15% of high-alumina bauxite particles with a particle size of less than 3mm, 15% of fused corundum particles with a particle size of less than 3mm, and synthetic mullite with a particle size of less than 3mm. 44% of the granular material is aggregate, add 15% of sillimanite powder with a particle size of 200 mesh, 5% of bonded clay with a particle size of 200 mesh, and add 30% of quartz sand powder with a particle size of less than 200 mesh and spodumene powder with a particle size of less than 200 mesh 10% cordierite powder with particle size less than 200 mesh 40% α-AI with particle size less than 500 mesh 2 o 3 6% of additives compounded with 20% powder and appropriate amount of water are prepared according to the following method:

[0023] Weigh the above-mentioned high-alumina bauxite, fused corundum, and synthetic mullite granules in proportion and mix them evenly ...

Embodiment 3

[0025] The high-load soft thermal shock-resistant refractory brick of the present invention is composed of 15% of high-alumina bauxite particles with a particle size of less than 3mm, 15% of fused corundum particles with a particle size of less than 3mm, and synthetic mullite with a particle size of less than 3mm. 35% of the granular material is aggregate, add 15% of sillimanite powder with a particle size of 200 mesh, 10% of bonded clay with a particle size of 200 mesh, and add 30% of quartz sand powder with a particle size of less than 200 mesh and spodumene powder with a particle size of less than 200 mesh 10% cordierite powder with particle size less than 200 mesh 40% α-AI with particle size less than 500 mesh 2 o 3 Additive 10% compounded by powder 20% and appropriate amount of water are prepared according to the following method:

[0026] Weigh the above-mentioned high-alumina bauxite, fused corundum, and synthetic mullite granules in proportion and mix them evenly in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com