Preparation method and application of normal-temperature ketone and hydrazine self-crosslinked nanometer epoxy resin emulsion

A technology of epoxy resin emulsion and epoxy resin, which is applied in coatings, anti-corrosion coatings, etc., can solve the problems of affecting performance, complicated reaction steps, and difficult to disperse, and achieve simple use process, reduce energy consumption, and good cross-linking effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Put 20g of epoxy resin E-06 into a four-necked flask equipped with a stirrer, thermometer and condenser tube, heat it to 100°C to melt it completely, add the remaining 80g of epoxy resin, 75g of lauric acid, 3g of four-necked Ethylammonium bromide, stirred, and after 1h, the temperature was raised to 110°C to continue the reaction, and the reaction was stopped when the acid value reached 3mg / L. Add 10g of n-butanol and 20g of propylene glycol monobutyl ether mixed solvent to dissolve, under the protection of nitrogen, stir and heat to 115°C, add 10g of methacrylic acid (MAA) and 20g of methyl methacrylate (MMA) dropwise continuously within 1h , 10g styrene (St), 40g butyl acrylate (BA), 3gDAAM and 3g dibenzoyl peroxide (BPO) mixed solution, constant temperature reaction for 4h, cooled to 50 ° C, dropwise added 10g triethylamine (TEA) To form a salt, add 250g of deionized water, and stir rapidly at 1000r / min for 30min to obtain a water-based epoxy emulsion. Adjust the pH...

Embodiment 2

[0040] Put 20g of epoxy resin E‐12 into a four-necked flask equipped with a stirrer, thermometer and condenser, heat it to 100°C to melt it completely, add the remaining 80g of epoxy resin, 75g of lauric acid, 3g of Ethylamine, stirred, and after 1 hour, the temperature was raised to 110°C to continue the reaction, and the reaction was stopped when the acid value reached 3 mg / L. Add 10g of n-butanol and 20g of propylene glycol monobutyl ether mixed solvent to dissolve, under the protection of nitrogen, stir and heat to 115°C, add 15g of acrylic acid (AA), 20g of MMA, 10g of St, 40g of BA, 2g of DAAM and 5g of azo continuously dropwise within 1h The mixed solution of diisobutylcyanide was reacted at constant temperature for 4 hours, cooled to 50°C, 10g of TEA was added dropwise to form a salt, and 250g of deionized water was added, and stirred rapidly at 1000r / min for 30min to obtain a water-based epoxy emulsion. Adjust the pH to 7, then add 2g of ADH aqueous solution, and stir...

Embodiment 3

[0043] Put 20g of epoxy resin E‐20 into a four-neck flask equipped with a stirrer, thermometer and condenser, heat it to 100°C to melt it completely, add the remaining 80g of epoxy resin, 75g of lauric acid, 3g of Phenylphosphine was stirred, and after 1 hour, the temperature was raised to 110°C to continue the reaction, and the reaction was stopped when the acid value reached 3 mg / L. Add 10g of n-butanol and 20g of propylene glycol monobutyl ether mixed solvent to dissolve, under the protection of nitrogen, stir and heat to 115°C, add 10gMAA, 20gMMA, 10gSt, 40gBA, 3gDAAM and 3g di-tert-butyl peroxide dropwise within 1h The mixed solution of the compound was reacted at constant temperature for 4 hours, cooled to 50°C, 10g of TEA was added dropwise to form a salt, and 250g of deionized water was added, and stirred rapidly at 1000r / min for 30min to obtain a water-based epoxy emulsion. Adjust the pH to 7, then add 3g of ADH aqueous solution, and stir for 20 minutes to obtain a ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

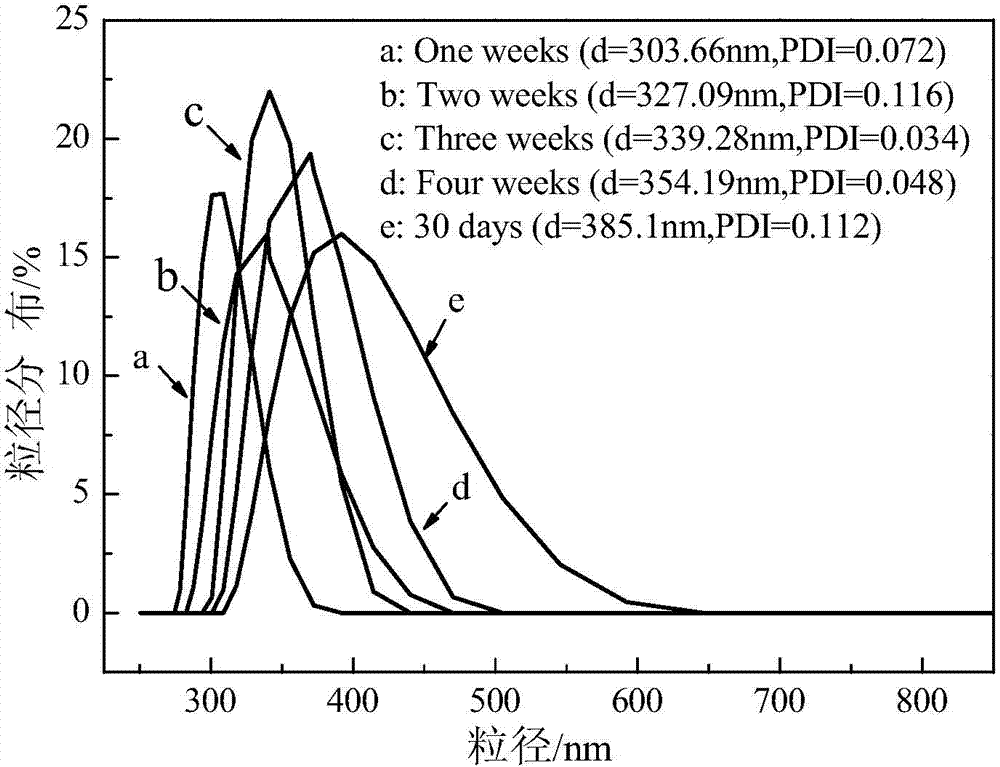

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com