Bracket for drying large-outer-diameter and high-thickness blanks and implementation method of bracket

A technology with large outer diameter and blank, applied in drying chamber/container, drying gas arrangement, drying, etc., can solve the problem of increased risk of product cracking or corner drop, slowing down air convection speed, large difference in blank moisture content, etc. problems, to achieve the effect of being easy to place or take out, increasing the speed of air convection, and speeding up the drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

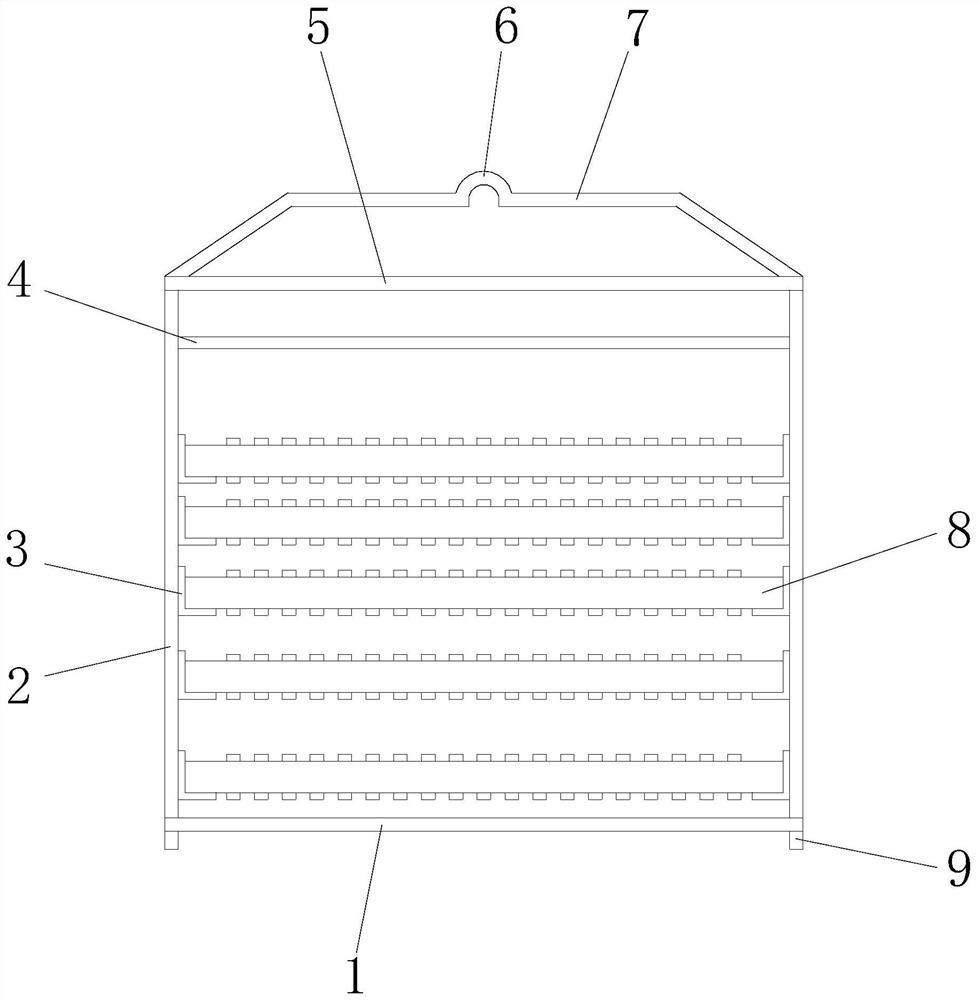

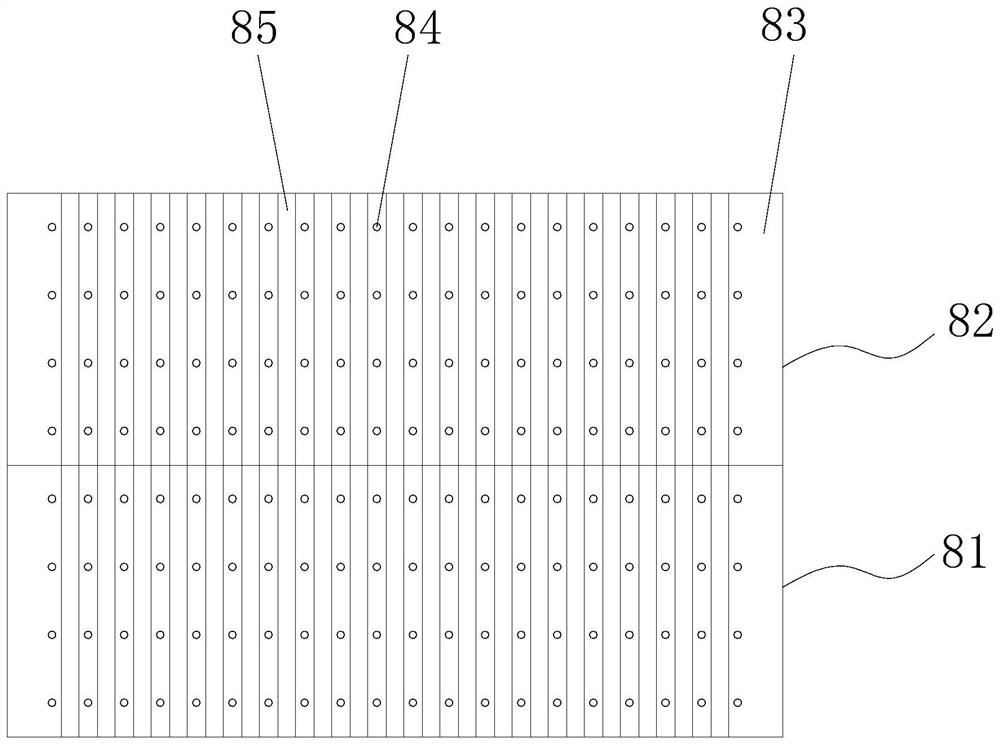

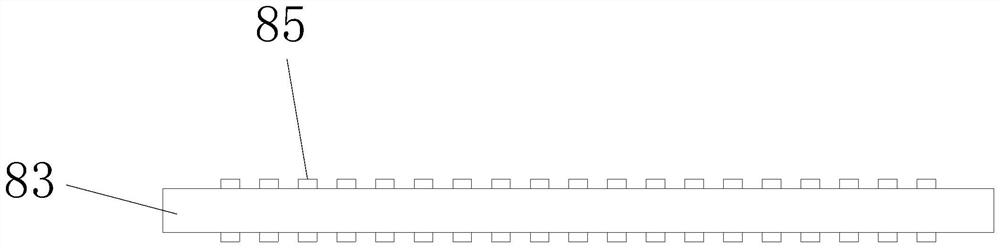

[0037] see Figure 1-3 , the present invention provides the following technical solutions: a large outer diameter and high thickness rough blank drying bracket, including a base 1, four corners above the base 1 are respectively provided with columns 2, the top of the column 2 is provided with a top seat 5, the top The top of the seat 5 is provided with a suspender 7, and the column 2 is provided with several layers of pallets 8. The pallet 8 includes a load-bearing plate 83. The load-bearing plate 83 is preferably a hard wood. The pad 85, the width, thickness and adjacent interval of the pad 85 are all preferably 1-1.5cm, and the present embodiment is preferably 1cm, and the pad 85 is preferably soft wood.

[0038] By adopting the above-mentioned technical scheme, the blank is supported by arranging several equally spaced pads 85 above the load-bearing plate 83, no more pads are needed, the speed of blank placement is accelerated, and the interval between the pads 85 is conduc...

Embodiment 2

[0042] This embodiment differs from Embodiment 1 in that: specifically, several through holes 84 are arranged at equal intervals between corresponding two adjacent pads 85 on the bearing plate 83, and the diameter of the through holes 84 is preferably 0.5-0.8 cm. An embodiment is preferably 0.6 cm.

[0043] By adopting the above-mentioned technical solution, the setting of the through hole 84 facilitates the convection of the upper and lower air, thereby further speeding up the drying speed of the blank.

Embodiment 3

[0045] The difference between this embodiment and Embodiment 1 lies in that: specifically, the lower part of the load-bearing plate 83 is provided with a pad strip 85 corresponding to the upper part.

[0046] By adopting the above technical solution, if heavy objects are placed on the wooden supporting board 8 in one direction for a long time, it is easy to cause the supporting board 8 to bend and deform downwards, which is not conducive to subsequent placement. Pad strips are provided on both sides of the load-bearing board 83 85. After using for a period of time, the blank can be turned over to place, so that the bending deformation of the supporting plate 8 can be avoided to a certain extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com