Patents

Literature

34results about How to "Consistent drying speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

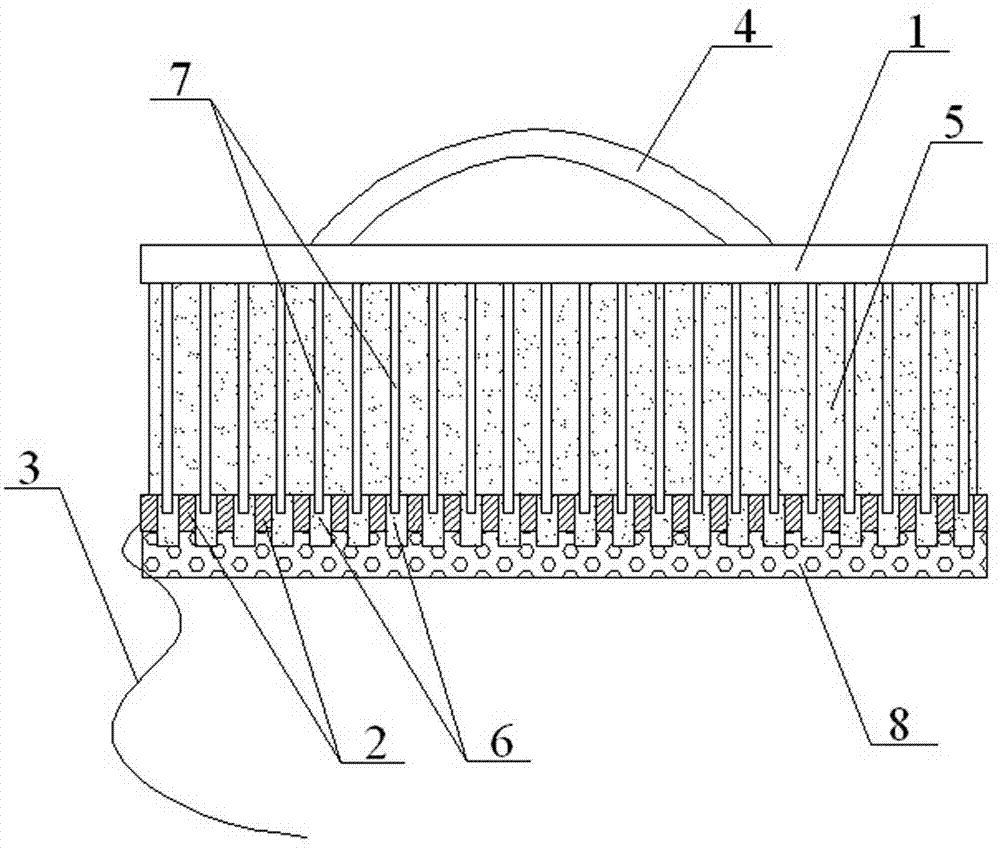

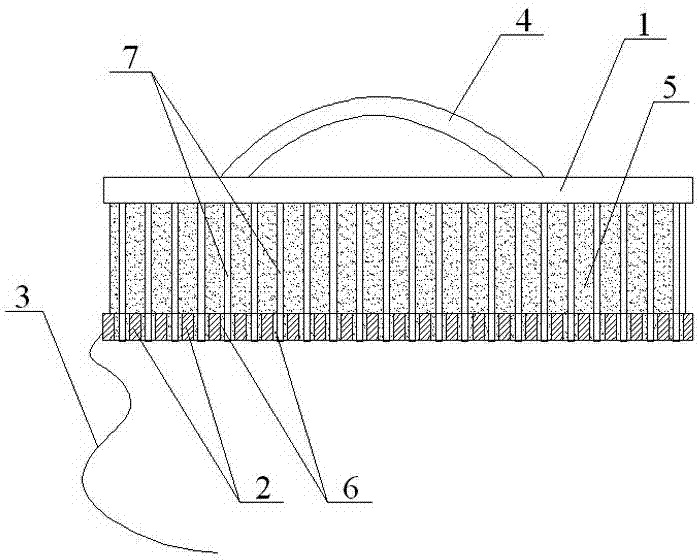

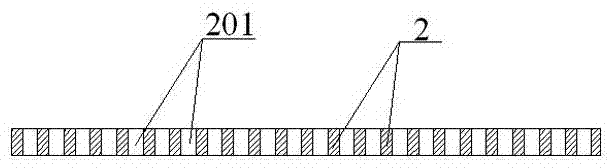

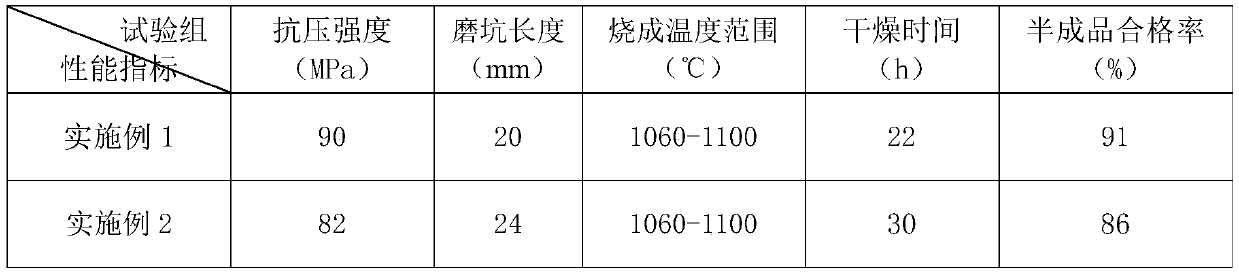

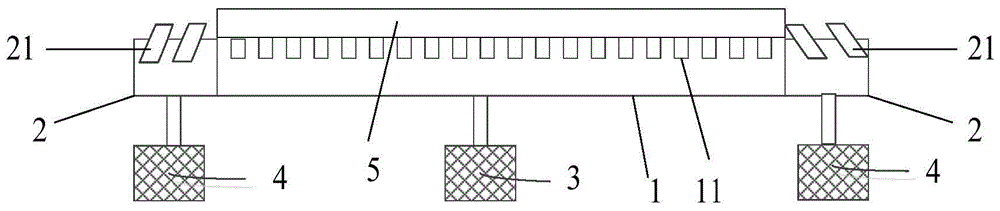

Printing base table and ink-jet printing method

ActiveCN104786656AConsistent dry atmosphereConsistent drying speedDuplicating/marking methodsOther printing apparatusLiquid-crystal displayEngineering

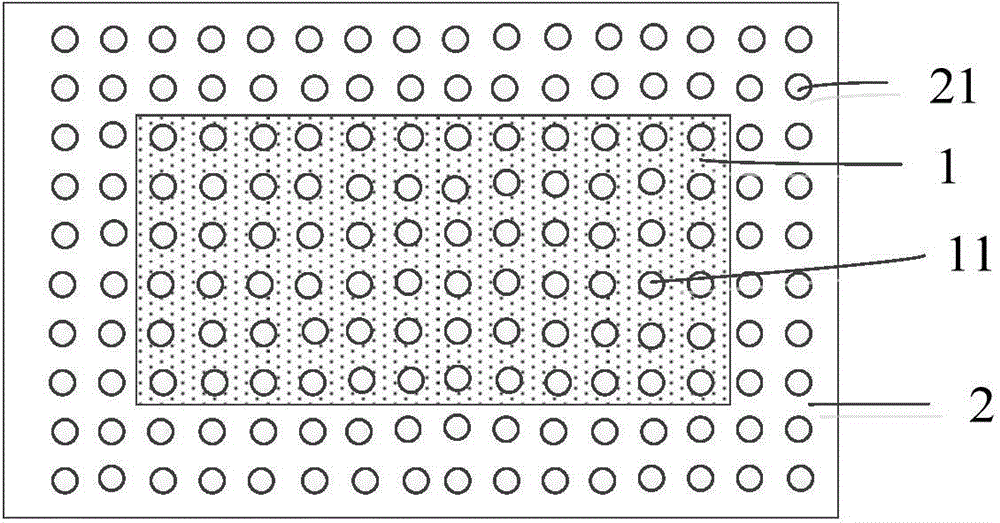

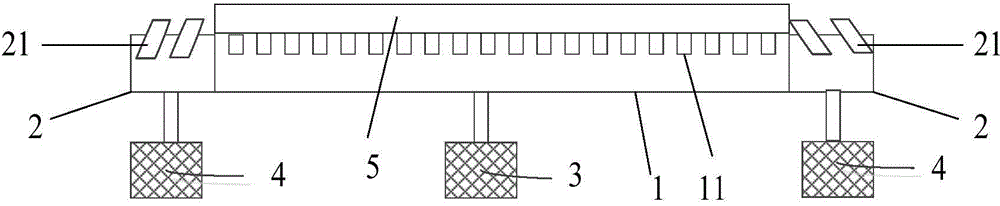

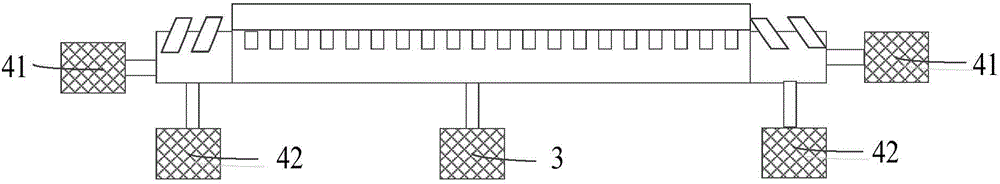

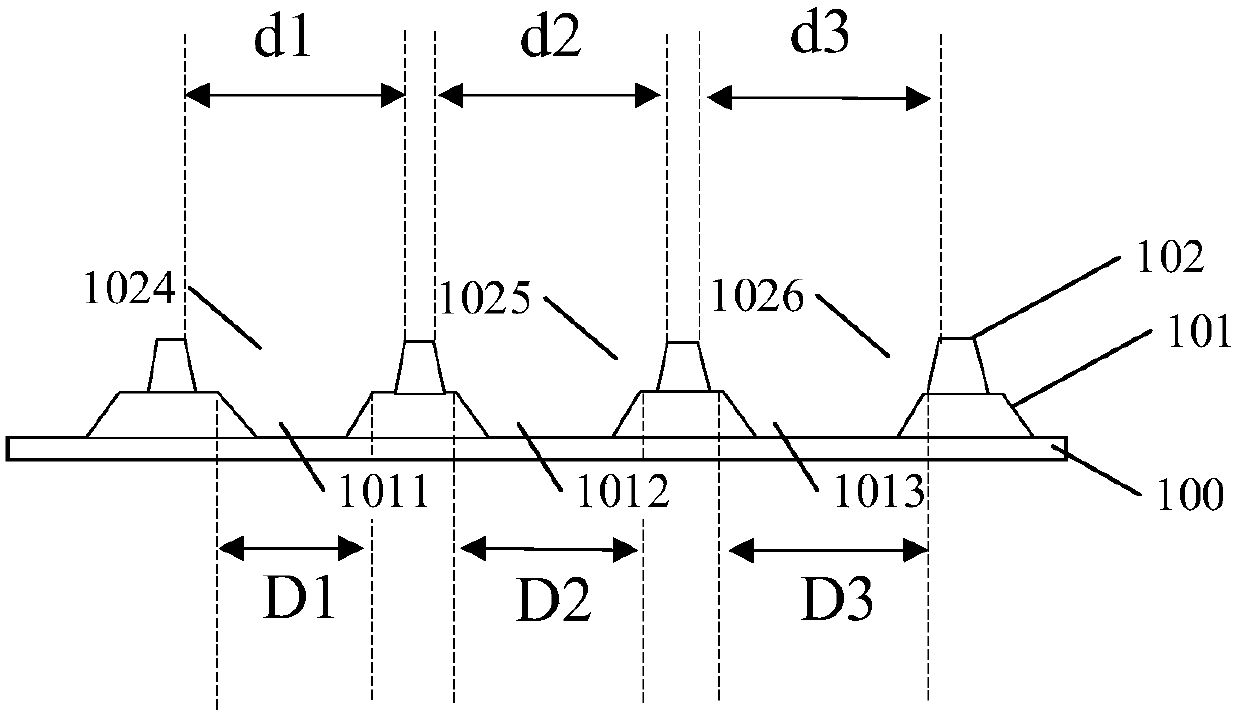

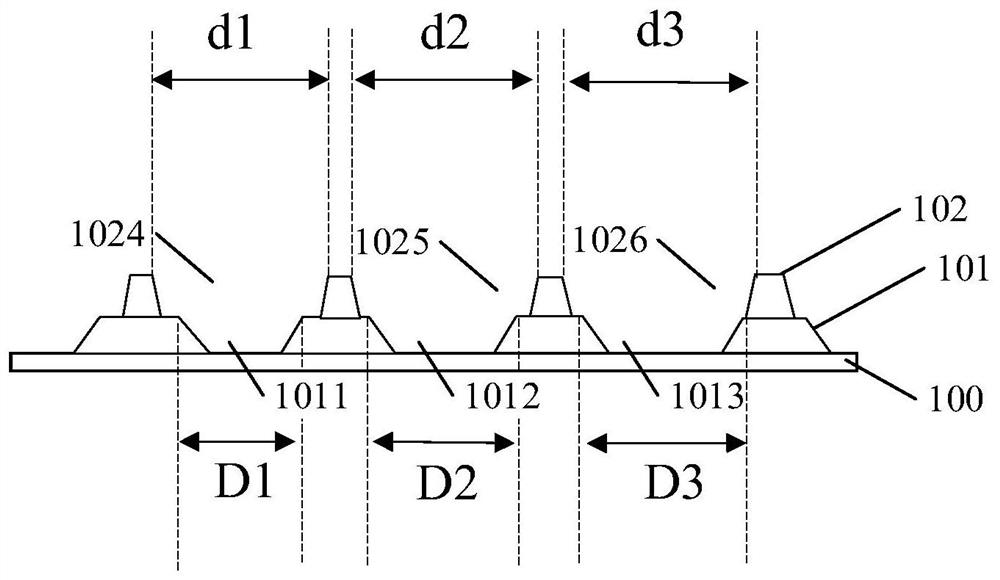

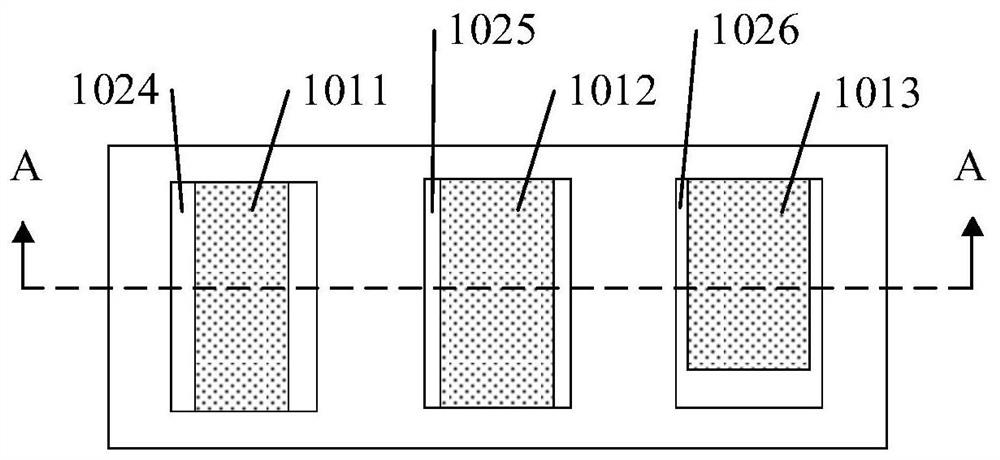

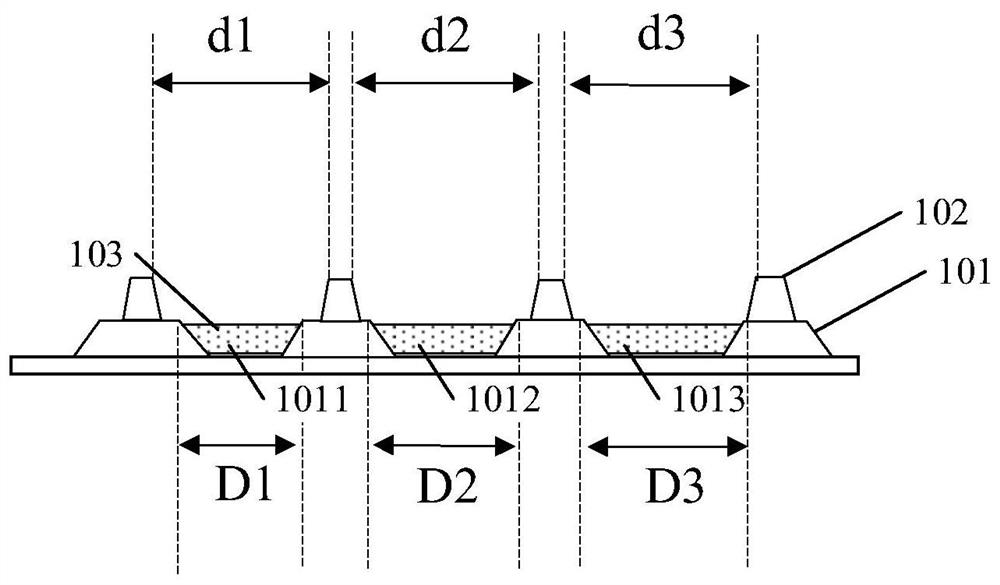

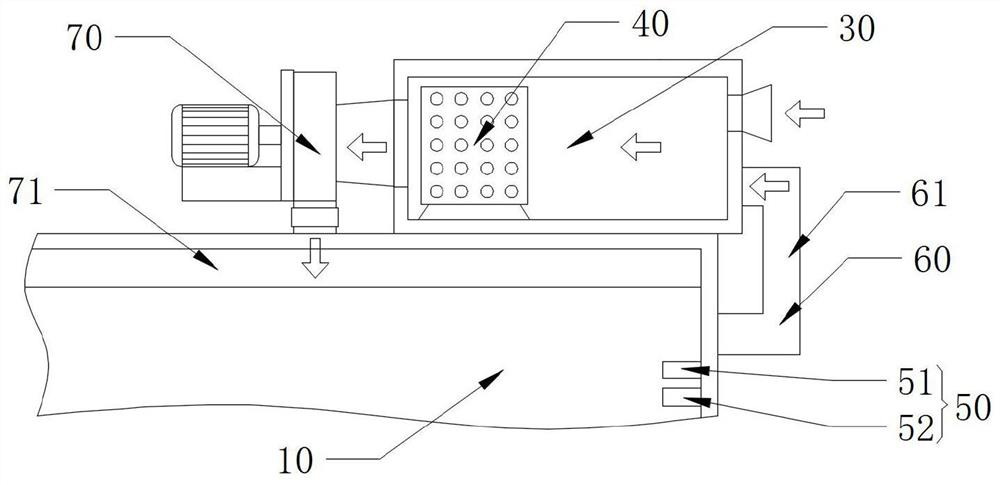

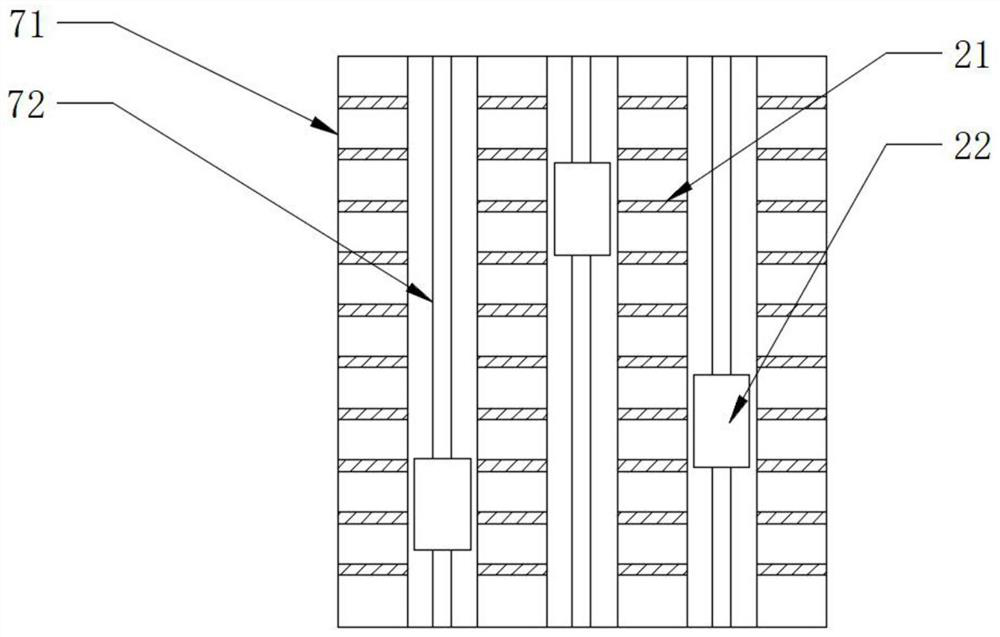

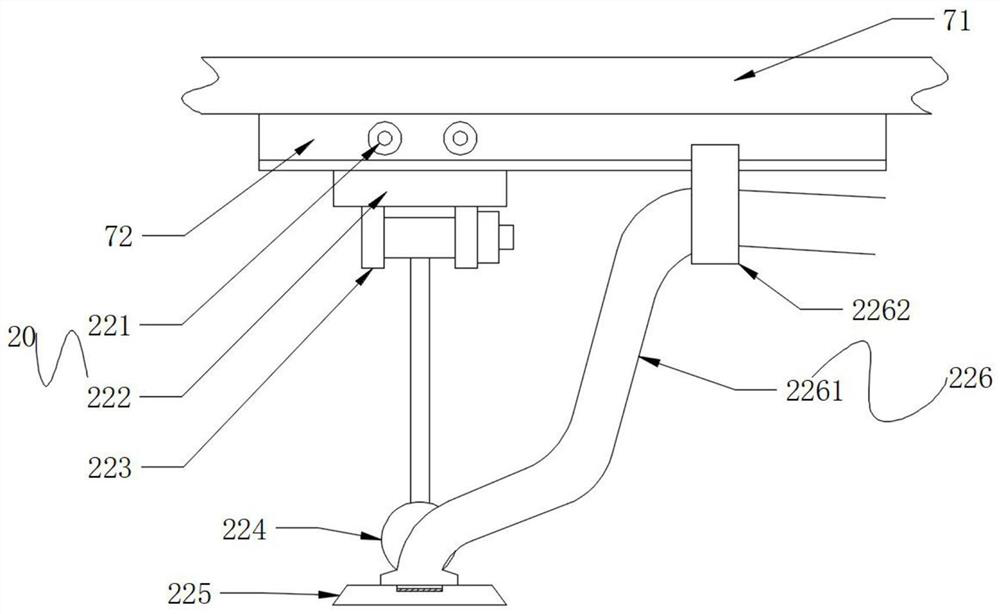

The invention discloses a printing base table and an ink-jet printing method, and belongs to the field of light-emitting device manufacturing. The printing base table comprises a carrying base table body, an expansion base table body, a vacuum pump and gas spraying valves. The expansion base table body is located on the periphery of the carrying base table body. The carrying base table body comprises at least one suction hole used for sucking a base plate. The expansion base table body comprises at least one jetting hole. The vacuum pump is connected with the sucking holes. The gas spraying valves are connected with the jetting holes. The gas spraying valves are used for spraying gas to the periphery of the carrying base table body through the jetting holes so that a solvent atmosphere can be formed on the periphery of the baste plate on the carrying base plate body and the drying atmospheres of edge pixels and middle pixels in the base plate can be consistent. The expansion base table body is added to the periphery of the carrying base table body, the testing area on the periphery of the display area in the base plate can be removed, the area of the display area is enlarged, and the frame width of a liquid crystal display panel is reduced.

Owner:BOE TECH GRP CO LTD

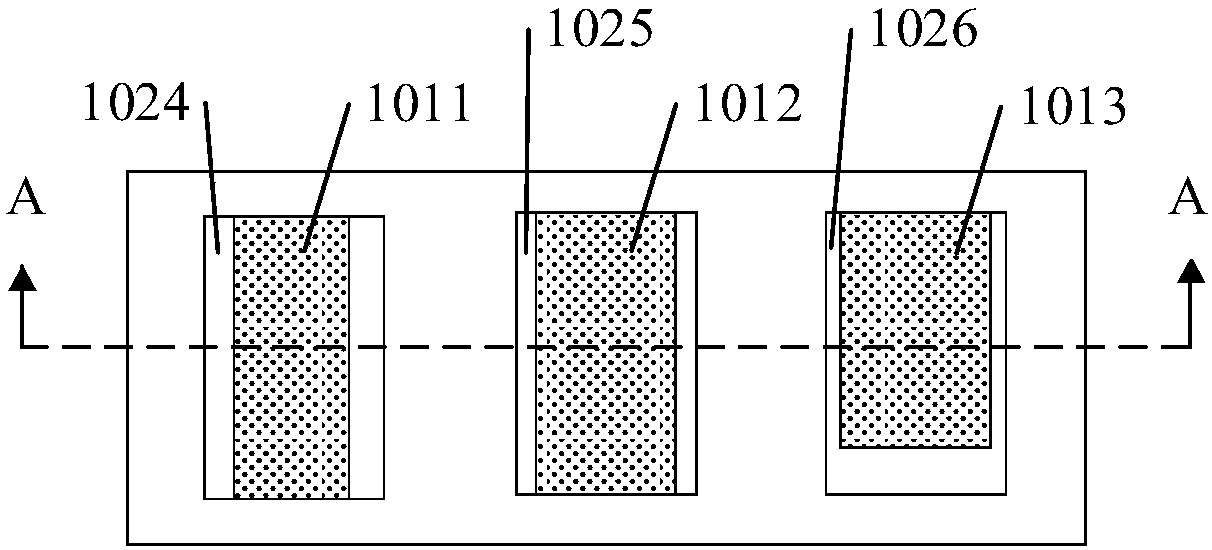

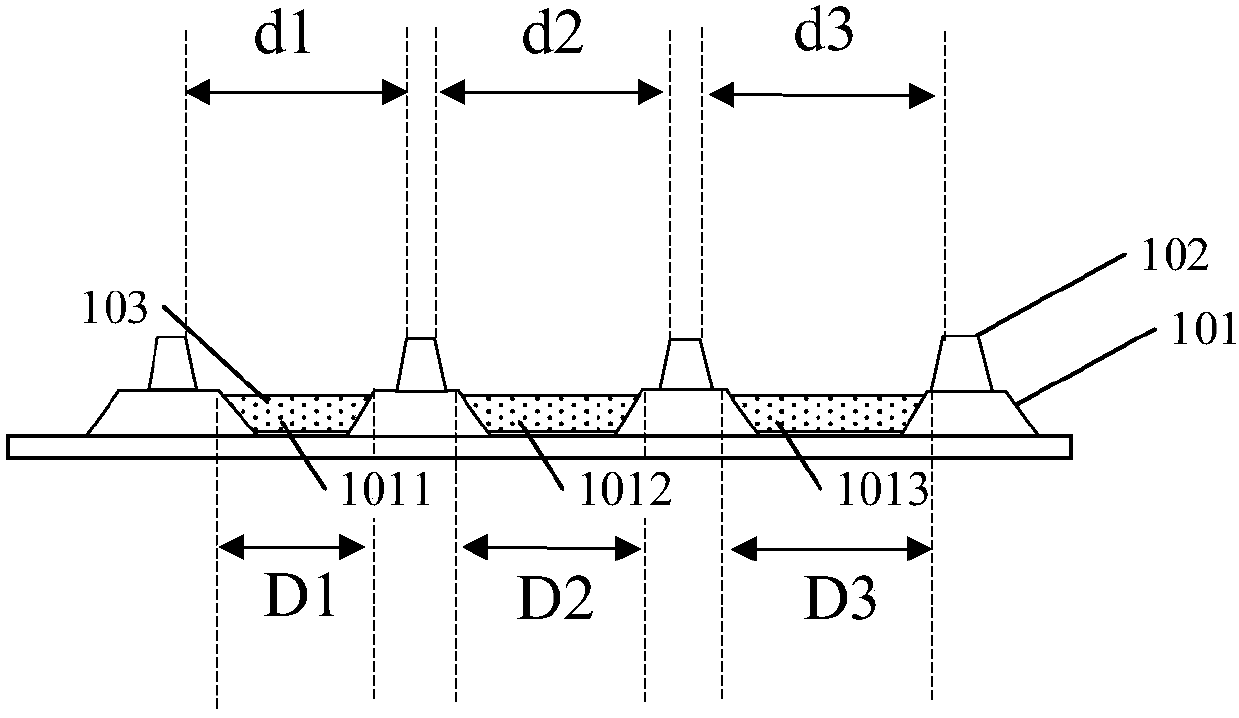

Pixel defining layer, display substrate, display device, and inkjet printing method

ActiveCN109860223AConsistent drying speedUniform film layerSolid-state devicesSemiconductor/solid-state device manufacturingInkjet printingComputer graphics (images)

The present invention provides a pixel defining layer, a display substrate, a display device and an inkjet printing method. The pixel defining layer comprises: a first pixel defining layer having a first opening, wherein the first opening comprises a first sub pixel opening and a second sub pixel opening which correspond to different sub pixels, and the size of the opening of the second sub pixelopening is larger than the size of the opening of the first sub pixel opening; and a second pixel defining layer located on the first pixel defining layer, wherein the second pixel defining layer hasa second opening, the second opening has a fourth sub pixel opening corresponding to and communicating with the first sub pixel opening and a fifth sub pixel opening corresponding to and communicatingwith the second sub pixel opening, and the difference of the opening size of the fourth sub pixel opening and the opening size of the first sub pixel opening is larger than the difference of the opening size of the fifth sub pixel opening and the second sub pixel opening. The pixel defining layer is employed for ink jet printing to allow the film layer obtained after ink is dried to be more uniform.

Owner:BOE TECH GRP CO LTD +1

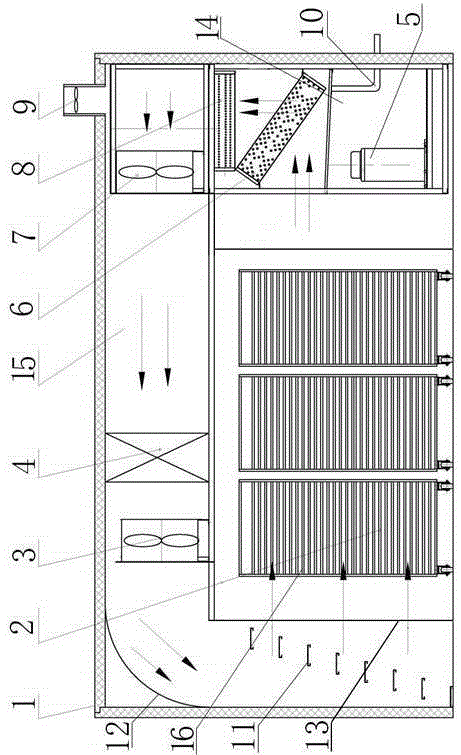

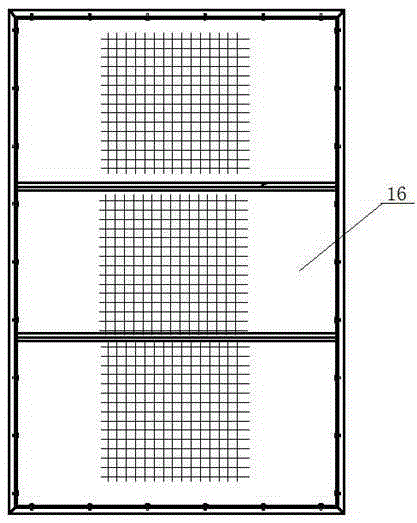

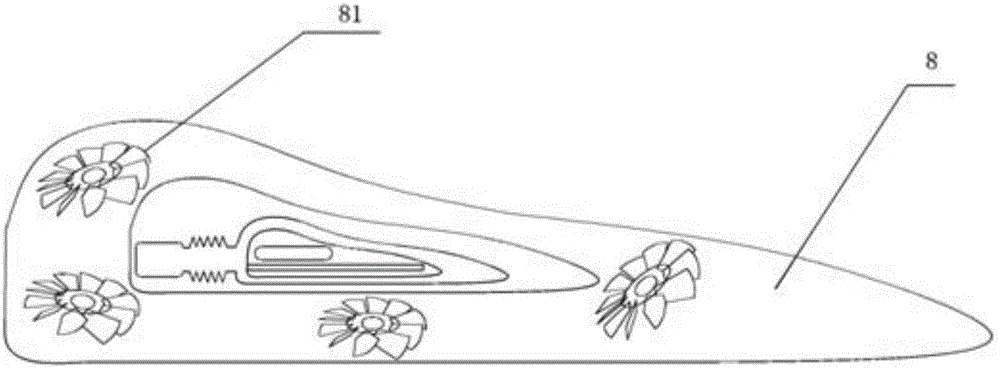

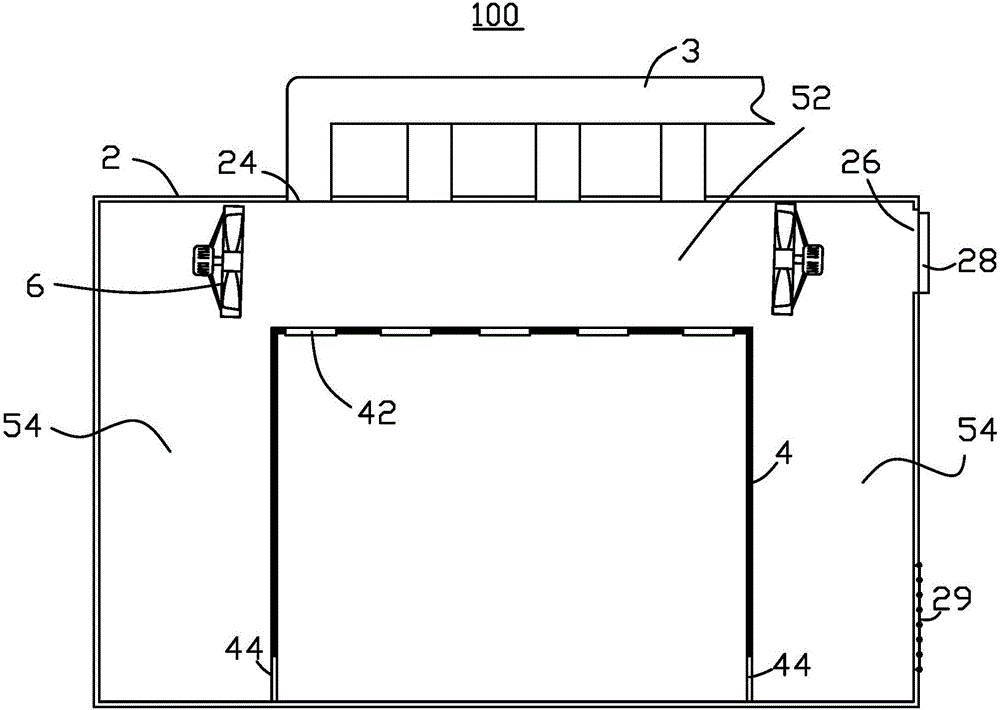

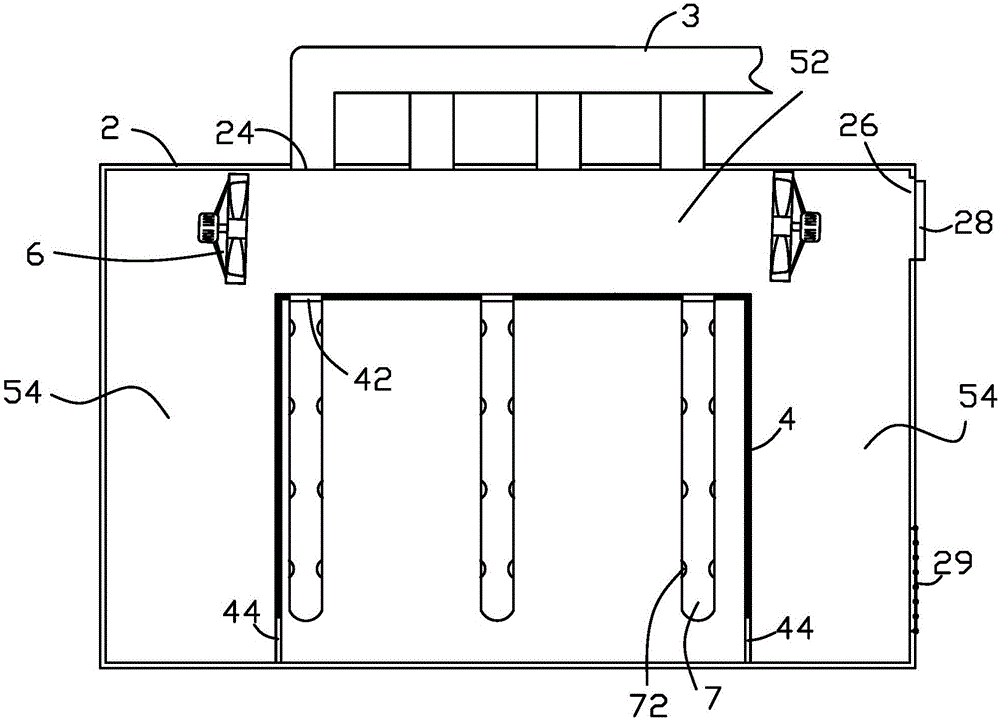

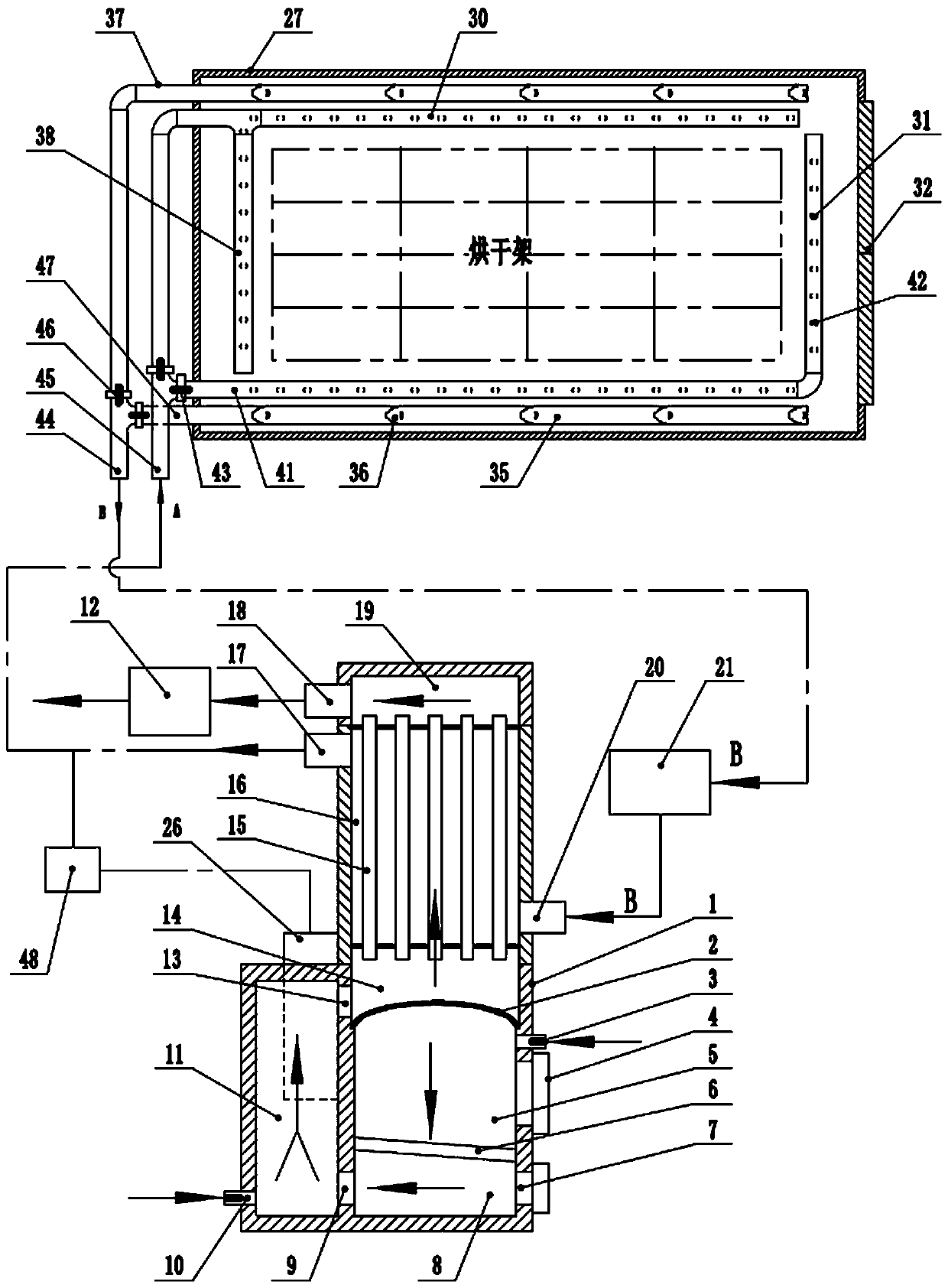

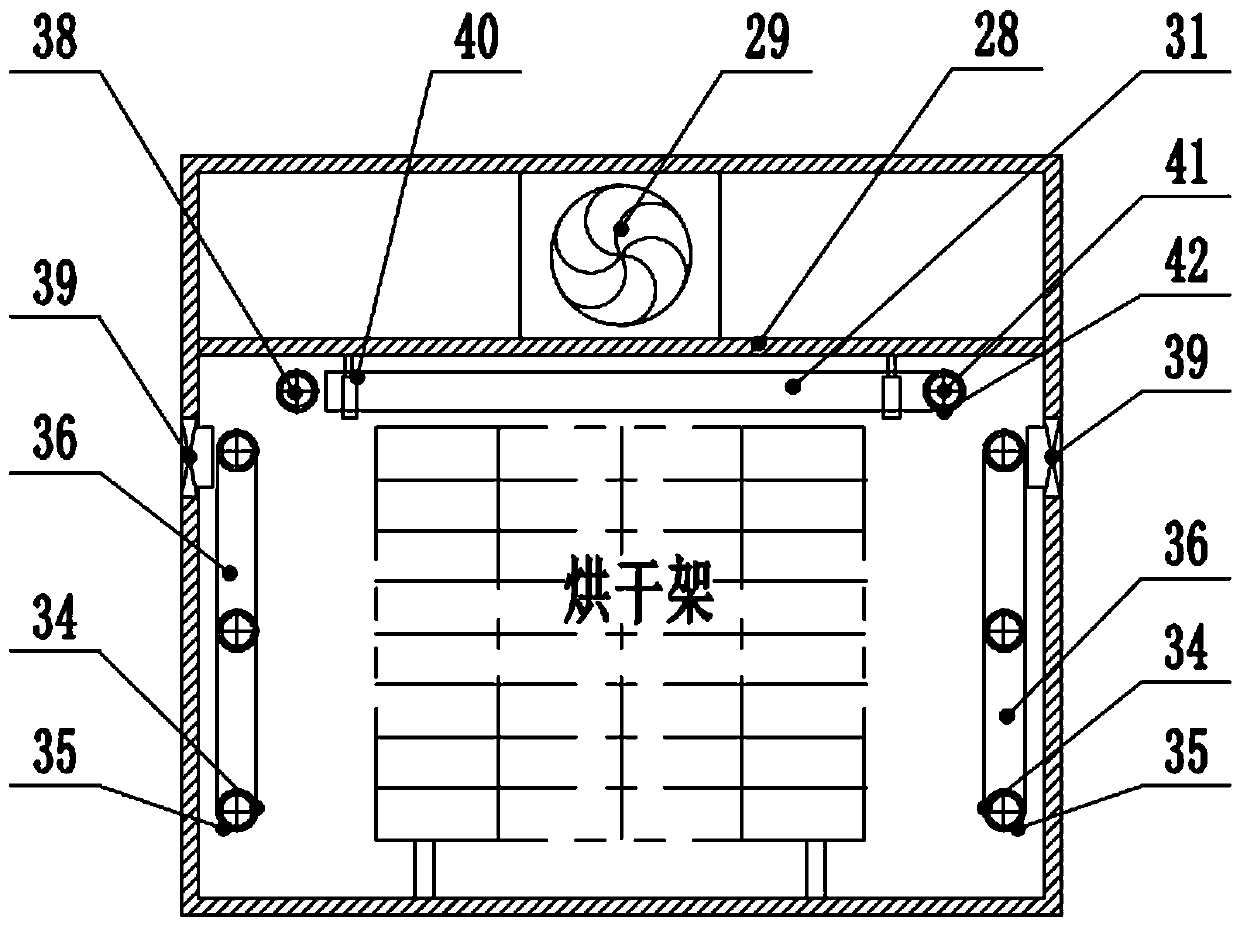

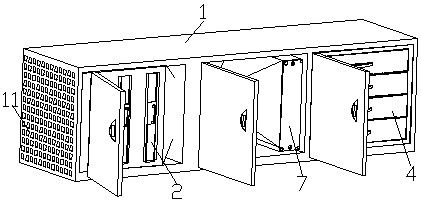

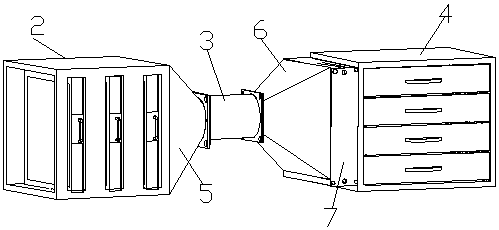

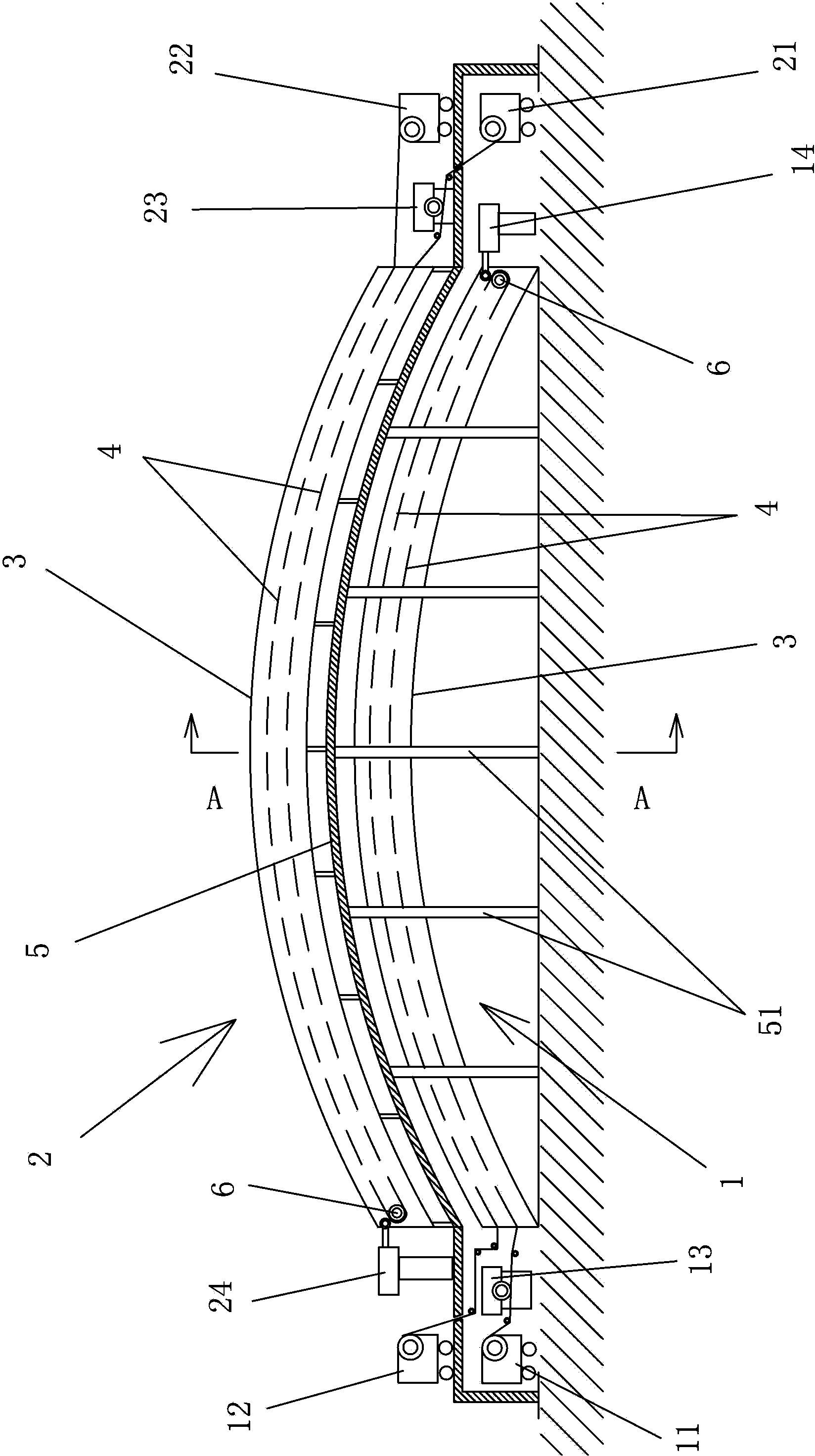

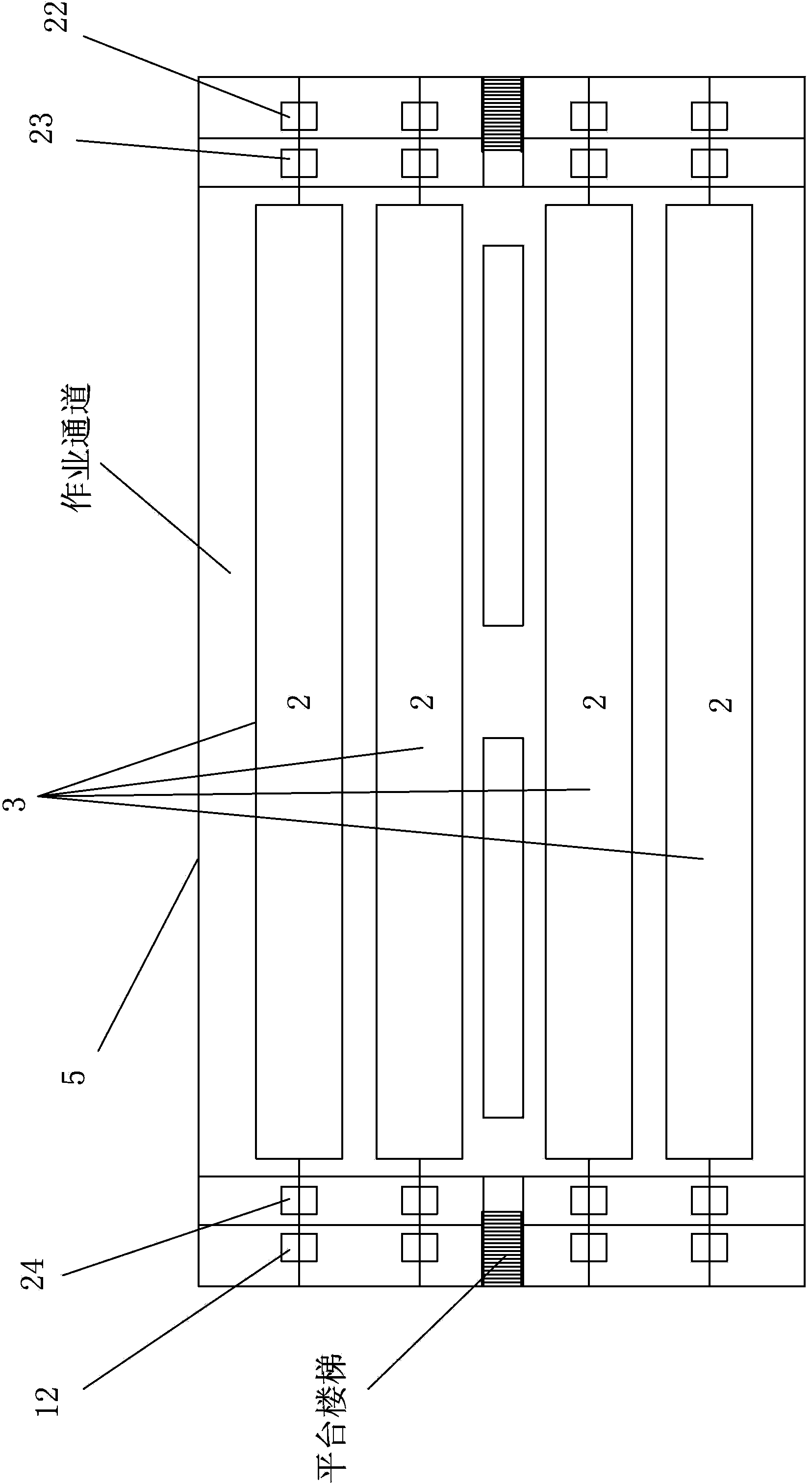

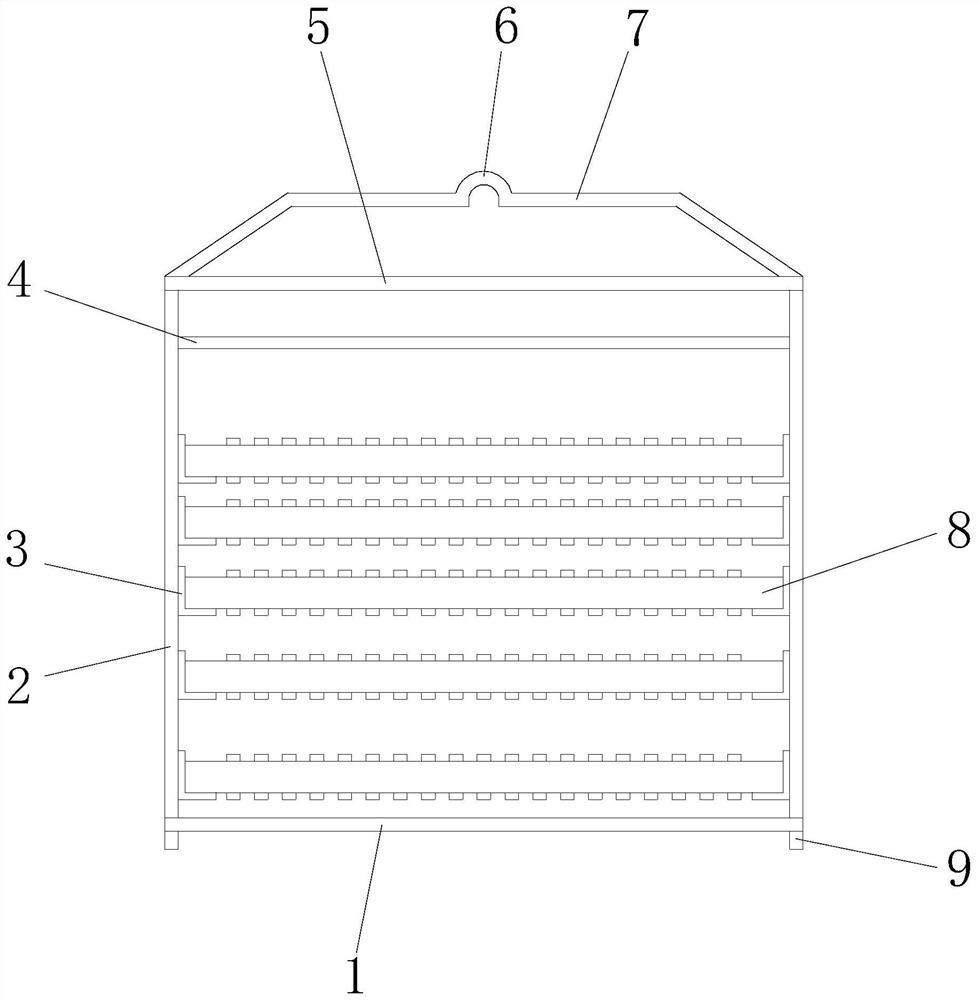

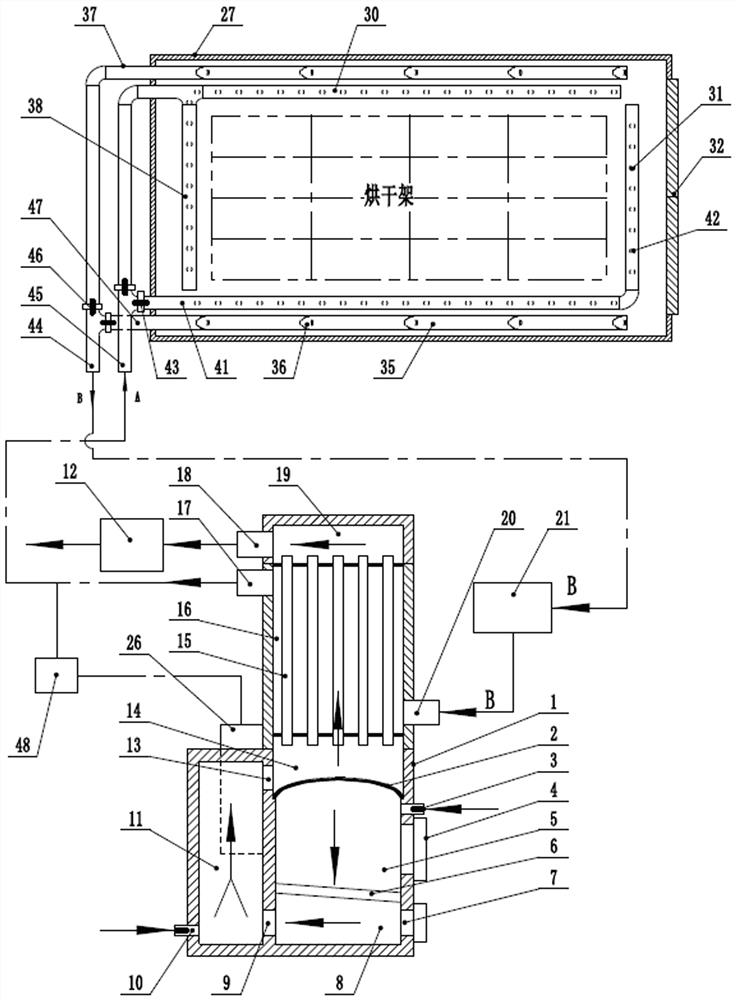

Three-dimensional box-type hot air circulation device

InactiveCN105300053AReduce lossesAchieve energy saving and emission reductionDrying gas arrangementsDrying chambers/containersControl flowHeat losses

The invention relates to the technical field of agricultural product processing equipment and discloses a three-dimensional box-type hot air circulation device. The three-dimensional box-type hot air circulation device comprises a box body composed of a main machine room, an air flue and a drying chamber, wherein the main machine room is located on one side of the drying chamber and the air flue is located above the drying chamber. A compressor and an evaporator are arranged in the main machine room, the evaporator is installed above the compressor in an inclined mode, a condenser is arranged above the evaporator, and the air outlet of the condenser is connected to one end of the air flue. A moisture removal fan is arranged at the top end of the air flue, a main fan is arranged at the part, close to the condenser, in the air flue, a circulating fan is arranged at the other end of the air flue, and an auxiliary heater is arranged between the circulating fan and the main fan. According to the invention, an arc-shaped air guide plate is adopted for guiding hot air, the hot air is prevented from suddenly turning and generating vortexes, and therefore loss of wind energy is prevented; air dividing plates are arranged to control flow of the hot air; the hot air mingled with moisture is recycled, so that heat loss is reduced. The three-dimensional box-type hot air circulation device effectively achieves energy conservation and emission reduction and is an environment-friendly and energy-saving device.

Owner:甘肃奥凯农产品干燥装备工程研究院有限公司

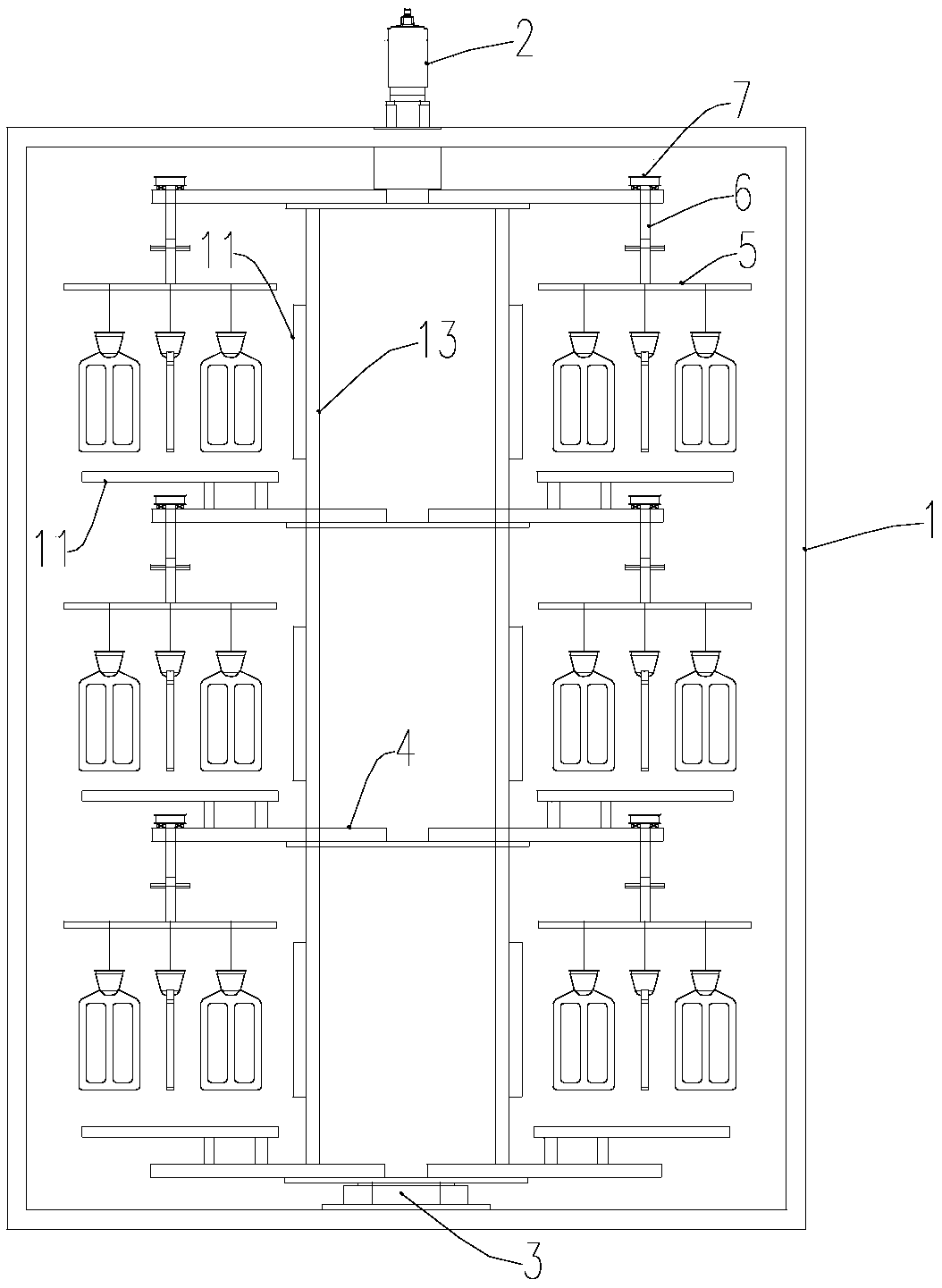

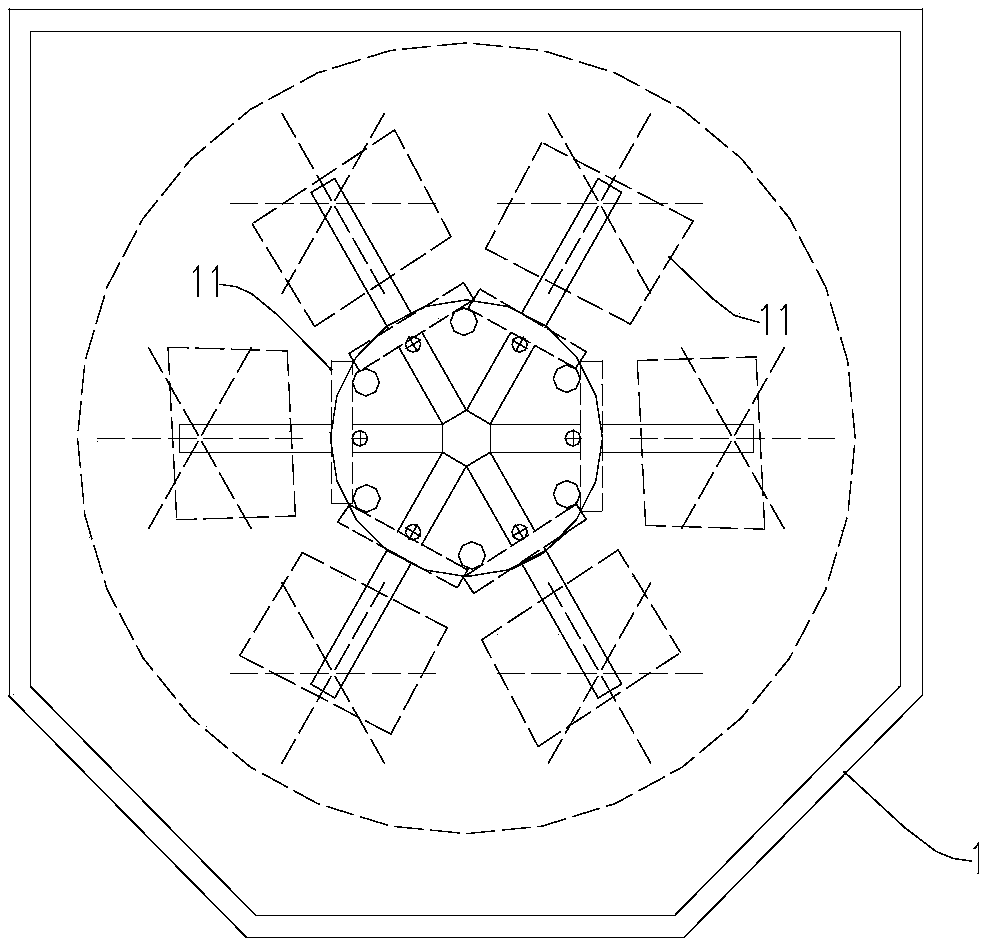

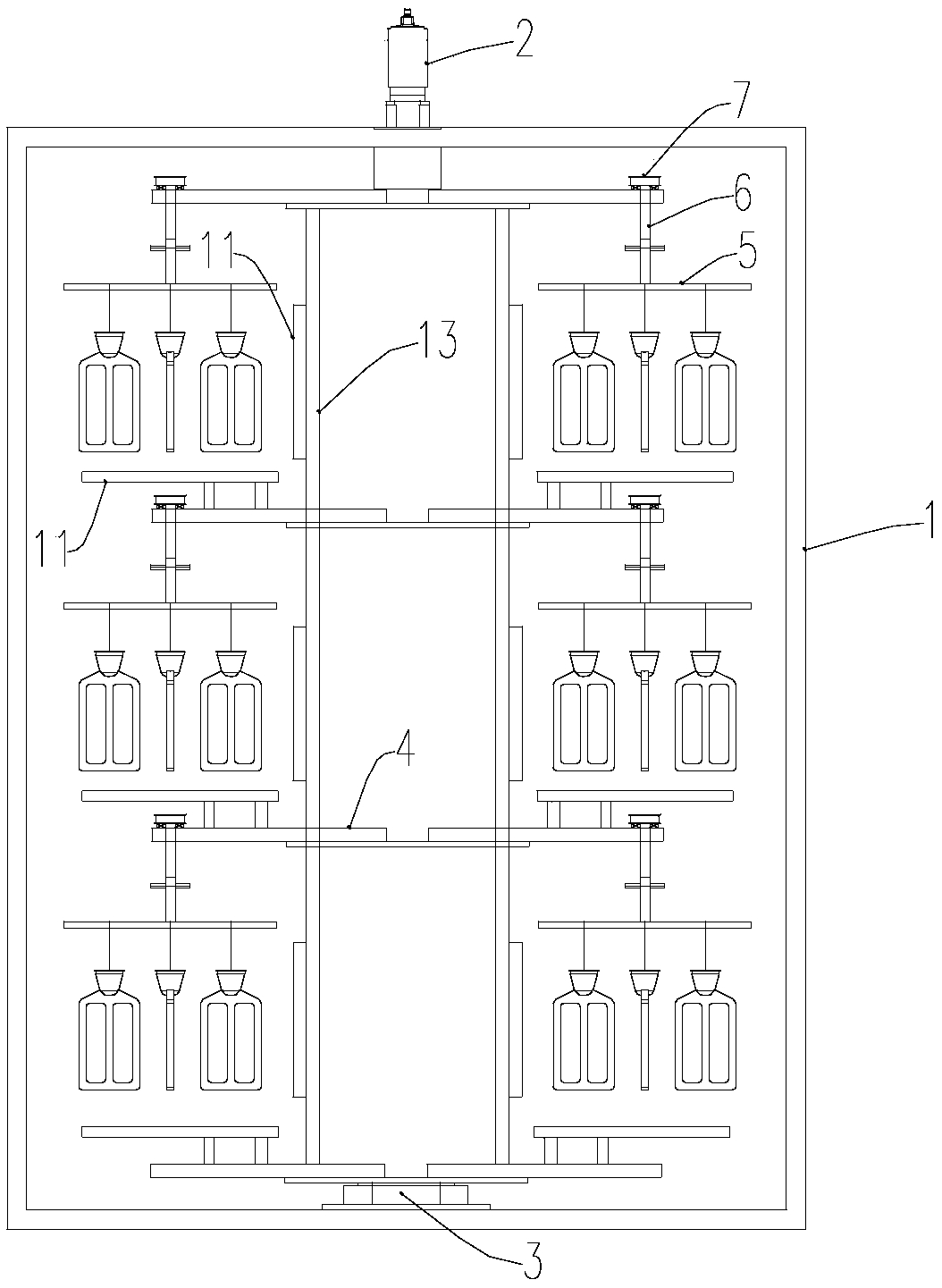

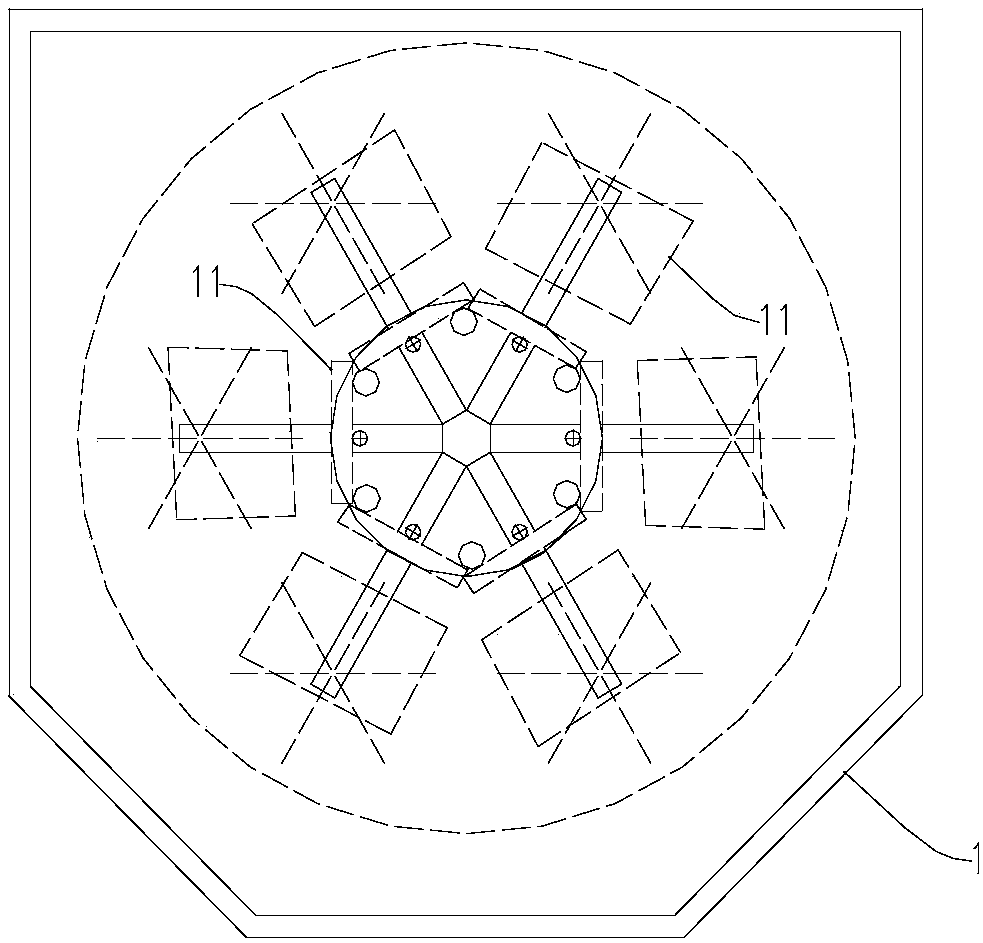

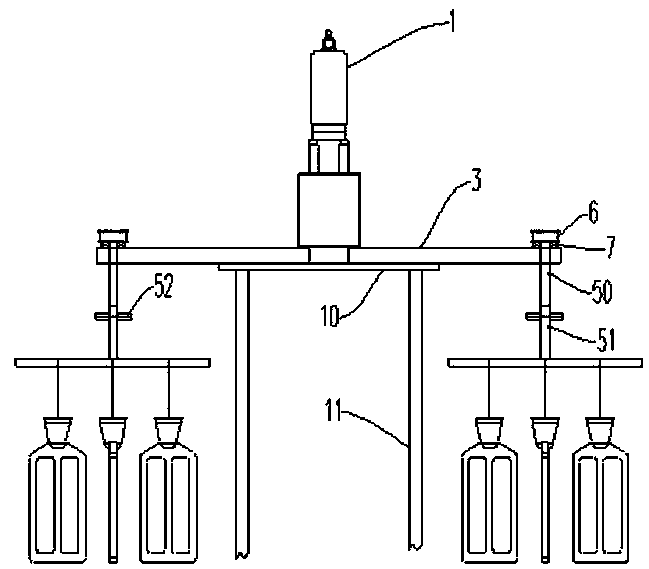

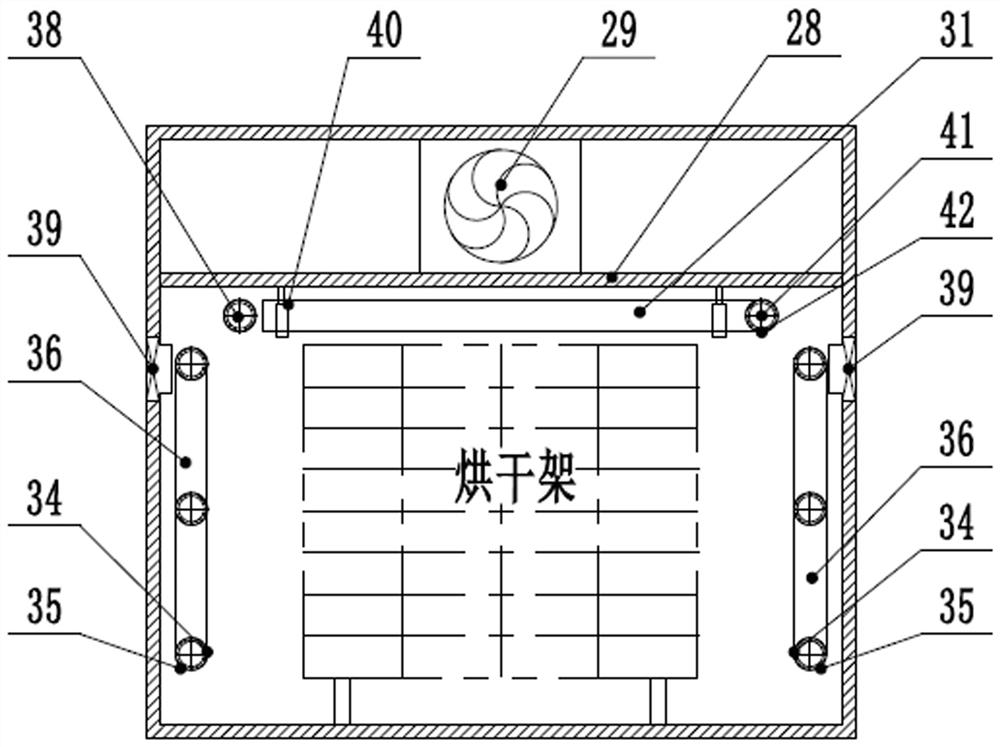

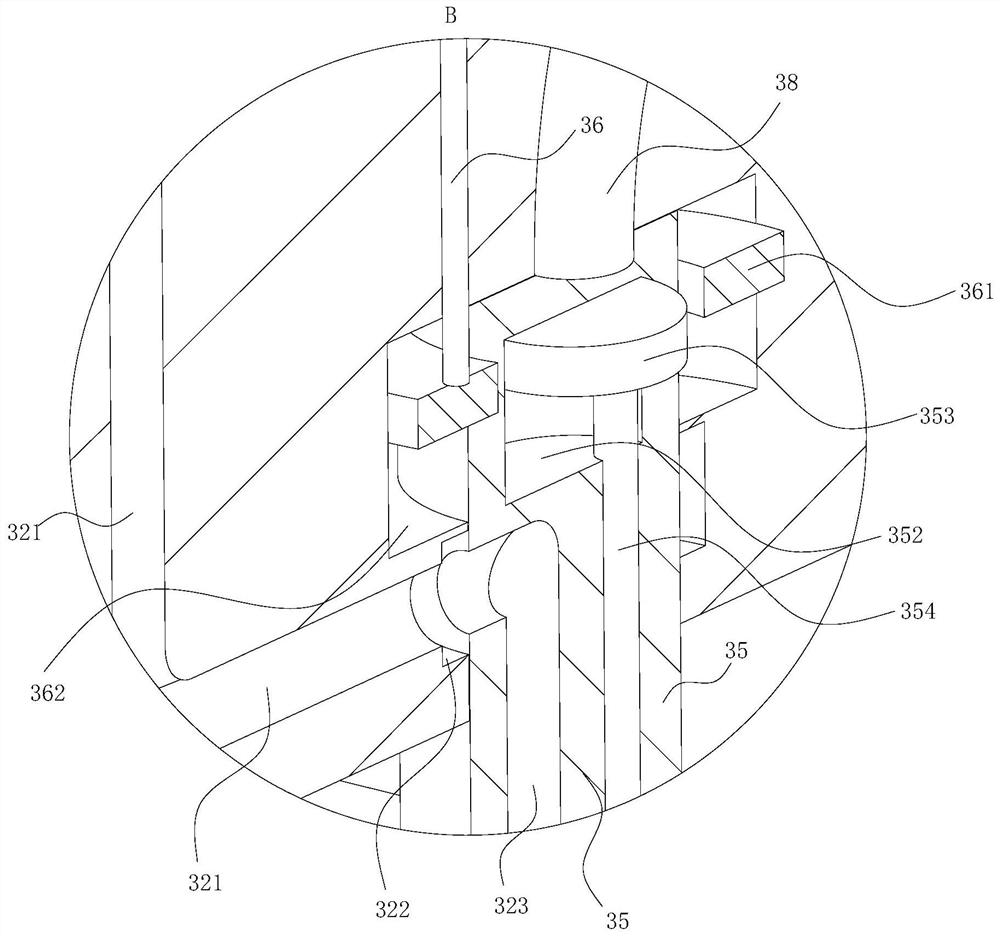

Intelligent adjustable formwork drying box suitable for intelligent robot formwork manufacturing line

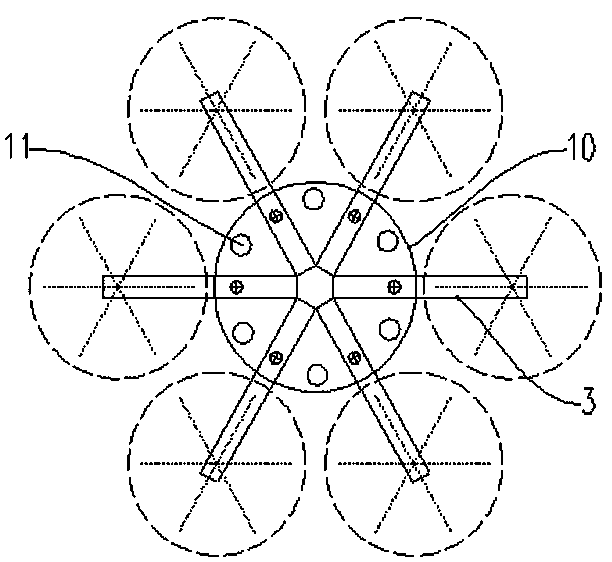

PendingCN109341292AIncrease or decrease the dehumidification effectEnhance or reduce thermal radiation powerDrying gas arrangementsDrying machines with non-progressive movementsDrive motorThermal radiation

The invention relates to an intelligent adjustable formwork drying box suitable for an intelligent robot formwork manufacturing line. The intelligent adjustable formwork drying box comprises a box body, a revolution mechanism and a rotation mechanism, and the revolution mechanism and the rotation mechanism are located in the box body. The rotation mechanism comprises a plurality of rotation units,and a plurality of formworks to be dried can be suspended on each rotation unit. The revolution mechanism comprises a first drive motor fixed to the top of the box body, and when the revolution mechanism revolves, the rotation units can be driven to rotate. A plurality of thermal radiation air supply assemblies are fixed to the revolution mechanism. The side portion and the bottom of each rotation unit are each provided with a thermal radiation air supply assembly correspondingly. Each thermal radiation air supply assembly comprises an electric heat regulator and a blast regulator. The firstdrive motor, the electric heat regulators and the blast regulators are all electrically connected with a PLC. The intelligent adjustable formwork drying box has the advantages that on the one hand, itis ensured that the formworks in the box are dried uniformly, on the other hand, personalized selection and program control of drying conditions of the formworks at the different rotation units in the box can also be achieved, the flexibility is good, and the degree of automation is high.

Owner:WUHAN ZONKING METAL PRODS

Hot air drying process for shiitake mushroom

InactiveCN105076356AConsistent drying speedSpread evenlyFruits/vegetable preservation by dehydrationShiitake mushroomsAir drying

The invention discloses a hot air drying process for shiitake mushroom. The hot air drying process includes the following steps: (1), pre-drying; (2), tempering ; (3) drying; (4), moistening; (5), shaping; (6), flavoring. The hot air drying process is simple in step, high in operability and suitable for industrialized production, dry shiitake mushroom products obtained through the hot air drying process are good in color and luster, strong in flavor, round in mushroom shape, complete and attractive, value is increased greatly, and the dry shiitake mushroom products have wide application popularization prospect.

Owner:张刚

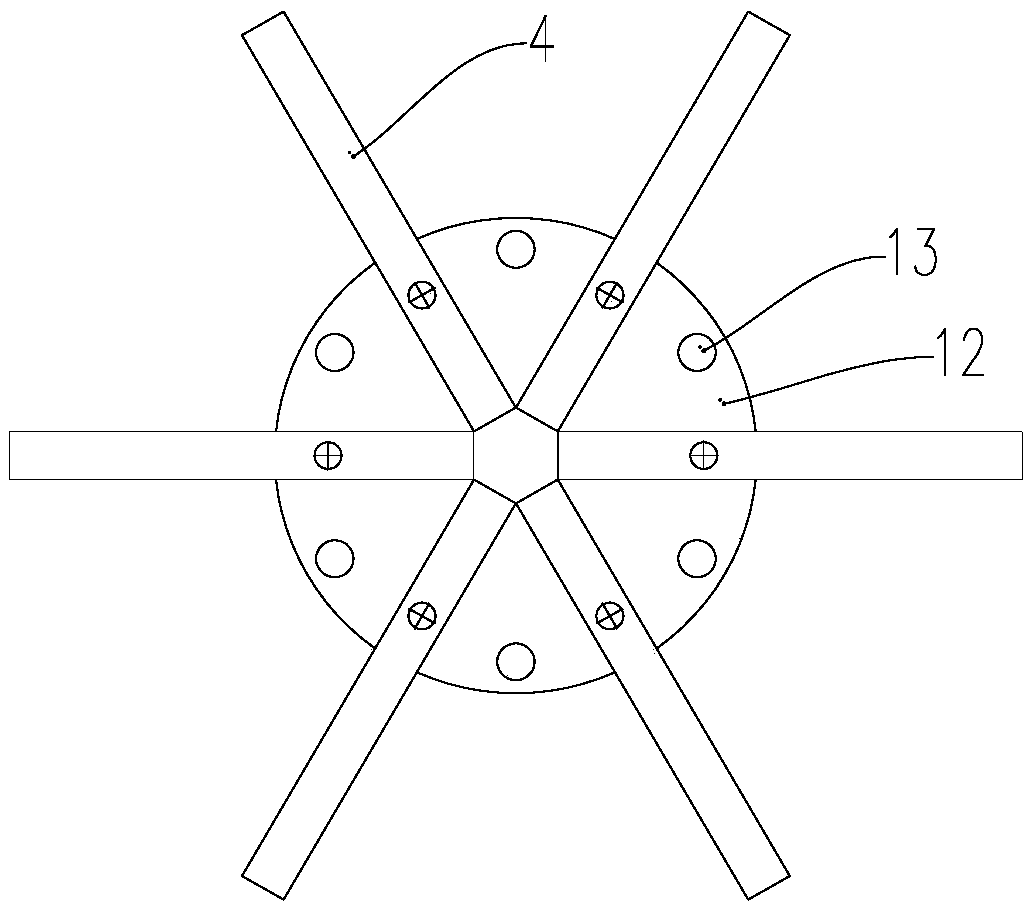

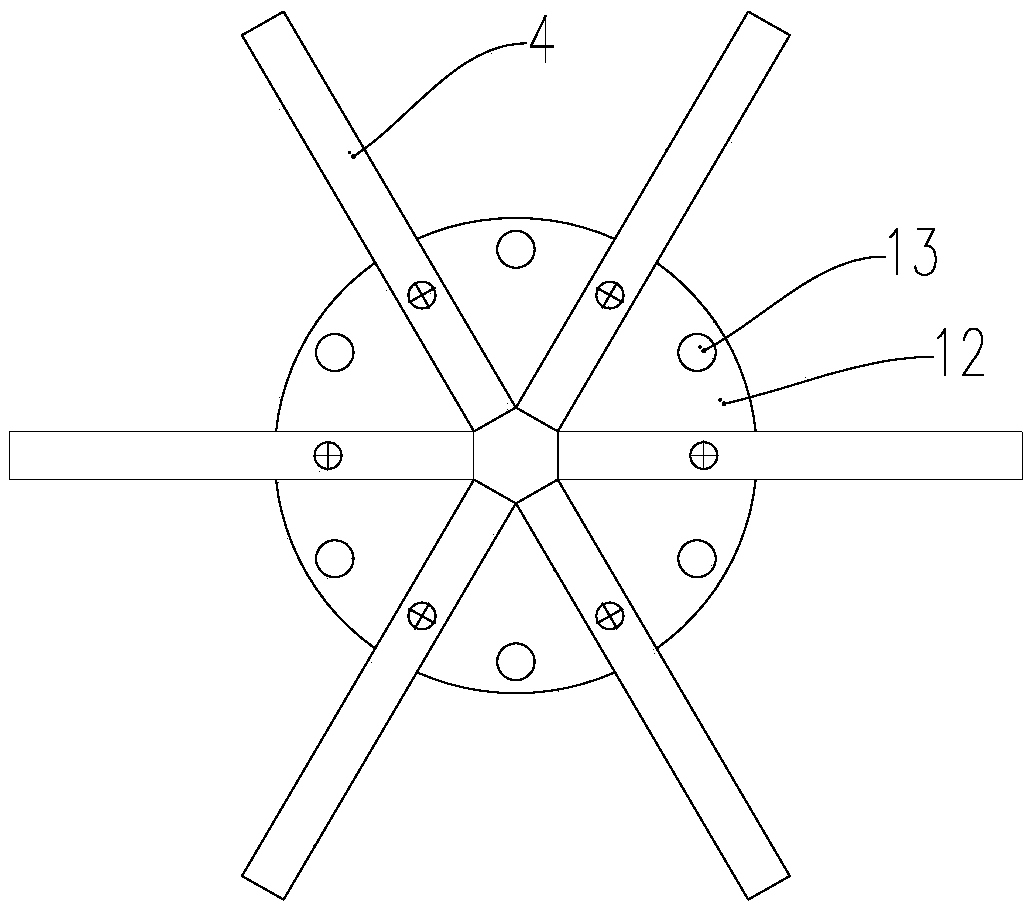

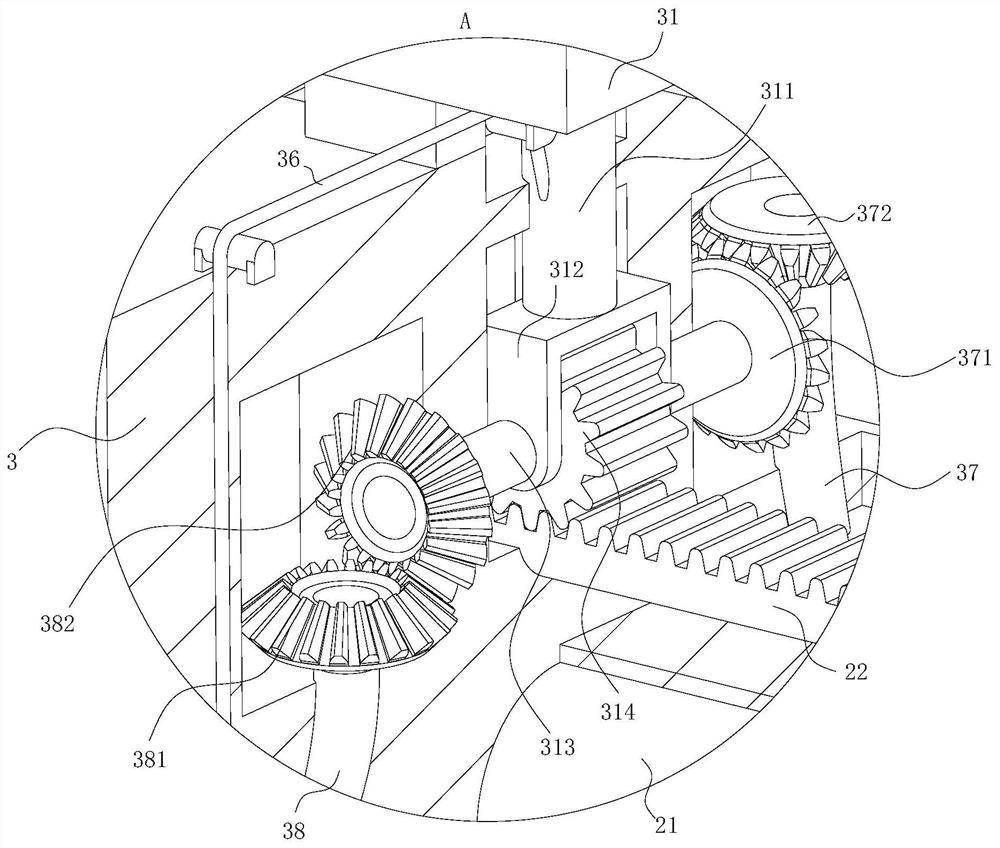

Formwork drying box with autorotation and revolution functions

PendingCN108855820AImprove qualityIncrease productivityPretreated surfacesCoatingsElectric machineryEngineering

The invention relates to a formwork drying box with autorotation and revolution functions. The formwork drying box comprises a box body, a drying mechanism, a revolution mechanism and an autorotationmechanism, the drying mechanism, the revolution mechanism and the autorotation mechanism are positioned in the box body, the autorotation mechanism comprises multiple autorotation units, the revolution mechanism comprises a first driving motor, a spindle and rotating support, a plurality of beam frames are vertically fixed on the spindle, each beam frame is composed of multiple cross beams, one end of each cross beam is correspondingly connected with an autorotation unit, each autorotation unit comprises a disc, a rotating shaft and multiple horizontal connecting rods, the upper end of each rotating shaft is fixedly connected with the center of a synchronous belt wheel after penetrating a through hole formed in one end of the cross beam, and multiple synchronous belt wheels are in transmission connection with a synchronous belt; the drying mechanism comprises multiple drying units fixed on the inner wall of the box or / and on the revolution mechanism. The formwork drying box has the advantages that the drying box can realize autorotation and revolution of multiple to-be-dried formworks during drying in the drying box in one time, and unfavorable impact of nonuniform temperature in the drying box and fixed wind direction during air blowing on formwork drying can be effectively eliminated.

Owner:WUHAN ZONKING METAL PRODS

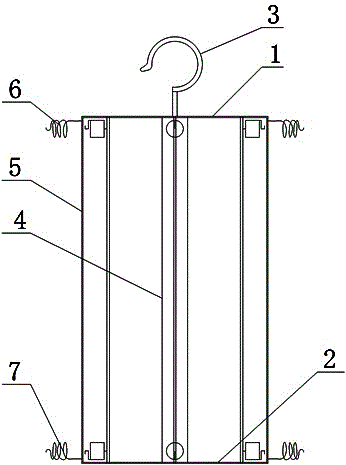

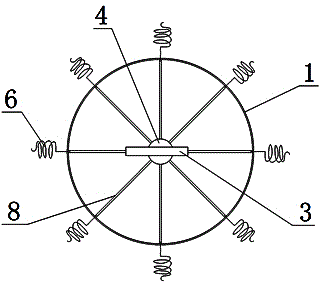

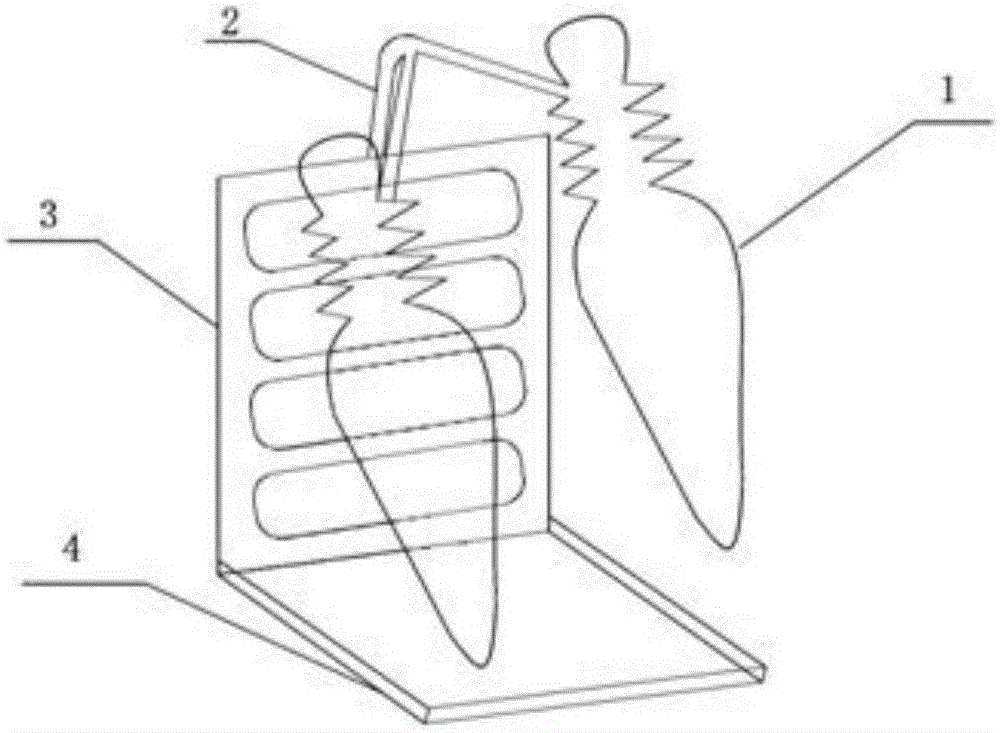

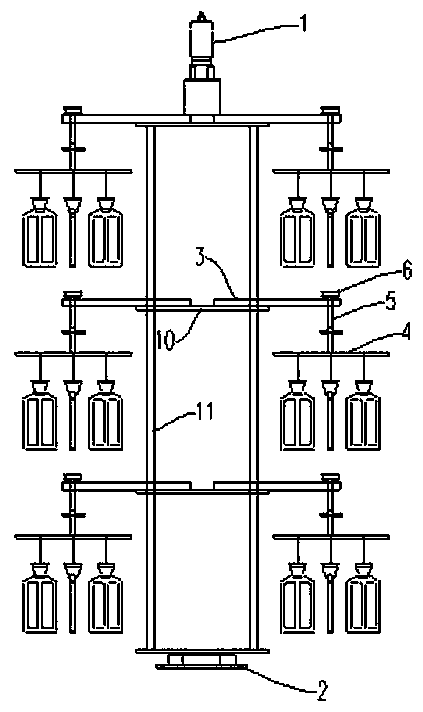

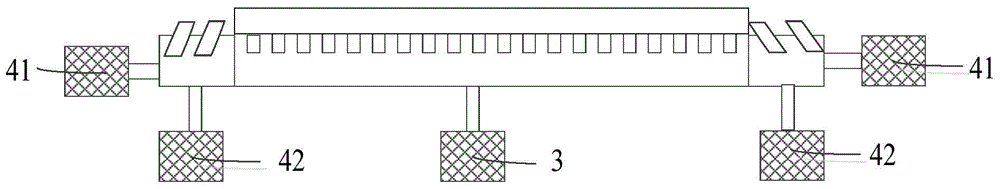

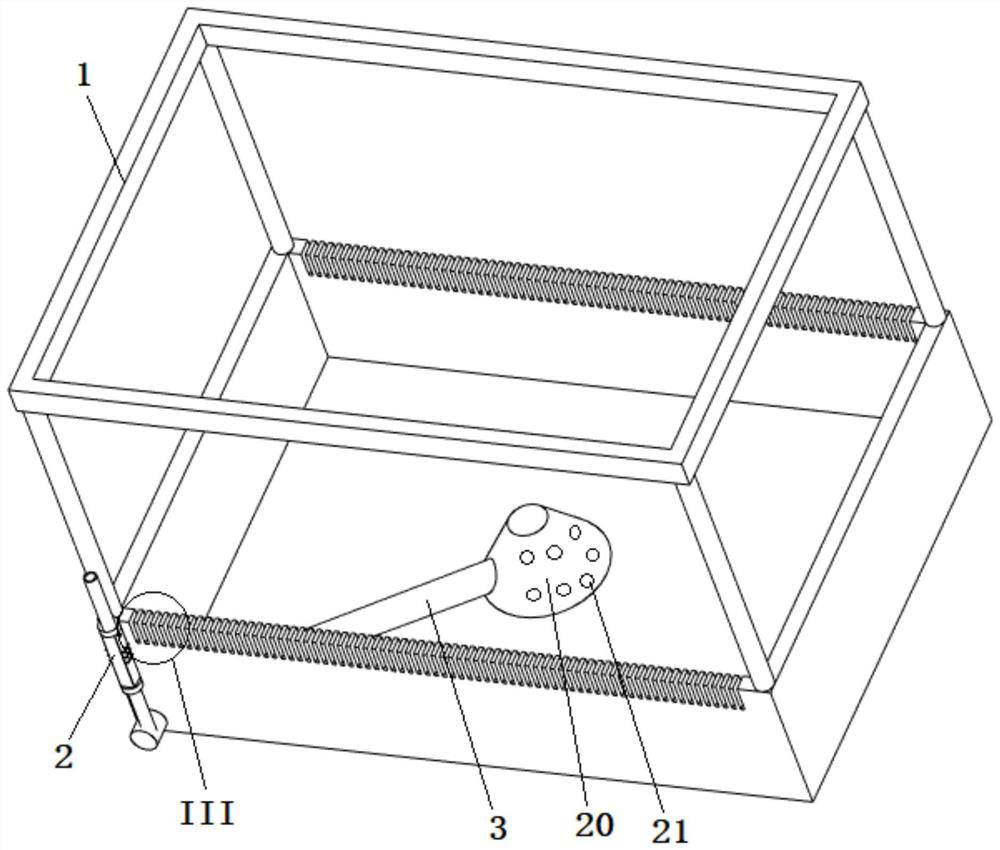

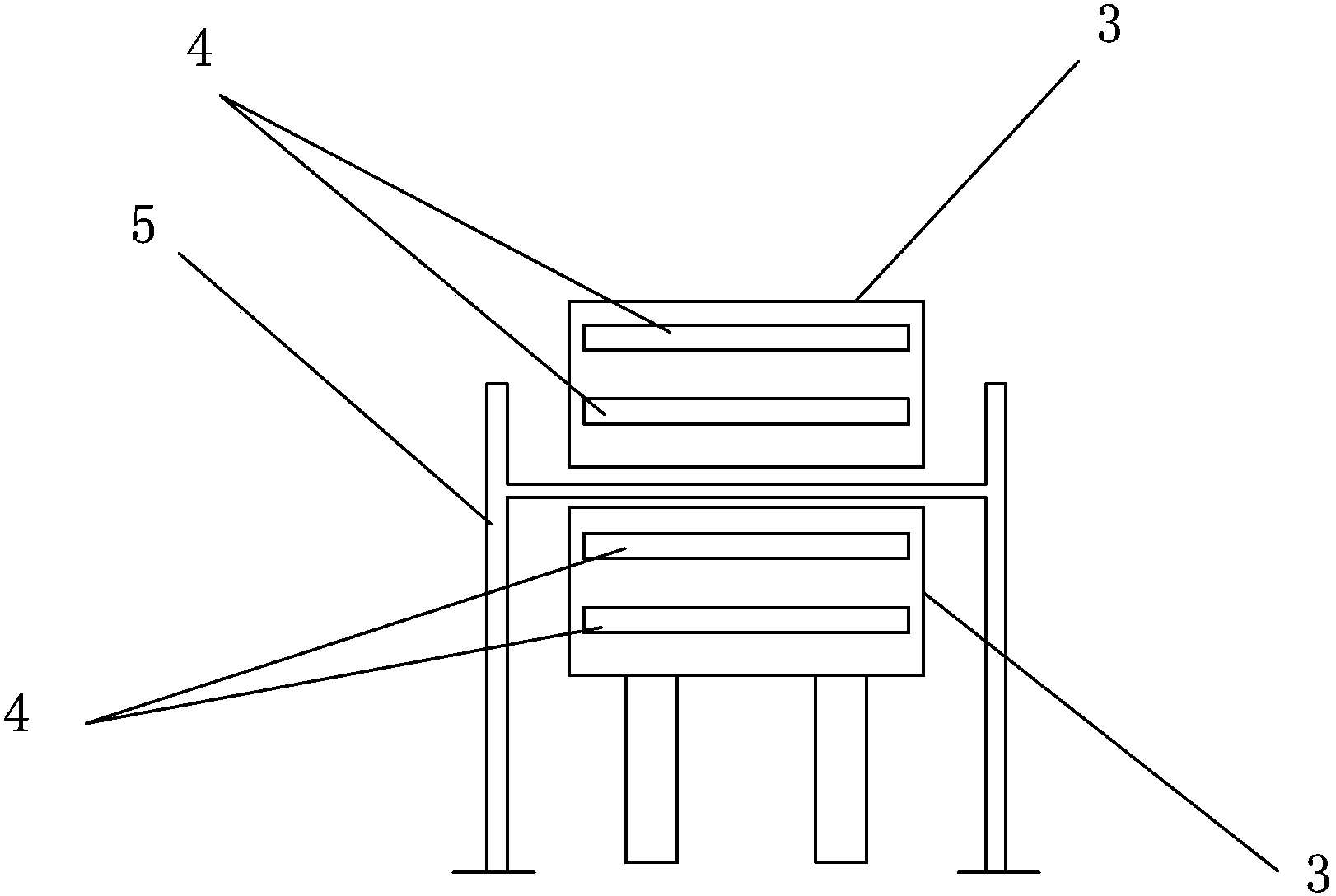

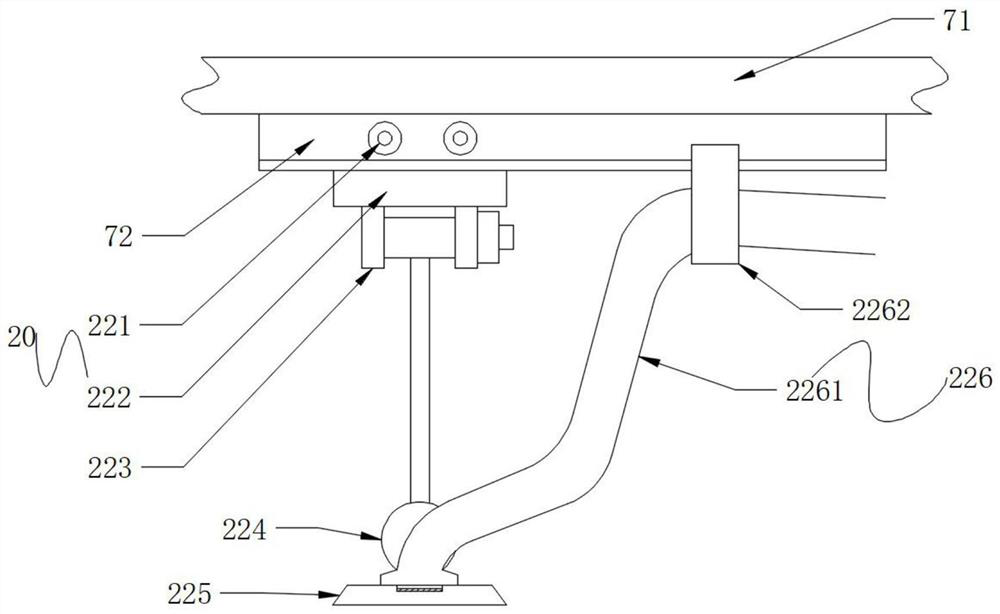

Rotary hanging frame for drying of shield support

ActiveCN106225430AConsistent drying speedSimple structureDrying solid materials without heatDrying chambers/containersEngineering

The invention relates to a rotary hanging frame for drying of a shield support. The rotary hanging frame comprises an upper fixed ring (1), a lower fixed ring (2), a hook (3), a vertical shaft (4), upper fixed support lugs (6) and lower fixed support lugs (7). The upper fixed ring (1) and the lower fixed ring (2) are both of a circular ring structure. The upper fixed ring (1) is fixed to the upper end of the vertical shaft (4) through a plurality of connection frameworks (8). The lower fixed ring (2) is fixed to the lower end of the vertical shaft (4) through a plurality of connection frameworks (8). The hook (3) is fixed to the upper end of the vertical shaft (4). The multiple upper fixed support lugs (6) are fixed to the outer side of the circumference of the upper fixed ring (1) evenly at intervals. The lower fixed support lugs (7) which are equal to the upper fixed support lugs (6) in number are fixed to the outer side of the circumference of the lower fixed ring (2) evenly at intervals, and the upper fixed support lugs (6) are aligned with the lower fixed support lugs (7) vertically and correspondingly. The rotary hanging frame has the advantages of being simple in structure, low in cost and capable of ensuring consistence of drying speed.

Owner:CHENGDU HOMIN TECH

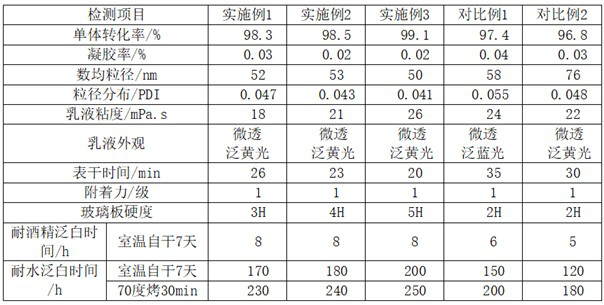

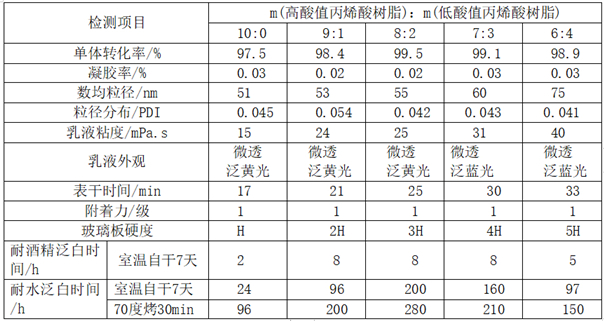

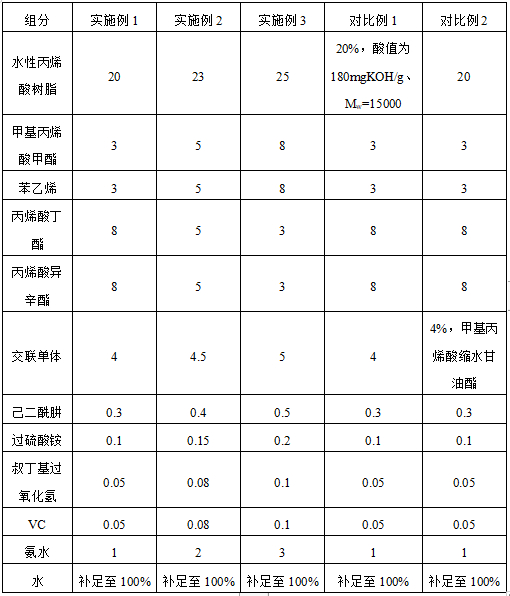

Soap-free self-crosslinking nano acrylic emulsion as well as preparation method and application thereof

PendingCN111662415AThe appearance of the coating film is transparentBright appearanceCoatingsIsooctyl acrylateDiacetonamine

The invention belongs to the technical field of water-based paint, and relates to a soap-free self-crosslinking nano acrylic emulsion, which comprises the following components: water-based acrylic resin, methyl methacrylate, styrene, butyl acrylate, 2-ethylhexyl acrylate, a crosslinking monomer, adipic dihydrazide, ammonium persulfate, tert-butyl hydroperoxide, VC, ammonia water and the balance ofwater. The cross-linking monomers are diacetone acrylamide and butyl acrylamide. The emulsion is 50-100 nm in particle size, good in wettability, good in permeability, low in minimum film forming temperature of a coating film, high in curing speed, high in gloss of the coating film and capable of being polished, and the hardness of the coating film reaches up to 3H-5H. The emulsion is low in foam, a wetting agent and a defoaming agent do not need to be added when the emulsion is applied to water-borne wood paint, and the emulsion is small in particle size, so that a paint film is good in woodcolor warming property and transparent.

Owner:恒昌涂料(惠阳)有限公司

Wall-mounted drying shoe rack

InactiveCN105011889AConsistent temperatureConsistent drying speedFootwear cleanersHeat conductingEngineering

The invention discloses a wall-mounted drying shoe rack. The wall-mounted drying shoe rack comprises a wall-mounted plate, a shoe support, a connecting frame, a dryer, a control unit and a deodorizing device. The shoe support is arranged in the horizontal direction perpendicular to the bottom of the wall-mounted plate, the dryer comprises a heating device and an air supply device installed in the heating device, the heating device comprises a heating tube and a heat conducting layer, the heat conducting layer is connected with the heating tube and in the same shape as the interior of the dryer, and multiple air outlets are evenly formed in the surface of the heat conducting layer; the dryer is an elastic cavity in a filling shape in a shoe; the connecting frame is hollow and connected with the dryer and the wall-mounted plate to form a closed space internally; a shaping shoe stretcher for supporting the shoe is arranged in the dryer; the control unit comprises a timing device, an indicator lamp and a gear switch, and the timing device, the indicator lamp, the heating device, the air supply device and an external power source are connected in series through a power line to form a closed circuit.

Owner:GUANGXI UNIV

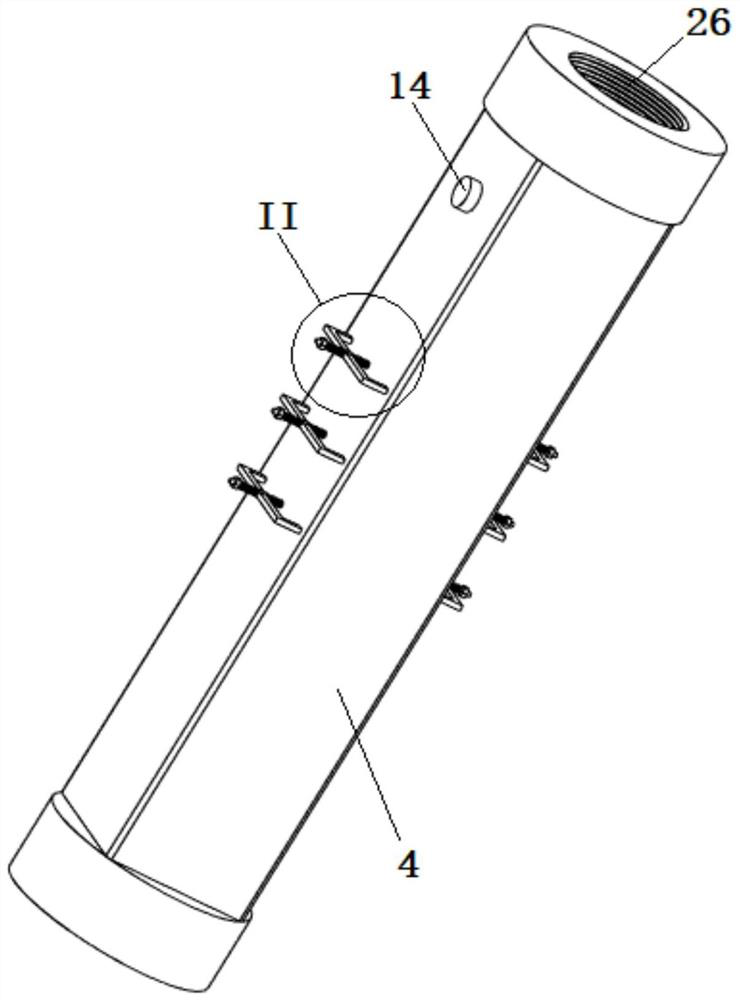

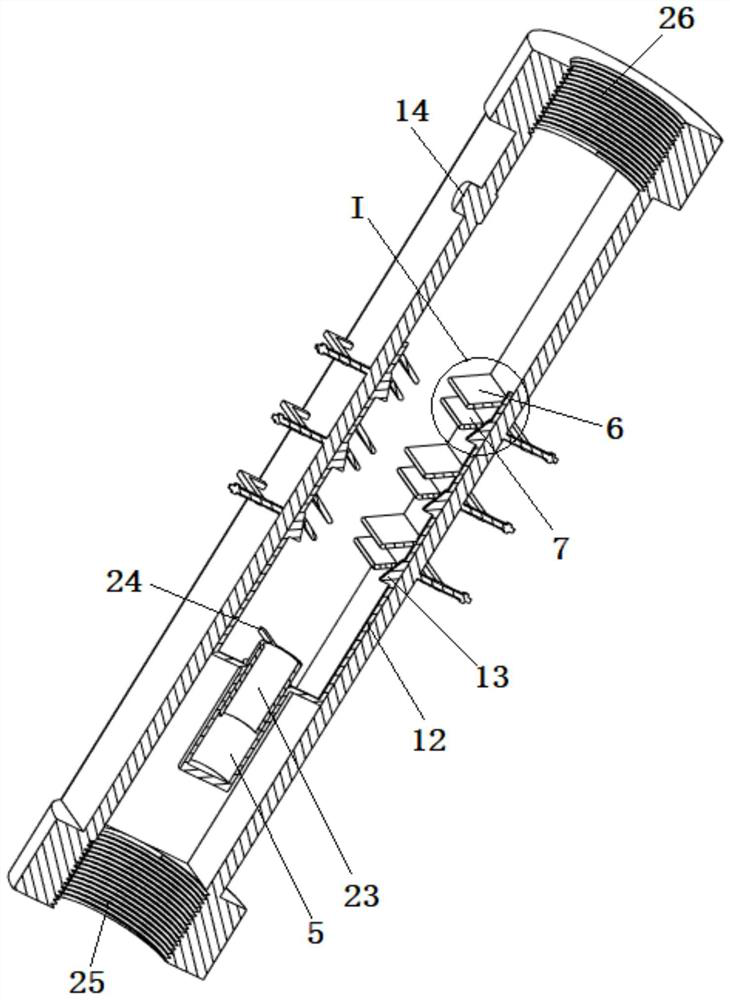

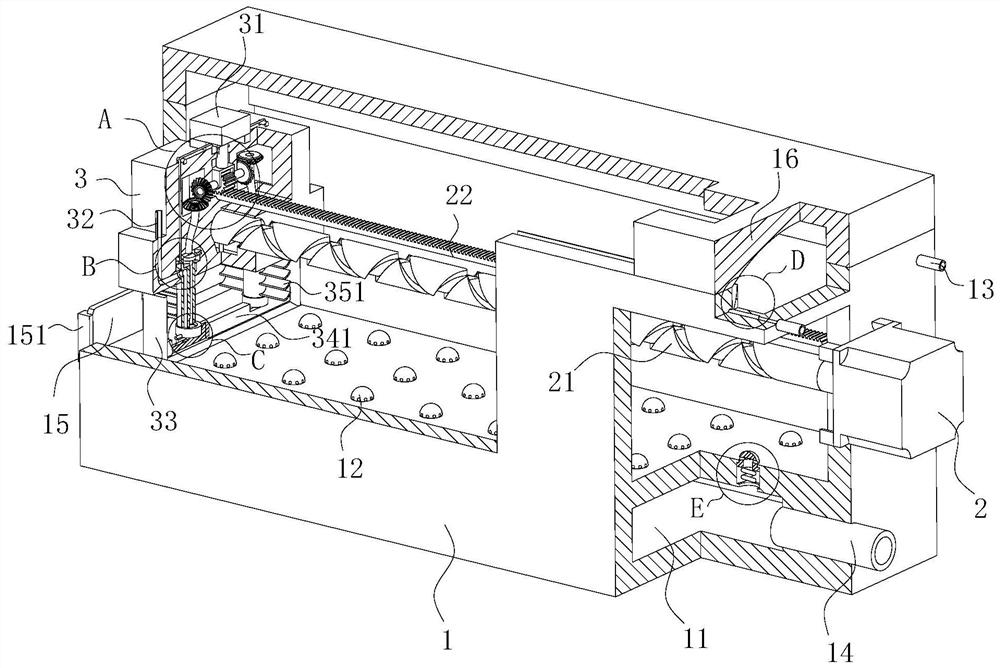

Hanging mechanism capable of rotation and revolution for mold shell drying

PendingCN109047674AConsistent drying speedConsistent drynessFoundry mouldsFoundry coresEngineeringSlewing bearing

The invention relates to a hanging mechanism capable of rotation and revolution for mold shell drying. The hanging mechanism comprises a revolution unit and a plurality of rotation units; the revolution unit comprises a first driving motor, a vertically arranged main shaft and a slewing bearing; the output end of the first driving motor is fixedly connected to the upper end of the main shaft, theslewing bearing is fixed on the bottom wall of a drying box, and the lower end of the main shaft is tightly pressed on the upper surface of the slewing bearing; a plurality of layers of beam frames are vertically fixed on the main shaft, each layer of beam frame is composed of a plurality of cross beams, and one end of each cross beam is correspondingly connected to one rotation unit; and the rotation units comprise disc bodies and rotating shafts, the upper ends of the rotating shafts penetrate through through holes formed in one ends of the cross beams and then are fixedly connected to centers of synchronous belt wheels, and a plurality of synchronous belt wheels are in transmission connection with the same synchronous belt. According to the hanging mechanism, rotation and revolution ofthe multiple batches of to-be-dried mold shells for drying in the drying box can be realized, so that the adverse effect on the drying of the mold shells due to the fact that the temperature in the drying box is not uniform and the wind direction is fixed during blowing can be overcome.

Owner:WUHAN ZONKING METAL PRODS

Energy-saving baking finish house

InactiveCN106513277AReduce power consumptionSave energyPretreated surfacesCoatingsEngineeringMechanical engineering

The invention provides an energy-saving baking finish house. The energy-saving baking finish house comprises a house body and a baking finish chamber arranged inside the house body. A steam inlet is formed in the top of the house body. An air inlet duct and two air return ducts are formed together between the house body and the baking finish chamber. The air inlet duct is located at the top of the baking finish chamber and communicates with the steam inlet. The two air return ducts are located at the two opposite sides of the baking finish chamber and communicate with the two opposite ends of the air inlet duct correspondingly. The end, close to the air inlet duct, of each air return duct is provided with a circulating fan, and thus gas in each air return duct can be exhausted into the air inlet duct. Air inlets communicating with the air inlet duct are formed in the top wall of the baking finish chamber. Air outlets are formed in the two opposite side walls of the baking finish chamber. Each air outlet is located in the bottom of the corresponding side wall, and the two air inlets communicate with the two air return ducts separately. By the adoption of the energy-saving baking finish house, baking finish operations can be performed on workpieces through high-temperature steam, and thus electric energy can be saved.

Owner:柳州誉配汽车零部件有限公司

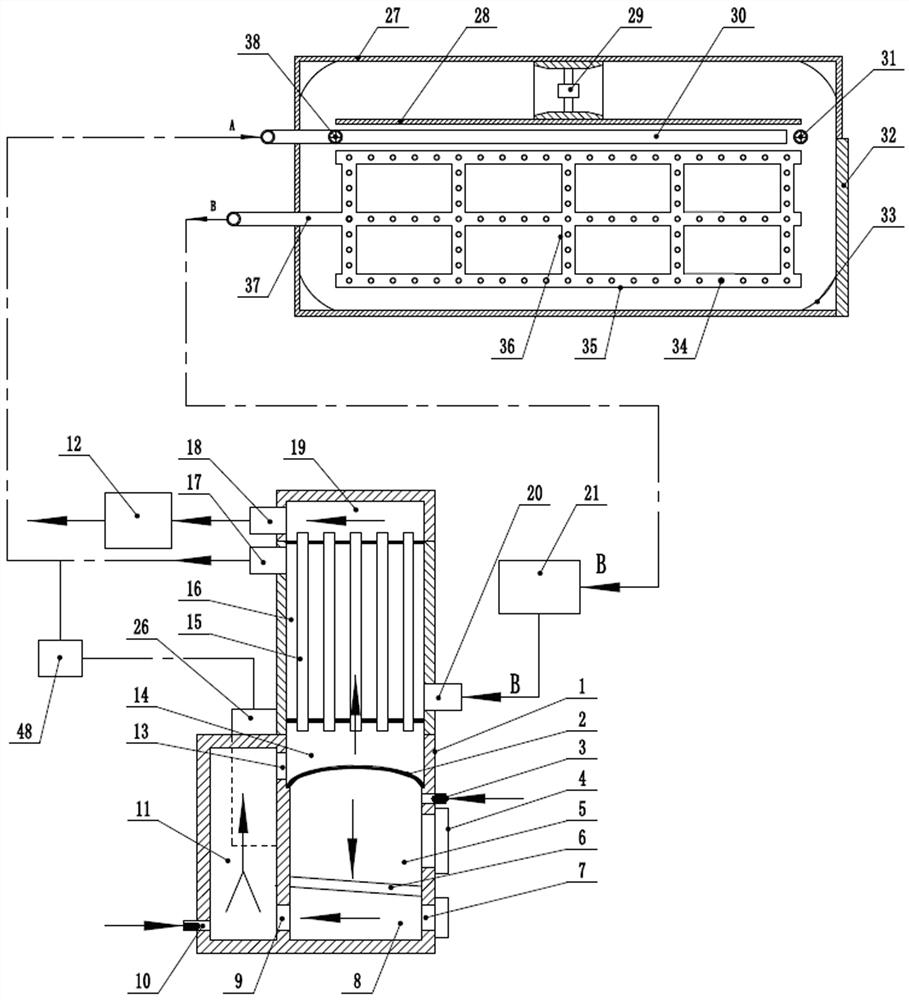

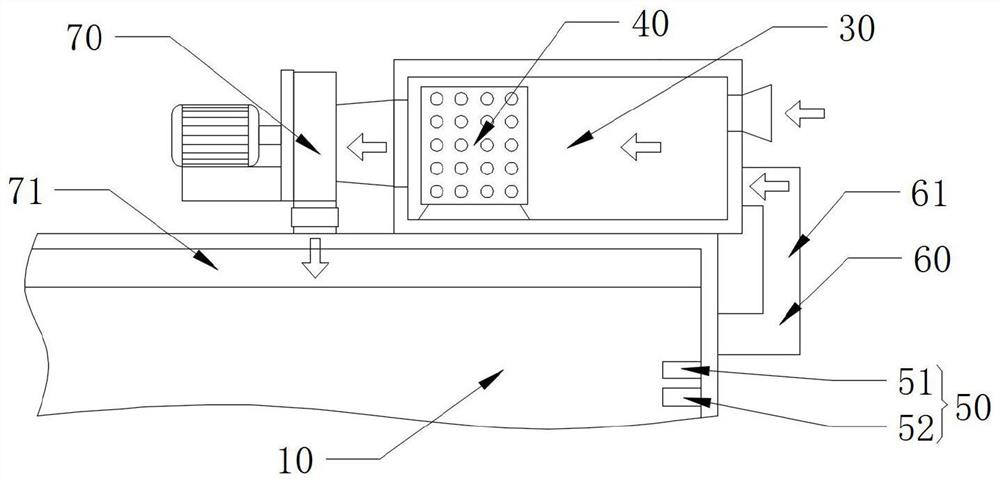

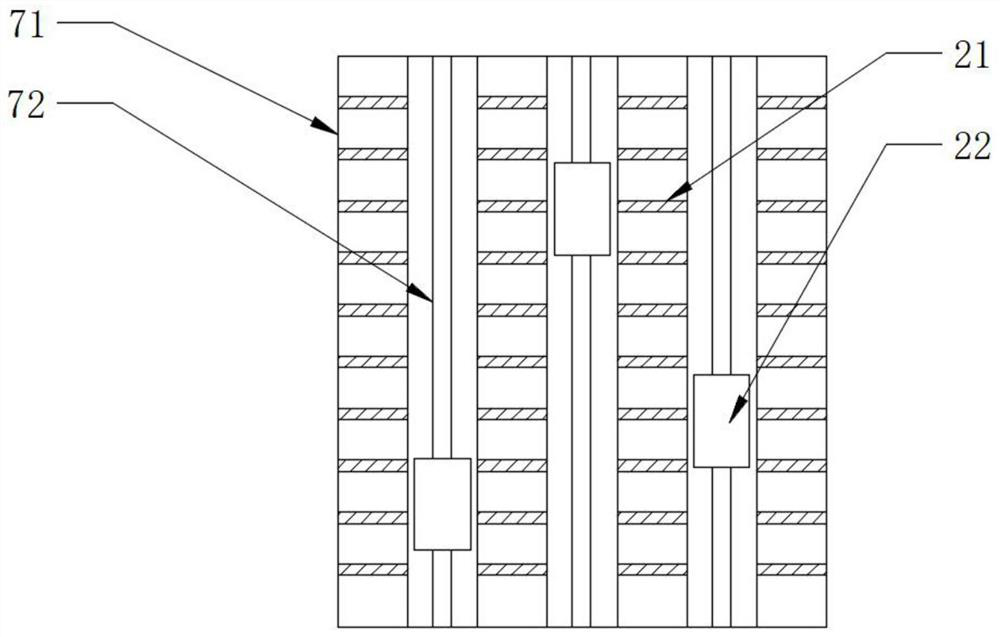

Drying equipment of agricultural products

ActiveCN111288751AUniform air suctionRealize multi-dimensional circulationDrying gas arrangementsDrying chambers/containersHot blastProcess engineering

The invention discloses drying equipment of agricultural products. The drying equipment comprises a hot blast stove and a drying room, the hot blast stove is a double-layer grate water-cooled steam hot-blast stove, the hot-blast stove is used for providing hot air for the drying room, air exhausted from the drying room is conveyed to the hot-blast stove through a circulating fan to be reheated andthen returns to the drying room, a closed-loop multi-dimensional circulation technology is adopted, hot air can circulate left and right and front and back in the drying room, the periphery of the agricultural products can make full contact with the hot air, heating is uniform, the dewatering and drying speed is consistent, the quality of the agricultural products is guaranteed, overturning is not needed in the drying process, and the labor cost is greatly saved. The adopted double-layer grate water-cooled steam hot-blast stove can enable fuel to be combusted sufficiently, black smoke cannotbe generated, and the heat conversion efficiency is high; a water-cooled grate cooling mode is adopted, the service life of a grate is prolonged, meanwhile, steam is generated in the cooling process,a heat source output mode is added for the hot-blast stove, and steam needed by green removal and humidity adjustment is provided for drying processing of the agricultural products.

Owner:广西格卡环保科技有限公司

Soil sample drying device

PendingCN108592534AAvoid cross contaminationAvoid pollutionPreparing sample for investigationDrying gas arrangementsEngineeringAir purification

The invention relates to a soil sample drying device which comprises a tank, an air purification part, a first connecting piece, a fan, a second connecting piece, a heating part and a soil sample drying part. The air purification part, the first connecting piece, the fan, the second connecting piece, the heating part and the soil sample drying part are sequentially arranged in the tank and communicate; a filter screen is arranged on the first side surface of the tank; the air purification part is arranged near the first side surface of the tank; and a vent hole is formed in the second side surface of the tank. The soil sample drying device provided by the invention has the beneficial effects that soil samples are placed in the soil sample drying part, so that the occurrence of the phenomenon that the soil samples are cross-contaminated since particles of the soil samples to be tested are easy to fly around is avoided.

Owner:MORAL ELECTRICAL APPLIANCE KUNSHAN

Paper ironing machine

InactiveCN104120632AConsistent drying speedGood cooperationOld paper after-treatmentWater storage tankWetting

A paper ironing machine comprises a water storage box and a heating ironing plate. A heating device is arranged in the heating ironing plate. The top of the water storage box is provided with an operation handle and a water injection opening. The heating ironing plate is a rectangular plate with a plurality of through holes. A sponge layer is arranged between the water storage tank and the heating ironing plate, and the bottom of the sponge layer is provided with a plurality of extension parts that can stretch out the through holes. The lower end surface of the water storage tank is provided with a plurality of small holes, each small hole is connected to a communicating pipe, each communicating pipe is arranged in a through hole after going through the sponge layer and the extension part, and when the sponge layer is in an uncompressed state, the position of the lower opening of each communicating pipe is higher than that of the lower end surface of the heating ironing plate. The paper ironing machine can quickly absorb water from wet paper to dry the paper, then press and recover the paper by utilizing the sponge's characteristics of water absorbing ability, breathability, and good deformability. Moreover, the paper ironing machine can flatten wrinkled paper by wetting, heating, and pressing the paper. The paper processed by the machine is flat and wrinkle resistant, and has a good recovery degree.

Owner:LUOYANG INST OF SCI & TECH

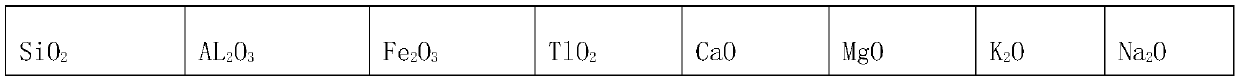

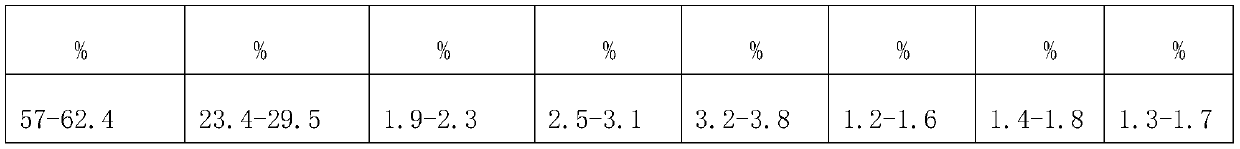

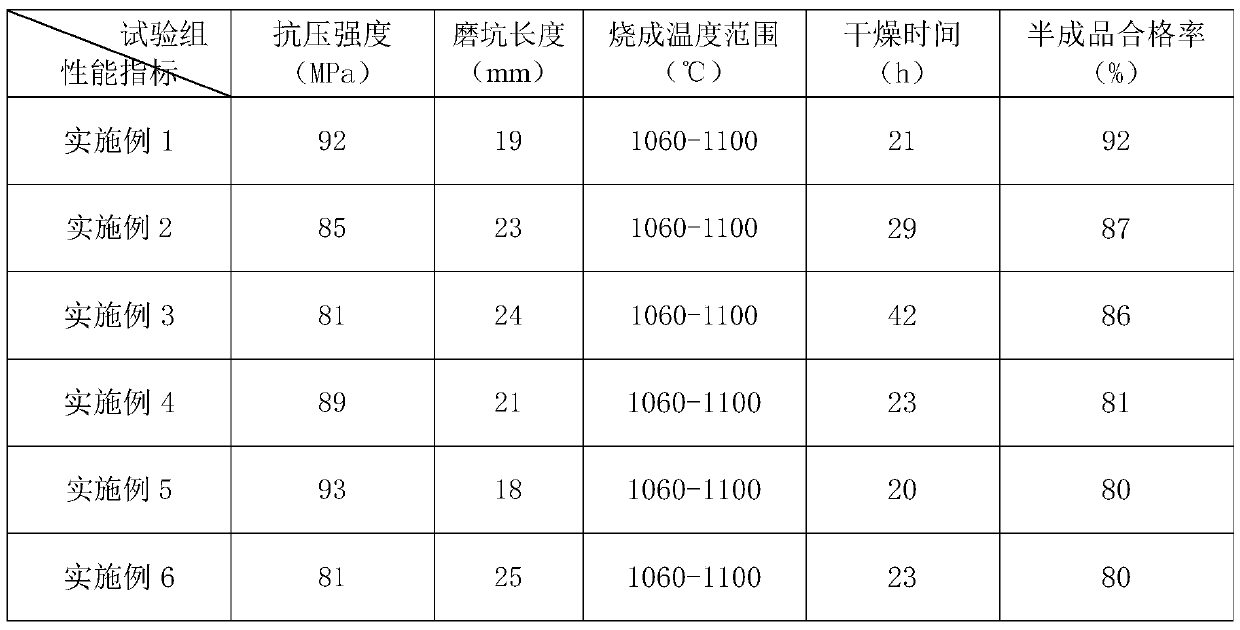

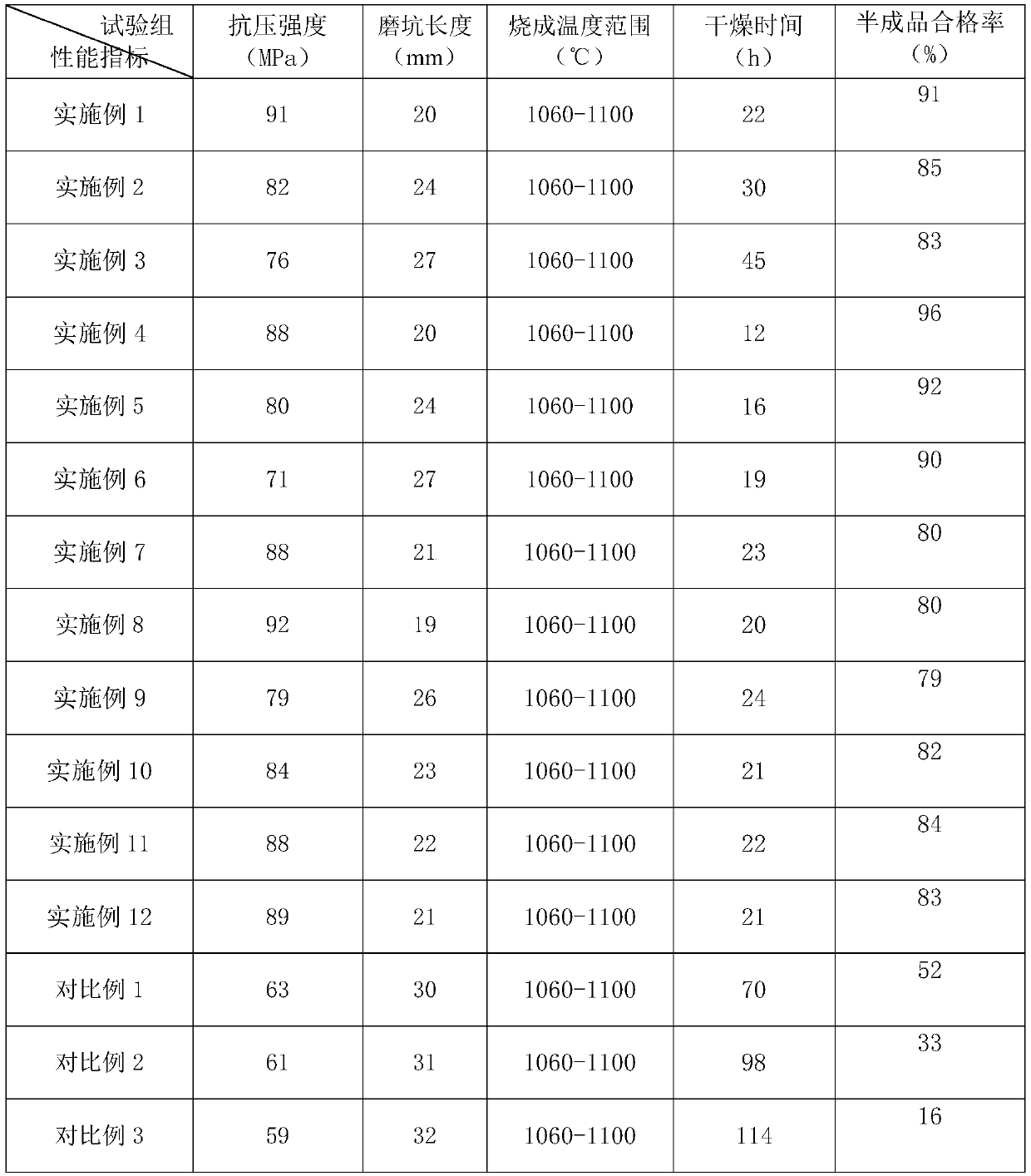

Large-sized high-strength environment-friendly clay brick

InactiveCN109734420AReduce dosageImprove breathabilityCeramic materials productionClaywaresBrickHigh intensity

The invention belongs to the technical field of building materials, and specifically discloses a large-sized high-strength environment-friendly clay brick. The large-sized high-strength environment-friendly clay brick is prepared from the raw materials: aggregate and at least one clay, wherein the weight ratio of the clay is not more than 50 percent. According to the scheme, by selecting the specific raw materials and strictly controlling the consumption of pottery clay, the clay brick has good air permeability, the cracking of the clay brick can be effectively avoided in the drying process, and the qualification rate of products is high.

Owner:成都坭韵陶坊有限公司

A printing base and inkjet printing method

ActiveCN104786656BConsistent dry atmosphereConsistent drying speedDuplicating/marking methodsOther printing apparatusLiquid-crystal displayEngineering

The invention discloses a printing base and an inkjet printing method, belonging to the field of light-emitting device manufacturing. The printing base includes: an object loading base, an extension base, a vacuum pump and an air jet valve; the extension base is located around the object loading base, the object loading base has at least one adsorption hole for absorbing the substrate, and the extension base has At least one injection hole; the vacuum pump is connected with at least one adsorption hole, and the gas injection valve is connected with at least one injection hole, and the gas injection valve is used to inject gas around the object base platform through at least one injection hole, so that the substrate on the object base platform A solvent atmosphere is formed all around, so that the dry atmosphere of the edge pixels and the middle pixels in the substrate are consistent. The present invention can remove the test area around the display area in the substrate by increasing the extension base around the object-carrying base, thereby increasing the area of the display area and further reducing the frame width of the liquid crystal display panel.

Owner:BOE TECH GRP CO LTD

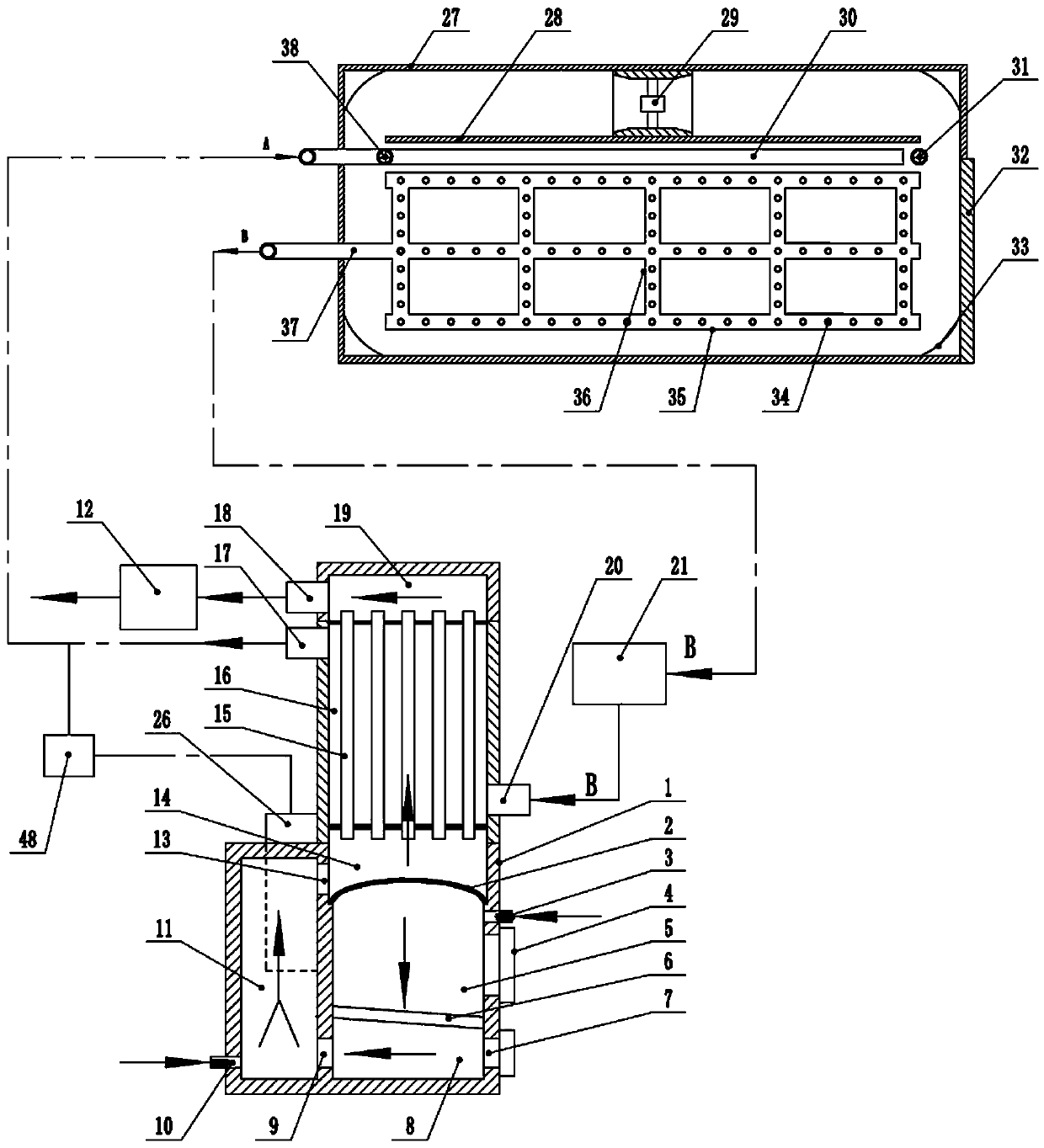

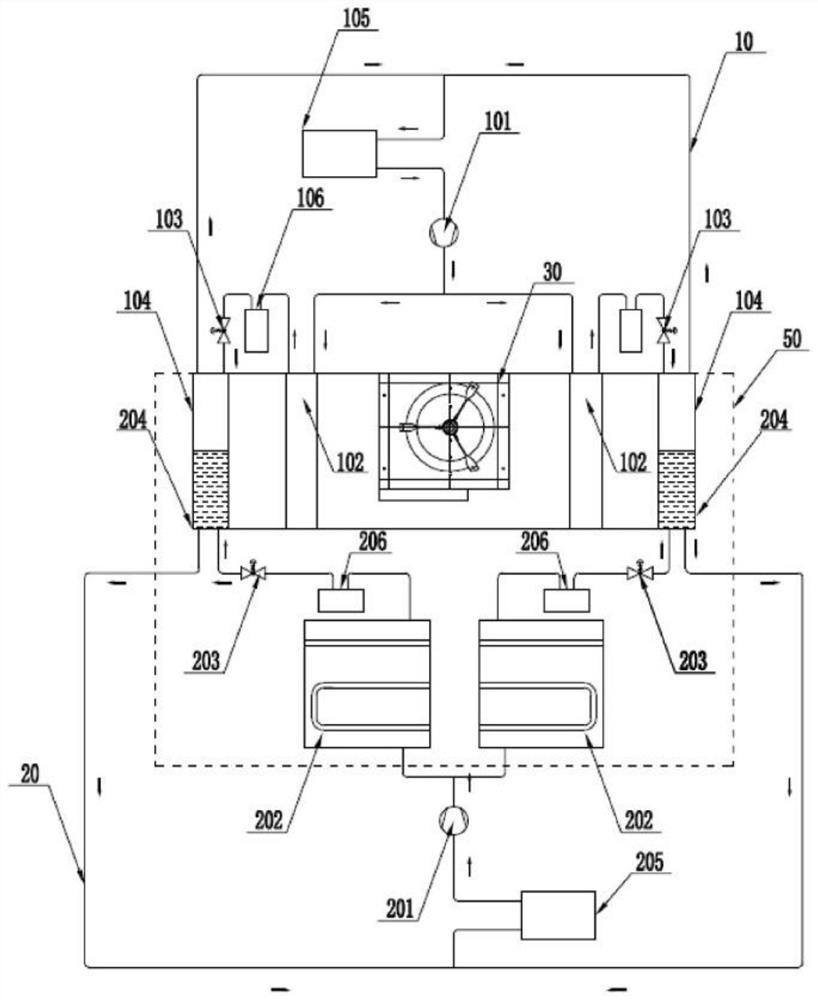

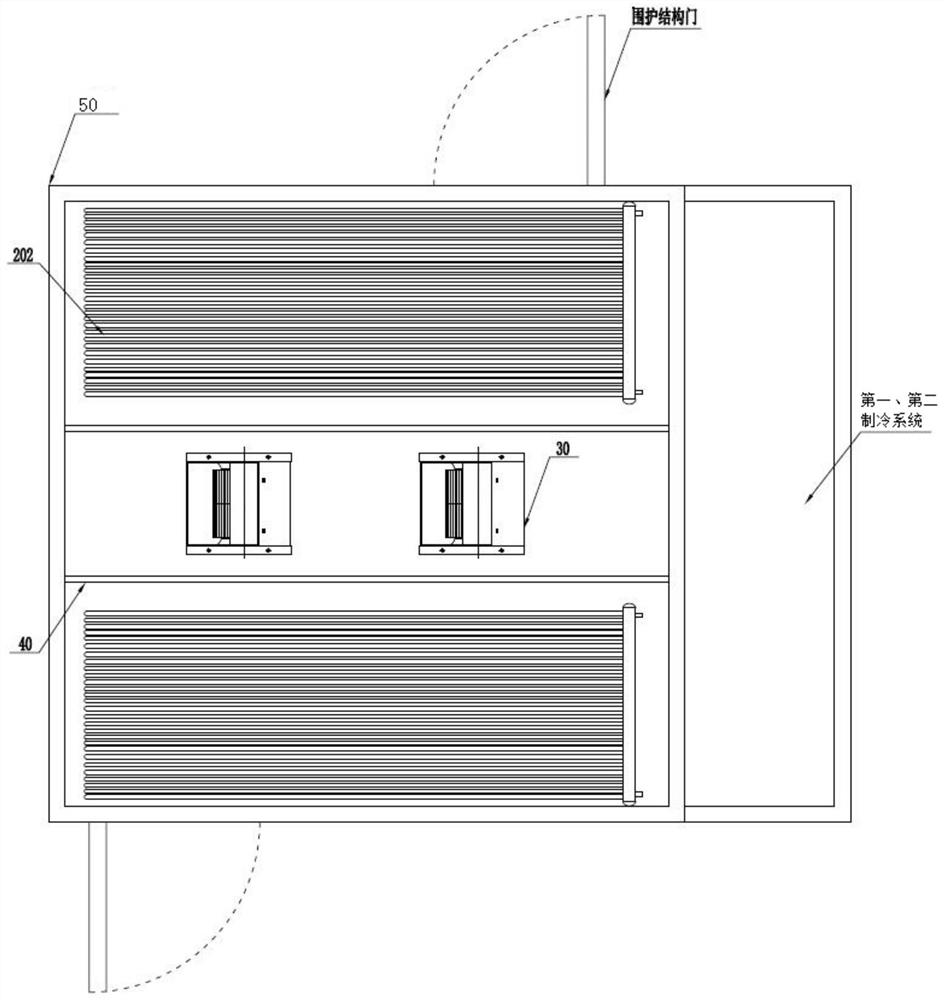

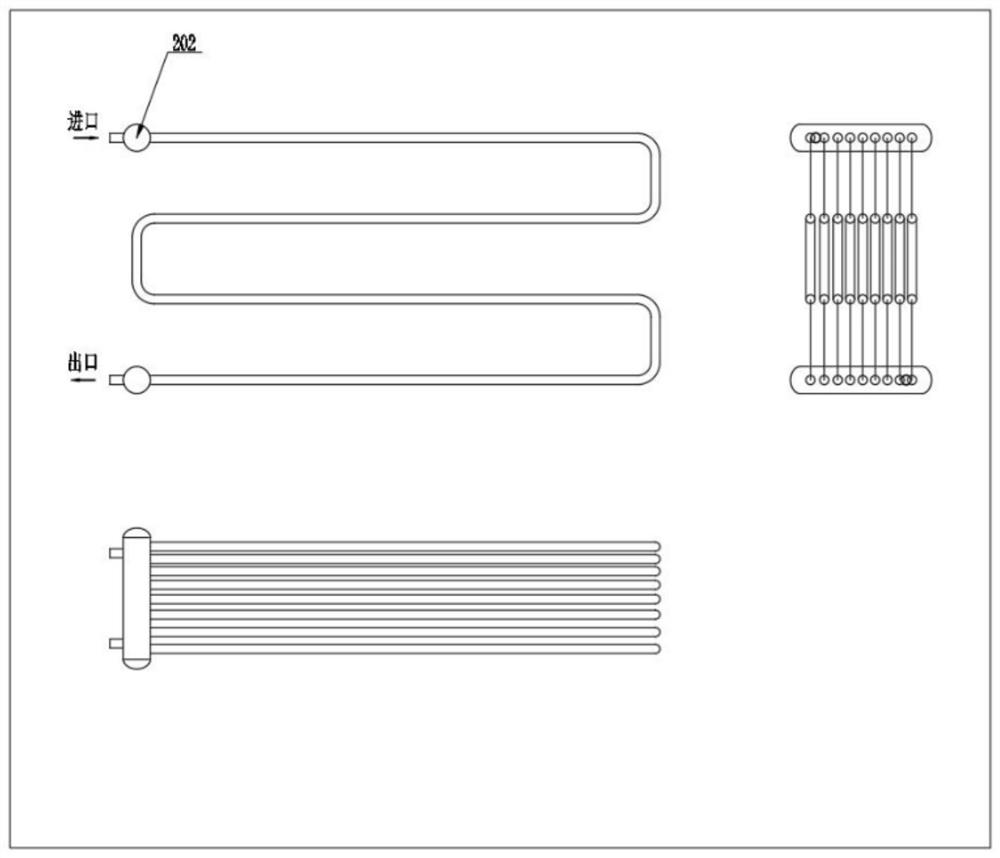

Stacked double-circulation low-temperature drying system, using method and application

PendingCN112781330AImprove securityNo mildewDrying gas arrangementsCompression machines with cascade operationEngineeringVapor–liquid separator

The invention belongs to the field of drying systems, and particularly relates to a stacked double-circulation low-temperature drying system. The drying system is a system with forward Carnot cycle heating and reverse Carnot cycle refrigeration and dehumidification functions. The stacked double-circulation low-temperature drying system comprises a first refrigerating system, a second refrigerating system, a circulating fan and an air distribution and guide plate, a group of first condensers, first evaporators and second evaporators are arranged on each of the two sides of the circulating fan; a first gas-liquid separator and a first refrigeration compressor of the first refrigeration system are sequentially connected with the first condensers; a second gas-liquid separator and a second refrigeration compressor of the second refrigeration system are sequentially connected with second condensers; and the air distribution and guide plate is arranged in a drying chamber. The drying system has the following advantages that the safety of materials to be dried is high, and a mildew phenomenon is avoided; the loss of nutritional ingredients is low; the energy consumption is reduced; and the drying system has the characteristics that he drying speed is high, the drying speed is consistent, and the environment is protected.

Owner:烟台睿加节能科技有限公司

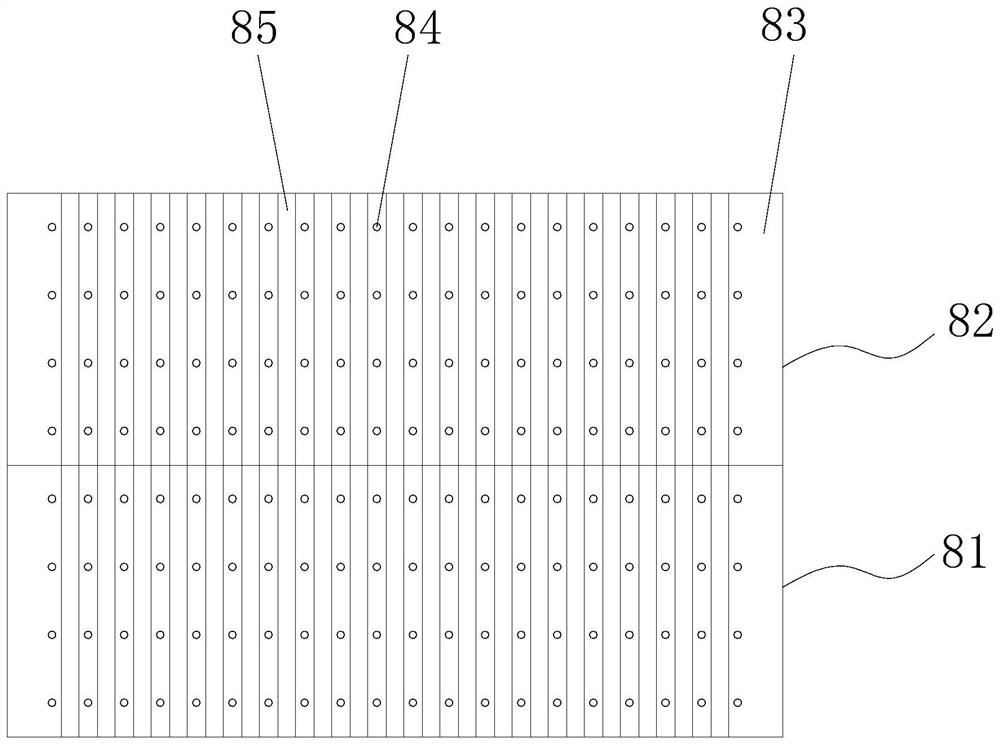

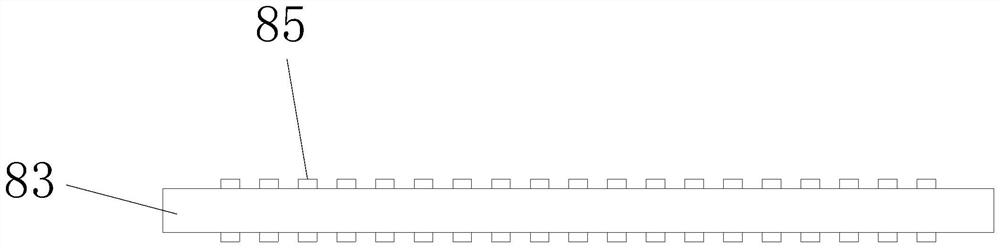

Intelligent placing support for stacking of multiple layers of boards

ActiveCN114152084AConsistent drying speedAvoid crackingDrying gas arrangementsDrying solid materialsStructural engineeringMultiple layer

The invention relates to a multilayer board stacking intelligent placing support which comprises a support body used for vertically placing multilayer boards, the support body is provided with a drying system, the drying system comprises a constant-current adjusting device, an air inlet of the constant-current adjusting device is communicated with an air outlet of an air heater, and the air outlet is connected with an air guide pipe so as to dry the multilayer boards placed on the support body. The technical problem of constant-current drying is solved.

Owner:江苏双川新材料科技有限公司

Pixel defining layer, display substrate, display device, inkjet printing method

ActiveCN109860223BConsistent drying speedSolid-state devicesSemiconductor/solid-state device manufacturingComputer graphics (images)Display device

Pixel defining layer, display substrate, display device, inkjet printing method. The pixel defining layer includes: a first pixel defining layer, the first pixel defining layer has a first opening, and the first opening includes a first sub-pixel opening and a second sub-pixel opening corresponding to different sub-pixels; The opening size of the second sub-pixel opening is larger than the opening size of the first sub-pixel opening; the second pixel defining layer is located on the first pixel defining layer, the second pixel defining layer has a second opening, and the second pixel defining layer has a second opening. The second opening includes a fourth sub-pixel opening corresponding to and connected to the first sub-pixel opening and a fifth sub-pixel opening corresponding to and connected to the second sub-pixel opening; the fourth sub-pixel opening is connected to the first sub-pixel opening. The opening size difference of the sub-pixel openings is greater than the opening size difference between the fifth sub-pixel opening and the second sub-pixel opening. Using the pixel defining layer to carry out inkjet printing can make the film layer obtained after the ink is dried more uniform.

Owner:BOE TECH GRP CO LTD +1

Energy-saving clay brick

InactiveCN109761582AReduce manufacturing costReduce viscosityCeramic materials productionClaywaresToxic industrial wasteMaterials science

The invention belongs to the technical field of construction and building materials, and particularly discloses an energy-saving clay brick. The energy-saving clay is prepared from industrial waste residue and at least one kind of clay, wherein the weight percent of the clay is lower than 50 percent. In the scheme, the using amount of the clay is reduced, and the industrial waste residue is introduced, so that the air permeability of clay brick mud is improved greatly, and the clay brick can be effectively prevented from cracking in a drying process; moreover, the clay brick has high strength,and the resources consumed in the clay brick production process are reduced greatly. The clay brick belongs to the energy-saving clay brick in a true sense.

Owner:成都坭韵陶坊有限公司

Circulating drying system for drying denitrification agent using natural gas heat source

The invention discloses a circulation drying system for drying a denitrification agent by using a natural gas heat source, which includes a drying chamber. It is used to distribute the air volume blown into the drying room from the air outlet; the heating module is used to fully burn natural gas to generate CO ) with H ) O, and connected to the heat exchange module to provide a heat source for the heat exchange module; the heat exchange module adopts the method of gas heating gas to exchange all the high-temperature gas after natural gas combustion through the heat exchange module; the measurement module is used to measure the temperature and humidity in the drying room , to monitor the temperature and humidity changes in the room; the return air module is used to return and reheat the hot air in the drying room; the air outlet module is used to send the hot air produced by the heat exchange module into the drying room. Through the air guide module, the drying speed of the catalyst in the drying chamber is consistent, and it is also possible to dry the local area independently and quickly.

Owner:安徽方信立华环保科技有限公司

Wafer drying method

PendingCN112017944AFlexible adjustment of moving speedAvoid reunionSemiconductor/solid-state device manufacturingWaferEngineering

The invention provides a wafer drying method, which comprises the following steps of: selecting at least one path from the whole preset moving path of a spray head to open the spray head so as to spray dry gas to the surface of a rotating wafer, and adjusting the moving speed of the spray head according to the change of a horizontal distance between the spray head and the center of the wafer. Thus, the opening distance and the moving speed of the spray head can be flexibly adjusted according to the difference between the linear speed and the centrifugal force of each position on the surface ofthe wafer, so that the drying speed of each position on the surface of the wafer tends to be consistent, the drying uniformity can be further improved, and the phenomenon of annular particle agglomeration on the surface of the wafer is avoided.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

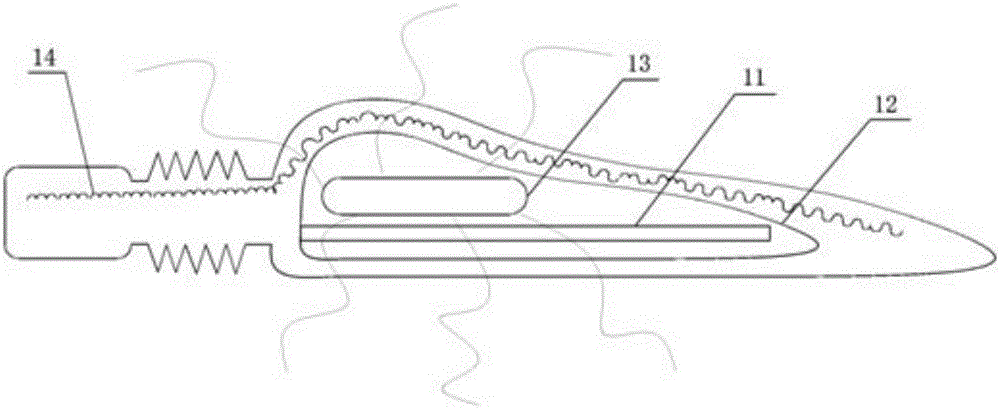

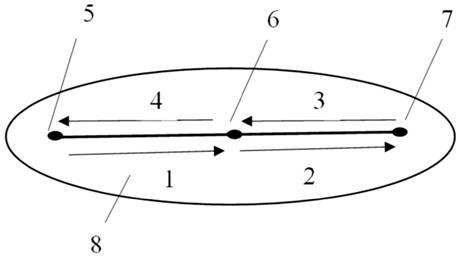

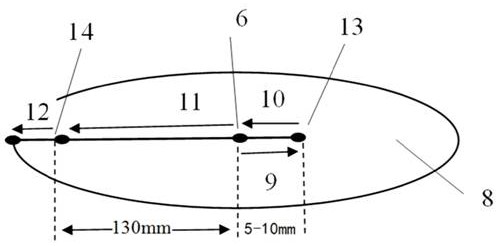

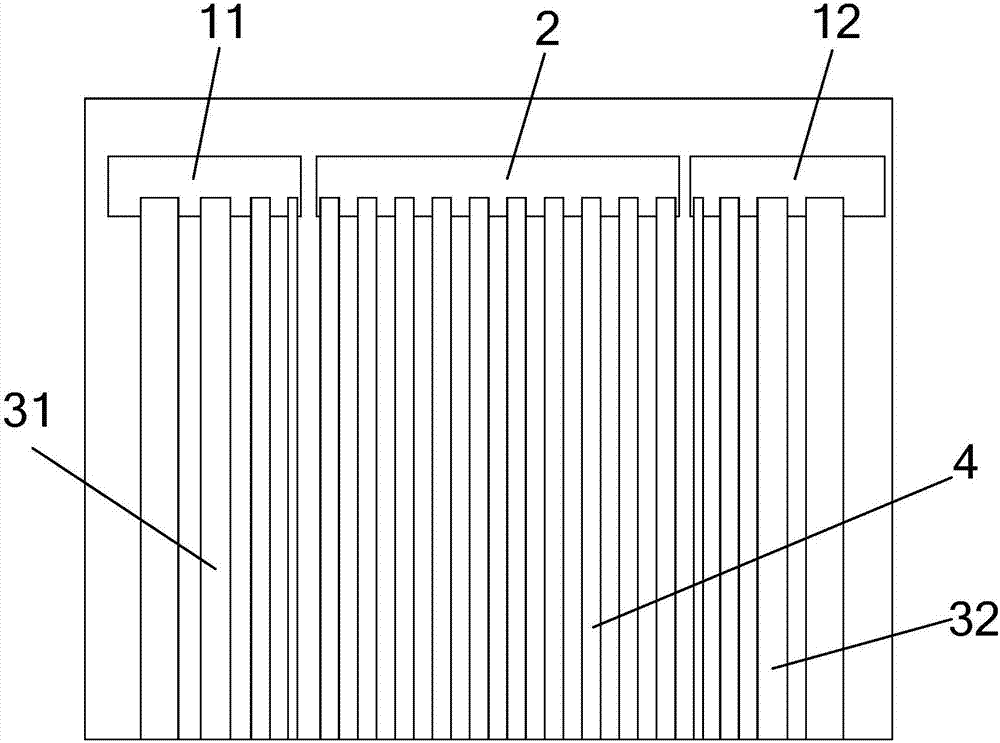

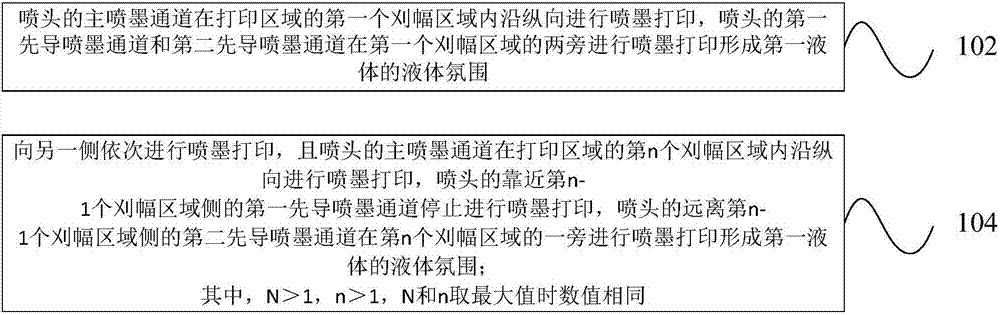

A nozzle, inkjet printing method and continuous inkjet printing method

ActiveCN106864039BReduce drying speedConsistent drying speedDuplicating/marking methodsAgricultural engineeringInternal zone

The invention discloses a nozzle, an inkjet printing method and a continuous inkjet printing method. A guiding ink inlet, a main ink inlet, a first guiding inkjet channel, a main inkjet channel and a second guiding inkjet channel are arranged on the nozzle. The guiding ink inlet and the main ink inlet are mutually independent; the first guiding inkjet channel and the second guiding inkjet channel are located on the two sides of the main inkjet channel; the guiding ink inlet communicates with the first guiding inkjet channel and the second guiding inkjet channel; liquid entering into the guiding ink inlet is sprayed after passing through the first guiding inkjet channel and the second guiding inkjet channel; the main ink inlet communicates with the main inkjet channel; and liquid entering into the main ink inlet is sprayed after passing through the main inkjet channel. When the nozzle provided by the invention is in use, the drying speed of each swath edge area in the printing process of multiple swathes can be slowed down, so that the drying speed is consistent with the drying speed of an inner area, and it is guaranteed that the pixel thickness and contour of each printing swath edge area are consistent with those of the inner area.

Owner:BOE TECH GRP CO LTD

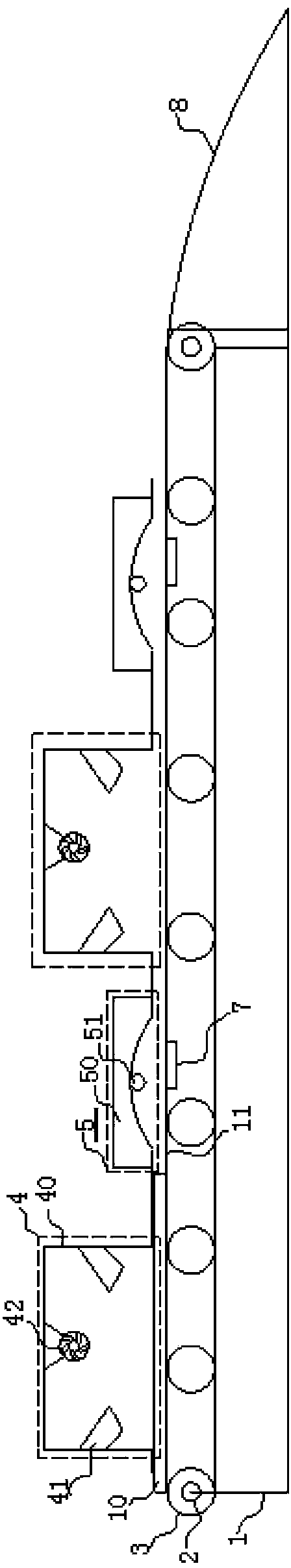

Efficient energy-saving combined type battery pole piece two-side coater

ActiveCN102698933BEvenly heatedConsistent drying speedLiquid surface applicatorsCoatingsDevice formElectrical battery

The invention discloses an efficient energy-saving combined type battery pole piece two-side coater, which fully utilizes space, saves land utilization cost, improves production efficiency and improves on-site management levels. The efficient energy-saving combined type battery pole piece two-side coater comprises a coating device formed by a forward coating head and a reverse coating head, an uncoiling machine, a coiling machine and a heat drying device, wherein two sets of individually-operated two-side coaters are divided into an upper coater and a lower coater which are arranged in an up-and-down superposition mode; the uncoiling machine, the coiling machine and the coating device are arranged at the two ends of the upper and lower coaters respectively; and the heat drying device consists of at least two flow equalization ovens with circulation flow equalization hot air devices. According to the coater, the floor space of the coater is greatly reduced, and the cost is saved; operating environments at the periphery of the coater are improved, and the management level of an operation site is improved; by the flow equalization ovens, the coating width of a battery pole piece can be adjusted to be 800mm, but the edge of the battery pole piece cannot be curled; and therefore, the drying device is lengthened, the operating speed of the coater is increased, and the production efficiency can be greatly improved.

Owner:东方醒狮新动力电池有限公司

High-load bearing performance pottery clay pavement brick

InactiveCN109914176AImprove carrying capacityHigh strengthSingle unit pavingsSidewalk pavingsRoad surfaceHigh load

The invention belongs to the technical field of building materials, and particularly discloses a high-load bearing performance pottery clay pavement brick. The high-load bearing performance pottery clay pavement brick comprises the following raw materials: sintered pottery clay, industrial waste residues and at least one pottery clay, wherein the proportion of the pottery clay is not higher than 50% by weight. According to a scheme, through selective use of the specific raw materials, the produced pottery clay pavement brick has high strength and load bearing performance, so that the breakagerate of the pottery clay pavement brick is greatly reduced and the service life is prolonged; meanwhile, in the scheme, the using amount of the pottery clay is also strictly controlled, so that the pottery clay brick is guaranteed to have high gas permeability, the pottery clay brick can be effectively prevented from cracking in the drying process, and the qualification rate of a product is high.

Owner:成都坭韵陶坊有限公司

Bracket for drying large-outer-diameter and high-thickness blanks and implementation method of bracket

ActiveCN114044233ASpeed up placementFast dryingDrying gas arrangementsDrying chambers/containersCushionIndustrial engineering

The invention discloses a bracket for drying large-outer-diameter and high-thickness blanks. The bracket comprises a base, stand columns are arranged at the four corners of the upper portion of the base respectively, a top seat is arranged above the stand columns, a hanging rod is arranged above the top seat, a plurality of layers of supporting plates are arranged on the stand columns, each supporting plate comprises a bearing plate, and a plurality of filler strips are arranged above the bearing plate at equal intervals. The invention further discloses an implementation method of the bracket for drying the large-outer-diameter and high-thickness blanks. According to the blank drying device, the multiple filler strips are arranged above the bearing plates at equal intervals to support blanks, a cushion does not need to be placed any more, the blank placing speed is increased, air circulation is facilitated through the intervals between the filler strips, and therefore the blank drying speed is increased. The distances between the multiple layers of supporting plates are sequentially increased, the lower-layer air convection speed is increased, and therefore the drying speed of lower-layer blanks is increased, it is guaranteed that the drying speeds of the upper-layer blanks and the lower-layer blanks are consistent as much as possible, and the consistency of the water content of the blanks is guaranteed.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Drying equipment for agricultural by-products

ActiveCN111288751BUniform air suctionRealize multi-dimensional circulationDrying gas arrangementsDrying chambers/containersHot air ovenProcess engineering

A drying equipment for agricultural and sideline products, including a hot blast stove and a drying room. The hot blast stove is a reverse-fired water-cooled steam hot blast stove. After being transported to the hot blast stove for reheating, it returns to the drying room. With the closed-loop multi-dimensional circulation technology, the hot air can realize left-right circulation and front-back circulation in the drying room, so that the agricultural and sideline products can fully contact with the hot air around them and be heated evenly. , The dehydration and drying speed is consistent, which ensures the quality and quality of agricultural and sideline products, and the drying process does not need to be turned, which greatly saves labor costs. The reverse-fired water-cooled steam hot blast stove adopted can fully burn the fuel without producing black smoke, and has high heat conversion efficiency; the water-cooled grate cooling method is used to improve the service life of the grate, and at the same time, steam is generated during the cooling process, Add a heat source output mode to the hot blast stove to provide the steam needed for greening and humidity control for the drying and processing of agricultural and sideline products.

Owner:广西格卡环保科技有限公司

Biological organic fertilizer and preparation method thereof

InactiveCN112225614ASpeed up dryingAvoid overall overheatingMagnesium fertilisersAlkali orthophosphate fertiliserLivestock manureSoil science

The invention belongs to the technical field of organic fertilizers, and particularly relates to a biological organic fertilizer and a preparation method thereof. The biological organic fertilizer isprepared from, by weight, 50-60 parts of crop straw, 40-50 parts of livestock manure, 30-35 parts of domestic sludge, 20-25 parts of a conditioner, 5-8 parts of diammonium hydrogen phosphate and 4-6 parts of a biological agent. The organic fertilizer is simple and convenient to prepare, wide in raw material source and low in production cost. Meanwhile, the fertilizer is sufficient in nutrient component and high in fertilizer retention and water storage capacity, has a certain soil improvement effect, and can effectively improve the yield and quality of fruits and vegetables.

Owner:当涂县江心仁贵家庭农场

Novel UV drying machine facilitating discharging

InactiveCN104289399AReduce drynessExtended protection timePretreated surfacesCoatingsEngineeringLighting system

The invention discloses a novel UV drying machine facilitating discharging. The novel UV drying machine comprises a rack, a driving device, a transmission carrier roller set, a conveying belt driven by the transmission carrier roller set, a machined piece feeding port and a machined piece discharging port are formed on the rack, UV lighting systems are arranged above the conveying belt, the number of the UV lighting systems is at least two, the UV lighting systems are distributed in the moving direction of machined pieces, cooling systems are arranged between the machined piece feeding port in the rack and the UV lighting systems and between the adjacent UV lighting systems respectively, and a discharging slope is arranged at the machined piece discharging port. By means of the technical scheme, the effect of paint film UV solidification is greatly improved, durability is improved, the maintaining cost is lowered, discharging and loading of the machined workpieces are facilitated, and the working efficiency is improved.

Owner:HUZHOU NANXUN SHUANGLIN ZHENSEN WOOD PROCESSING FACTORY

Circulating drying system for drying denitration agent by using natural gas heat source

The invention discloses a circulating drying system for drying a denitration agent by using a natural gas heat source. The system comprises a drying chamber, an air guide module, a heat exchange module, a heating module, a measuring module, an air return module and an air outlet module; the air guide module is used for distributing air blown into the drying chamber from an air outlet; the heating module is used for fully combusting natural gas to generate CO2 and H2O and communicates with the heat exchange module to provide a heat source for the heat exchange module; the heat exchange module exchanges heat energy of all high-temperature gas generated after natural gas is combusted through the heat exchange module in a mode that gas is heated by gas; the measuring module is used for measuring the temperature and humidity in the drying chamber so as to monitor indoor temperature and humidity changes; the air return module is used for conducting air return and reheating on hot gas in the drying chamber; and the air outlet module is used for feeding hot air produced by the heat exchange module into the drying chamber. Through the air guide module, a drying speed of a catalyst in the drying chamber is consistent, and local areas can be independently and rapidly dried.

Owner:安徽方信立华环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com