Patents

Literature

151 results about "Diacetonamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Room-temperature multi-self-crosslinked core-shell type copolymer emulsion as well as preparation method and application thereof

The invention relates to a room-temperature multi-self-crosslinked core-shell type copolymer emulsion as well as a preparation method and application thereof and belongs to the field of high molecular materials. The preparation method comprises the following steps: reacting by taking 15-35 parts of hard monomers, 15-35 parts of soft monomers and 1-2 parts of diacetone acrylamide as core layer monomers, and a reaction / non-reaction type emulsifying agent and 0.1-0.3 part of persulfate as an initiator at 60-90 DEG C through a seeded emulsion polymerization process, so as to obtain a core layer copolymer emulsion; and on the basis, reacting by taking 15-35 parts of the hard monomers, 15-35 parts of the soft monomers, 1-5 parts of acrylic acid phosphate, 1-2 parts of acrylamide monomers and 1-2 parts of vinyl alkoxy silane as shell layer monomers and persulfate as an initiator at 60-90 DEG C, so as to obtain the good-stability room-temperature multi-self-crosslinked core-shell type copolymer emulsion. By adding various functional aids, a water-based anticorrosive coating is prepared. After a steel plate is coated, self-crosslinking is realized during the drying of a paint film, and an obtained coating layer has good corrosion resistance.

Owner:BEIJING UNIV OF CHEM TECH

Self-crosslinking acrylic resin leather finishing agent and preparation method thereof

InactiveCN102199389AAchieve room temperature controllable self-crosslinkingExcellent adhesionProtein coatingsLeather surface finishingCross-linkEmulsion

The invention provides a self-crosslinking acrylic resin leather finishing agent and a preparation method thereof. The preparation method comprises the following steps: firstly, carrying out radical polymerization on acrylate, methacrylic acid and diacetone acrylamide so as to prepare an acrylic resin emulsion; regulating the pH of the emulsion to 5-6; and adding a substance with a water-soluble protide structure as a cross-linking agent, so as to prepare a novel self-crosslinking acrylic resin leather finishing agent. According to the invention, the protide substance is used as the cross-linking agent of the acrylic resin, thereby achieving the room temperature controllable self-crosslinking of the acrylic resin, effectively promoting the physical property of a film and simplifying the production process of the acrylic resin film. The hot adhesive and cold short defects of the acrylic resin finishing agent are improved through crosslinking action; and simultaneously, the protide substance is introduced in the acrylic resin molecular chain, thus the resin film has a property of a protide film-forming agent and good comprehensive property.

Owner:SHAANXI UNIV OF SCI & TECH

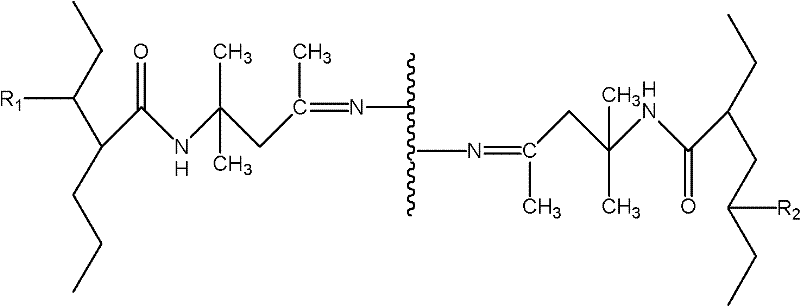

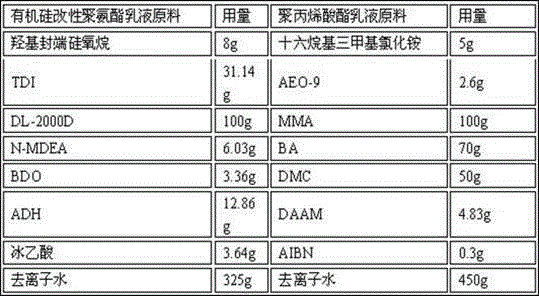

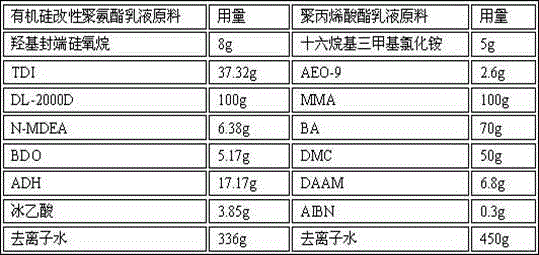

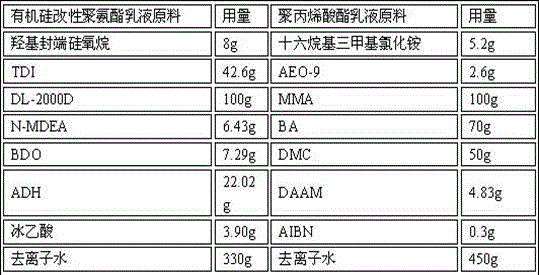

Cationic organosilicon modified waterborne PUA fabric coating adhesive with self crosslinking structure and preparation method thereof

InactiveCN106149381AImprove mechanical propertiesImprove water resistanceFibre treatmentPolyesterDiacetonamine

The present invention discloses a preparation method of a cationic organosilicon modified waterborne PUA fabric coating adhesive with a self crosslinking structure, the method is as follows:(1)using polyisocyanate and hydroxyl-terminated polysiloxane for synthesis of an-NCO-group-terminated prepolymer;(2)adding polyether or polyester glycol for reaction;(3)reacting with a cationic hydrophilic chain extender for a period of time, and further reacting with adipic dihydrazide(ADH)to obtain a hydrazine-terminated cationic waterborne polyurethane emulsion;(4)using acrylate monomers and diacetone acrylamide(DAAM)for preparing a hydrazide-group-containing polyacrylate emulsion; and(5)mixing the hydrazine-terminated cationic waterborne polyurethane emulsion and the hydrazide-group-containing polyacrylate emulsion in a certain proportion to obtain the self-crosslinking cationic organosilicon modified waterborne PUA fabric coating adhesive. The self-crosslinking cationic organosilicon modified waterborne PUA fabric coating adhesive avoids the use of a harmful crosslinking agent, has the advantages of being environmental-friendly, high in water pressure resistance, good in mechanical properties, low in cost, and dyeable and the like, and can be used for coating finishing of nylon fabrics.

Owner:WUYI UNIV

Water-based laminated adhesive and preparation method thereof

ActiveCN104263292AImprove adhesionLower surface energyEster polymer adhesivesAdhesive cementDiacetonamine

The invention discloses a water-based laminated adhesive and a production technique thereof. The water-based laminated adhesive mainly comprises deionized water, butyl acrylate, methyl methacrylate, acrylic acid, diisooctyl maleate, diacetone acrylamide, diamidohydrazine adipate, methacrylamido ethyl ethylene urea, an emulsifier, an initiator, a buffering agent, a defoaming agent, a film formation assistant and a preservative. A pre-emulsification technique is utilized to prepare the milk white liquid with blue fluorescence on appearance; the viscosity is 100-500 mPa.s, and the solid content is 48-55%; the film forming material is colorless and transparent, and the pH value is 7-9; the emulsion belongs to a self-crosslinking type; the macromolecules are automatically crosslinked in the compounding process, so the adhesive has high peel strength; and the emulsion has higher solid content, so the adhesive satisfies the requirement of dry-type composite quick drying.

Owner:浙江春雨新材料科技有限公司

Sewage treatment agent

ActiveCN104944603AQuick responseNothing producedScale removal and water softeningDiacetonaminePyrrolidinones

The invention relates to a sewage treatment agent. The sewage treatment agent is composed of, by mass, 20-40 parts of polyamino polyether methylene phosphonate, 20-40 parts of diazolidinyl urea, 10-30 parts of methylisothiazolinone, 15-30 parts of medical stone particles, 40-60 parts of sodium lignin sulfonate, 20-40 parts of chitosan, 20-40 parts of polyvinylpyrrolidone, 20-40 parts of polysilicate aluminium sulphate, 20-40 parts of diacetone acrylamide, 20-40 parts of phosphonate and 50-100 parts of deionized water. According to the sewage treatment agent, the reaction speed is high, poisonous and pernicious gas is not produced in the treatment process, products are stable after reactions, and the products do not break down into toxic substances; by means of the sewage treatment agent, efficient and non-poisonous effects are achieved, corrosion to human bodies and objects does not occur after and before the reactions, and the treatment efficiency to sewage is high.

Owner:SHENGDA ENVIRONMENTAL ENG CO LTD

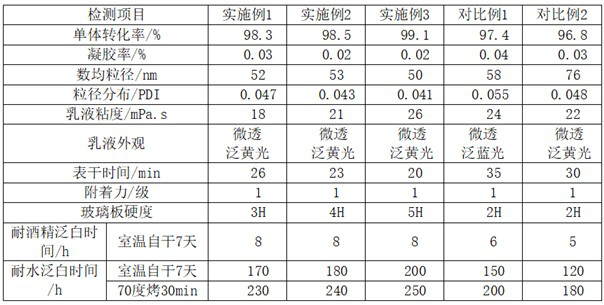

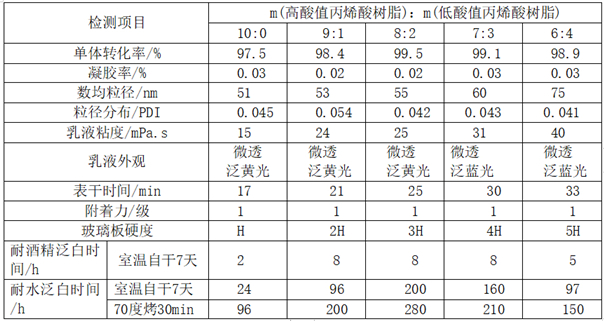

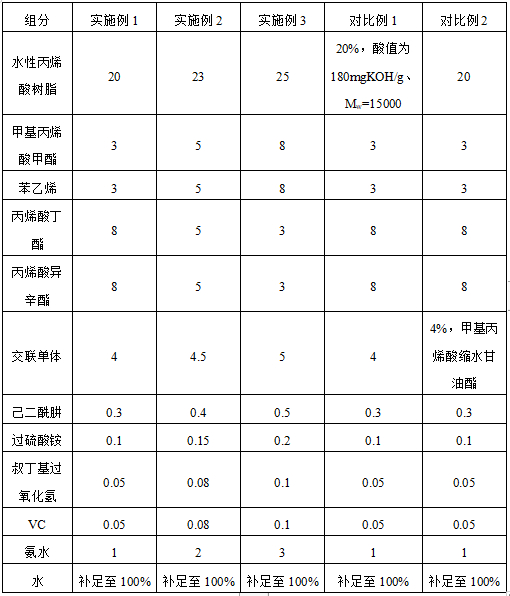

Self-crosslinking acrylic emulsion and preparation method thereof

The invention relates to the technical field of acrylic emulsions, and particularly relates to a self-crosslinking acrylic emulsion and a preparation method thereof. The self-crosslinking acrylic emulsion is prepared from the following raw materials in parts by weight: a component A, namely 130-150 parts of crylic acid solid resin, 350-450 parts of water and 40-60 parts of ammonium hydroxide or monoethanolamine or triethanolamine, a component B, namely 5-12 parts of an emulsifier and 15-25 parts of water, a component C, namely 1-3 parts of persulfate and 5-12 parts of water, a component D 1, namely 85-95 parts of methyl methacrylate and 70-80 parts of ethyl acrylate, a component D 2, namely 85-95 parts of methyl methacrylate and 70-80 parts of ethyl acrylate, a component E, namely 0.8-1.5 parts of persulfate and 5-15 parts of water, a component F, namely 5-12 parts of diacetone-acryloamide and 25-35 parts of water, and a component G, namely 2-5 parts of adipic dihydrazide and 25-35 parts of water. The self-crosslinking acrylic emulsion does not contain a toxic solvent, so that the VOC content is low; and the self-crosslinking acrylic emulsion does not contain TDI and various heavy metals, so that the self-crosslinking acrylic emulsion is environment-friendly and safe, has the advantages of relatively good levelling property and film surface smoothness, shows a bright effect after forming a film, and is free of a white scar or dusting when rubbed and kneaded.

Owner:广东佳景科技股份有限公司

Self-Crosslinking Alkyd Dispersion

A coating composition is produced by forming an aqueous dispersion of a crosslinking agent and a resin that comprises the reaction product of an alkyd polymer, an optional surfalkyd, diacetone acrylamide, another acrylate monomer and optionally aromatic monomers wherein the reaction product is neutralized with either ammonia or an amine. A coating of the aqueous dispersion on wood exhibits at least some of the following desired properties: rapid dry time, good tannin blocking, good resistance to picking up dirt, good hot box stability and good exterior durability. Additionally, the inventive coatings appear to provide improved crosslinking compared to coatings comprising resins not neutralized with an amine or ammonia and / or not containing a surfalkyd.

Owner:ARKEMA INC

Synthesis technology of diacetone acrylamide

InactiveCN102060730AImprove pollutionOmit the caustic wash stepOrganic compound preparationCarboxylic acid amides preparationDistillationAcrylonitrile

The invention relates to a synthesis technology of diacetone acrylamide, belonging to the technical field of chemical materials. The synthesis technology comprises the following steps: reacting acetone and acrylonitrile in concentrated sulfuric acid, neutralizing by sodium hydroxide, filtering and layering the filtrate to obtain the crude product of diacetone acrylamide. The synthesis technology is characterized by also comprising the following steps: extracting the crude product of diacetone acrylamide with water; extracting with cyclohexane; salting out by NaCl; under a vacuum condition of 666KPa, separating the acrylamide byproduct by reduced pressure distillation according to the characteristic that the difference between the boiling points of acrylamide and diacetone acrylamide is higher than 40 DEG C; after diluting by toluene, drying by anhydrous sodium sulfate and decolorizing by activated carbon, carrying out reduced pressure distillation again, and collecting the distillate at 120-130 DEG C / 666Pa; and finally obtaining the finished product of diacetone acrylamide the quality purity of which is above 98% and the melting point of which is 54-56 DEG C. The invention omits a caustic washing step in the purification process, thus simplifying the purification step and reducing the product loss. The yield of the product is close to 70%, the purity of the product exceeds 98%, and the yield is higher than that (40-50%) of the existing technology.

Owner:FUZHOU NINGCHUANG AGRI RESOURCES DEV

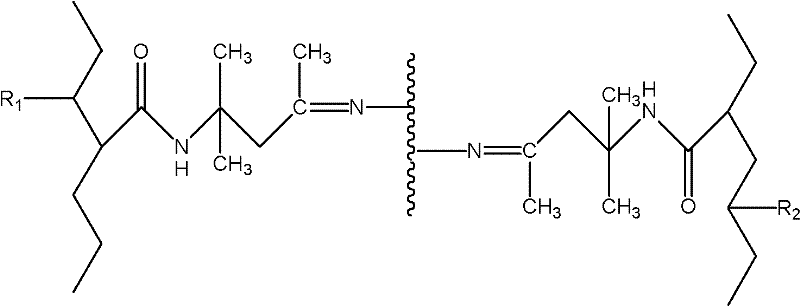

Modified nano silicon dioxide and organic and inorganic hybridized polyacrylate emulsion adopting modified nano silicon dioxide

InactiveCN108676116AGood compatibilityImprove dispersion uniformityCoatingsPigment treatment with organosilicon compoundsEmulsionEmulsion polymerization

The invention relates to modified nano silicon dioxide and organic and inorganic hybridized polyacrylate emulsion adopting the modified nano silicon dioxide. The modified nano silicon dioxide is prepared from 100 parts of nano silicon dioxide, 0.2 to 2 parts of gamma-aminopropyltriethoxysilane, 4 to 40 parts of ethanol, 0.2 to 2 parts of diacetone acrylamide and 1000 parts of a solvent. By adopting the modified nano silicon dioxide, the problem in the prior art about the compatibility between the nano silicon dioxide and polyacrylate in a process of preparing the organic and inorganic hybridized polyacrylate emulsion by adopting the nano silicon dioxide is solved; the surface of the nano silicon dioxide is modified and a diacetone group with bioactivity is introduced; the group can keep stable in an emulsion polymerization process and a storage process and can participate in a curing crosslinking reaction in a hybridized emulsion curing and film forming process; the nano silicon dioxide and the polyacrylate are connected together through a chemical bond, so that the aim of improving the compatibility between the nano silicon dioxide and the polyacrylate is realized.

Owner:DEYANG YONGSHENG NONWOVEN PROD +1

Crosslinked acrylic emulsion for waterproofing paints and preparation method thereof

The invention discloses a crosslinked acrylic emulsion for waterproofing paints, which comprises the following components in percentage by weight of the emulsion: 35-40% of butyl acrylate, 10-15% of styrene, 0.5-1% of hydroxymethyl acrylamide, 1.0-1.5% of diacetone-acryloamide, 1-3% of emulsifier, 0.2-0.5% of persulfate, 0.05-0.08% of adipic dihydrazide, 0.3% of defoamer, 40-50% of water and neutralizer, wherein the use amount of neutralizer is enough for adjusting the pH value of the emulsion to 6.5-7.5. According to the invention, hydroxymethyl acrylamide and diacetone-acryloamide are used as crosslinking monomers and adipic dihydrazide serves as a curing agent; and after being crosslinked and cured, a paint film is high in crosslinking density and excellent in adhesion to a cement base material. The crosslinked acrylic emulsion has the advantages of high crosslinking density, strong adhesion, high film strength, excellent cement coagulation delaying capability and is applicable to both single-component and double-component waterproofing paints.

Owner:WEIFANG HUANYU PAINT IND

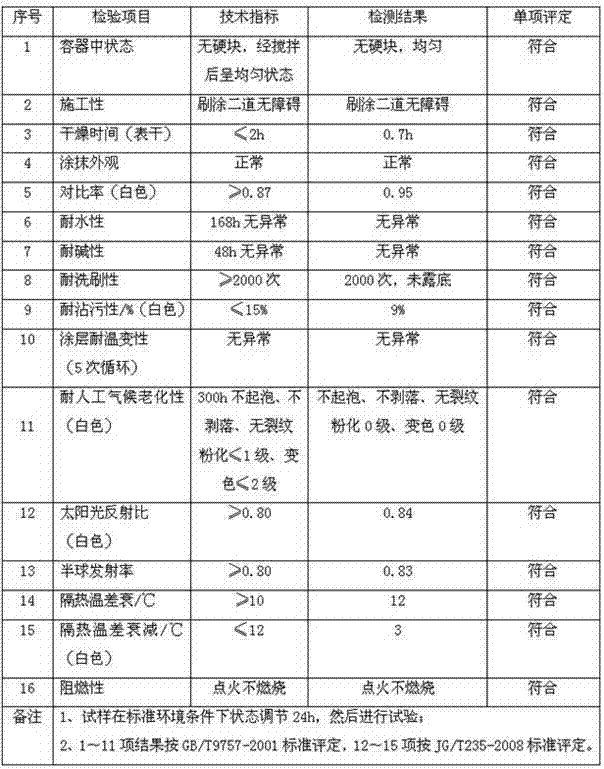

Heat-preservation and thermal-insulating water-based paint for glass sliding door and preparation method of water-based paint

InactiveCN104342000AImprove antifouling performanceImprove the bactericidal effectPaints with biocidesPolyurea/polyurethane coatingsTripropylene glycolDiacetonamine

The invention discloses heat-preservation and thermal-insulating water-based paint for a glass sliding door. The water-based paint is prepared from the following raw materials in parts by weight: 48-53 parts of waterborne polyurethane resin, 16-19 parts of waterborne hydroxyl acrylic acid, 0.2-0.4 part of polypropylene oxide glyceryl ether, 1-3 parts of tripropylene glycol monobutyl ether, 0.3-0.6 part of alkylol amine titanate, 7-10 parts of modified pure acrylic emulsion, 0.2-0.5 part of polyether modified organo-polysiloxane, 0.2-0.4 part of dimethicone, 0.2-0.4 part of an accelerant TMTM, 0.3-0.6 part of butyl glycidyl ether, 0.3-0.6 part of guar gum, 0.3-0.5 part of diacetone-acryloamide, 0.4-0.9 part of zeolite powder, 1-2 parts of pigment, 1-3 parts of hollow glass microspheres, 2-3 parts of silica sol and 12-16 parts of deionized water. Due to adoption of the silica sol in the water-based glass paint disclosed by the invention, the hardness of a paint film is improved, and the paint film is not easy to peel off and is smooth and flat; due to adoption of the hollow glass microspheres, the heat preservation and thermal insulation effects are achieved, and the cost is lowered; due to adoption of the modified pure acrylic emulsion, properties such as the flouring resistance, the bactericidal activity, the scrubbing resistance and the weather resistance of the water-based paint are improved; the water-based paint is high in practicability and applicable to popularization.

Owner:凤阳徽亨商贸有限公司

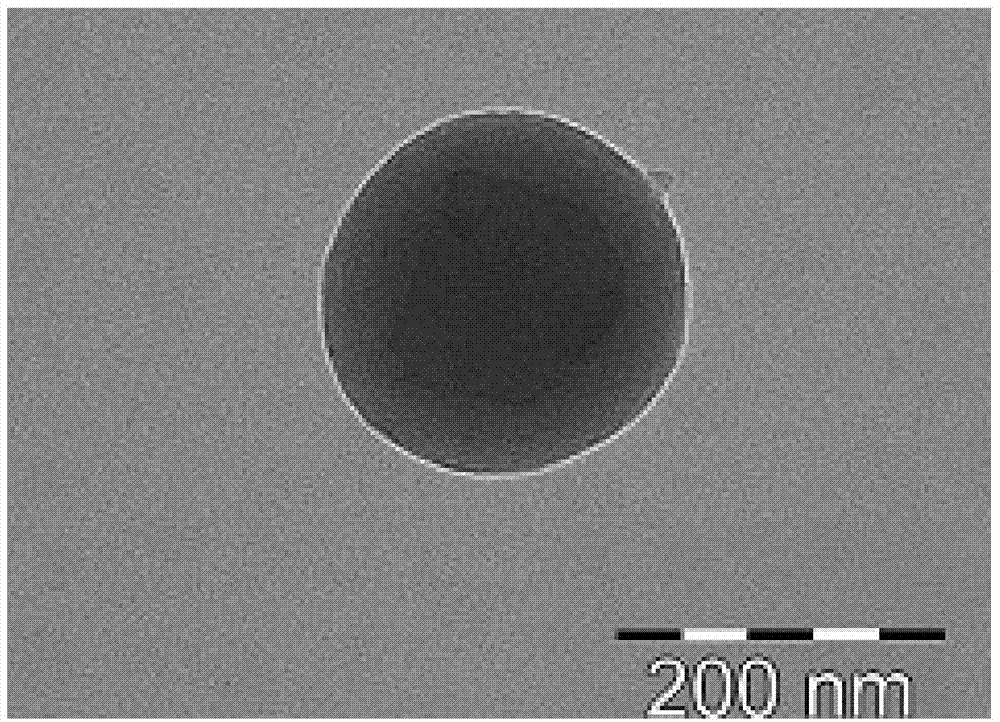

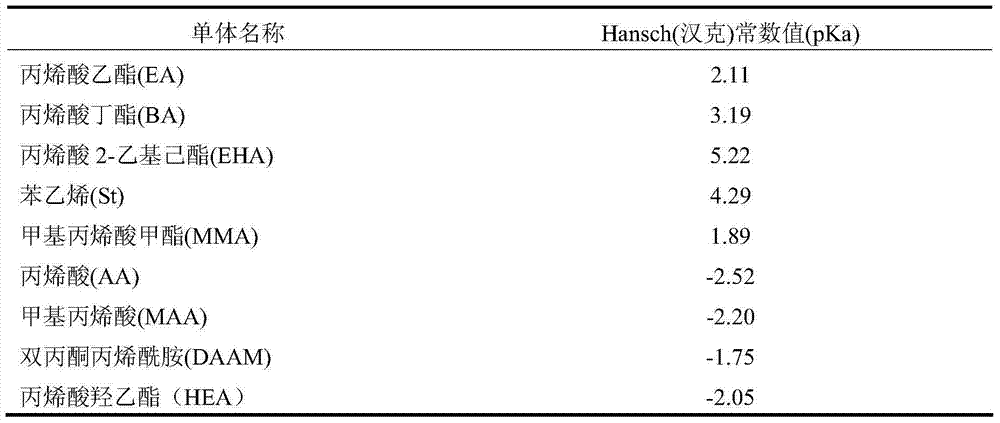

Aqueous binder emulsion for pre-coating and thermally laminating PET film and preparation method thereof

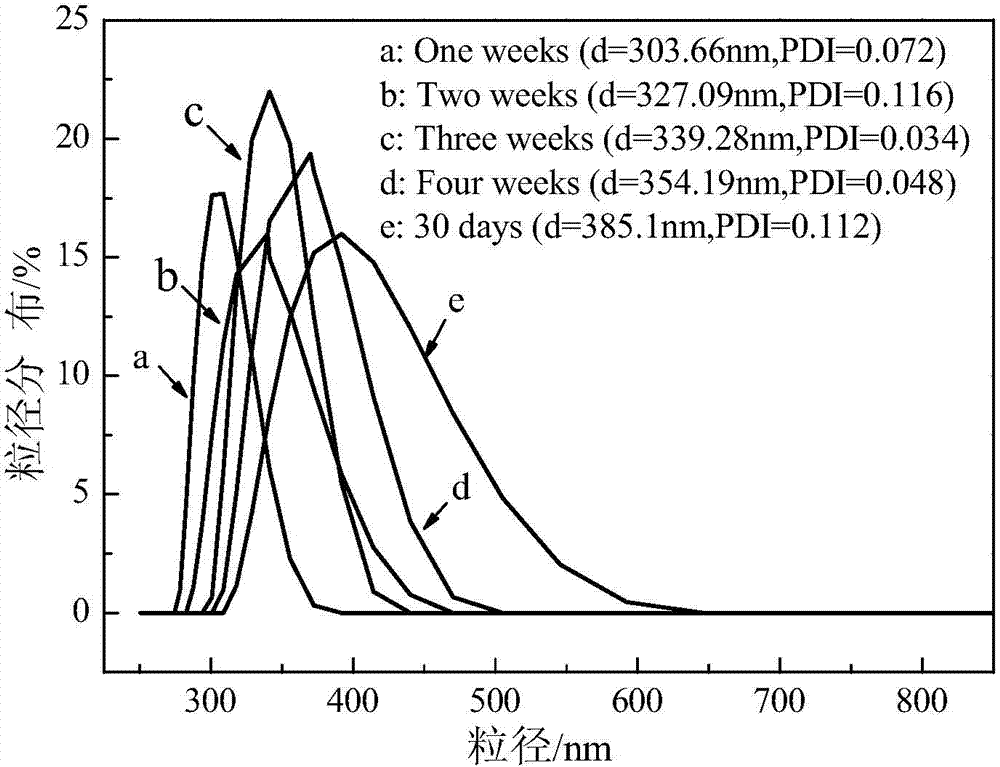

ActiveCN103936916AParticle size andSmall particle sizeFilm/foil adhesivesEster polymer adhesivesPolyesterSurface-active agents

The invention provides an aqueous binder emulsion for pre-coating and thermally laminating a PET film for a crystal album, and a preparation method of the aqueous binder emulsion. The aqueous binder emulsion is characterized in that seed emulsion containing styrene (St), methyl methacrylate (MMA) and ethyl acrylate (EA) of which the hydrophily is mild and the number-average diameter is less than 50nm is adopted; styrene (St), butyl acrylate (BA), acrylic acid (AA), hydroxyethyl acrylate (HEA), and 2-ethyl hexyl acrylate (EHA) are copolymerized with crosslinking monomer, namely, diacetone-acryloamide or vinyl urea monomer in the presence of proper amount of emulsifying agent and multifunctional additive or surface active agent, so as to obtain the aqueous binder emulsion. The binder is transferred and coated on the PET polyester film, and then dried through a drying channel and combined with a PE film, and finally a user removes the PE film and laminates the PET film with the hot pre-coating binder to a photo album.

Owner:ANHUI DEPU POLYMER MATERIAL

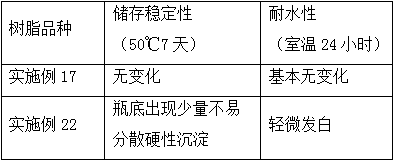

Preparation method and application of normal-temperature ketone and hydrazine self-crosslinked nanometer epoxy resin emulsion

The invention discloses a preparation method and an application of normal-temperature ketone and hydrazine self-crosslinked nanometer epoxy resin emulsion. The preparation method comprises the following steps: firstly opening a ring of epoxy resin by using lauric acid; consuming away epoxy groups; performing grafting polymerization by using diacetone-acrylamide and an acrylic acid type monomer; neutralizing the emulsion and adding water for dispersion to obtain grafted epoxy emulsion; and adding hexane diacid dihydrazide to prepare normal-temperature self-crosslinked nanometer epoxy resin emulsion. The solid content of the emulsion disclosed by the invention is 45% to 55%; the particle size is 80nm to 100nm; the storage stability is above 6 months; the adhesive force reaches 0-1 grade after the emulsion becomes a film by room temperature curing; the hardness of a pencil is H to 2H; the impact resistance is 50kg.cm to 65kg.cm; the flexibility is 2mm to 3mm; the water resistance is 120h to 150h; and the resistance to 3% NaCl solution is 100h to 180h. The emulsion disclosed by the invention can be widely applied to the fields of water-based anticorrosive paints, water-based wood paints, water-based automobile paints, water-based building paints and the like as base resin.

Owner:SOUTH CHINA UNIV OF TECH

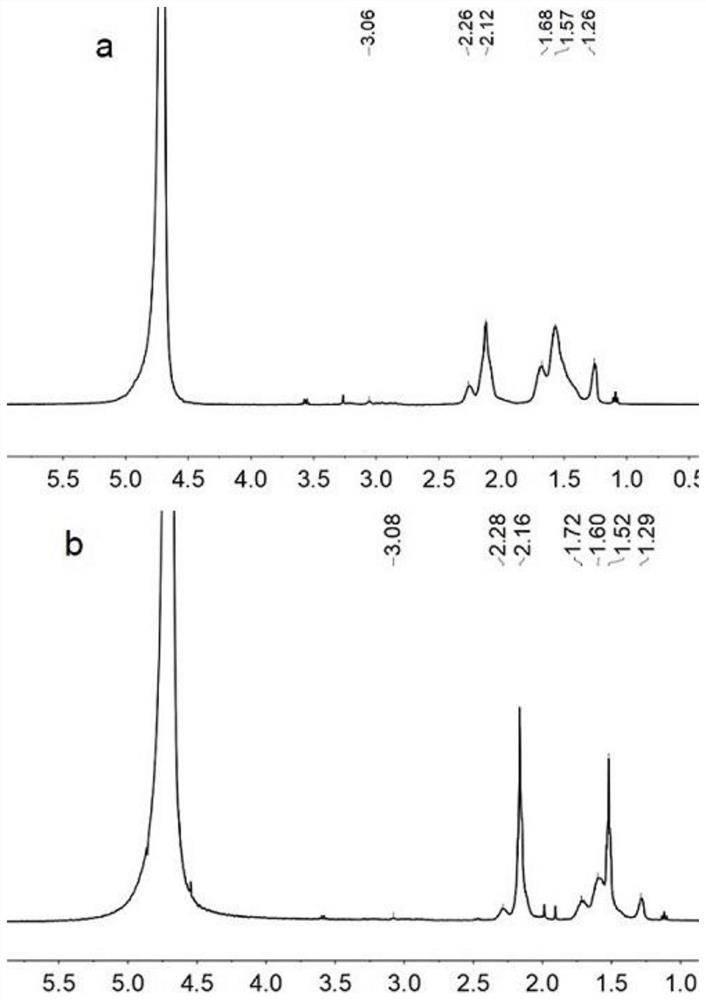

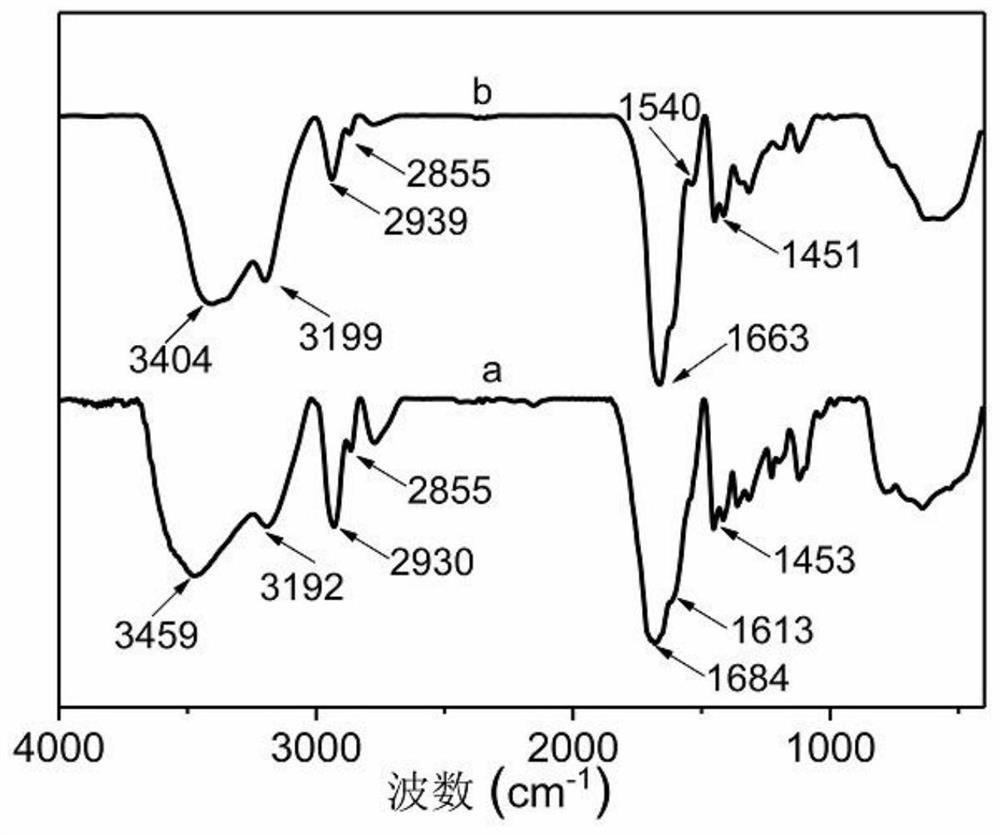

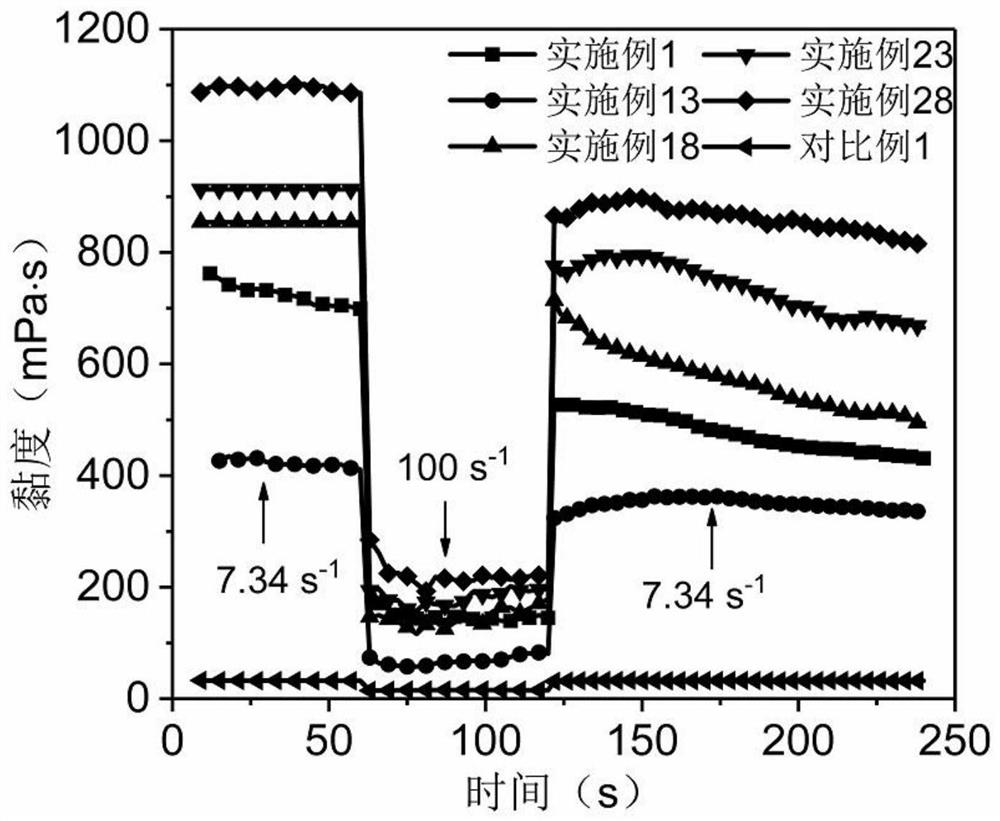

Dynamic covalent bond cross-linked oil displacement polymer and preparation method thereof

ActiveCN113321824AIncrease the lengthIncrease frictional resistanceDrilling compositionDiacetonaminePolymer science

The invention relates to a dynamic covalent bond cross-linked oil displacement polymer and a preparation method thereof. According to the invention, acrylamide is used as a main monomer to increase the length of molecular chains, so that the frictional resistance between the molecular chains is increased to improve the viscosity of a solution, diacetone acrylamide is used as a functional monomer to copolymerize with acrylamide to introduce keto-carbonyl into a polymer chain to realize crosslinking with adipic dihydrazide, and thus the nonionic polymer cross-linked by the dynamic acylhydrazone bonds is obtained. The polymer chain does not have ions, so that charge shielding and flocculation effects of various salt ions are avoided, and relatively high viscosity can be kept in hypersalinity water. The polymer takes an acylhydrazone bond which can be dynamically formed and dissociated as a chemical crosslinking point, and the acylhydrazone bond is used as a stimulus-responsive dynamic chemical bond, so that the reversibility of physical crosslinking is maintained, the strength of chemical crosslinking is also realized, and reversible formation and fracture can be realized under the stimulation of an external environment so as to overcome the defect of poor shear resistance of a traditional polymer.

Owner:SHANDONG UNIV

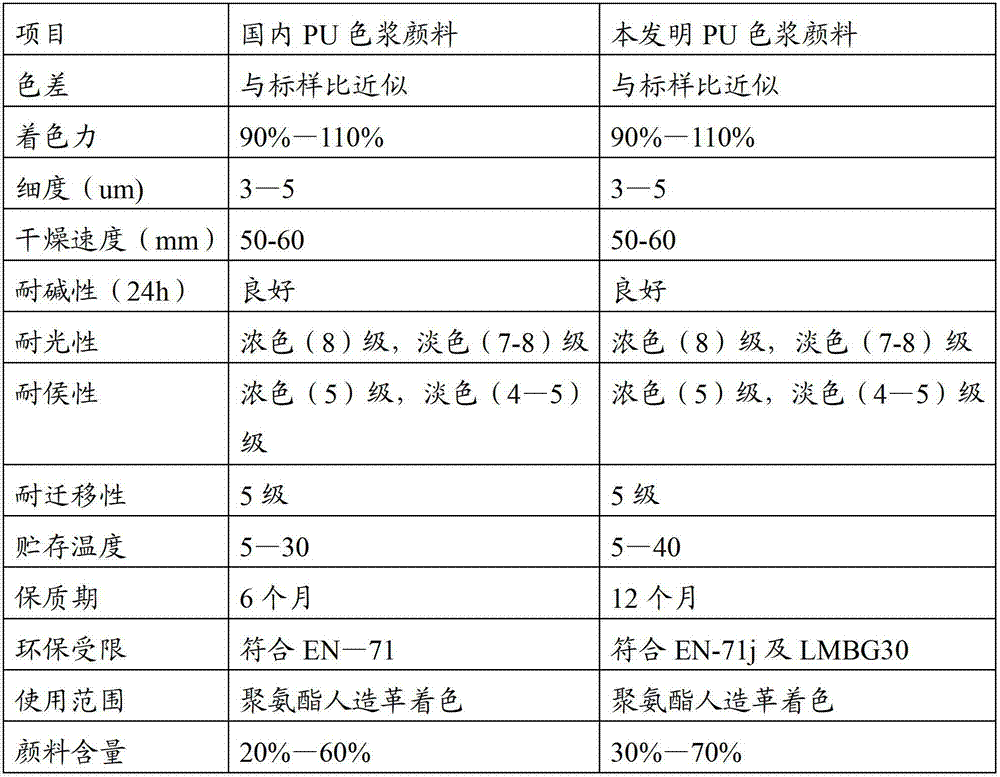

Polyurethane artificial leather coloring agent and preparation method thereof

InactiveCN102775854AFast evaporationWeak volatilization rateTextiles and paperPigment pastesDiacetone alcoholSodium Bentonite

The invention relates to the field of pigment and color paste used for leather and particularly relates to a polyurethane leather coloring agent and a preparation method thereof. The invention aims at providing an artificial leather coloring agent which is high in tinting strength, low in cost, good in stability, weak in volatility, light in solvent taste, less in air pollution and environmentally-friendly. The technical scheme of the invention is to provide a polyurethane artificial leather coloring agent which is prepared by raw materials according to the following parts by weight: 10-30 parts of propylene glycol methyl ether acetate, 15-45 parts of diacetone alcohol, 5-15 parts of PU (polyurethane) anti-yellowing resin, 3-9 parts of bentonite, 10-60 parts of toner, 0.5-1.5 parts of dispersant, 0.1-0.3 part of flatting agent and 0.1-0.3 part of defoaming agent. According to the invention, propylene glycol methyl ether acetate and diacetone alcohol are used for replacing traditionally used organic solvents with higher toxicity, strong smell and high volatilization speed, so that the prepared polyurethane artificial leather coloring agent is high in product tinting strength, low in cost, good in stability, weak in volatility, light in solvent smell and less in air pollution, thus belonging to environment-friendly artificial leather color paste.

Owner:福建宝利特新材料科技有限公司

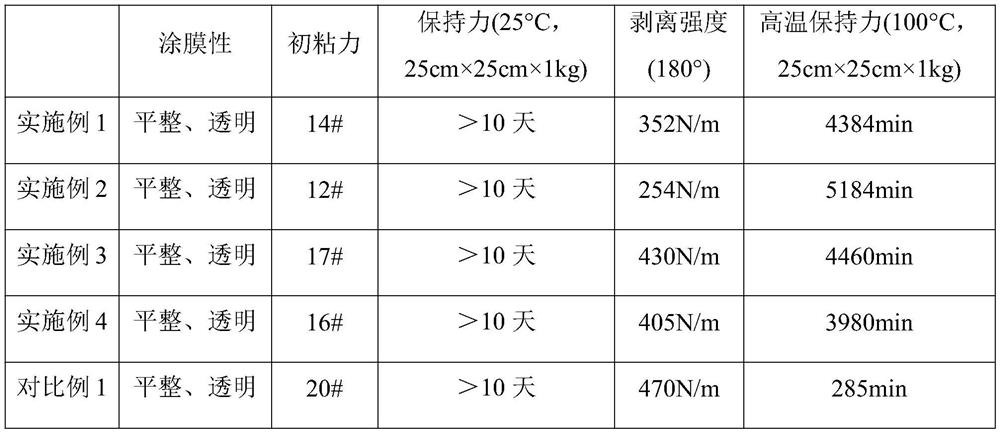

Water-based acrylate pressure-sensitive adhesive and preparation method thereof

InactiveCN113999632AHigh solid contentNo pollution in the processEster polymer adhesivesMethacrylateDiacetonamine

The invention discloses a water-based acrylate pressure-sensitive adhesive and a preparation method thereof. The pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 0.5 to 5 parts of acrylic acid or methacrylic acid, 30 to 50 parts of acrylate monomer, 1 to 10 parts of crosslinking functional monomer, 0.1 to 1 part of initiator, 0.5 to 5 parts of emulsifier, 0.01 to 0.5 part of buffering agent, 0.05 to 3 parts of molecular weight regulator, 0.5 to 10 parts of tackifying resin, 0.5 to 5 parts of pH regulator, 45 to 60 parts of deionized water and 0.5 to 5 parts of water-based additive, wherein the cross-linking functional monomer is at least one of beta-carboxyethyl acrylate, diacetone acrylamide, glycidyl methacrylate, acetoacetic acid ethyl methacrylate, methacrylamide ethyl ethylene urea, ethylidene urea ethyoxyl methacrylate and trimethylolpropane trimethacrylate; and the emulsifier comprises an anionic emulsifier and a nonionic emulsifier, and the weight percentage of the anionic emulsifier in the emulsifier is at least 10%. The water-based acrylate pressure-sensitive adhesive has the advantages of high peel strength, high retention, high adhesion and wide use temperature range.

Owner:ETERNAL CHEM (CHINA) CO LTD

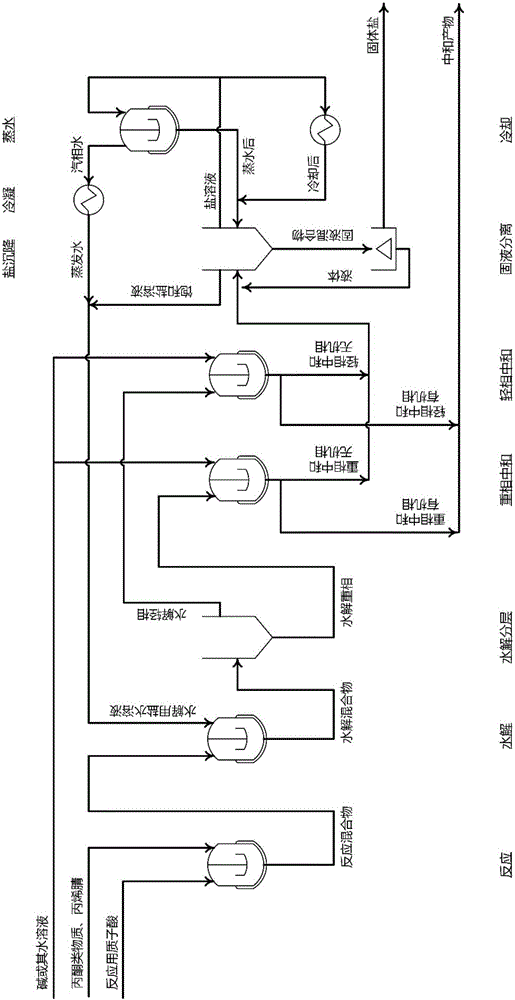

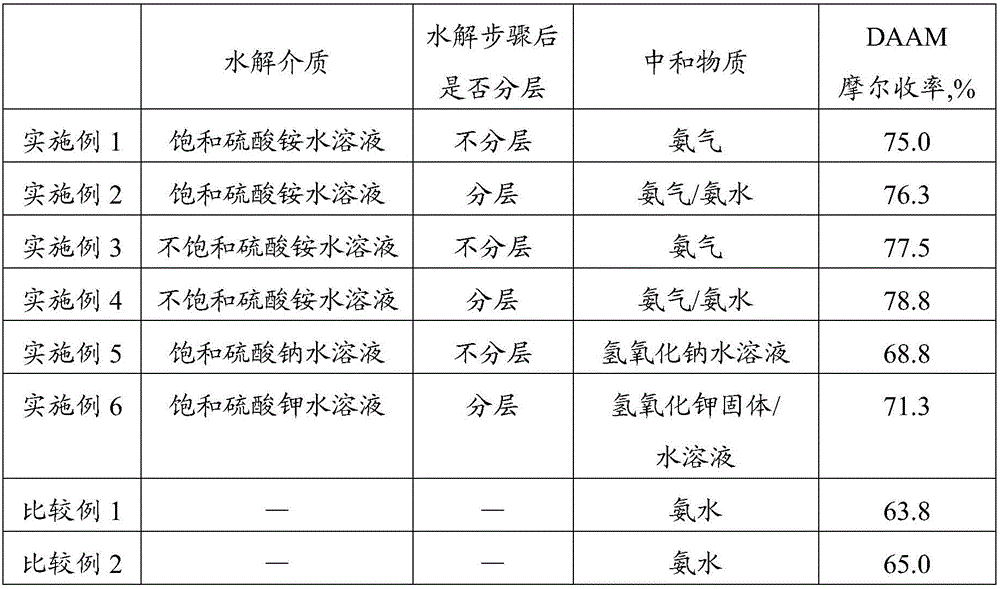

After-reaction processing method for preparation of diacetone-acrylamide

InactiveCN106117074ARealize closed loopNo emissionsCarboxylic acid amide separation/purificationOrganic layerHydrolysis

The invention discloses an after-reaction processing method for preparation of diacetone-acrylamide. The method comprises the steps that a hydrolysis medium is added into a protonic acid containing diacetone-acrylamide reaction mixture for a hydrolysis reaction, and a hydrolysis mixture is obtained; alkaline matter is added into the hydrolysis mixture and carries out a neutralization reaction with protonic acid, and a neutralization mixture is obtained; the neutralization mixture is layered, and separation is conducted to obtain a protonic acid salt solid, a protonic acid salt water solution and a diacetone-acrylamide containing organic layer. The method can be used for processing the reaction mixture obtained during preparation of diacetone-acrylamide and can also be used for processing diacetone-acrylamide or acrylamide containing mixtures obtained in other ways.

Owner:张华堂

Polyurethane waterproof flame-retardant paint and preparation method thereof

InactiveCN104745071AImprove waterproof performanceExtend your lifeFireproof paintsPolyurea/polyurethane coatingsDiacetonaminePolymer science

The invention discloses a polyurethane waterproof flame-retardant paint and a preparation method thereof. The paint comprises polyurethane prepolymers, diacetone acryloamide, buty stearate, titanate coupling agent TMC-311 and titanium pigment. The paint further comprises polydimethyl siloxane, white carbon black, mixed solvent and flame-retardant materials. The preparation method comprises the following steps: dissolving the diacetone acrylamide by ethanol of which the volume concentration is 65-80%, wherein the adding amount of the ethanol is 1.5 kilograms in per kilogram of diacetone acrylamide on the basis of weight; mixing the dissolved diacetone acrylamide with the polyurethane prepolymers in a reaction kettle, wherein the reaction temperature is 75-119 DEG C and the reaction time is 1.2-1.5 hours; adding the titanate coupling agent TMC-311 into the mixture and further reacting for 3-6 hours; then adding buty stearate, the rutile-type titanium pigment, polydimethyl siloxane, the flame-retardant materials, the white carbon black and the mixed solvent into the mixture and uniformly mixing, so that the polyurethane waterproof flame-retardant paint product is obtained. The paint prepared by the preparation method is good in waterproof and flame-retardant effects, friendly to the environment and not easy to age.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP +1

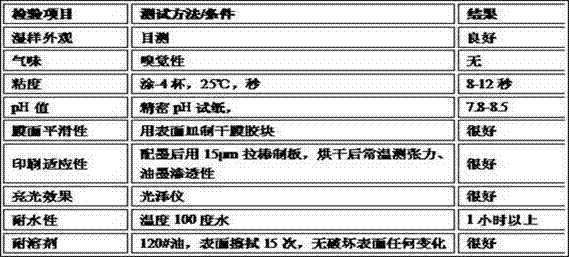

Water-based polishing printing ink for online polishing printing and preparation method

The invention discloses water-based polishing printing ink for online polishing printing and a preparation method. The water-based polishing printing ink for online polishing printing is prepared from methyl methacrylate, n-butyl acrylate, diacetone-acryloamide, hydroxyethyl acrylate, vinyl versatate, acrylic acid, adipic dihydrazide, potassium peroxodisulfate, an emulsifier OP-21, an emulsifier SDS, an emulsifier MS-1, deionized water, water-based color paste, ethanol, a leveling agent RM-2020, a defoamer DefomW-0506, wax slurry 2340 and a water-based wetting agent LevelolW-469 in certain amounts. The preparation method comprises the following steps: firstly, synthesizing water-based acrylate resin in a core-shell structure; then, adding an adipic dihydrazide crosslinking monomer aqueous solution to mix; and finally, adding various functional auxiliaries and the water-based color paste to be uniformly mixed to obtain the water-based polishing printing ink for online polishing printing with high glossiness and excellent wear resistance and water resistance.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

Contamination-resistant and heat insulation aqueous coating and preparation method thereof

InactiveCN104277697AImprove heat resistanceGood heat insulationAntifouling/underwater paintsAnti-corrosive paintsDiacetonamineSodium stearate

The invention discloses a contamination-resistant and heat insulation aqueous coating. The contamination-resistant and heat insulation aqueous coating is characterized in that the contamination-resistant and heat insulation aqueous coating is prepared from the following raw materials in parts by weight: 48-53 parts of aqueous polyurethane resin, 20-26 parts of an elastic pure acrylate emulsion, 1-2 parts of polyoxypropylene glycol, 1-2 parts of melamine, 1-2 parts of a fluorescent whitener, 0.8-1.6 parts of triethanolamine, 1-2 parts of diethylenetriamine, 0.5-0.8 part of dimethicone, 1-2 parts of guar gum, 2-3 parts of titanium dioxide, 1-3 parts of silicon oxide, 0.4-0.6 part of polyoxyethylene cetyl ether, 2-3 parts of methyl-ethyl paraben, 1-2 parts of sodium stearate, 1-3 parts of bentonite, 2-3 parts of bamboo powder, 7-9 parts of heat insulation slurry, 0.7-1.4 parts of diacetone acrylamide and 14-20 parts of deionized water. The aqueous coating disclosed by the invention has excellent heat resistance, heat insulation, contamination resistance, corrosion resistance and the like, water is adopted as a dilution solvent, and the aqueous coating is safe, environment-friendly, low in toxicity and low in cost; and furthermore, the aqueous coating is good in film-forming ability after curing, smooth, high in hardness, good in adhesion and less prone to shedding and has a wide range of applications.

Owner:ANHUI LENCAQI BUILDING MATERIAL

Moisture barrier layer dielectric for thermoformable circuits

This invention is directed to a polymer thick film moisture barrier layer dielectric composition comprising thermoplastic urethane resin, thermoplastic phenoxy resin, diacetone alcohol and fumed silica. Dielectrics made from the composition can be used in various electronic applications to protect electrical elements and particularly to insulate and protect both the conductive thermoformable silver above it and the polycarbonate substrate below it in capacitive switch applications.

Owner:DU PONT CHINA LTD

Preparation method of acrylate emulsion for novel wood lacquer coating

InactiveCN110669181AImprove stabilityNarrow particle size distributionAntifouling/underwater paintsPaints with biocidesDiacetonaminePolymer science

The invention relates to a preparation method of an acrylate emulsion for a novel wood lacquer coating. According to the preparation method, a dianionic emulsifier composition is adopted as an acrylate emulsion seed emulsifier, and an alkylphenol-free hydroxyl ester is adopted as a reaction emulsifier. The acrylate emulsion is prepared by copolymerization of an alkene monomer, an emulsifier, an alkene functional group monomer, a cross-linking agent, vinyl silane, a persulfate, a coalescing agent and deionized water. According to the invention, one selected from diacetone acrylamide and Methylene-Bis-Acrylamide is introduced for copolymerization with a N-substituted maleimide combined cross-linking agent and vinyl silane coupling agent; the preparation method is safe and friendly to the environment; a prepared adhesion product possesses following advantages compared with a pressure-sensitive adhesive prepared from acrylate emulsion prepared by combining a traditional anionic emulsifierthat no yellowing is caused, stripping force is high and the like; and meanwhile, the elongation at break, the tensile strength and the stripping strength are greatly improved; meanwhile, the coalescing agent and an auxiliary coalescing agent are introduced, so that the applied wood lacquer coating has the characteristics of high drying speed, high hardness, transparency, stain resistance and thelike.

Owner:江苏艾萨斯新型肥料工程技术有限公司

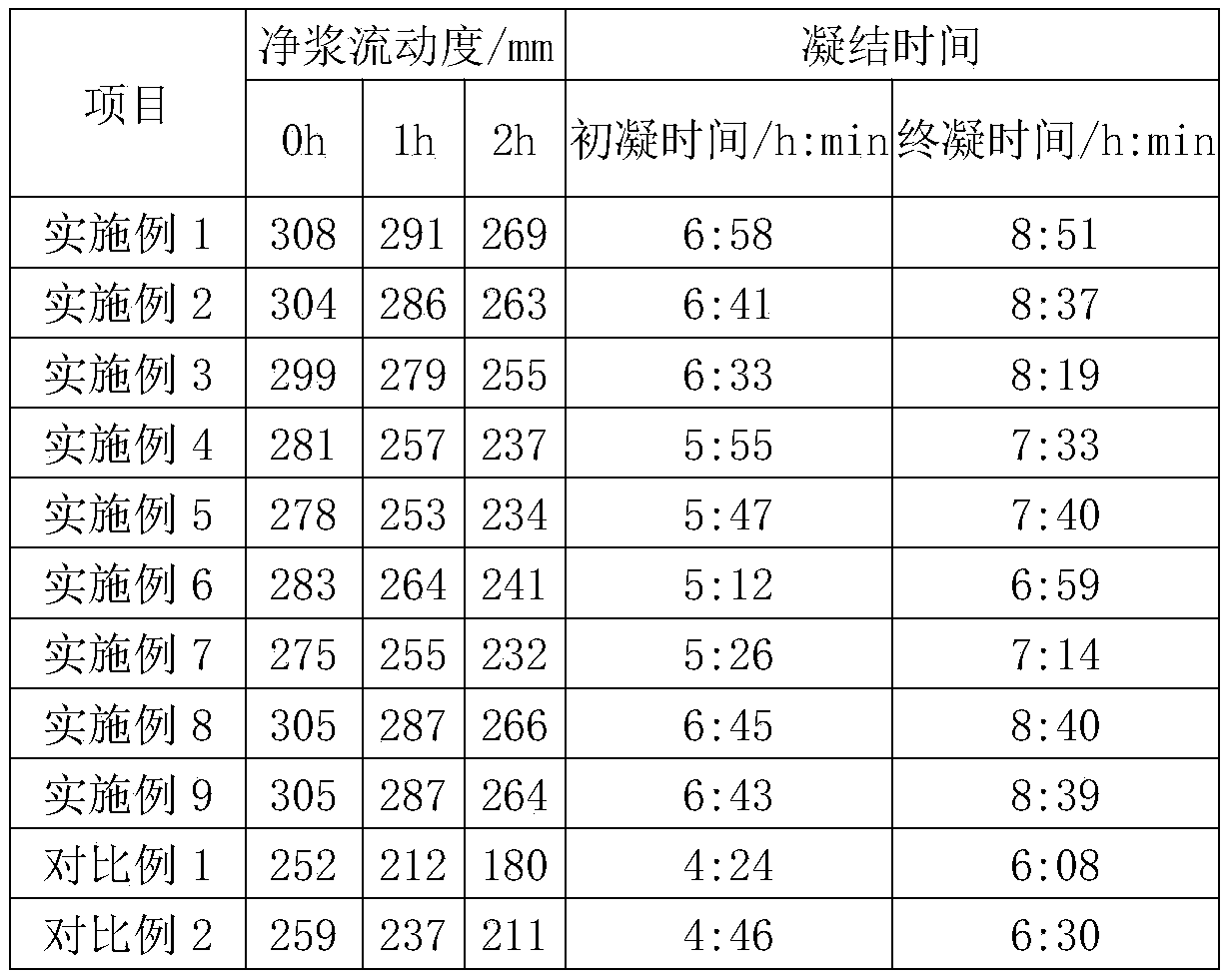

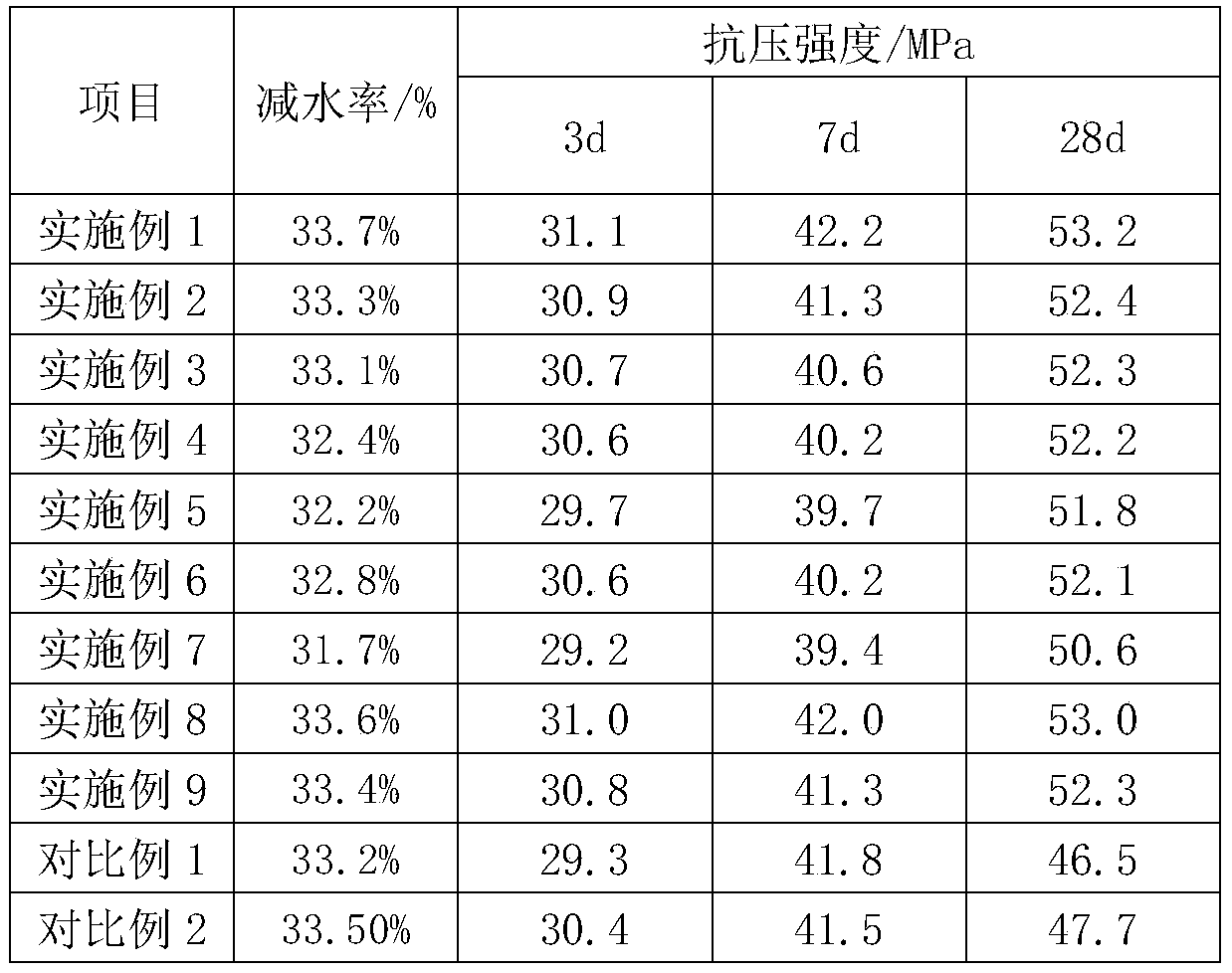

Amphoteric polycarboxylate superplasticizer and preparation method thereof

The invention provides an amphoteric polycarboxylate superplasticizer and a preparation method thereof. The superplasticizer comprises an unsaturated polyether macromonomer, an acrylamide monomer containing phenylate, diacetone acrylamide, (methyl) acrylic acid, (methyl) propylene sulfonate, an initiator, a reducing agent and a chain transfer agent. The acrylamide monomer containing phenylate is obtained by carrying out amidation reaction on acryloyl chloride and aminophenyl ether, and each benzene ring in the aminophenyl ether structure is provided with at least one amino group. The superplasticizer comprises a long side chain formed by the unsaturated polyether macromonomer and a short side chain formed by other monomers, the long-chain and short-chain comb-shaped structure and functional group matched superplasticizer can give full play to the effect of functional groups to form yin-yang amphoteric property, embedding of the functional groups and entanglement between long side chains are avoided, and the retarding effect can be improved under the condition that dispersity and fluidity are not reduced. The superplasticizer is high in water reducing rate, good in slump loss resistance, simple in synthesis process, low in energy consumption, green and environmentally friendly.

Owner:四川金江建材科技有限公司

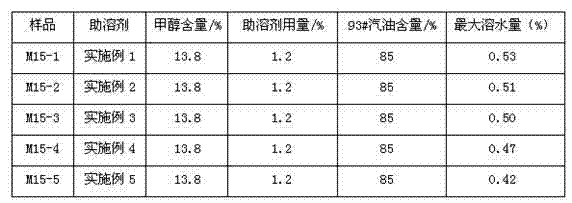

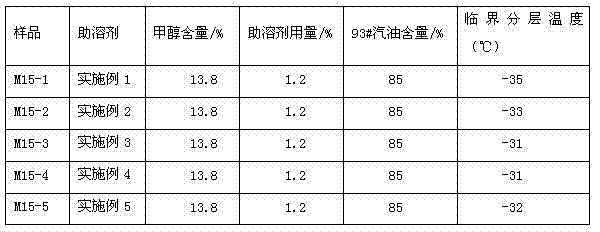

Vehicle methanol gasoline cosolvent

ActiveCN103695052AImprove stabilityStrong solubility aidLiquid carbonaceous fuelsDiacetone alcoholHeptyl alcohol

The invention belongs to the technical field of vehicle fuel oil additives, and relates to efficient vehicle methanol gasoline cosolvent which is a mixture comprising the following seven different alcohols: 3-20 parts of ethylene glycol monobutyl ether oleate, 2-5 parts of diacetone alcohol, 4-10 parts of glycol monoethyl ether, 10-80 parts of butanol, 5-50 parts of pentanol, 5-20 parts of hexanol, 0.5-10 parts of heptanol and 0.5-10 parts of octanol. According to the invention, the cosolvent has high hydrotropy; prepared methanol gasoline can be stored for long time under a low-temperature condition of -30 DEG C, and the water resistance capability is up to 0.5%; and the efficient cosolvent is free of metal and other elements, is reasonable in element variety and has no adverse influence on an engine, and the combustion performance of the cosolvent is approximate to that of gasoline. The efficient vehicle methanol gasoline cosolvent is a brand new technology and product in the field of methanol gasoline, and is of far reaching importance in improving the quality of methanol gasoline and standardizing industrial additive technologies.

Owner:YANKUANG GRP CO LTD +1

Coating of transfer paper and preparation method thereof

InactiveCN111304957AGuaranteed integrityGuaranteed finenessDuplicating/marking methodsPaper coatingDiacetonaminePolymer science

The invention provides a coating of transfer paper. The coating comprises the following components in parts by weight: 0.5-50 parts of modified polyvinyl alcohol, 0.02-20 parts of a cross-linking agent, 5.0-99.3 parts of water-soluble polysaccharide, 0.1-90 parts of a drying agent and 0.1-2 parts of a defoaming agent, wherein the coating of transfer paper is obtained through a cross-linking reaction, and the modified polyvinyl alcohol is at least one selected from a group consisting of itaconic acid modified polyvinyl alcohol, maleic acid modified polyvinyl alcohol, acetoacetyl modified polyvinyl alcohol, carboxyl modified polyvinyl alcohol and diacetone modified polyvinyl alcohol. The coating of the transfer paper forms a macromolecular reticular structure, so the integrity of the coatingcan be ensured during printing with the maximum ink amount, image cracking is prevented, and reduction in definition caused by migration and diffusion of ink to the periphery is prevented; and moreover, the coating of the transfer paper has the capacity of resisting ink to migrate and permeate into the paper, more effective components of the ink can be accumulated on the surface of the coating, and the transfer rate of the ink is increased.

Owner:GUANGDONG GUANHAO HIGH TECH

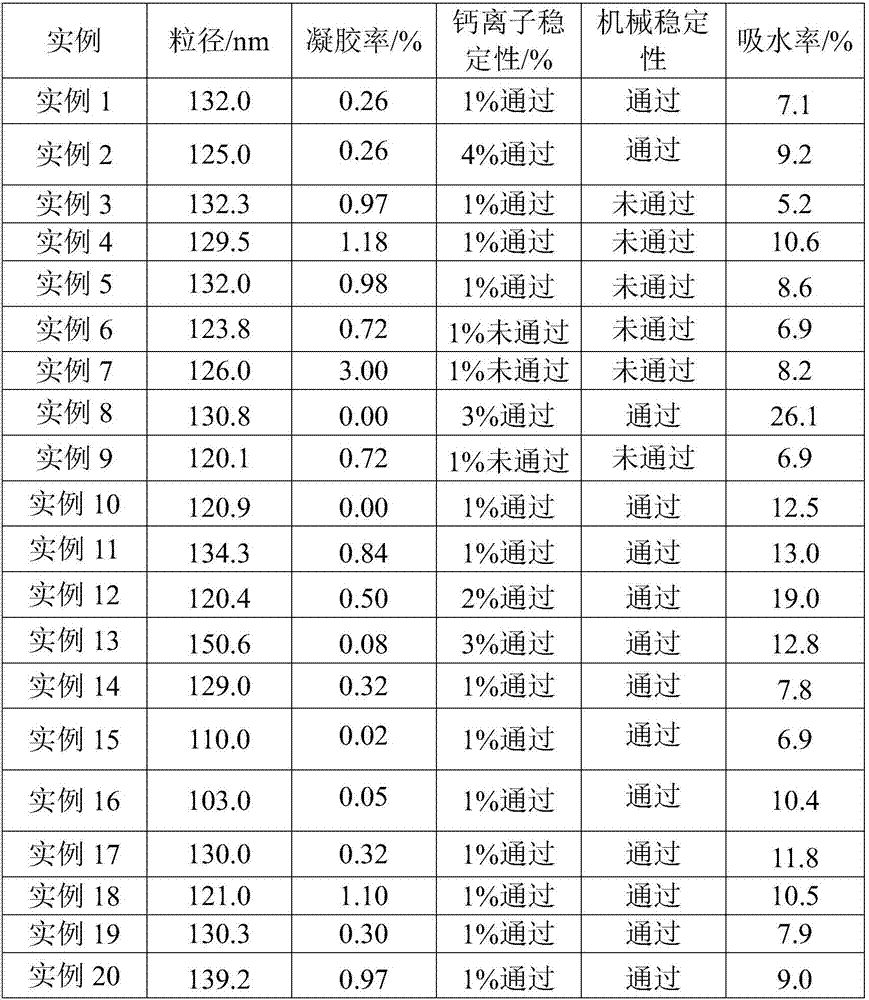

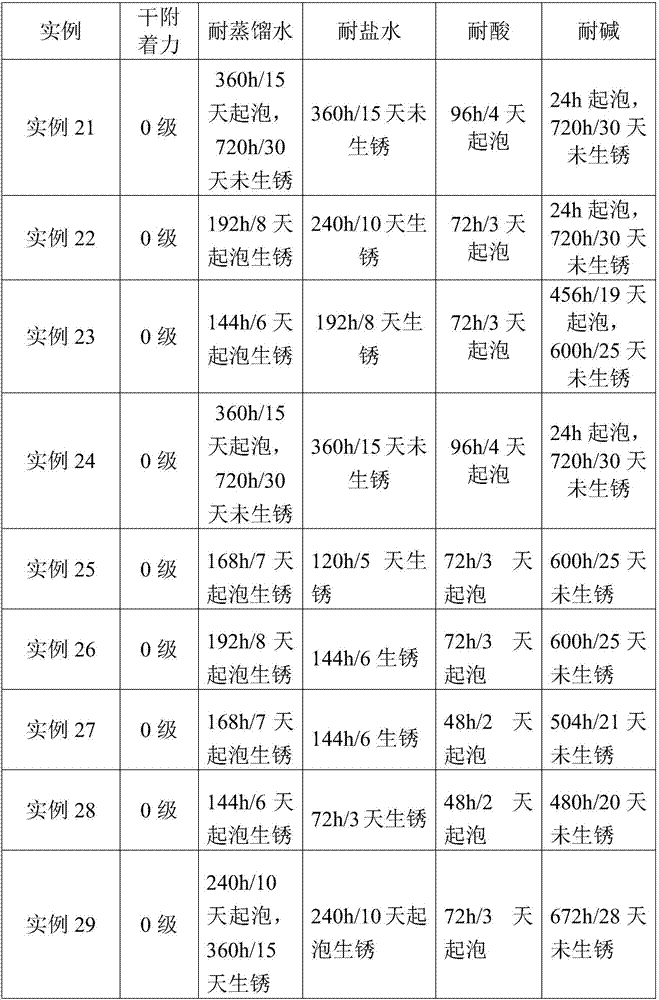

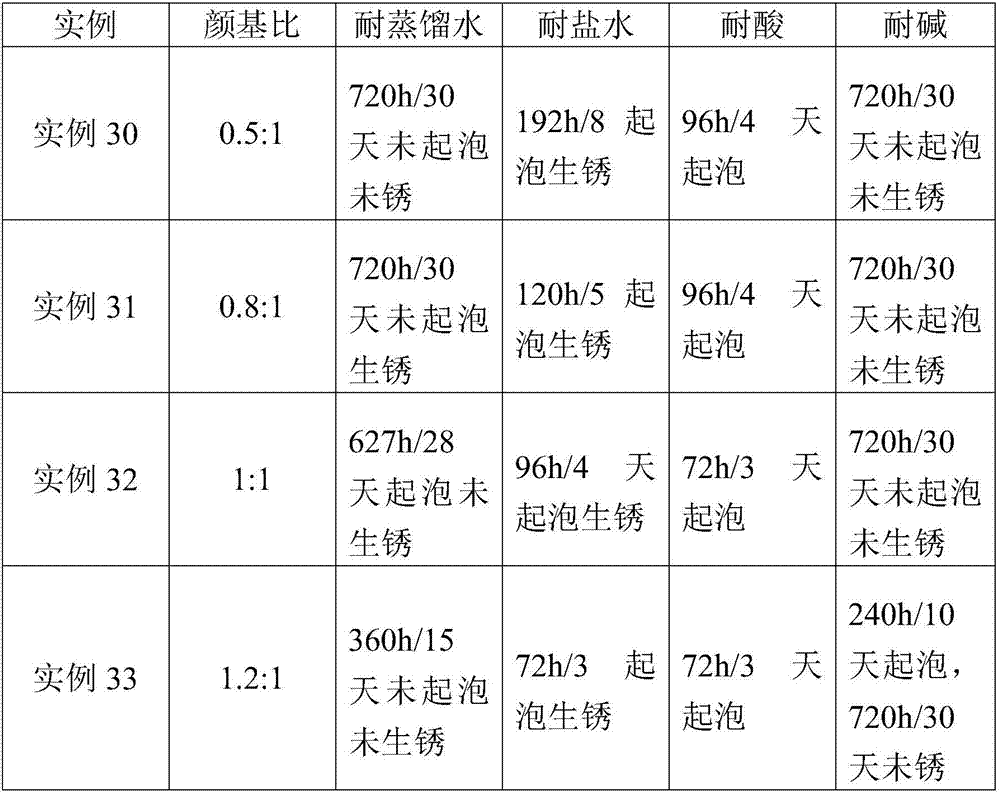

Soap-free self-crosslinking nano acrylic emulsion as well as preparation method and application thereof

PendingCN111662415AThe appearance of the coating film is transparentBright appearanceCoatingsIsooctyl acrylateDiacetonamine

The invention belongs to the technical field of water-based paint, and relates to a soap-free self-crosslinking nano acrylic emulsion, which comprises the following components: water-based acrylic resin, methyl methacrylate, styrene, butyl acrylate, 2-ethylhexyl acrylate, a crosslinking monomer, adipic dihydrazide, ammonium persulfate, tert-butyl hydroperoxide, VC, ammonia water and the balance ofwater. The cross-linking monomers are diacetone acrylamide and butyl acrylamide. The emulsion is 50-100 nm in particle size, good in wettability, good in permeability, low in minimum film forming temperature of a coating film, high in curing speed, high in gloss of the coating film and capable of being polished, and the hardness of the coating film reaches up to 3H-5H. The emulsion is low in foam, a wetting agent and a defoaming agent do not need to be added when the emulsion is applied to water-borne wood paint, and the emulsion is small in particle size, so that a paint film is good in woodcolor warming property and transparent.

Owner:恒昌涂料(惠阳)有限公司

Preparation method for gravure ink connecting emulsion for water-based OPP packaging film

The invention discloses a preparation method for gravure ink connecting emulsion for a water-based OPP packaging film. The preparation method comprises the following steps: adding water into a reaction container, heating the water as bottoming water, and adding methyl methacrylate, butyl acrylate, diacetone acrylamide and methylacrylic acid into a dodecyl sodium thionate solution to emulsify; then, adding the emulsified solution into the bottoming water, adding an initiator, and heating after reacted liquid is transparent and has blue opalescence; and emulsifying and adding butyl acrylate, methyl methacrylate, methacrylic acid, diacetone acrylamide and dodecanethiol into the reaction container, then, adding the initiator, cooling, adding hydroxyethyl acrylamide, carrying out oxidation and reduction after preserving the heat to remove smell, adding adipic dihydrazide after cooling, and cooling and discharging after reaction is completed, thereby obtaining a semi-transparent emulsion sample with blue light. The obtained emulsion is relatively small in emulsion particle size, is uniform in arrangement, and is circular in surface. The emulsion is prepared into gravure ink for the packaging film, so that drying is quick and sticking resistance is good.

Owner:上海百道成新材料科技有限公司

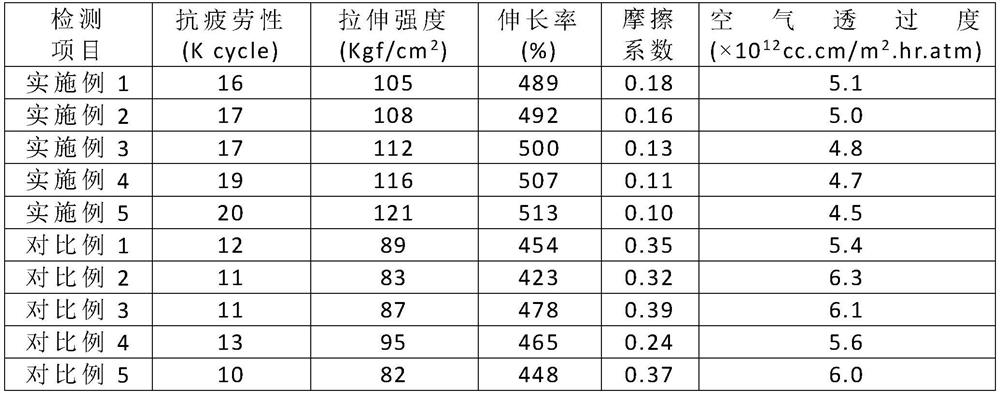

Environment-friendly tire rubber material and preparation method thereof

The invention discloses an environment-friendly tire rubber material and a preparation method thereof. The material is prepared from the following components in parts by weight: 30-40 parts of sulfonamide / carboxyl-terminated liquid fluororubber polycondensate, 10-15 parts of castor oil-based hyper-branched epoxy resin, 40-60 parts of diacetone acrylamide / N-(4-cyano-3-trifluoromethylphenyl) methacrylamide / 2-(ethyleneoxy) ethylamine / 4-acyl-18 crown ether-6 copolymer, 15-25 parts of fly ash 4-8 parts of graphene hollow nano fibers, 3-5 parts of a vulcanizing agent, 1-3 parts of a vulcanization accelerator and 1-2 parts of a coupling agent. The invention also discloses a preparation method of the environment-friendly tire rubber material. The environment-friendly tire rubber material disclosedby the invention is excellent in environmental protection property and fatigue resistance, and good in mechanical property, road holding property, wear resistance, air tightness and performance stability.

Owner:王玉龙

Field bactericide

InactiveCN103583526AEfficient killingReduce manufacturing costBiocideFungicidesDiacetonamineTrichloroisocyanuric acid

The invention discloses a field bactericide which comprises the following components in parts by weight: 5-10 parts of trichloroisocyanuric acid, 30-35 parts of copper diacetonamine, 1-3 parts of tetraconazole, 7-10 parts of an auxiliary and 100-150 parts of water. The field bactericide disclosed by the invention not only can effectively kill pythium aphanidermatum in soil, but also is low in production cost, so that the field bactericide is applicable to popularization and application in agricultural production.

Owner:QINGDAO SANDING SANITARY PROD

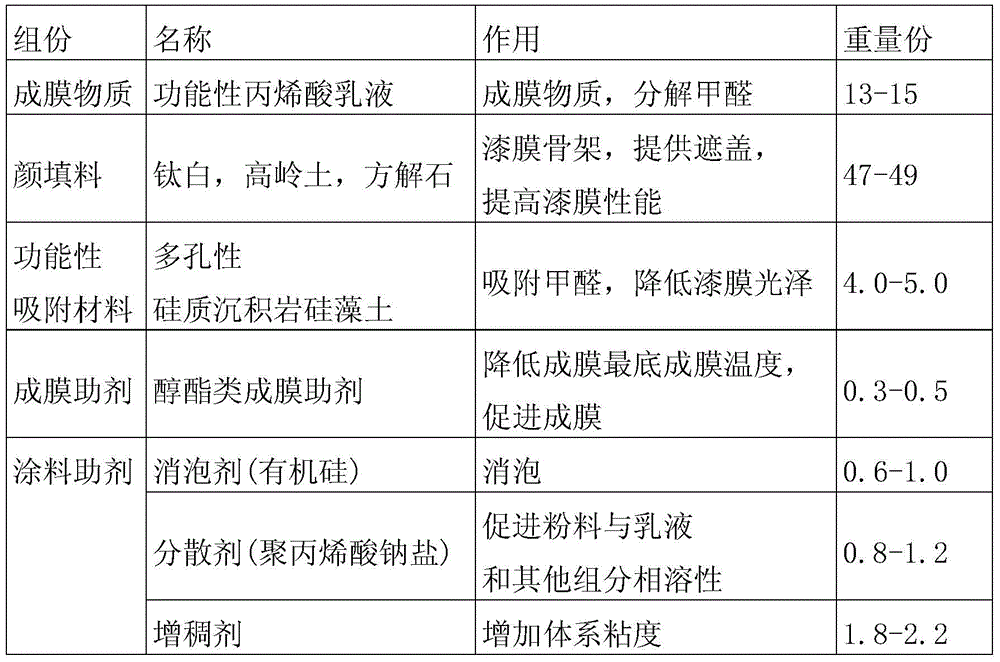

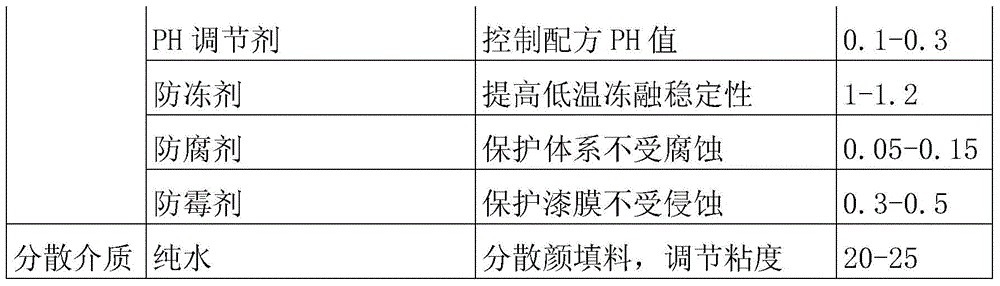

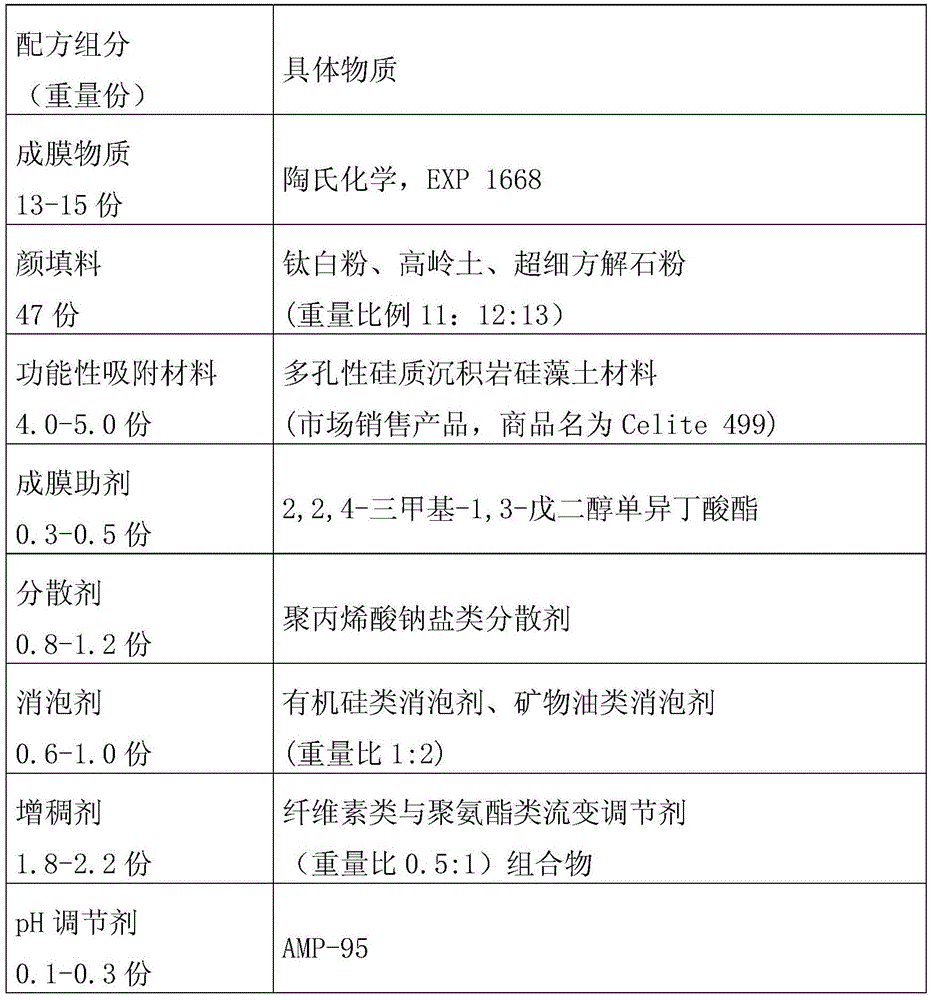

A high pvc latex paint composition with low odor that reduces indoor formaldehyde content

The invention discloses a low-smell high PVC emulsion paint composition capable of reducing the indoor formaldehyde content. The composition contains, by weight, 13-15 parts of a film forming material, 47-49 parts of a pigment filler, 4-5 parts of a functional adsorption material, 3-6 parts of a coating additive, 0.3-0.5 parts of a film forming aid and dilution water, wherein the film forming material is an acrylic copolymer emulsion with a diacetone active functional group, the functional adsorption material is porous silicastone diatomite, and the volume concentration of the pigment is 70-75. High PVC emulsion paints prepared by using the composition have very good routine performances of a coating, can adsorb and decompose formaldehyde, and can meet many demands of consumers.

Owner:NIPPON PAINT CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com