Vulcanization forming mold and manufacturing method of specially-shaped saturated nitrile rubber laminated cloth diaphragm

A technology of nitrile rubber and cloth diaphragm, which is applied in the field of rubber cloth products, can solve the problems of surface wrinkling and deformation, cloth breakage, etc., so as to improve the qualified rate, ensure uniformity, and avoid wrinkling and cloth breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

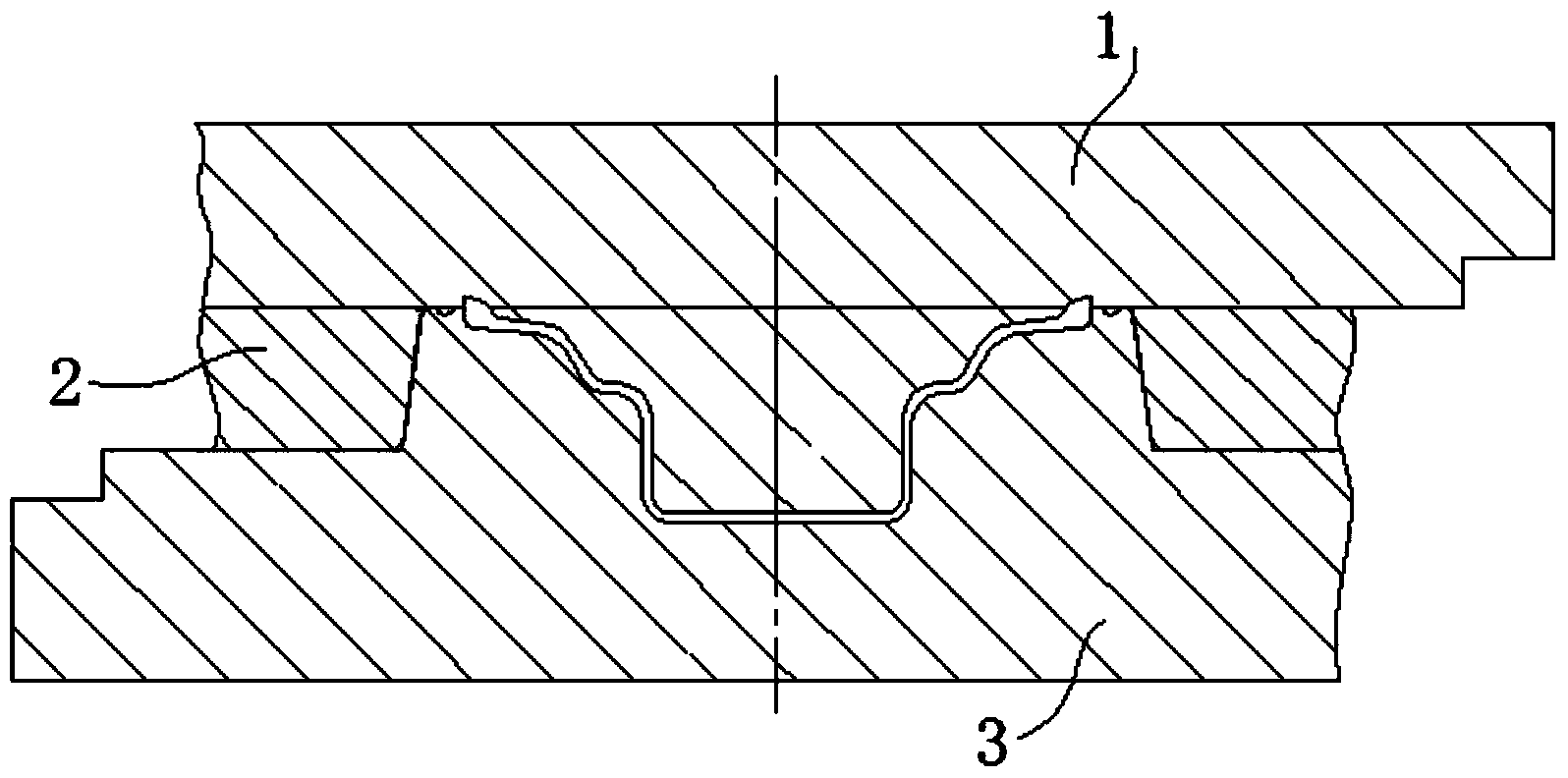

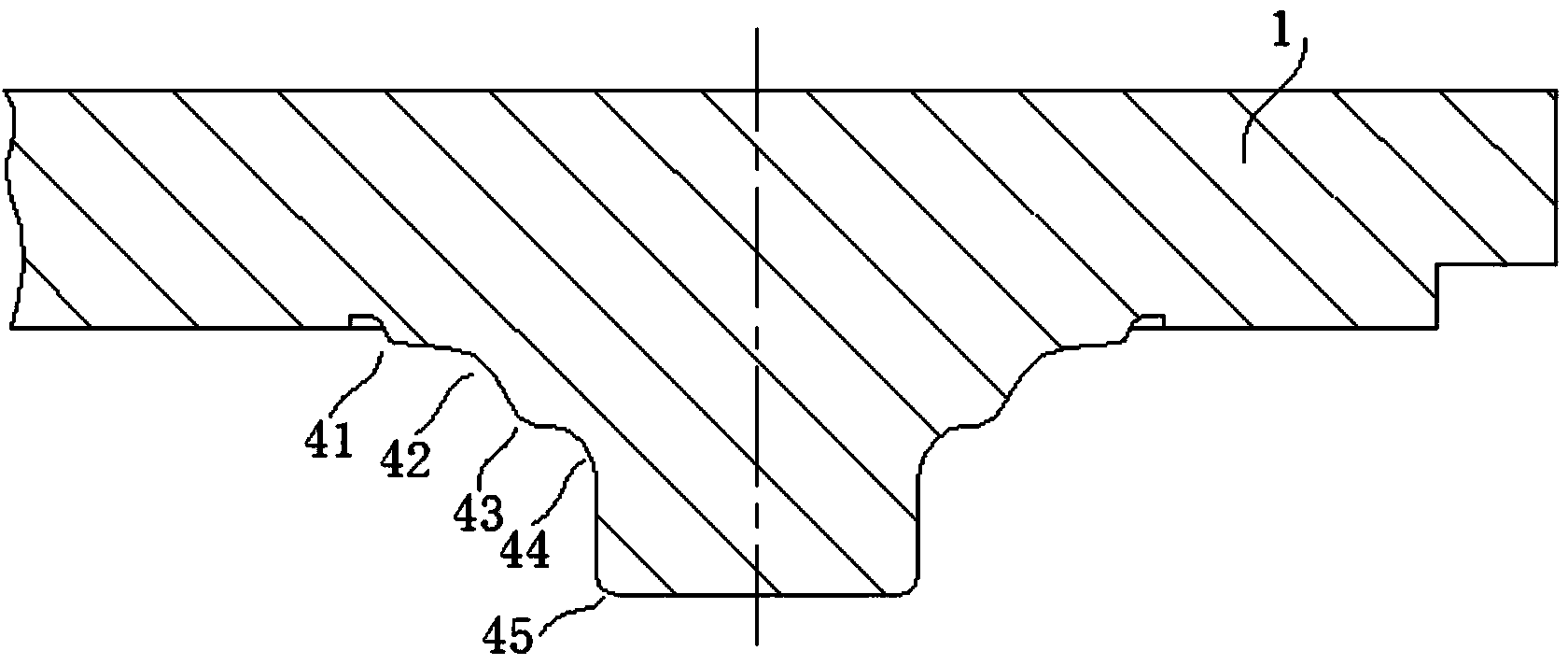

[0037] In conjunction with the accompanying drawings, a vulcanization molding die of a kind of special-shaped saturated nitrile rubber cloth diaphragm of the present embodiment includes a mold upper mold 1, a mold middle mold 2 and a mold lower mold 3 (such as figure 2 shown). The bottom of the mold upper mold 1 of the present embodiment is an outwardly protruding rotating body (such as image 3 shown), the side of the section of the rotating body includes the first arc segment 41 of the upper die, the second arc segment 42 of the upper die, the third arc segment 43 of the upper die, the fourth arc segment 44 of the upper die and the upper die arc segment 44 connected sequentially from top to bottom. As for the fifth arc segment 45, the bottom surface of the above-mentioned rotating body is a planar structure. The first arc section 41 of the patrix in the present embodiment, the second arc section 42 of the patrix, the third arc section 43 of the patrix, the fourth arc secti...

Embodiment 2

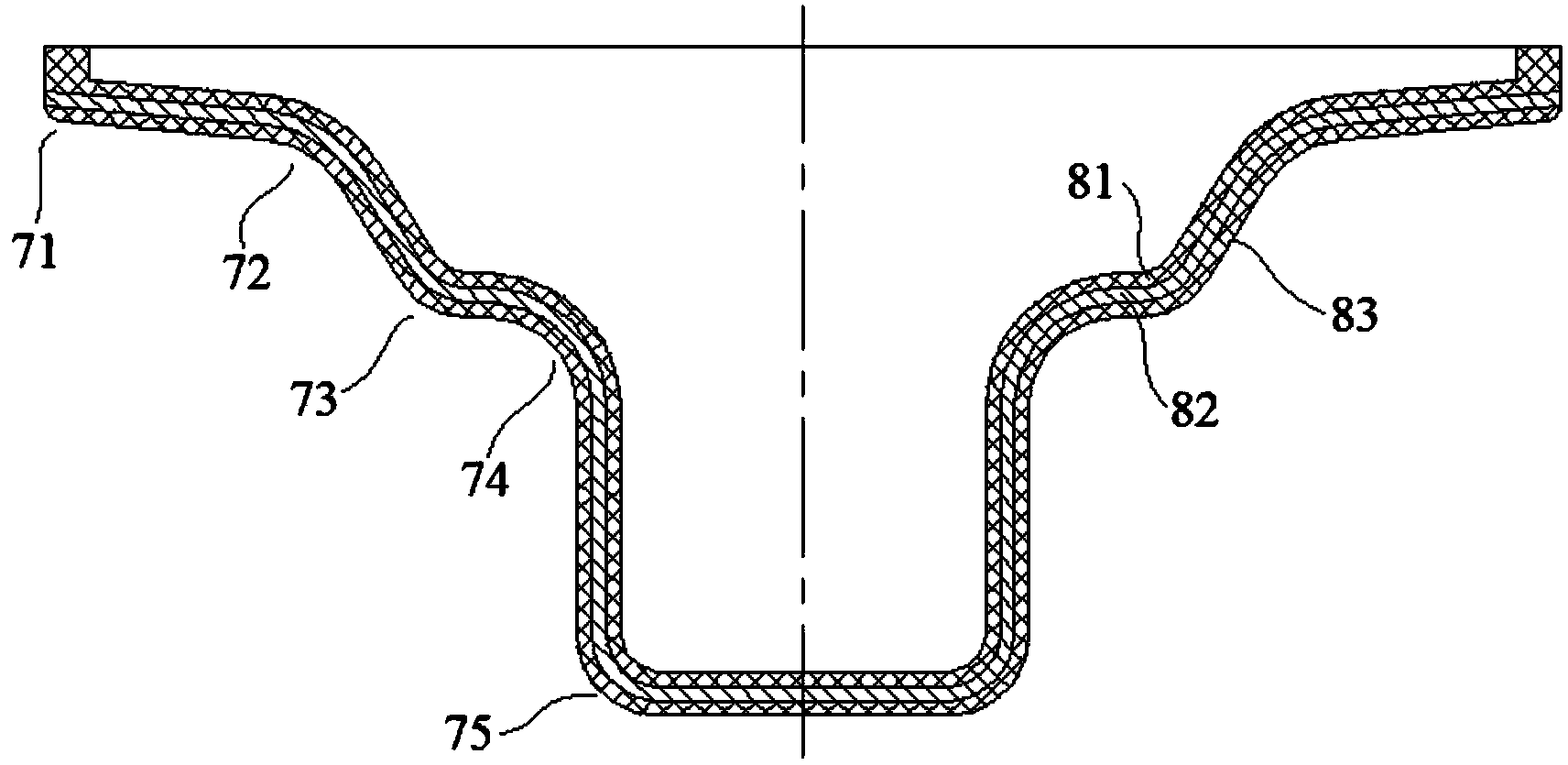

[0053] The vulcanization molding die of a kind of special-shaped saturated nitrile rubber cloth cloth diaphragm of the present embodiment, its basic structure is the same as embodiment 1, the difference is: the arc of the bottom arc section 21 of the trapezoidal hole side in the mold 2 The radius is 4mm. A kind of manufacturing method of the special-shaped saturated nitrile rubber cloth diaphragm of the present embodiment, its basic preparation steps are the same as embodiment 1, the difference is: the thickness of the fabric cloth 82 in step 1 is 0.2mm; The body 81 and the material blank of the outer diaphragm body 83 are composed of the following components in parts by weight: saturated nitrile rubber: 100 parts, carbon black: 70 parts, light calcium carbonate: 15 parts, zinc oxide: 8 parts, Liquid nitrile rubber: 10 parts, accelerator CZ: 1.5 parts, accelerator TT: 1.5 parts, sulfur: 0.5 parts, vulcanizing agent double 25: 5 parts, accelerator TAC: 4 parts; vulcanization te...

Embodiment 3

[0055] The vulcanization molding die of a kind of special-shaped saturated nitrile rubber cloth cloth diaphragm of the present embodiment, its basic structure is the same as embodiment 1, the difference is: the arc of the bottom arc section 21 of the trapezoidal hole side in the mold 2 The radius is 5mm. A kind of manufacturing method of the special-shaped saturated nitrile rubber cloth diaphragm of the present embodiment, its basic preparation steps are the same as embodiment 1, the difference is: the thickness of step 1 fabric cloth 82 is 0.4mm; 81 and the material blank of the outer diaphragm body 83 are composed of the following components in parts by weight: saturated nitrile rubber: 90 parts, carbon black: 50 parts, light calcium carbonate: 10 parts, zinc oxide: 5 parts, liquid Nitrile rubber: 5 parts, accelerator CZ: 0.5 parts, accelerator TT: 0.5 parts, sulfur: 0.3 parts, vulcanizing agent double 25: 2 parts, accelerator TAC: 1 part; vulcanization temperature control o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com