Method for producing high-capacity 523-type ternary positive material

A cathode material, high-capacity technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of unstable grain structure, poor control of crystal transformation, and low bonding coefficient of ternary composite materials, and achieve significant implementation effects. , Wide range of uses, good product technical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

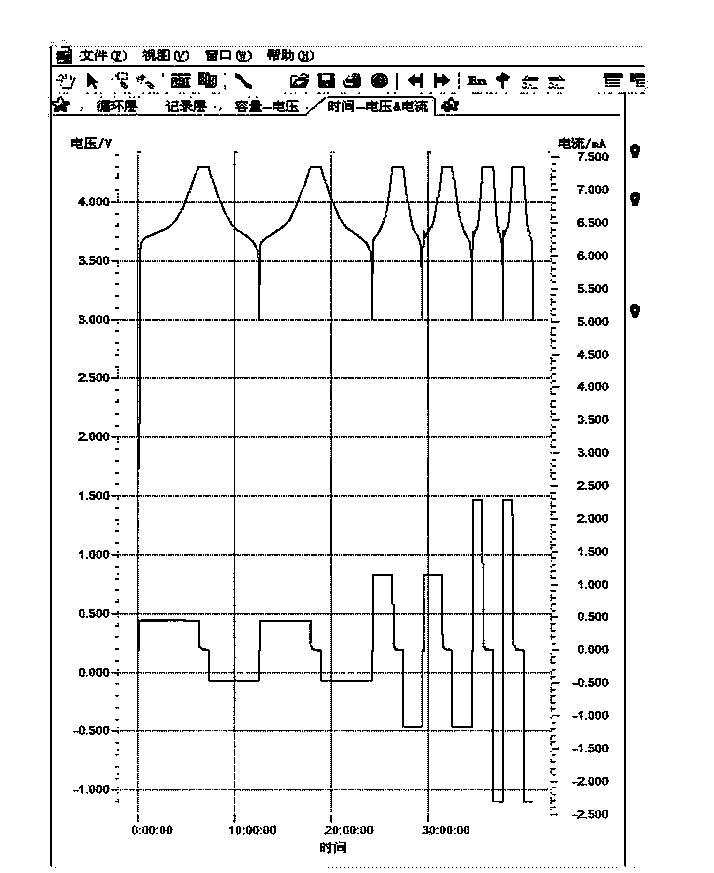

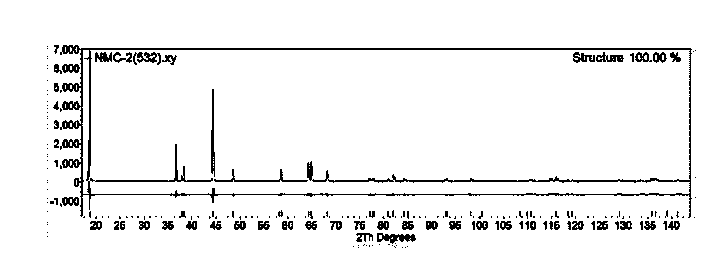

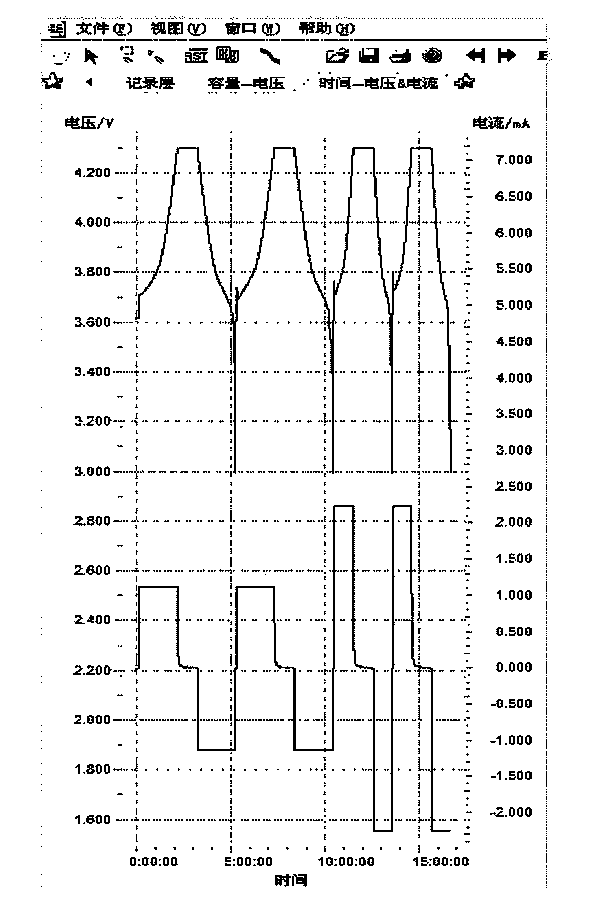

Embodiment 1

[0029] A method for producing a high-capacity 523-type ternary cathode material, comprising the steps of:

[0030] a. Raw material mixing: use nickel hydroxide cobalt manganese Ni 0.5 co 0.2 mn 0.3 (OH) 2 The ternary precursor is 75kg, the molar ratio of lithium carbonate content and nickel, cobalt and manganese content is 1.04:1, and the high-speed mixer is used to dry mix evenly, so as to realize the molecular level mixing of lithium, nickel, cobalt, manganese and additive elements;

[0031] b. Three times of sintering: the uniformly mixed raw materials are sintered in a tunnel kiln once, sintered at 650°C for 5 hours, the ternary semi-finished products sintered for the first time are crushed, and then put into the roller kiln for the second sintering, and the sintering temperature is 815°C for 10 hours; The secondary sintered ternary product is pulverized and put into the roller kiln for third sintering; the sintering temperature is 915°C and kept for 10 hours; during the ...

Embodiment 2

[0035] A method for producing a high-capacity 523-type ternary cathode material, comprising the steps of:

[0036] a. Raw material mixing: use nickel hydroxide cobalt manganese Ni 0.5 co 0.2 mn 0.3 (OH) 2 The ternary precursor is 75kg, the molar ratio of lithium carbonate content and nickel-cobalt-manganese content is 1.06:1, and titanium dioxide with a finished product content of 0.4% is added as an additive, and the high-speed mixer is used for dry mixing to achieve lithium, nickel, cobalt, manganese, and additives. Elements are mixed at the molecular level;

[0037] b. Three times of sintering: the uniformly mixed raw materials are sintered in a tunnel kiln once, sintered at 645°C for 4 hours, the ternary semi-finished products sintered for the first time are crushed, and then put into the roller kiln for the second sintering, and the sintering temperature is 810°C for 12 hours; then The secondary sintered ternary product is pulverized and put into a roller kiln for ...

Embodiment 3

[0040] A method for producing a high-capacity 523-type ternary cathode material, comprising the steps of:

[0041] a. Raw material mixing: use nickel hydroxide cobalt manganese Ni 0.5 co 0.2 mn 0.3 (OH) 2 The ternary precursor is 75kg, the molar ratio of lithium carbonate content and nickel-cobalt-manganese content is 1.06:1, and titanium dioxide with a finished product content of 0.4% is added as an additive, and the high-speed mixer is used for dry mixing to achieve lithium, nickel, cobalt, manganese, and additives. Elements are mixed at the molecular level;

[0042] b. Three times of sintering: the uniformly mixed raw materials are sintered in a tunnel kiln once, sintered at 640°C for 4.5 hours, the ternary semi-finished products sintered at the first sintering are crushed, and then put into the roller kiln for the second sintering, and the sintering temperature is 830°C for 13 hours; The secondary sintered ternary product is pulverized and put into a roller kiln for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com