Photosensitive composite containing photoinitiator of diphenyl sulfide based ketoxime esters and application thereof

A technology of photosensitive composition and ester compound, which is applied in optics, optical filters, photomechanical equipment, etc., can solve the problem that the photosensitive composition cannot meet the application requirements, and achieve excellent curing effect, high optical transparency, Good pattern integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0039] (1) Photosensitive composition No.1-1

[0040] 25 parts by mass of carbon black

[0041] 32 parts by mass of alkali-soluble resin

[0042] [Benzyl methacrylate / methacrylic acid / hydroxyethyl methacrylate / acrylic acid ester of formula (II) (molar ratio is 55 / 10 / 15 / 10) copolymer] (Mw: 12000)

[0043] 16 parts by mass of dipentaerythritol hexaacrylate

[0044] Formula (I) ketoxime ester compound 8 parts by mass

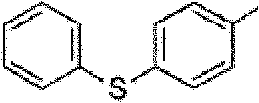

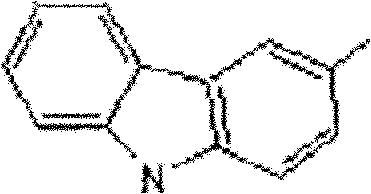

[0045] (R 1 where n=1, m=3; R 2 is phenyl; R 3 for diphenyl sulfide group )

[0046] Dispersant FC-4430 0.1 parts by mass

[0047] (2) Preparation of black matrix BM

[0048] The components of the above composition are mixed and dissolved in 100 parts by mass of solvent propylene glycol monomethyl ether acetate (PGMEA) to form a liquid composition;

[0049] Use a spin coater to coat the liquid composition on a glass substrate, dry at 90°C for 5 minutes to remove the solvent, and form a coating film with a film thickness of 1.5 μm; in order to obtain a co...

Embodiment 2-1

[0081] (1) Red photosensitive composition No.2-1

[0082] C.I. Pigment Red 254 18 parts by mass

[0083] 40 parts by mass of alkali-soluble resin

[0084] [Benzyl methacrylate / methacrylic acid / hydroxyethyl methacrylate / acrylic acid ester of formula (II) (molar ratio is 60 / 10 / 10 / 10) copolymer] (Mw: 10000)

[0085] 15 parts by mass of dipentaerythritol hexaacrylate

[0086] 7 parts by mass of formula (I) ketoxime ester compound

[0087] (R 1 where n=1, m=3; R 2 is phenyl; R 3 for diphenyl sulfide group )

[0088] Dispersant FC-4430 0.05 parts by mass

[0089] (2) Preparation of filter color film

[0090] The components of the above composition are mixed and dissolved in 100 parts by mass of solvent propylene glycol monomethyl ether acetate (PGMEA) to form a liquid composition;

[0091] Apply the liquid composition on the substrate with the black matrix BM, dry at 90°C for 5 minutes to remove the solvent, and form a coating film with a film thickness of 1.5 μm; in orde...

Embodiment 3-1

[0104] (1) Green photosensitive composition No.3-1

[0105] C.I. Pigment Green 36 16 parts by mass

[0106] 27 parts by mass of alkali-soluble resin

[0107] [Benzyl methacrylate / methacrylic acid / hydroxyethyl methacrylate / acrylic acid ester of formula (II) (molar ratio is 60 / 5 / 15 / 10) copolymer] (Mw: 20000)

[0108] 18 parts by mass of dipentaerythritol hexaacrylate

[0109] Formula (I) ketoxime ester compound 6 parts by mass

[0110] (R 1 where n=1, m=3; R 2 is phenyl; R 3 for diphenyl sulfide group )

[0111] Dispersant FC-4430 0.05 parts by mass

[0112] Using the above composition, a filter color film was prepared and performance evaluated in the same manner as in Example 2-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com