Mobile tunnel furnace

A tunnel kiln and mobile technology, applied in the field of tunnel kiln, can solve the problems of relying on manpower and lack of power devices, and achieve the effect of ensuring drying quality, less investment and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

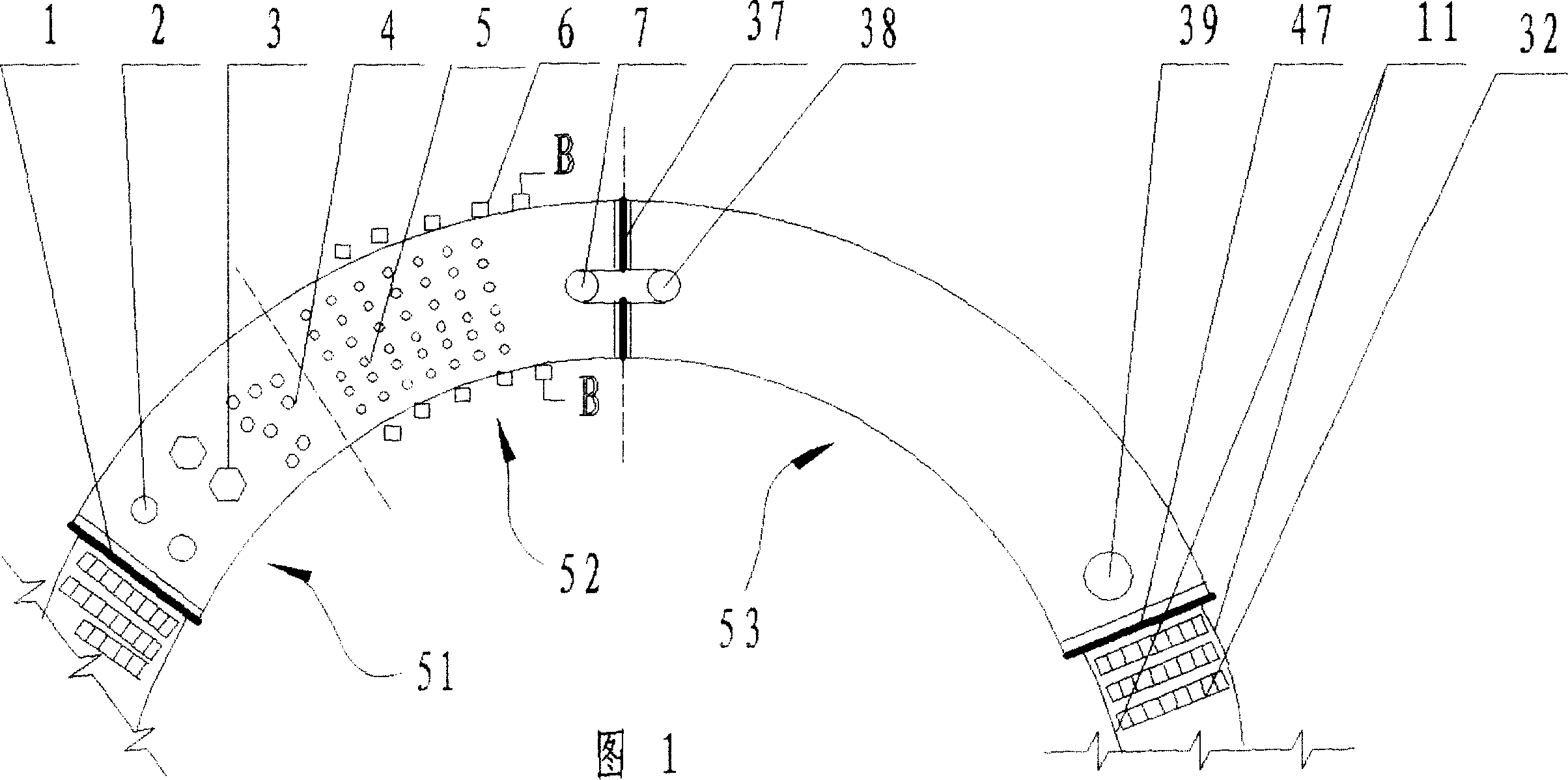

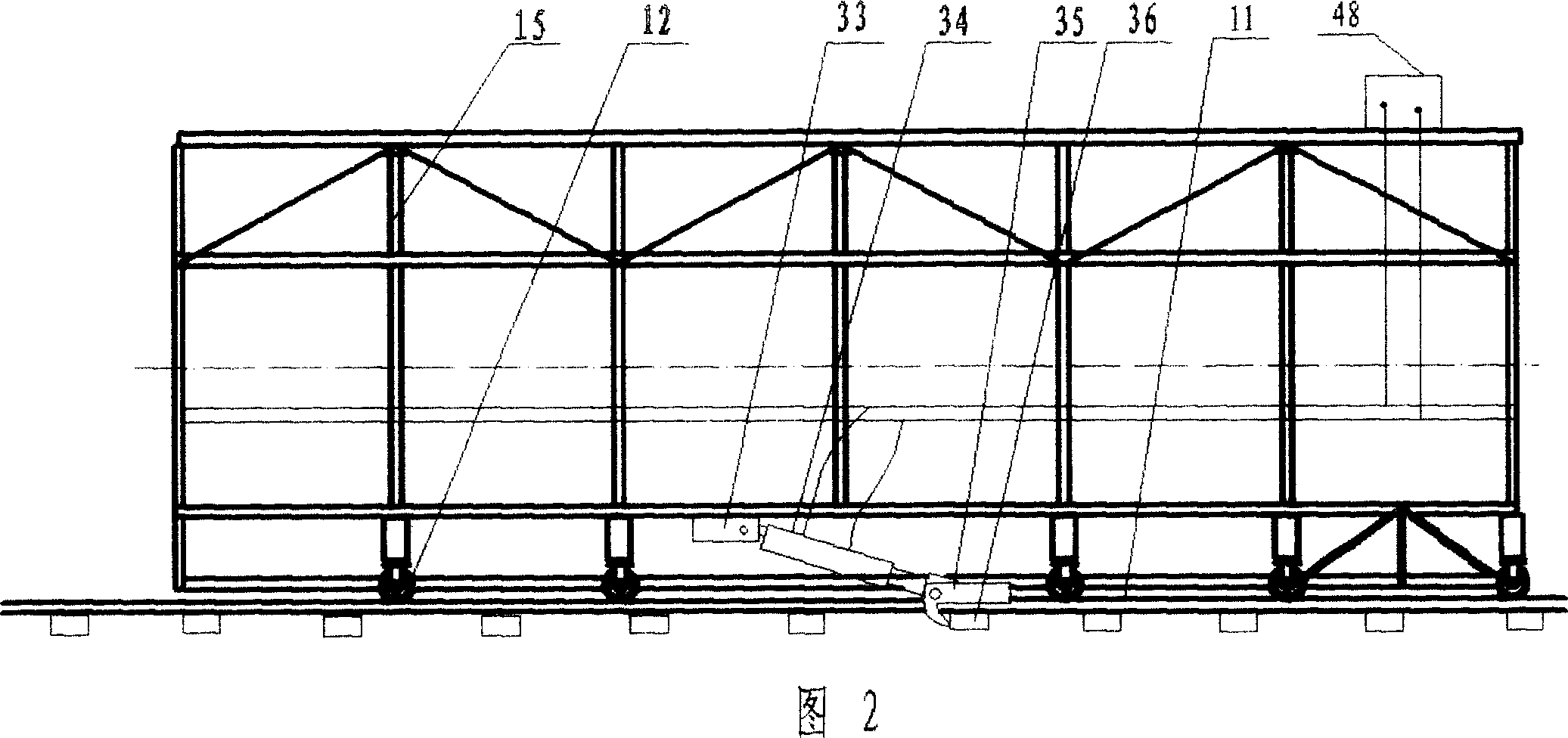

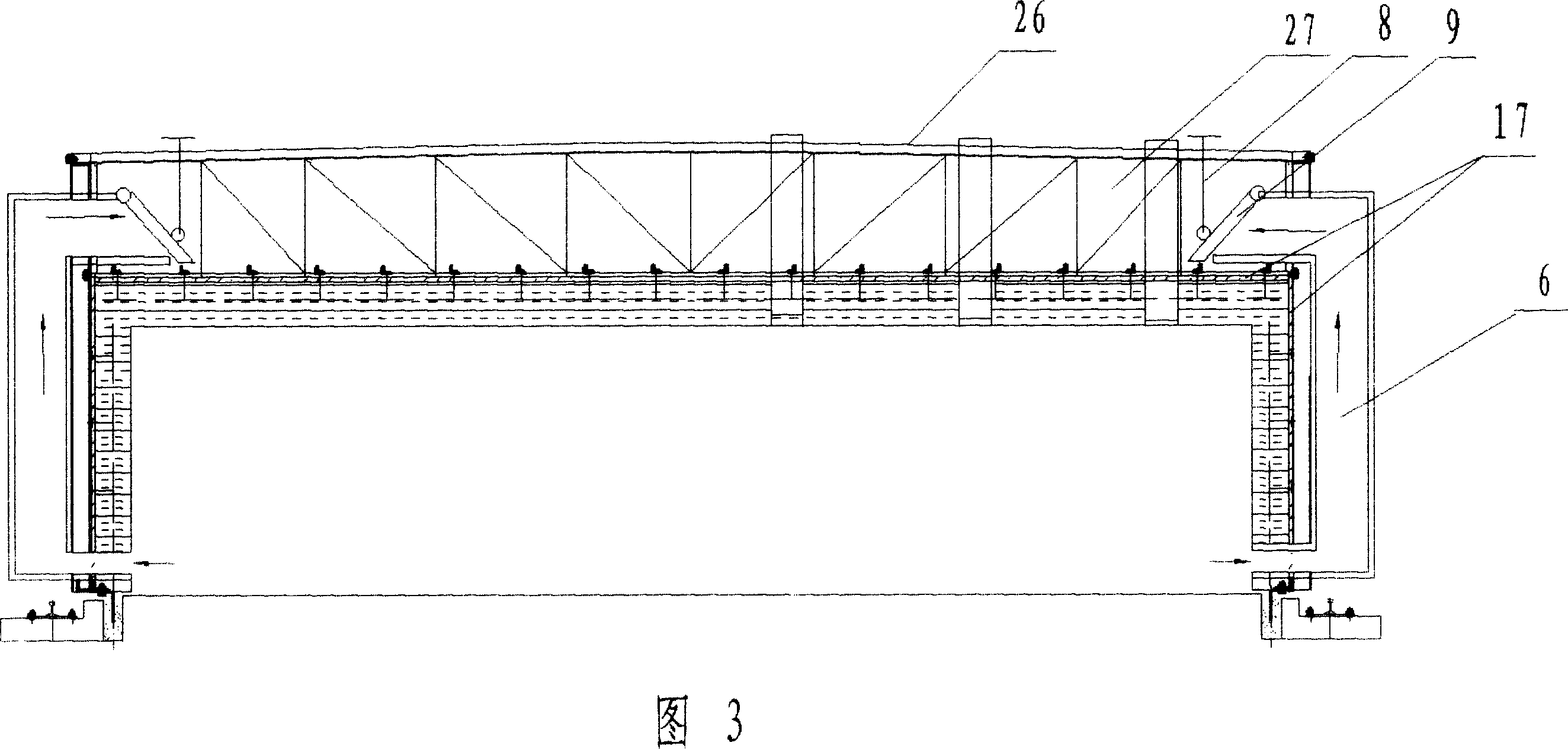

[0020] Referring to accompanying drawings 1-2, the kiln body of the mobile tunnel kiln of the present invention is made of a kiln frame and a heat-preserving refractory material fixed on the kiln frame, wherein the kiln frame is welded by profiles. The insulation refractory material adopts different materials for different sections. Rollers 12 are arranged on the kiln frame outside the kiln body, and the kiln body is placed on the ground track 11 through the rollers 12, and sleepers 10 are arranged at the lower part of the track. Power equipment is fixed on the kiln body, and the power equipment can be directly driven by connecting the motor and the reducer with the roller through the connecting rod mechanism; the diesel engine can also be used to drive the roller to rotate through the belt pulley. The power equipment of this embodiment adopts hydraulic equipment. That is, the power equipment of hydraulic cylinder plus hydraulic station.

[0021] As shown in Figure 2, an oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com