Method for manufacturing high-performance permeable bricks by using ceramic waste

A technology of ceramic waste and manufacturing method, which is applied in the production, application, and household appliances of ceramic materials, etc., can solve the problems of high strength, high price, poor water permeability, etc., achieve the unification of economic and social benefits, make up for groundwater, and adjust climate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

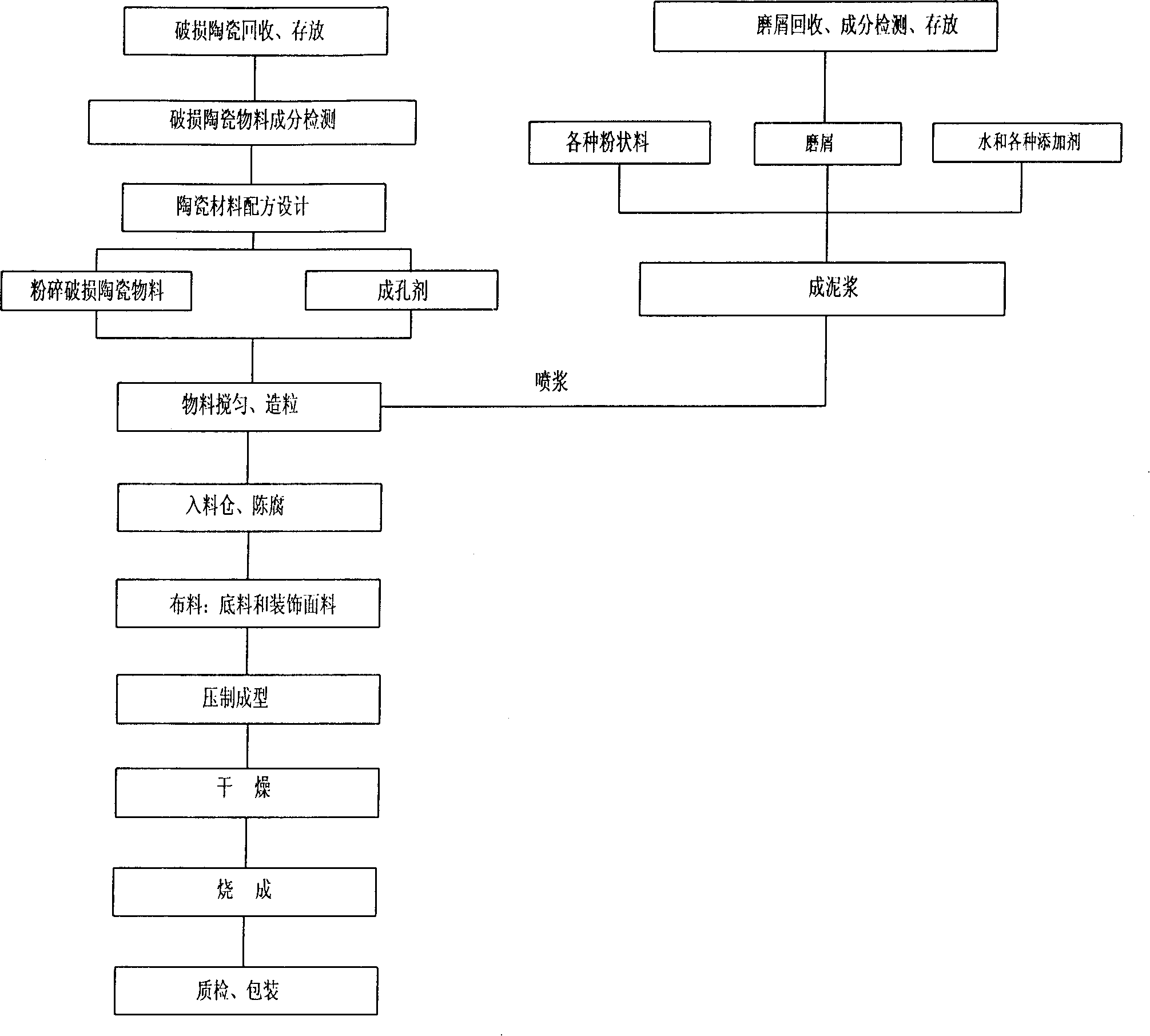

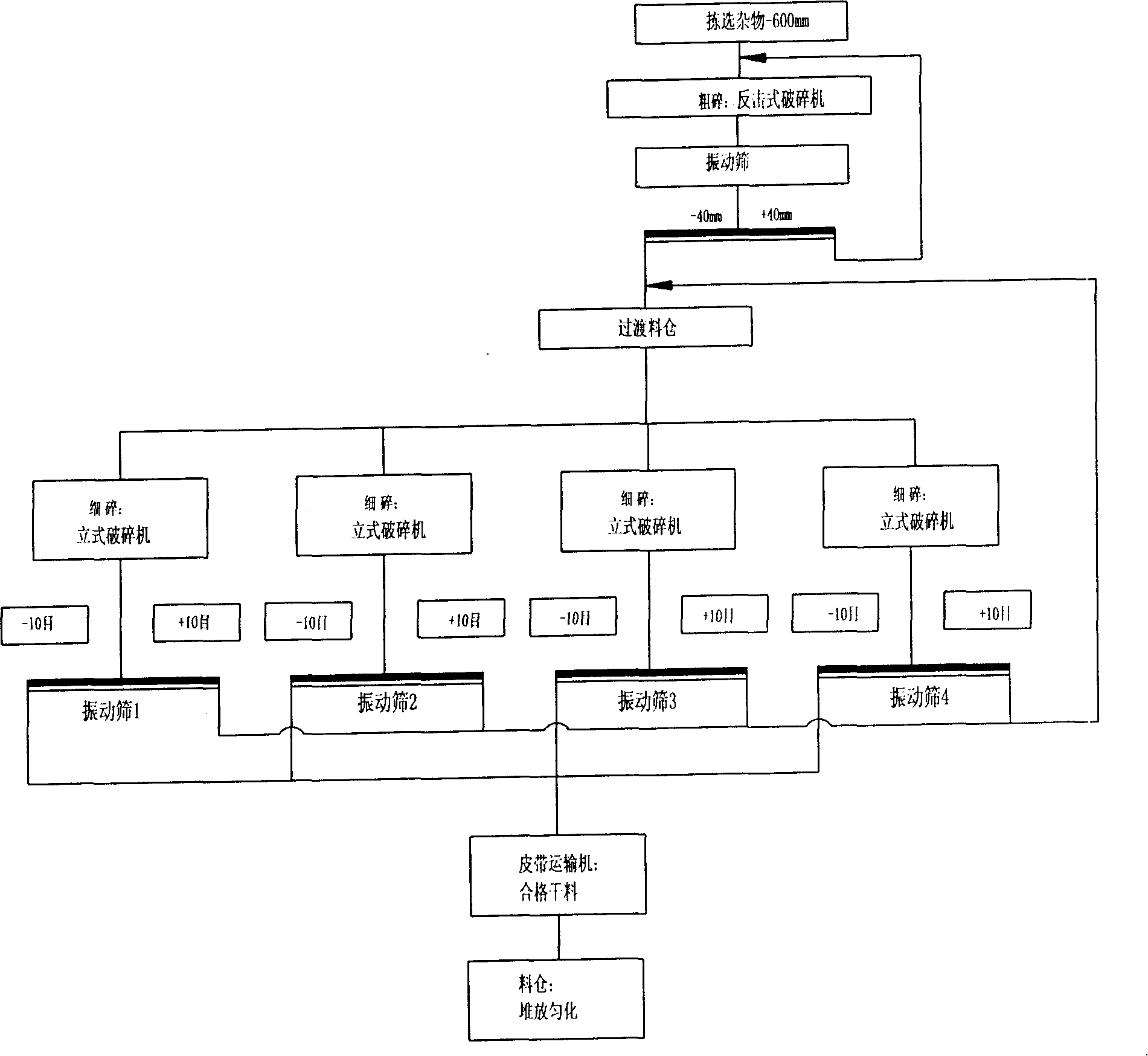

[0018] like figure 1 , figure 2 As shown, this study invented a fabrication method to produce high-performance permeable bricks from damaged ceramics and ceramic waste. First of all, this embodiment shows that sanitary ware products, defective products of various wall and floor tiles, damaged ceramics and polished tiles are respectively recovered, stored, and component tested; Defective and damaged ceramics of finished wall and floor tiles are crushed into particles with a particle size of less than 10 mesh (less than 1.65mm); the crushed particles are used as aggregates for the production of permeable bricks, with a content of 80 wt%, and then added by stirring or spraying 5wt% polishing brick grinding dust, 4wt% clay, 7wt% flux raw materials, organic additives, a small amount of pore forming agent and a very small amount of other raw materials (total 4wt%). Mix these raw materials evenly to make powder; after being clothed, it is pressed on a 800-1000-ton press, dried for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com