Wafer drying method

A drying method and wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as uneven drying of the wafer surface, achieve the effect of improving drying uniformity and avoiding particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the technical solution of the present invention, the wafer drying method provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

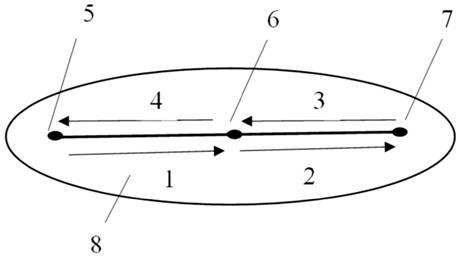

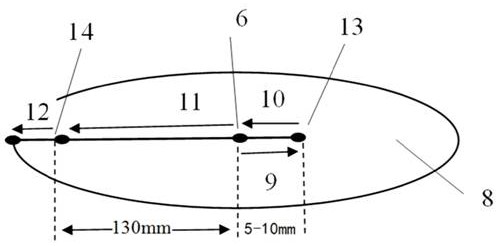

[0036] The wafer drying method provided by the present invention includes moving the shower head according to a preset path, and selectively opening the shower head in at least a section of the preset path to spray dry gas to the surface of the rotating wafer; at the same time, according to the shower head The variation of the horizontal spacing between the center of the wafer and the center of the wafer adjusts the speed at which the shower head moves so that the drying speed on the wafer surface tends to be consistent. Wherein, the so-called horizontal distance refers to the radial distance between the point where the center of the showerhead is vertically projected on the wafer surface and the center of the wafer. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com