Pole Clamp

a technology of pole clamps and clamping rods, which is applied in the field of pole clamps, can solve the problems of not being able to adapt to be used with different diameter poles, and achieve the effects of reducing the effort a user has to spend, facilitating the user to turn the shaft, and being convenient to us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

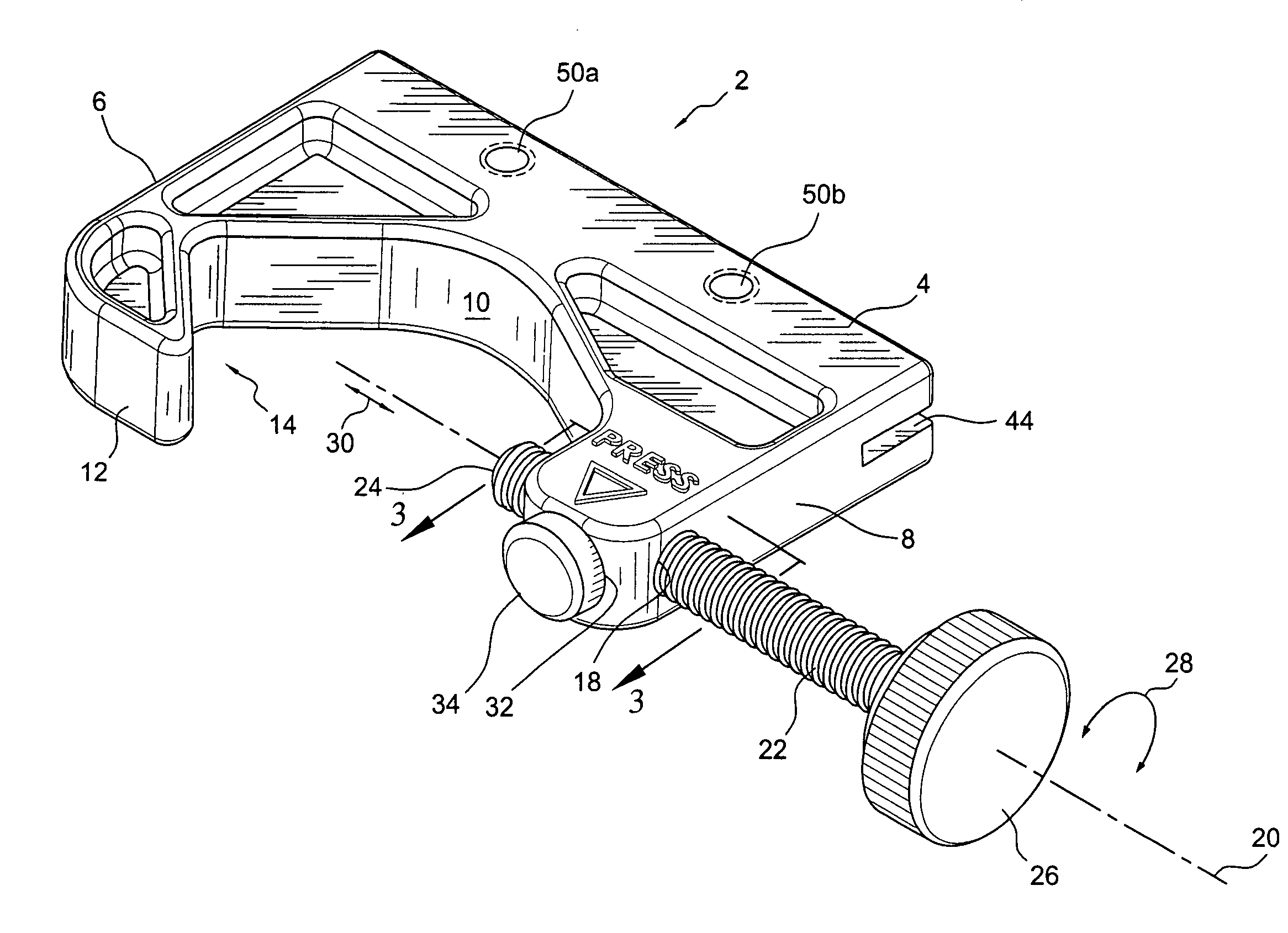

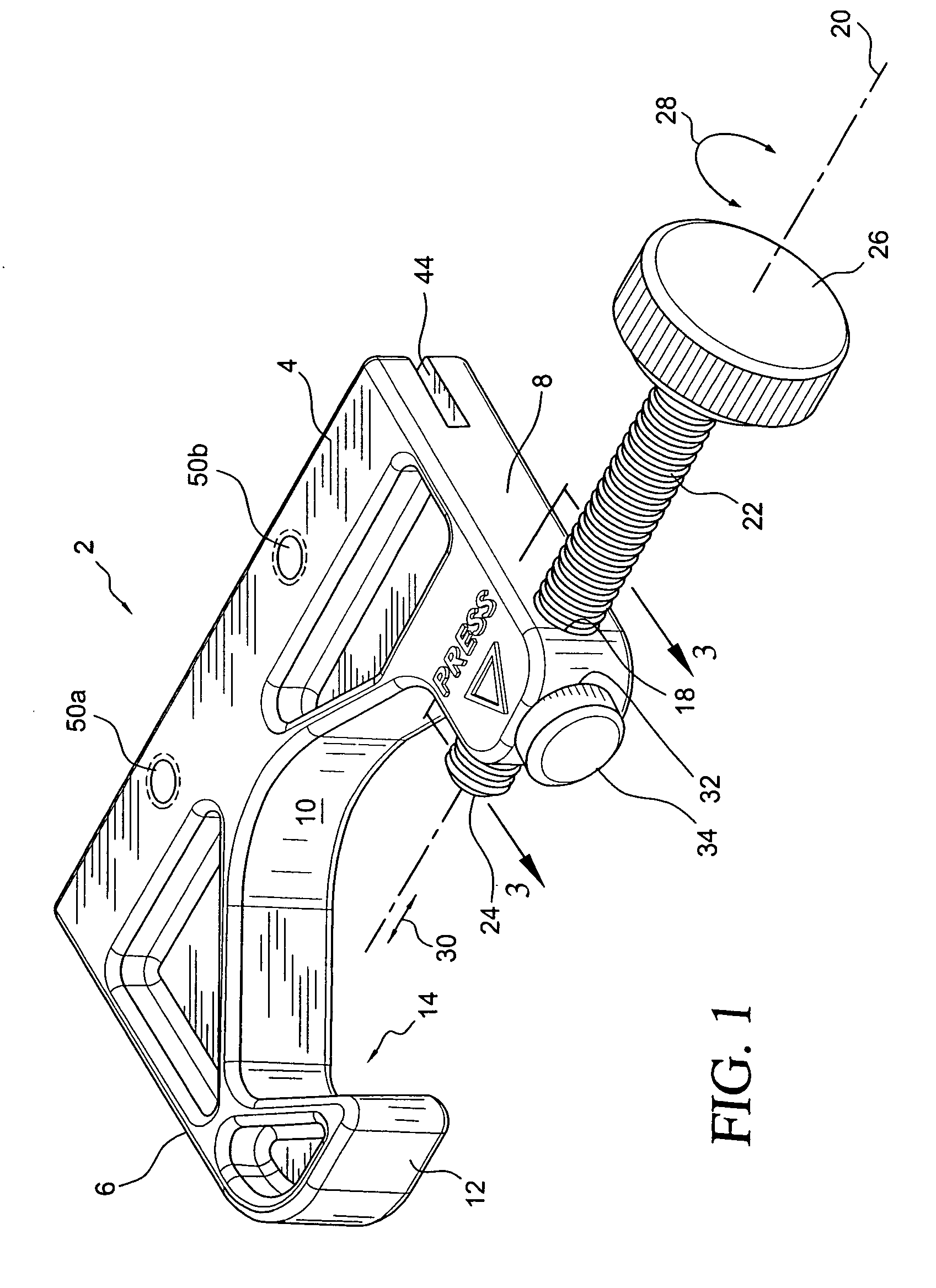

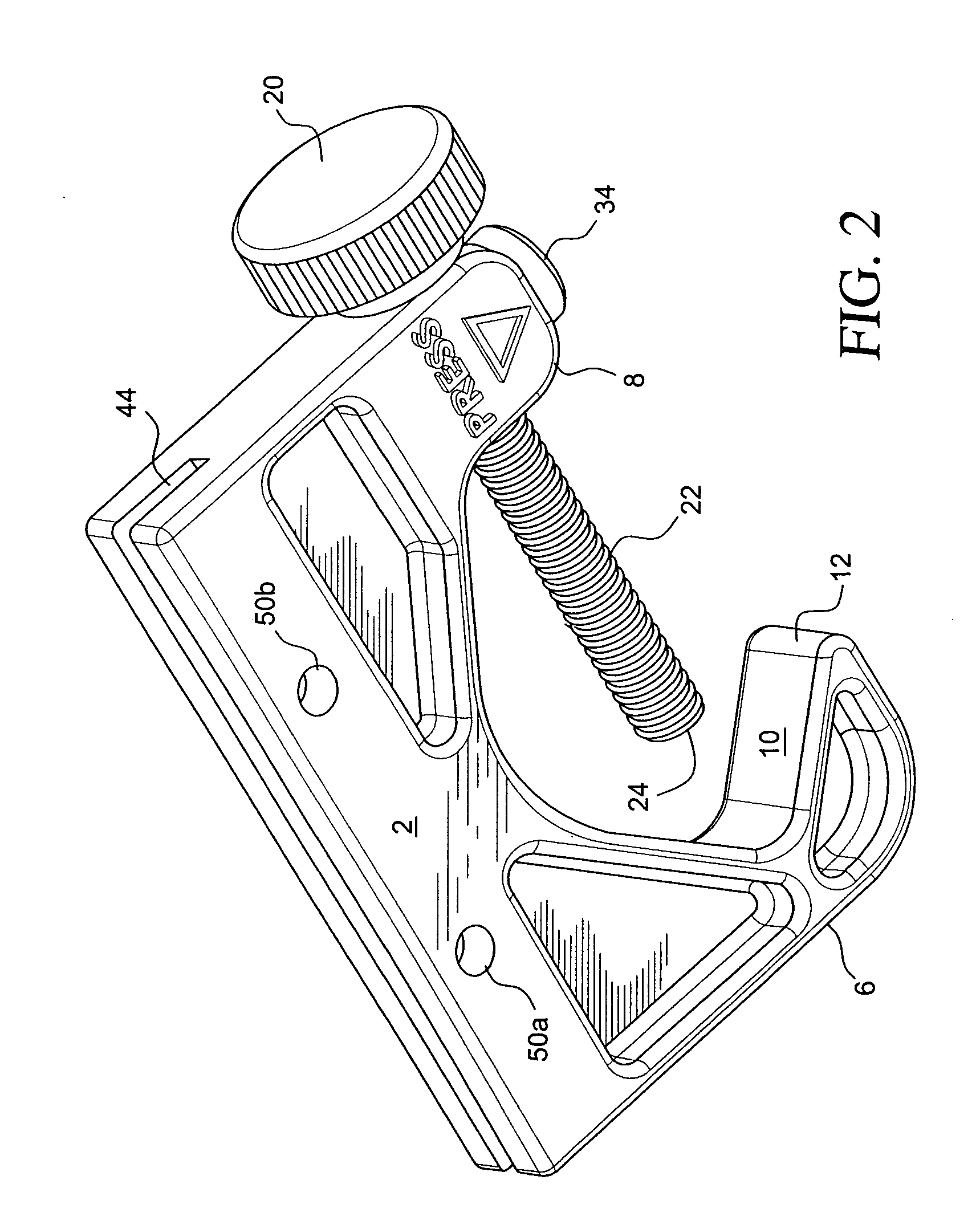

[0022]With reference to FIG. 1, a pole clamp 2 of the instant invention is shown to have a substantially U-shaped body or member 4 with a first leg 6 and a second leg 8 extending from body 4. For the exemplar pole clamp 2 shown, member 4 has an elongated body with a concave interior wall 10 that extends to leg 6, which has a finger portion 12 extending outwardly, so that leg 6 is substantially V-shaped, per shown by directional arrow 14 pointing to the valley of leg 6. So configured, the interior wall 10 of leg 6 is adapted to grippingly contact a first side of the circumferential surface of a pole, such as pole 16 shown in FIG. 5, and firmly hold the pole were a force applied against the opposite side surface of the pole. It should be noted that the particular shape of leg 6 is not of utmost import to the invention so long as it is understood that leg 6 may have any interior wall adaptable to hold a side surface of a pole placed between legs 6 and 8.

[0023]Extending from member 4 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com