A chip adsorption device and chip bonding system

A technology for adsorption devices and chips, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of reduced yield, increased cost, and decreased work efficiency, and can improve the moving speed and placement speed and reduce the accuracy Requirements, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

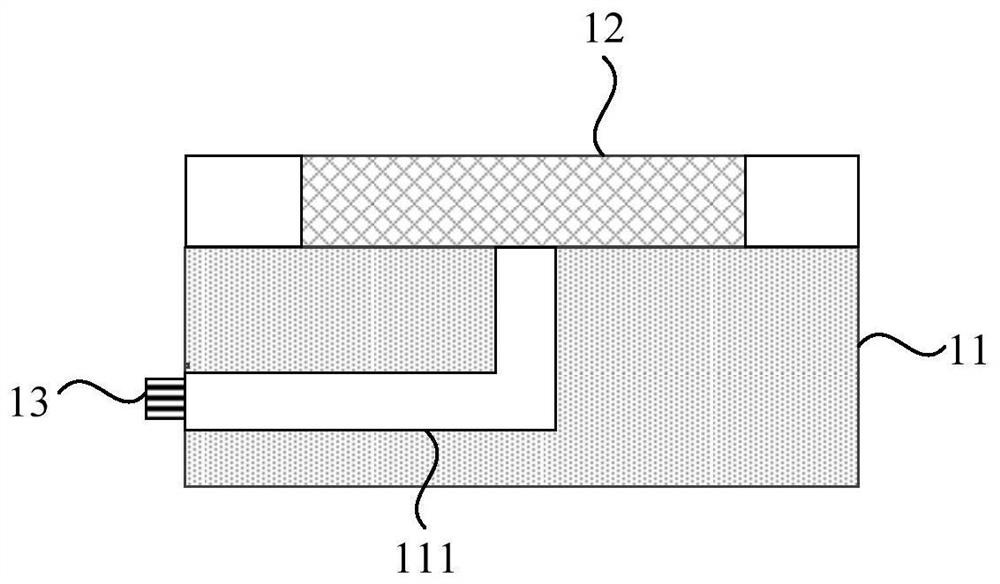

[0032] figure 1 It is a schematic structural diagram of a chip adsorption device provided in Embodiment 1 of the present invention, refer to figure 1 , the chip adsorption device includes: a base plate 11, a porous ceramic chuck 12 positioned on the base plate, and a vacuum source 13; the inside of the base plate 11 is provided with a first air guide channel 111 that is in contact with the non-adsorption surface of the porous ceramic chuck 12, the second A first end of an air guide channel 111 communicates with the air holes exposed on the non-adsorption surface of the porous ceramic suction cup 12 , and a second end of the first air guide channel 111 communicates with the vacuum air source 13 .

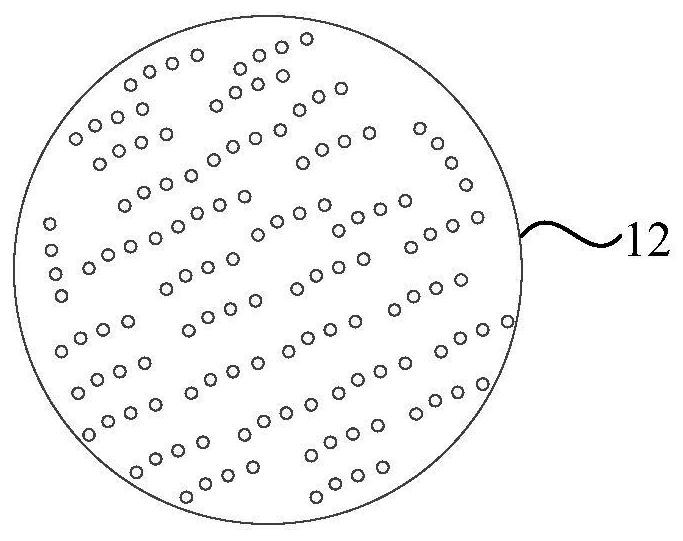

[0033] figure 2 It is a structural schematic diagram of a porous ceramic sucker provided in Embodiment 1 of the present invention, refer to figure 2 , the porous ceramic chuck 12 contains air holes with a pore size on the order of microns, and the air holes communicate with each ...

Embodiment 2

[0038] The traditional vacuum control method usually adopts the method of vacuuming all the pores of the suction cup when the adsorption device absorbs the chip. This vacuum control method can easily cause the suction cup to absorb dust and impurities in the area not covered by the chip, which affects the adsorption of other larger-sized chips. As a result, the service life of the chip adsorption device is reduced, and the difficulty of cleaning is also increased.

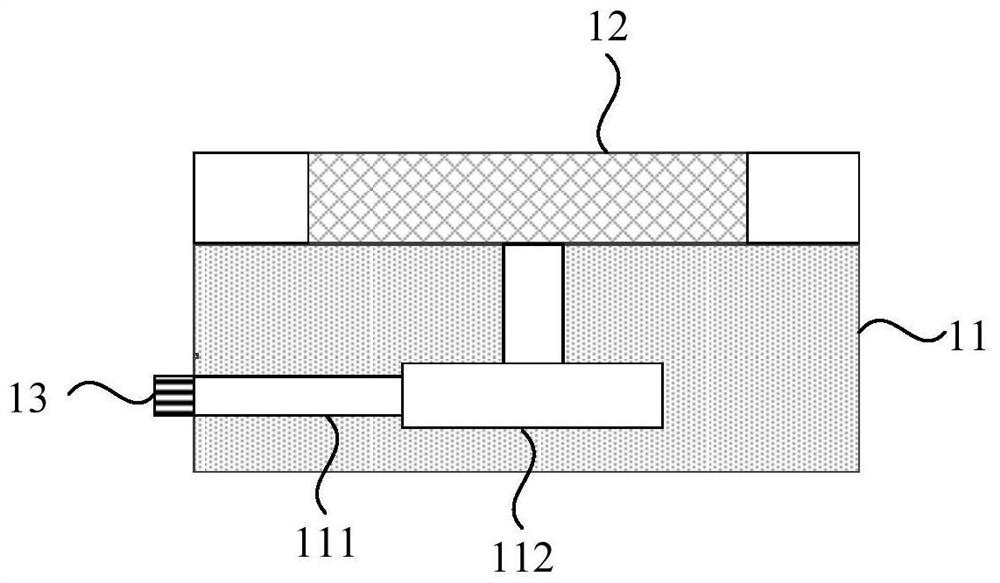

[0039] Figure 4 It is a schematic structural diagram of a chip adsorption device provided in Embodiment 2 of the present invention, refer to Figure 4, the vacuum adsorption device comprises a base plate 11, a porous ceramic chuck 12 positioned on the base plate and a vacuum source 13; the inside of the base plate 11 is provided with a first air guide channel 111 in contact with the non-adsorption surface of the porous ceramic chuck 12, the first The first end of the air guide channel 111 communicates with the ai...

Embodiment 3

[0049] Figure 11 It is a schematic structural diagram of a chip bonding system provided in Embodiment 3 of the present invention, refer to Figure 11 , the chip bonding system includes a bonding hand 100 , a stage 200 , a bonding stage 300 and at least one chip adsorption device 400 according to any one of the previous embodiments arranged on the stage 200 . Wherein, the chip 500 is adsorbed on the stage 200 by the chip adsorption device 400 .

[0050] Refer below figure 1 and Figure 11 The working process of the chip bonding system is introduced: first, the stage 200 moves to the transfer position, and the picker (not shown in the figure) places the chip 500 on the chip adsorption device 400 of the stage 200, and the chip adsorption device 400 The vacuum air source 13 in the vacuum chamber is activated, and the porous ceramic chuck 12 is provided with a vacuum through the second air guide channel 111, and the porous ceramic chuck 12 is equipped with a suction force under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com