Circulating drying system for drying denitration agent by using natural gas heat source

A technology of circulating drying and natural gas, applied in the directions of drying gas arrangement, drying, drying machine, etc., can solve the problems of uneven drying speed of catalyst, uneven distribution of air outlet, and inability to dry catalyst quickly, and achieve consistent drying speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

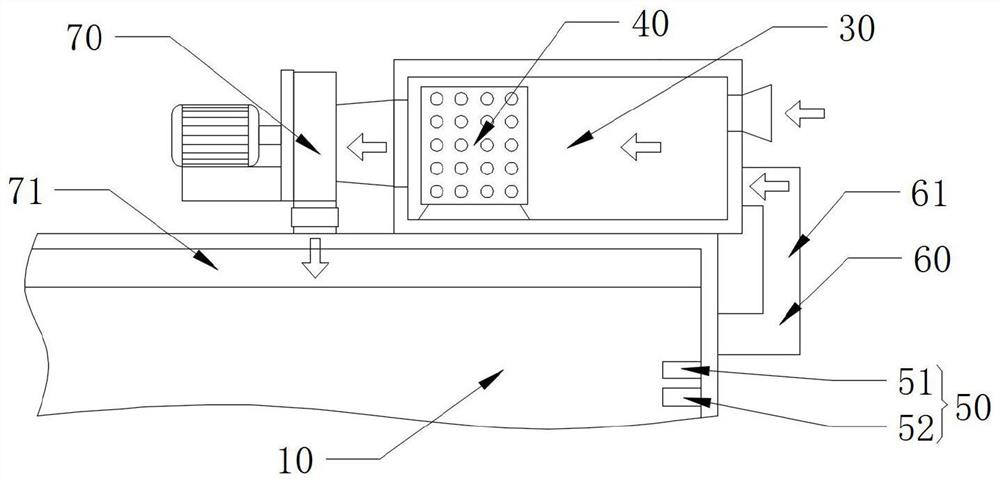

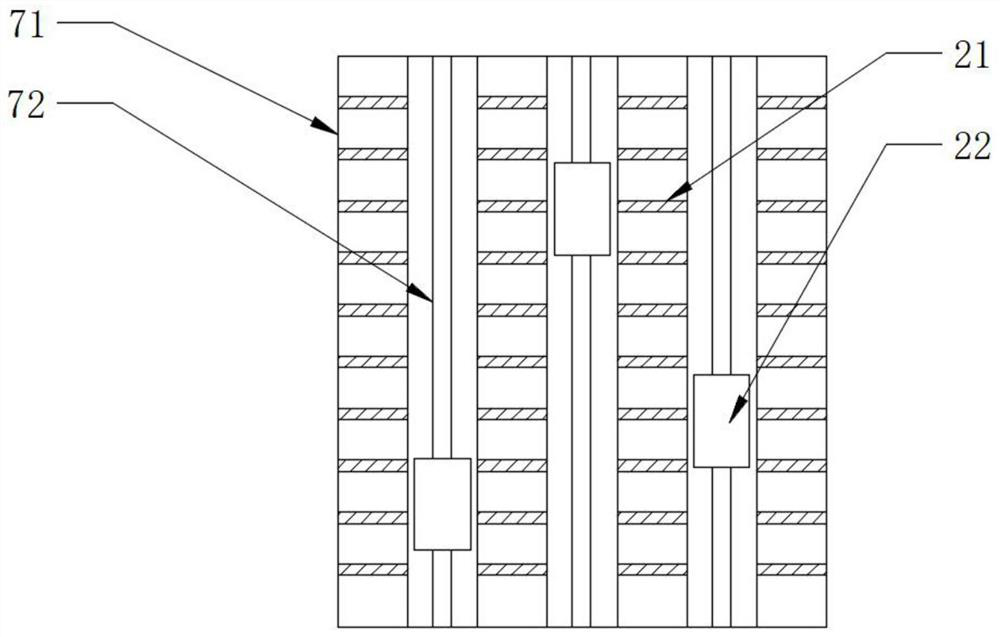

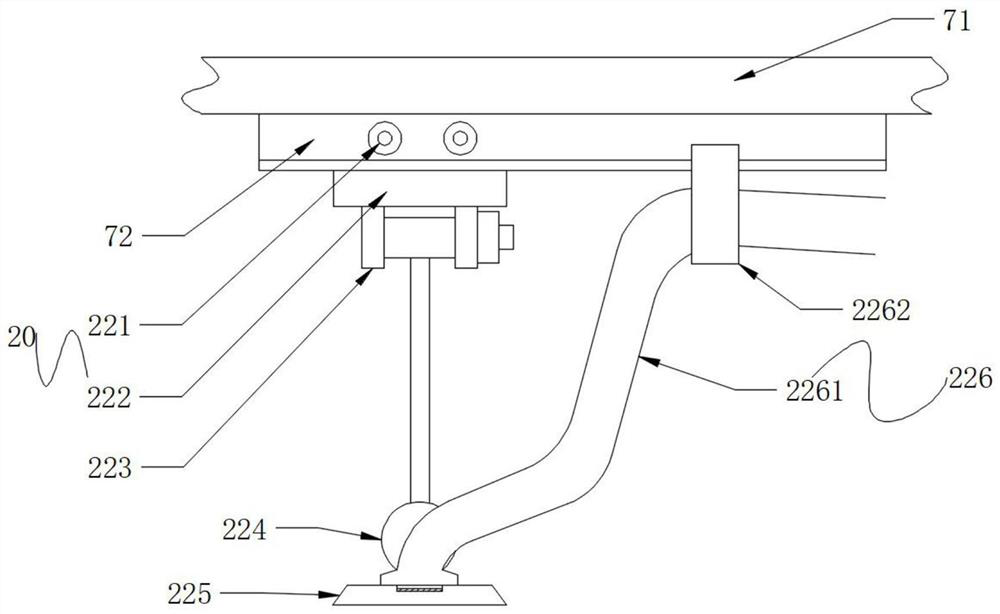

[0030] Such as figure 1 As shown, the circulating drying system for drying the denitration agent by using natural gas heat source in the present invention includes a drying chamber 10, and the circulating drying system includes: an air guide module 20, a heat exchange module 40, a heating module 30, a measurement module 50, Air return module 60, air outlet module 70; air guide module 20 is used for distributing the air volume blown into the drying chamber 10 by the air outlet; since the natural gas itself contains some impurities, it will form particles after burning, if the hot air is used directly To dry the base material, these particles may be left on the surface of the product and become an unqualified product. Therefore, the heat exchanger in the heat exchange module 40 is used to heat the gas with gas, and all the high-temperature gas after natural gas combustion is heat-exchanged The module replaces heat energy; the heating module 30 is used to fully burn natural gas t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com