Cationic organosilicon modified waterborne PUA fabric coating adhesive with self crosslinking structure and preparation method thereof

A cationic, self-crosslinking technology, applied in the field of environmental protection fabric finishing, can solve the problem of no cationic water-based coating adhesive, and achieve the effect of eliminating the preparation steps, good water resistance and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

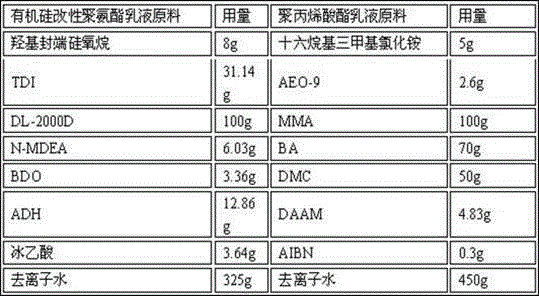

Embodiment 1

[0042] (1) Synthesis of aqueous polyurethane emulsion containing polysiloxane segments and hydrazine-terminated

[0043] Add hydroxyl-terminated polysiloxane (molecular weight of about 2000, self-made) and polypropylene glycol ether glycol with molecular weight of 2000 (DL-2000D, Shandong Dongda Lanxing Chemical Industry Co., Ltd.) 1000ml four-neck flask, at 90-110 o C vacuum dehydration for 1h, the vacuum degree is about 0.060kPa.

[0044] The reaction was then cooled to 75 o C, pass into N 2 Protect. The polyisocyanate TDI was added and 2 drops of catalyst were added dropwise. After reacting for 2 hours, add hydrophilic chain extender N-methyldiethanolamine (N-MDEA) and chain extender 1,4-butanediol (BDO) for chain extension, at 80 o C for 2 hours. Add adipate dihydrazide (ADH) to end-cap the end-NCO, and react for 1 h. During this period, acetone was added appropriately to reduce the viscosity of the system. cool down to 40 oC Next, glacial acetic acid was added f...

Embodiment 2

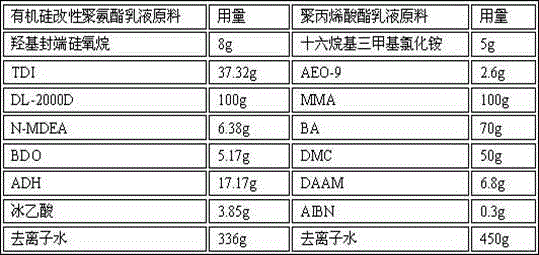

[0053] According to the method of Example 1, using the same reaction conditions, the silicone-modified polyurethane emulsion and polyacrylate emulsion were prepared respectively, and the raw materials used and their ratios are shown in Table 2.

[0054] Table 2 Synthesis of silicone-modified polyurethane emulsion and polyacrylate emulsion formulations

[0055]

[0056] Mix the aqueous polyurethane emulsion and polyacrylate emulsion obtained above at a weight ratio of 1:1.8, and discharge after stirring for 15 minutes to obtain a ketone-hydrazine self-crosslinking silicone-modified PUA composite coating glue.

Embodiment 3

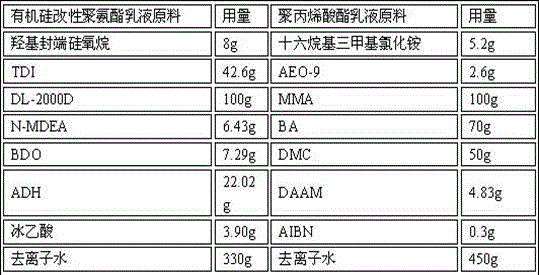

[0058] According to the method of Example 1, using the same reaction conditions, the silicone-modified polyurethane emulsion and polyacrylate emulsion were prepared respectively, and the raw materials used and their ratios are shown in Table 3.

[0059] Table 3 Synthesis of silicone-modified polyurethane emulsion and polyacrylate emulsion formula

[0060]

[0061] Mix the aqueous polyurethane emulsion and polyacrylate emulsion obtained above at a weight ratio of 1:1.7, and discharge after stirring for 15 minutes to obtain a ketone-hydrazine self-crosslinking silicone-modified PUA composite coating glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com