Drying equipment of agricultural products

A technology for agricultural and sideline products and drying equipment, which is applied in drying, drying machines, lighting and heating equipment, etc., and can solve problems such as difficulty in ensuring the quality and quality of agricultural and sideline products, high energy consumption in the drying room, and lack of heat recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

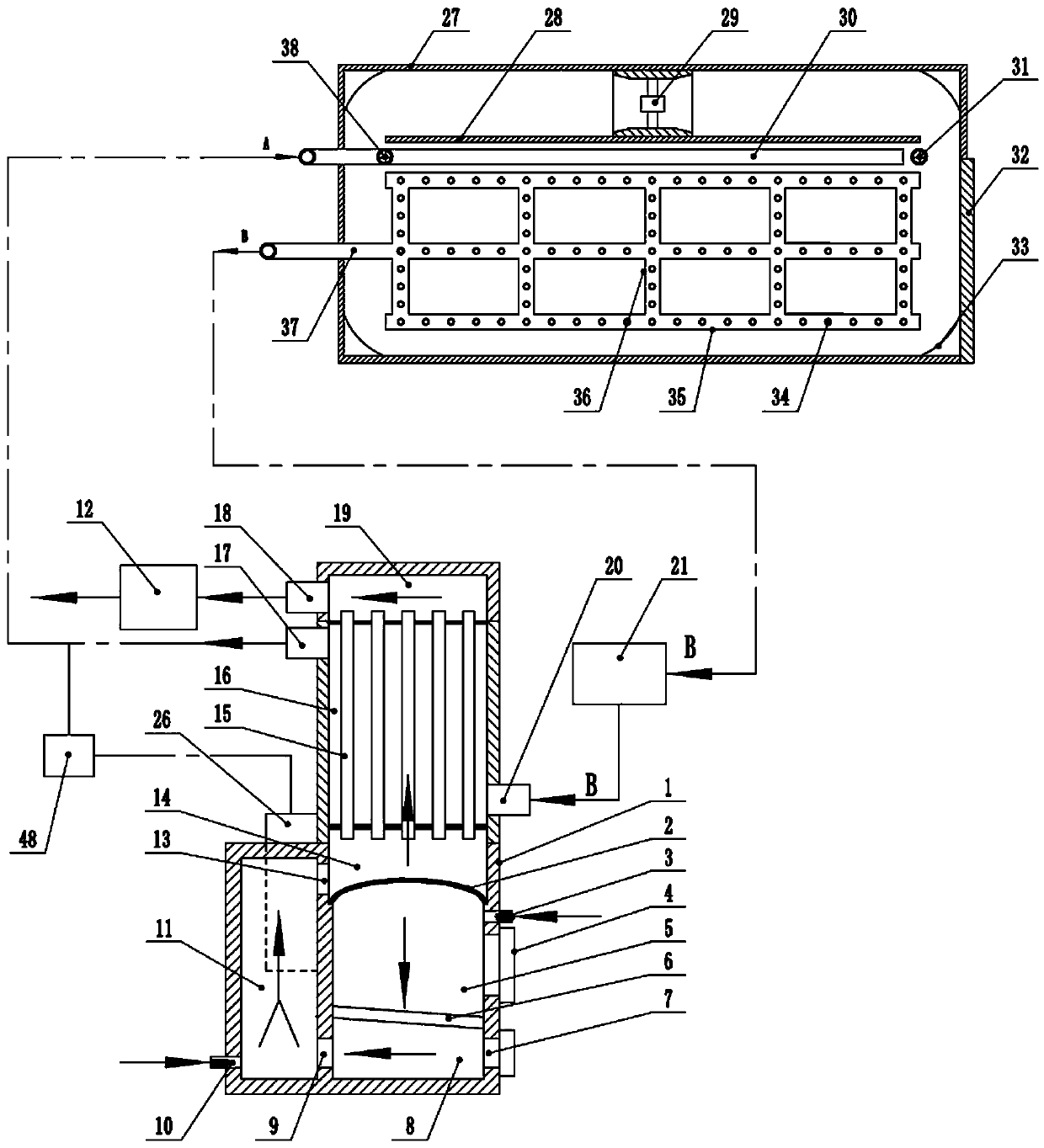

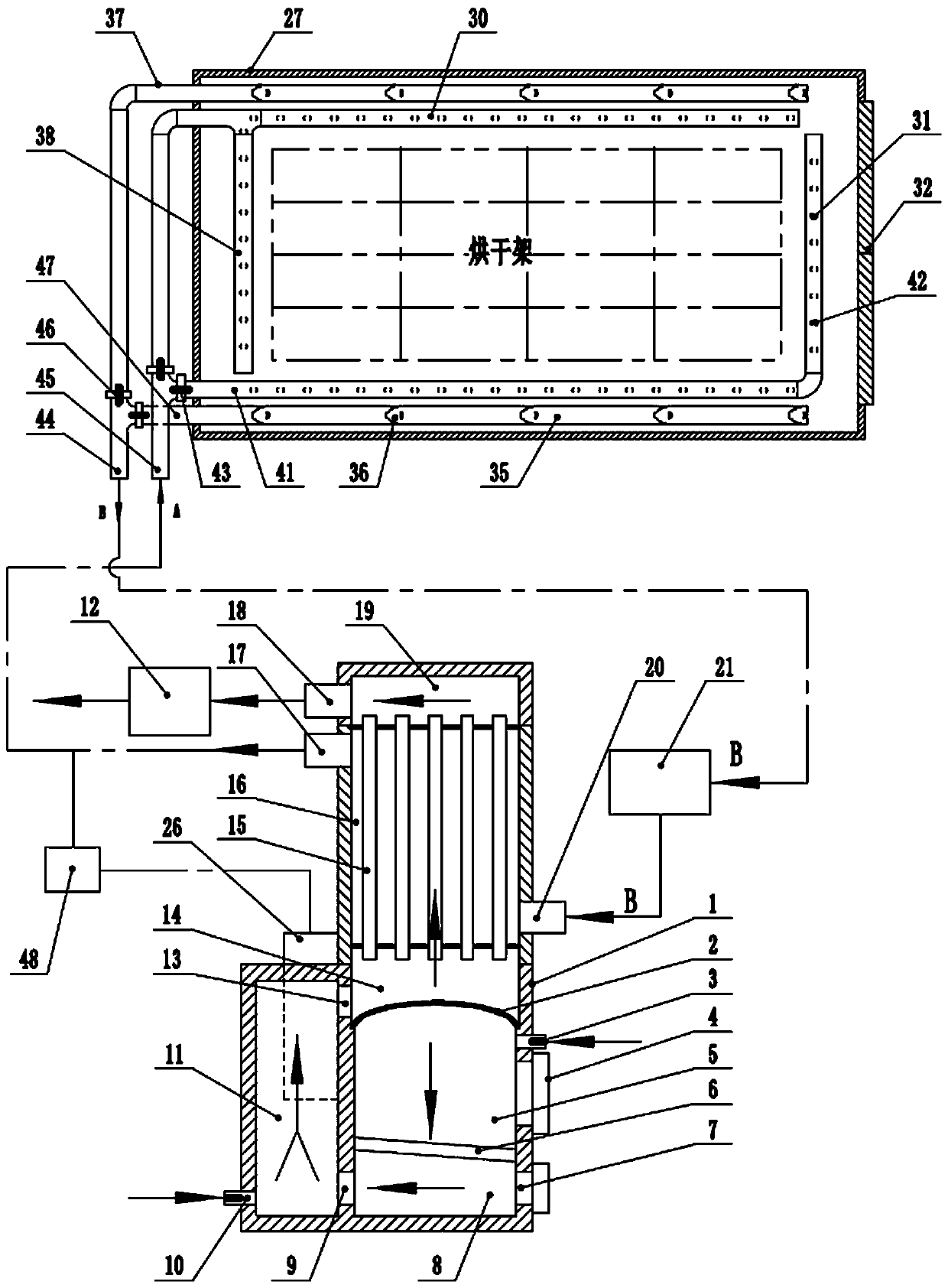

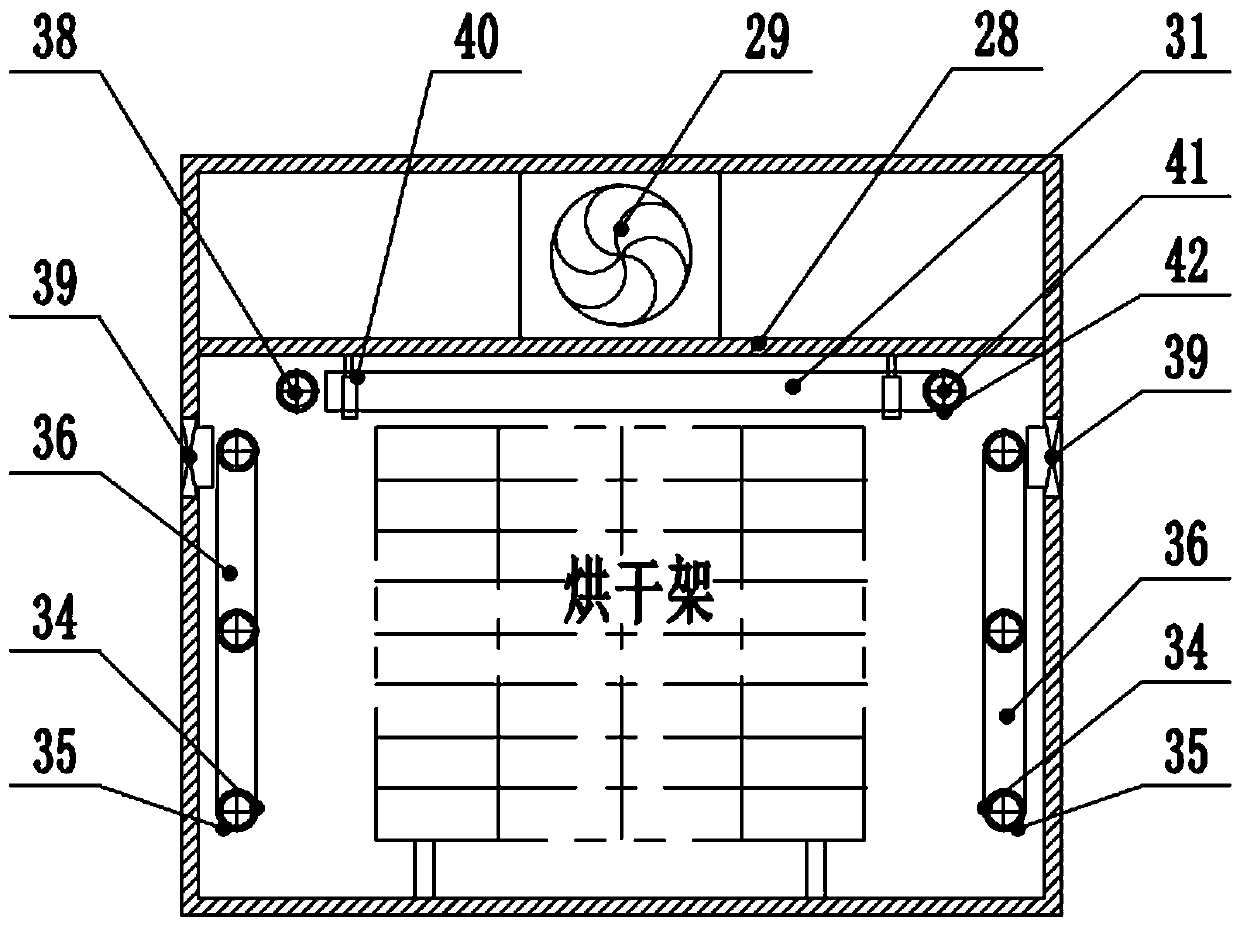

[0031] A drying equipment for agricultural and sideline products, including a hot blast stove and a drying room, characterized in that: the hot blast stove is a reverse-fired water-cooled steam hot blast stove, which includes a furnace body 1 and a fire grate 6, and the fire grate 6 is set on In the lower part of the furnace body 1, the interior of the furnace body 1 is divided into a furnace 5 and an ash collection chamber 8; Partition plate 2 divides the inner top of body of heater 1 into smoke chamber 14; Hot blast stove also comprises secondary combustion chamber 11, and the bottom of secondary combustion chamber 11 is communicated with ash collection chamber 8 by burner opening 9, and secondary combustion chamber 11 The upper part communicates with the smoke distribution chamber 14 through the smoke port 13; the upper part of the furnace 5 is provided with a primary oxygen inlet 3, and the lower part of the secondary combustion chamber 11 is provided with a secondary oxyge...

Embodiment 2

[0034] A drying equipment for agricultural and sideline products, including a hot blast stove and a drying room, characterized in that: the hot blast stove is a reverse-fired water-cooled steam hot blast stove, which includes a furnace body 1 and a fire grate 6, and the fire grate 6 is set on In the lower part of the furnace body 1, the interior of the furnace body 1 is divided into a furnace 5 and an ash collection chamber 8; Partition plate 2 divides the inner top of body of heater 1 into smoke chamber 14; Hot blast stove also comprises secondary combustion chamber 11, and the bottom of secondary combustion chamber 11 is communicated with ash collection chamber 8 by burner opening 9, and secondary combustion chamber 11 The upper part communicates with the smoke distribution chamber 14 through the smoke port 13; the upper part of the furnace 5 is provided with a primary oxygen inlet 3, and the lower part of the secondary combustion chamber 11 is provided with a secondary oxyge...

Embodiment 3

[0045] A drying equipment for agricultural and sideline products, including a hot blast stove and a drying room, characterized in that: the hot blast stove is a reverse-fired water-cooled steam hot blast stove, which includes a furnace body 1 and a fire grate 6, and the fire grate 6 is set on In the lower part of the furnace body 1, the interior of the furnace body 1 is divided into a furnace 5 and an ash collection chamber 8; Partition plate 2 divides the inner top of body of heater 1 into smoke chamber 14; Hot blast stove also comprises secondary combustion chamber 11, and the bottom of secondary combustion chamber 11 is communicated with ash collection chamber 8 by burner opening 9, and secondary combustion chamber 11 The upper part communicates with the smoke distribution chamber 14 through the smoke port 13; the upper part of the furnace 5 is provided with a primary oxygen inlet 3, and the lower part of the secondary combustion chamber 11 is provided with a secondary oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com