Paper ironing machine

A technology of paper ironing machine and ironing board, which is applied in the post-processing of waste paper, etc., can solve the problems of inconsistent drying speed of paper, inability to distribute steam in time, and inconsistent drying from top to bottom, etc., and achieves the effects of simple structure, wrinkle prevention, and consistent drying speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

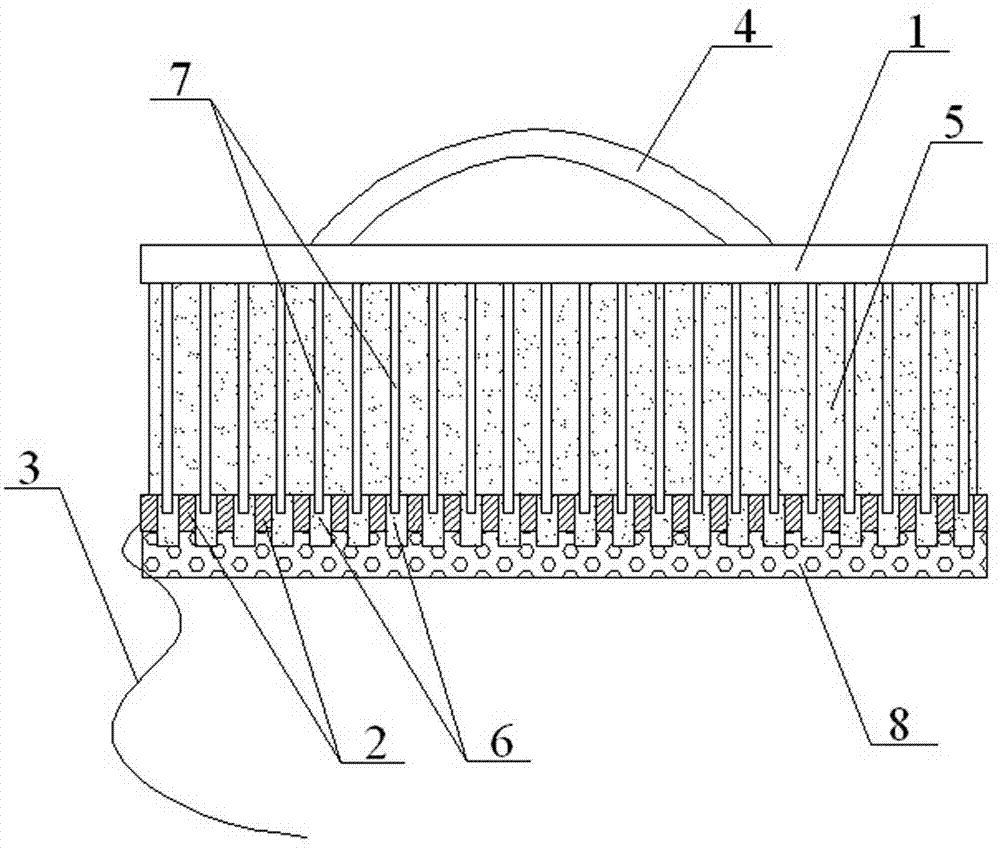

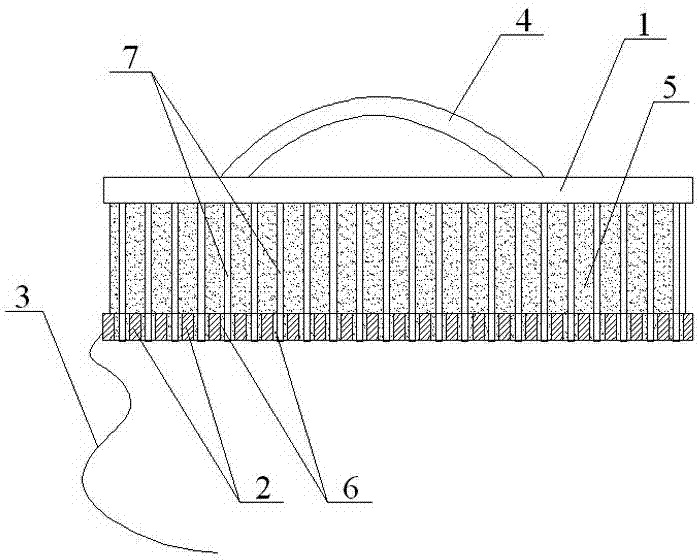

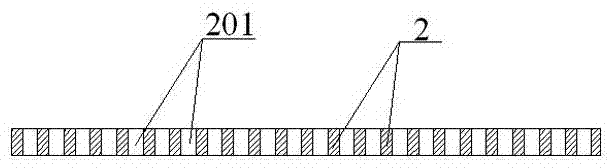

[0021] A paper ironing machine, comprising a water storage tank 1 arranged in parallel up and down and a heating ironing board 2, the heating ironing board 2 is provided with a heating device connected to an external power line 3, the heating device 4 is a resistance wire, heating The ironing board 2 is also provided with a temperature controller connected to the heating device 4, and the upper end surface of the water storage tank 1 is provided with an operating handle 4 and a water injection port. Rectangular plate structure, a sponge layer 5 is arranged between the water storage tank 1 and the heating ironing board 2, and the bottom of the sponge layer 5 also extends downwards to provide a plurality of extensions 6 that can protrude from the through holes 201. A plurality of small holes are evenly opened on the lower end surface of the water storage tank 1, and each small hole is connected with a communication pipe 7 for leading out the water in the water storage tank 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com