Stacked double-circulation low-temperature drying system, using method and application

A drying system and double-circulation technology, applied in the direction of drying solid materials, drying gas arrangement, local stirring dryer, etc., can solve the problems of spoilage and deterioration of materials to be dried, high initial investment cost and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

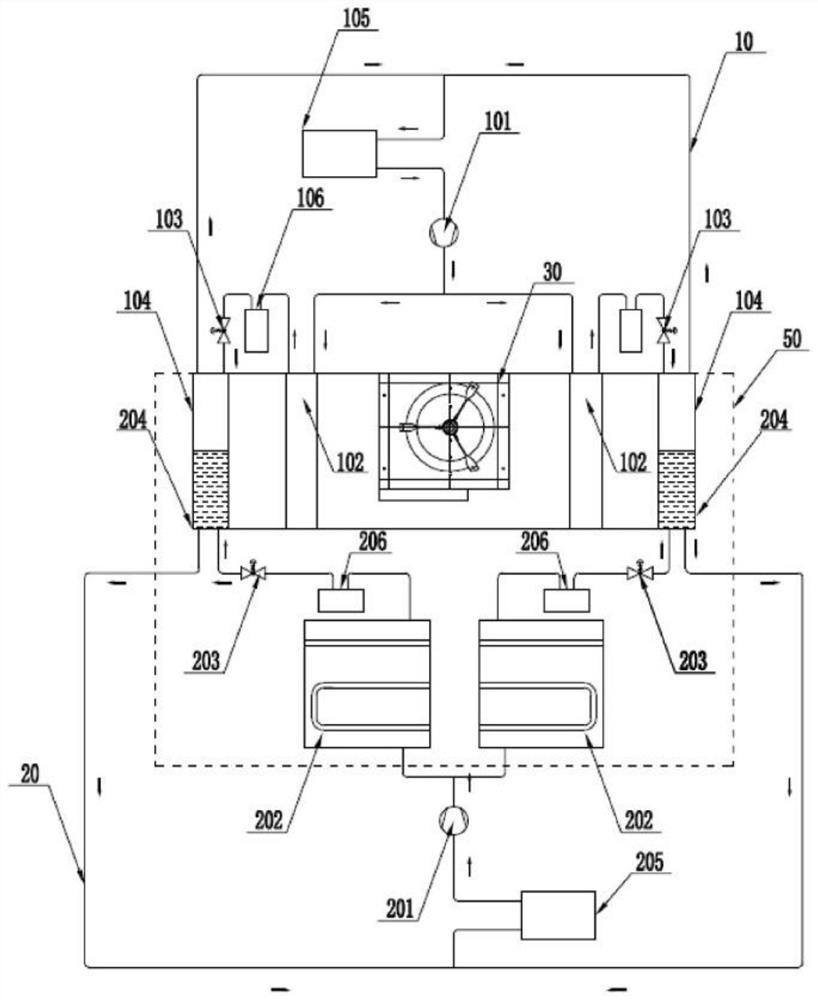

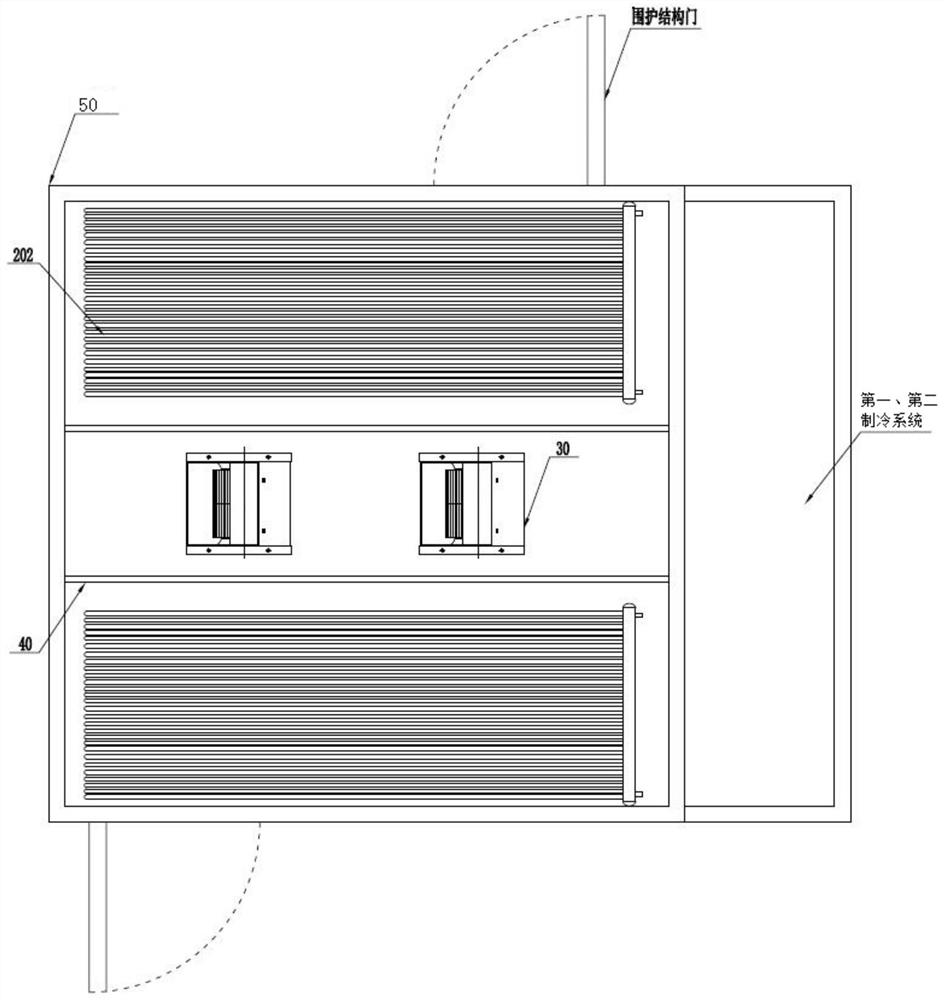

[0061] The superimposed double-cycle low-temperature drying system includes: a first refrigeration system 10, a second refrigeration system 20, two sets of circulation fans 30, and air distribution deflectors 40; some intervals are left between the two sets of circulation fans 30;

[0062] The first refrigeration system 10 includes: a first gas-liquid separator 105, a first refrigeration compressor 101,

[0063] Two first condensers 102 and two first evaporators 104 are located on both sides of the two sets of circulating fans 30 and arranged symmetrically from the inside to the outside;

[0064] The outlet of the first gas-liquid separator 105 is connected with the first refrigerating compressor 101, and the first refrigerating compressor 101 is divided into two branches, which lead to the first condenser 102 positioned at both sides of the two groups of circulating fans 30 respectively;

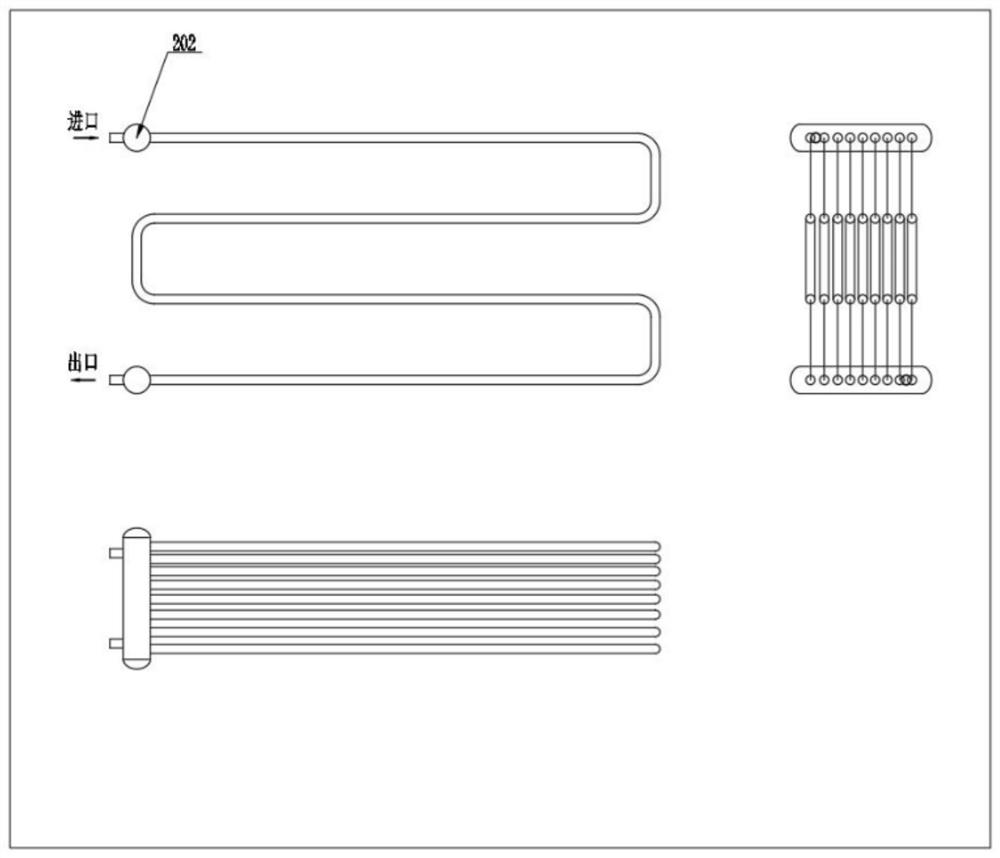

[0065] The first condenser 102 and the first evaporator 104 are connected through pipel...

Embodiment 2

[0091] The difference from Embodiment 1 is that the first evaporator 104 is located above the second evaporator 204 and the first evaporator 104 is located on the support structure (ie frame or frame structure) shared by the second evaporator 204 ); the rest of the structure is the same as in Example 1.

Embodiment 3

[0093] The difference from Embodiment 1 is that, alternatively, the first evaporator 104 is located in parallel with the second evaporator 204, the first evaporator 104 is located outside the second evaporator 204, and the first evaporator 104 and the second evaporator 204 Correspondingly, there are respective supporting structures (that is, frames or frame structures) arranged below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com