Novel UV drying machine facilitating discharging

A dryer, a new type of technology, applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problem of reducing the integrity and durability of the paint film, incomplete curing of the inner layer paint, affecting the curing of the paint film. Effectiveness and other issues, to achieve the effect of reducing maintenance costs, reducing steric hindrance effect, and long-term protection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

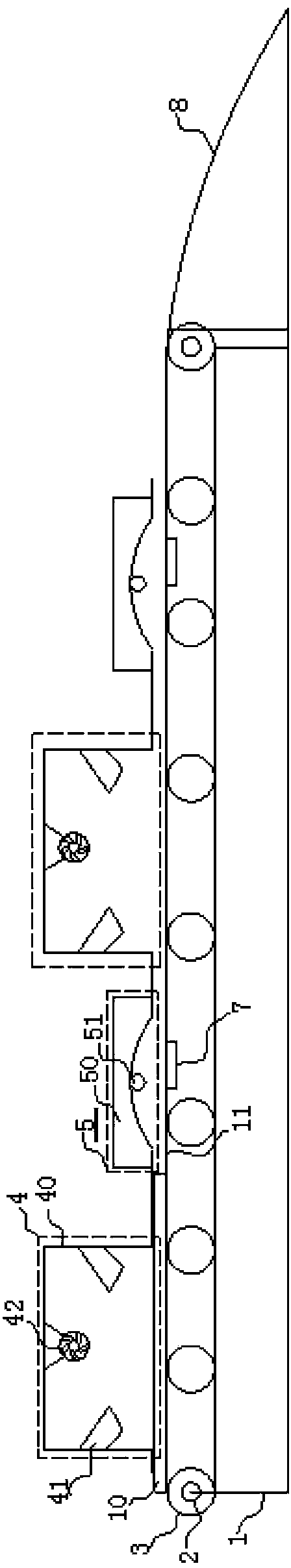

[0014] Example 1. A new type of UV dryer that is convenient for discharging, which is composed of figure 1 As shown, it includes a frame 1, which is provided with a driving device 2, a transmission idler group 3, a conveyor belt 11 driven by the transmission idler group 3, a workpiece inlet and a workpiece outlet, and the conveyor belt The top of 11 is provided with UV lighting system 5, and the quantity of UV lighting system 5 is at least two and is distributed along the moving direction of workpiece, between the workpiece feeding port on the frame 1 and UV lighting system 5, relative A cooling system 4 is provided between the adjacent UV lighting systems 5, and an arc-shaped discharge slope 8 is provided at the discharge port of the workpiece.

[0015] The cooling system 4 includes a cooling system cover 40 , and the inner wall of the cooling system cover 40 is provided with a coolant outlet 41 connected with a gas refrigerator and an exhaust fan 42 .

[0016] The coolant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com