Patents

Literature

34results about How to "Dyeing achieved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

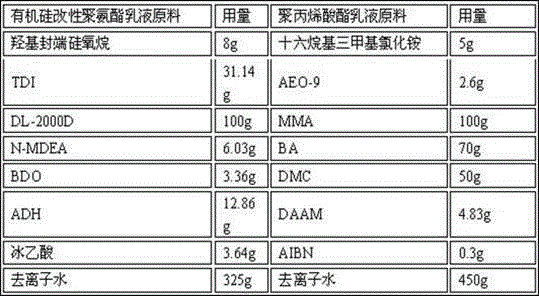

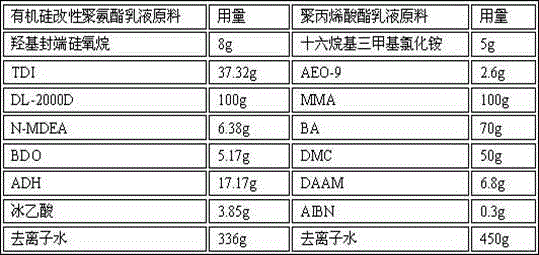

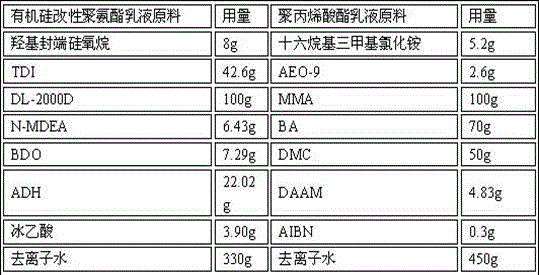

Cationic organosilicon modified waterborne PUA fabric coating adhesive with self crosslinking structure and preparation method thereof

InactiveCN106149381AImprove mechanical propertiesImprove water resistanceFibre treatmentPolyesterDiacetonamine

The present invention discloses a preparation method of a cationic organosilicon modified waterborne PUA fabric coating adhesive with a self crosslinking structure, the method is as follows:(1)using polyisocyanate and hydroxyl-terminated polysiloxane for synthesis of an-NCO-group-terminated prepolymer;(2)adding polyether or polyester glycol for reaction;(3)reacting with a cationic hydrophilic chain extender for a period of time, and further reacting with adipic dihydrazide(ADH)to obtain a hydrazine-terminated cationic waterborne polyurethane emulsion;(4)using acrylate monomers and diacetone acrylamide(DAAM)for preparing a hydrazide-group-containing polyacrylate emulsion; and(5)mixing the hydrazine-terminated cationic waterborne polyurethane emulsion and the hydrazide-group-containing polyacrylate emulsion in a certain proportion to obtain the self-crosslinking cationic organosilicon modified waterborne PUA fabric coating adhesive. The self-crosslinking cationic organosilicon modified waterborne PUA fabric coating adhesive avoids the use of a harmful crosslinking agent, has the advantages of being environmental-friendly, high in water pressure resistance, good in mechanical properties, low in cost, and dyeable and the like, and can be used for coating finishing of nylon fabrics.

Owner:WUYI UNIV

Modified wood dyeing method

The invention provides a modified wood dyeing method. A modified wood board or modified wood powder is put in a dyeing container of supercritical CO2 fluid dyeing equipment for dyeing with CO2-H2O serving as a dyeing medium, disperse dye serving as a dyeing agent, the temperature of 100-140 DEG C, the pressure of 10-40 MPa and the time of 10-600 minutes. After the dyeing is finished, the CO2 and the disperse dye are recovered by reducing the pressure and the temperature so as to obtain the dyed modified wood board or the dyed modified wood powder; and the hot press molding can be further performed for the dyed modified wood powder to obtain the dyed modified wood board. The dyed wood board has such effects as rich colors, bright colors and uniform colors; and the dyeing process has such advantages as cleanness and environmental protection. The color board can be applied to the indoor or outdoor decoration engineering, can particularly serve as a beautiful decoration material in a humid environment, and has wide application prospect.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

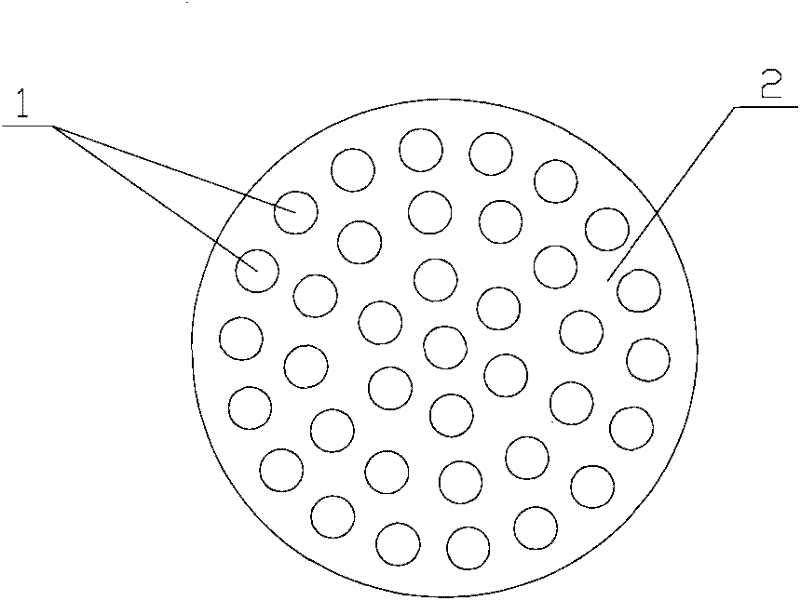

Island-fixed sea-island short fiber and its preparation method

InactiveCN102260929ALoose molecular structureImprove the setting effectFilament/thread formingConjugated synthetic polymer artificial filamentsPolybutylene terephthalateMaterials science

The invention provides an island-fixed type sea-island short fiber, the island component of the island-fixed type sea-island short fiber is polybutylene terephthalate, and the sea component is alkali-soluble polyester. The present invention also provides a method for preparing the sea-island short fiber, comprising: melting the island component in a first screw extruder; melting the sea component in a second screw extruder; The molten body of the first screw extruder and the molten body of the second screw extruder are extruded through the spinning assembly to obtain nascent sea-island fibers; the nascent sea-island fibers are sequentially cooled, oiled, drawn, After crimping, loosening and setting, cut to obtain island-fixed short fibers. The PBT superfine fiber fabric prepared by adopting the island-fixing type sea-island short fiber provided by the invention has soft texture and good elasticity, and can be dyed under normal pressure conditions.

Owner:XIAMEN HONGXIN SPECIAL FIBER CO LTD

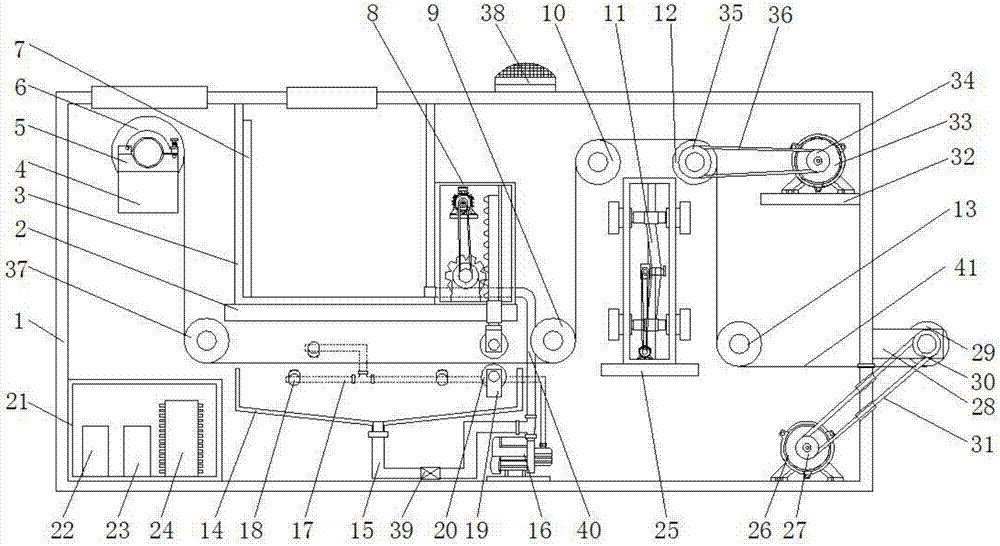

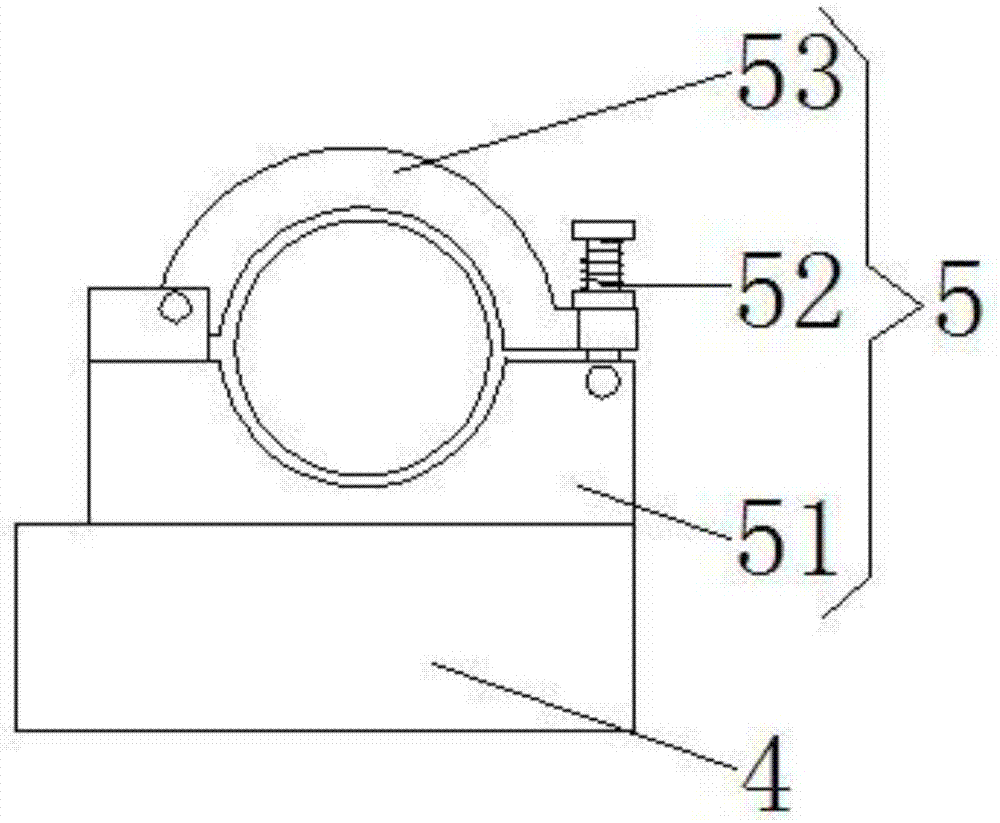

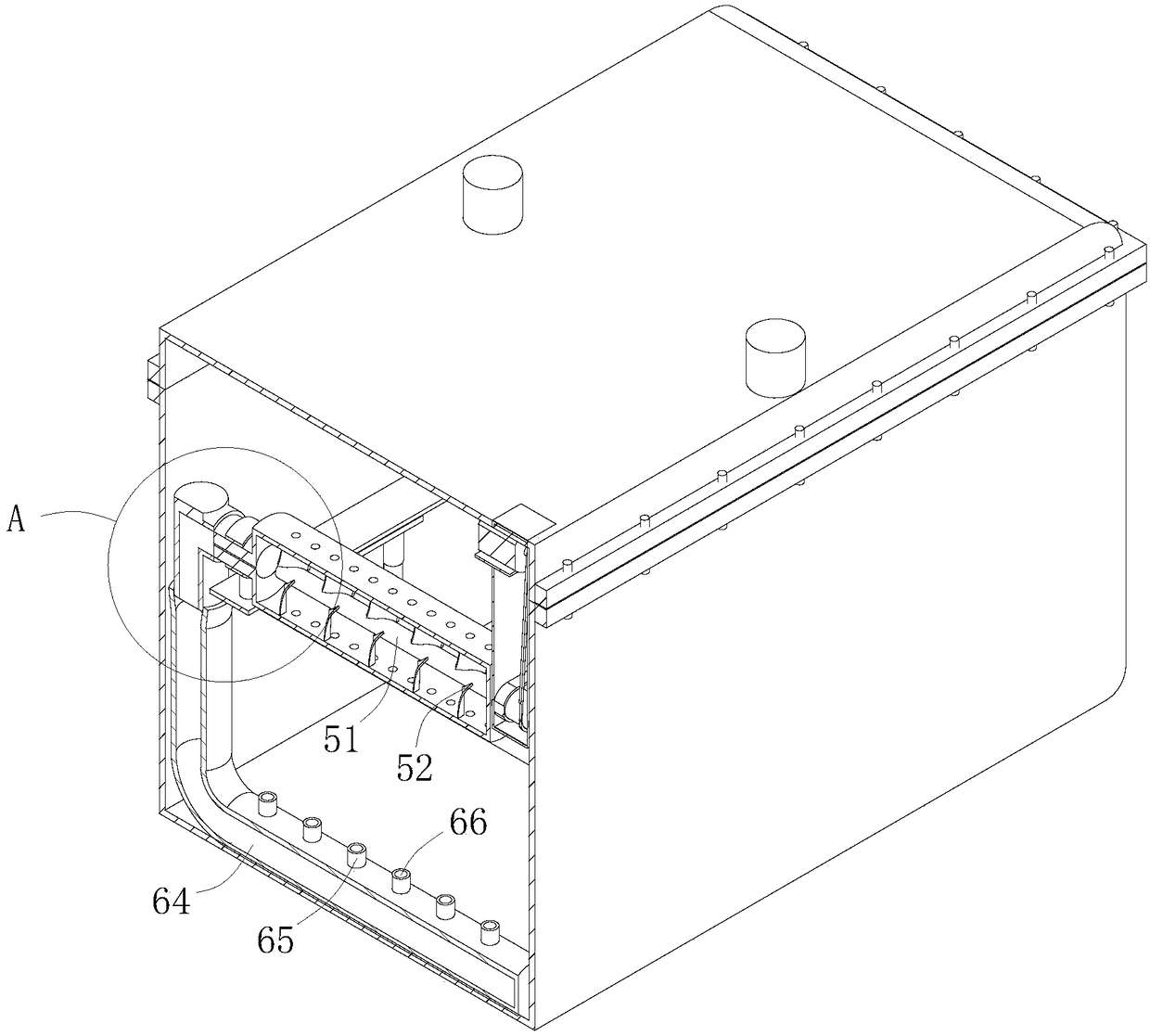

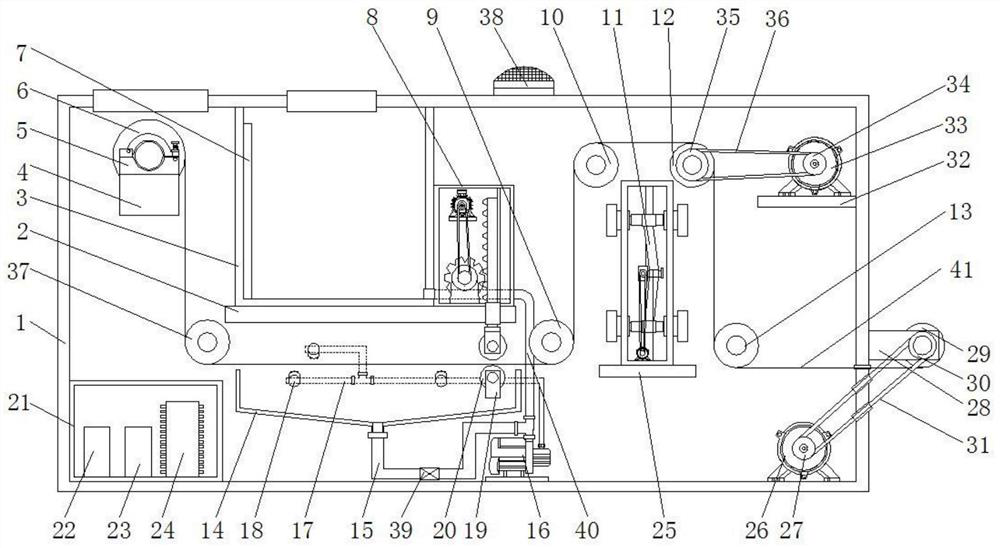

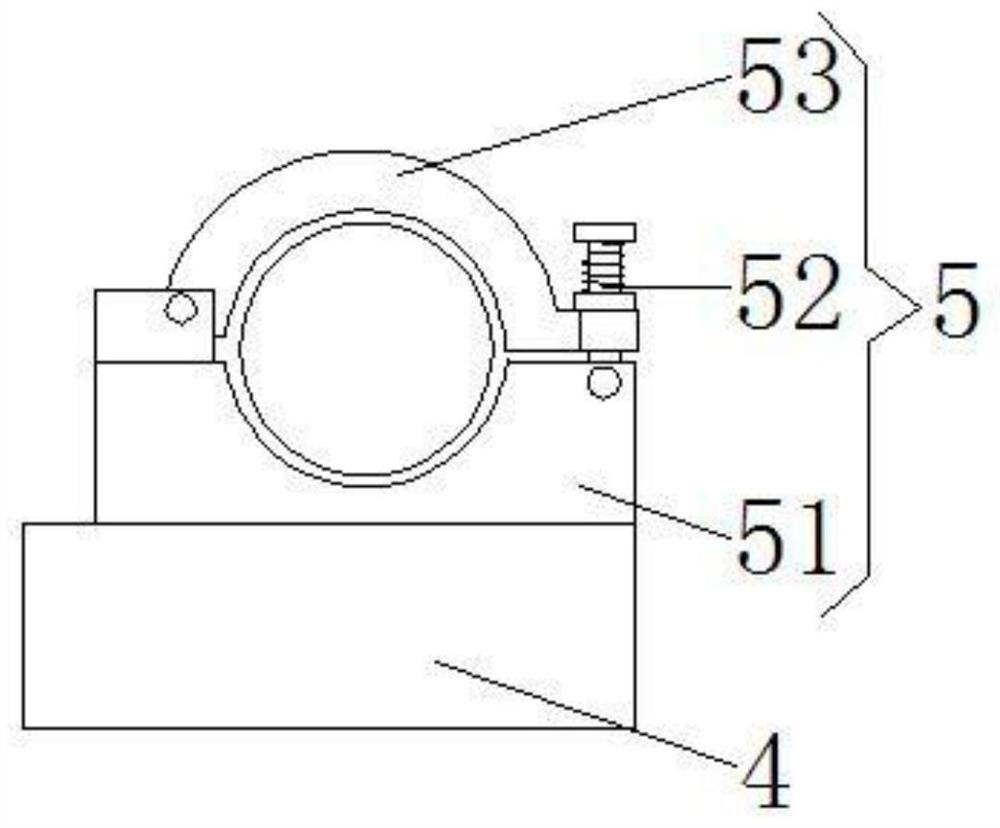

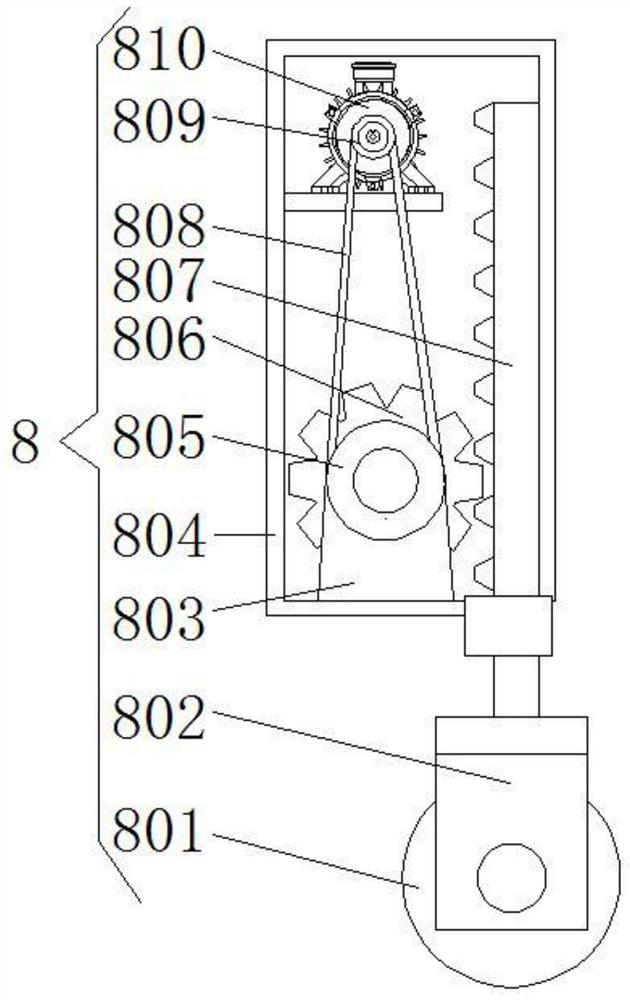

Textile dyeing device capable of saving dyes

InactiveCN107488959ARealize deliveryAvoid damageLiquid/gas/vapor removalTextile treatment machine arrangementsEngineeringDrying time

The invention discloses a textile dyeing device capable of saving dyes. The textile dyeing device comprises a box body, a dye box is fixedly connected between two opposite sides of the inner wall of the box body through a supporting plate, the two opposite sides of the inner wall of the box body are fixedly connected with a fixing device through fixing blocks, one side of the top of the supporting plate is fixedly connected with a pressing device, a leaky bucket is fixedly connected between two opposite sides of the inner wall of the box body, the bottom of the leaky bucket communicates with a first dye tube, one end of the first dye tube communicates with a water pump, the outlet end of the water pump is connected with a spray dyeing tube through a second dye tube, the two opposite sides of the inner wall of the box boy are fixedly connected with a pair of cushioning devices, the centers of the cushioning devices are rotatably connected with pressed roller wheels, and a drying device is fixedly connected between the two opposite sides of the inner wall of the box body through a fixing plate. The invention relates to the technical field of textile processing. The textile dyeing device capable of saving the dyes improves the dyeing efficiency, shortens the drying time, saves the dyes, reduces the labor intensity and improves the work efficiency.

Owner:李文艳

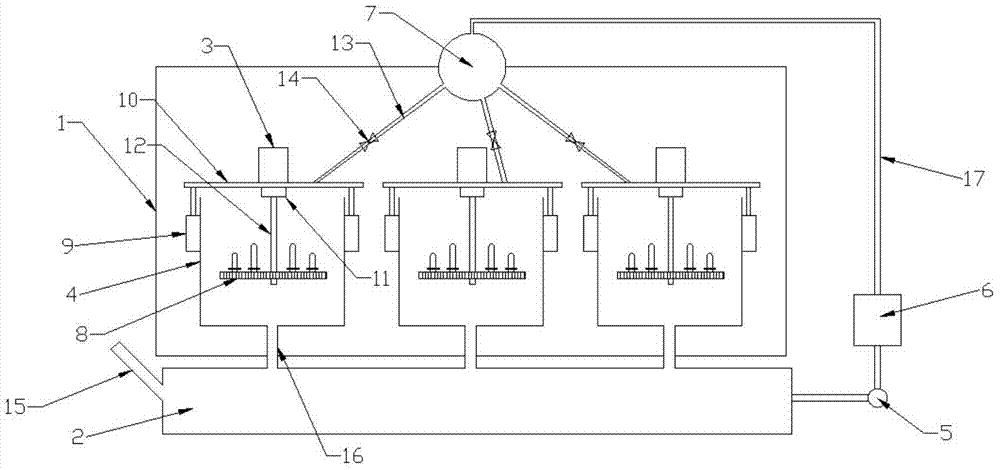

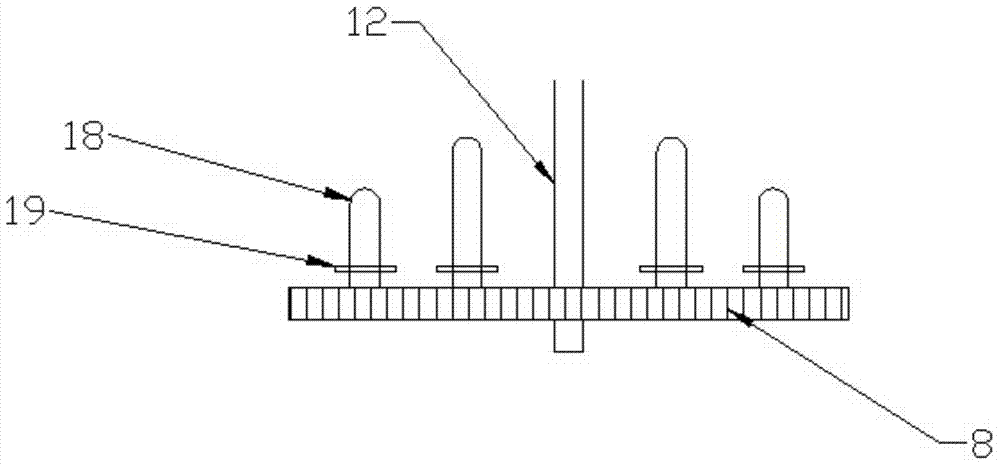

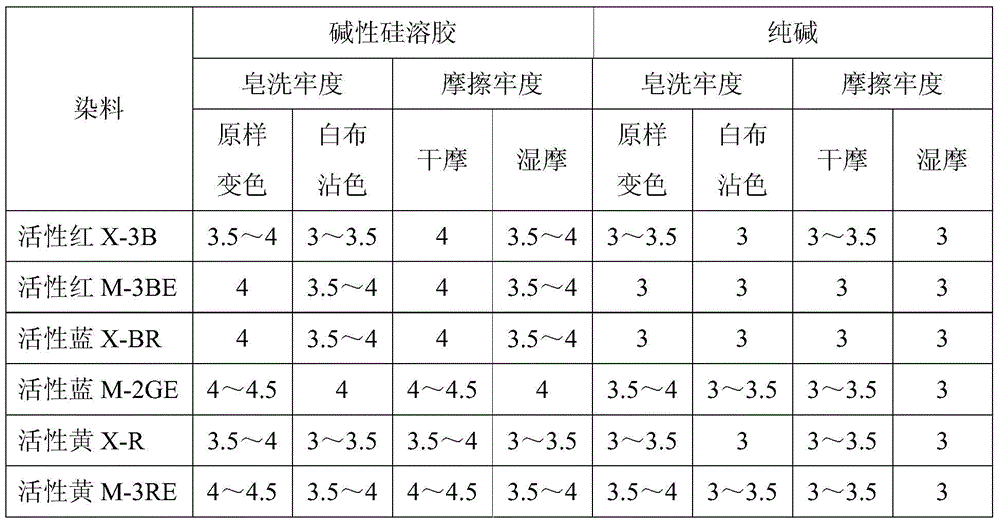

Efficient dyeing machine

ActiveCN104120570AUniform dyeingDyeing achievedTextile treatment machine partsTextile treatment by spraying/projectingWater pipeDyeing

The invention discloses an efficient dyeing machine which comprises a supporting frame, a motor, machine bodies, a water suction pump, a movable cover, a hose and a water pipe. Three sets of the machine bodies of identical structures are fixed in the supporting frame. Two telescopic sleeves on the same horizontal plane are mounted on the outer wall of each machine body. The telescopic sleeves are mounted vertically, and movable rods of the telescopic sleeves are fixedly connected to the lower surface of the movable cover in an upward mode. The motor is mounted on the upper face of the movable cover. An output shaft of the motor stretches into the machine bodies, and a reducer is connected to the output shaft of the motor. Cloth rotates on a hanging tray and makes full contact with liquid for dyeing, and dyeing is uniform; multiple sets of machine bodies are arranged, a great amount of cloth can be dyed, energy can be saved, and a power supply does not need to be started or shut down frequently; the cloth is convenient to load and unload, airtightness of the inner portions of the machine bodies is guaranteed at the same time, and the efficient dyeing machine improves the dyeing speed and dyeing quality of products.

Owner:徐州国宏包装有限公司

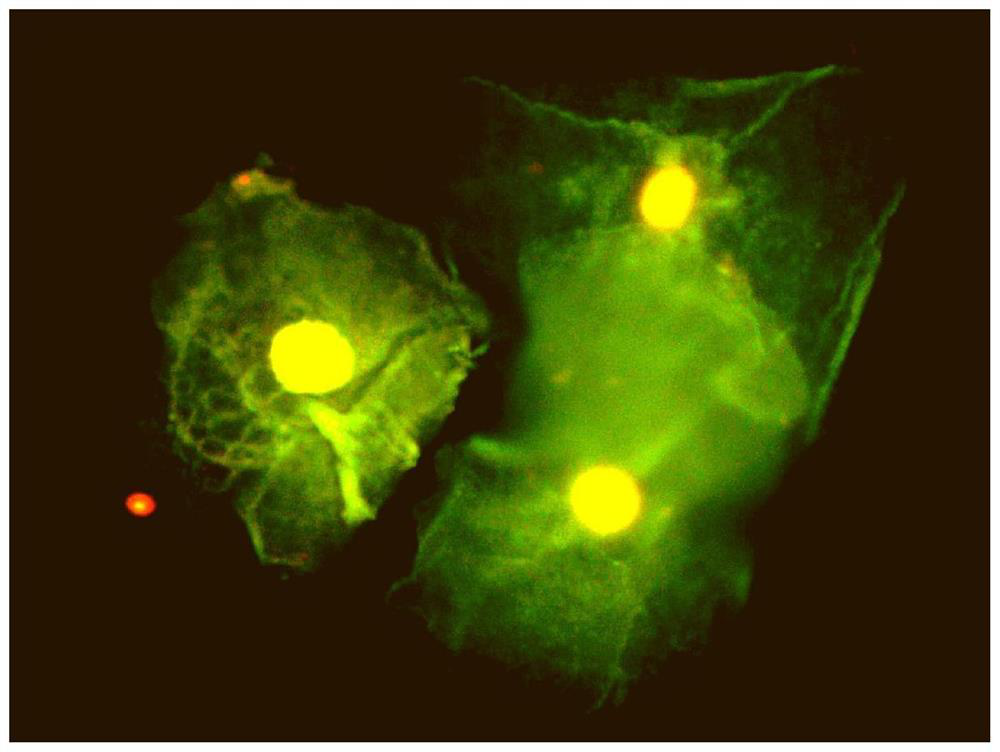

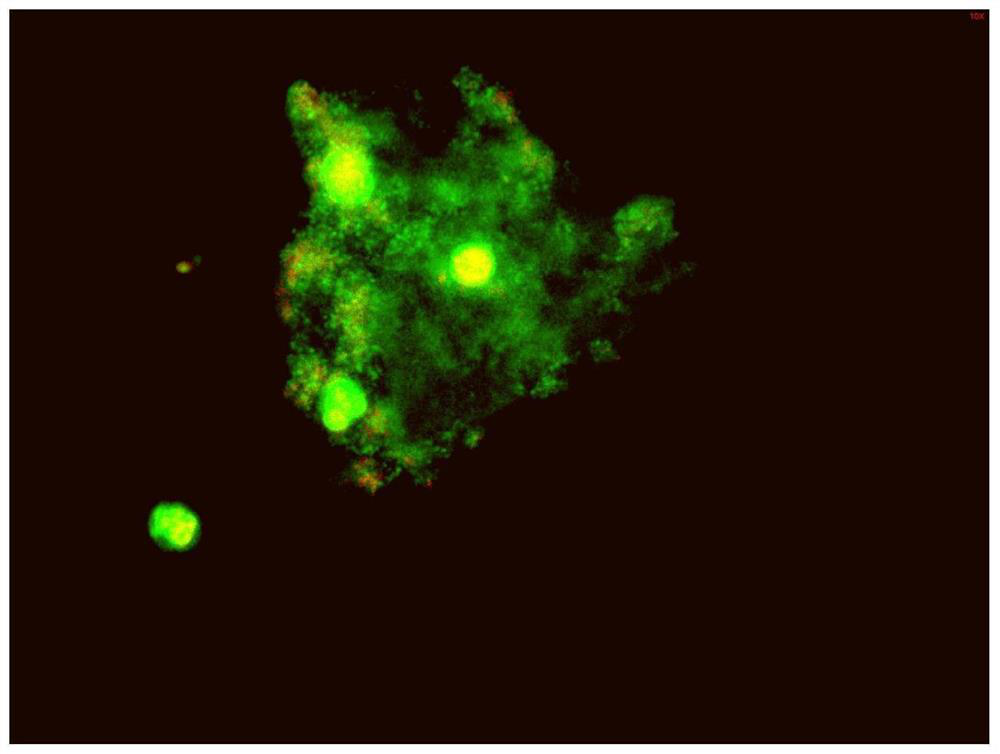

Microbial fluorescent staining solution and application thereof

ActiveCN111019999ADyeing achievedReasonable judgmentMicrobiological testing/measurementFluorescence/phosphorescenceNucleic acidFungus

The invention relates to a microbial fluorescent staining solution and an application thereof. The microbial fluorescent staining solution comprises lectin, fluorescein, nucleic acid dye, a buffer solution, an anti-quenching agent, a bacteriostatic agent and water; the microbial fluorescent staining solution can be used in microbial dyeing, specific recognition of agglutinin on glycoprotein and specific staining of nucleic acid by nucleic acid dye are utilized, according to the invention, the fungi are blue, green or red, the bacteria are red, the morphology is combined to achieve the detection on the microorganisms in a vaginal secretion sample, a cervical exfoliated cell sample, a skin sample and a sputum sample, the detection result can be visualized, and the microorganism variety can be directly and reasonably judged.

Owner:江苏美克医学技术有限公司

Printing and dyeing technology with high dyeing automation degree

ActiveCN108796882AConsistent chromaImprove dyeing effectSingeingTextile treatment machine arrangementsState of artPulp and paper industry

The invention discloses a printing and dyeing technology with high dyeing automation degree. The printing and dyeing technology with high dyeing automation degree comprises the following steps that (1), a fabric is placed on a conveying belt and conveyed to a singeing machine through the conveying belt, and the singeing machine burns off fluff on the fabric; (2), the fabric burned by the singeingmachine is conveyed to a desizing machine through the conveying belt, and the desizing machine conducts desizing treatment on the fabric; (3), the fabric after the desizing treatment is conveyed to ascouring machine through the conveying belt, and the scouring machine conducts high-temperature scouring treatment on the fabric; (4), the fabric after the scouring treatment is subjected to impurityremoving treatment conducted by an impurity removing device of the scouring machine; (5) the fabric after the impurity removing treatment is washed in a washing groove; (6), the fabric after washing is conveyed to a dyeing machine through the conveying belt and dyed by the dyeing machine, and a dyeing solution is stirred by a stirring piece. Compared with the prior art, the technology greatly improves the dyeing efficiency in the fabric dyeing process, the dyeing effect is good, and the dyeing automation degree is high.

Owner:ASHFORD TEXTILE ZHANGZHOU

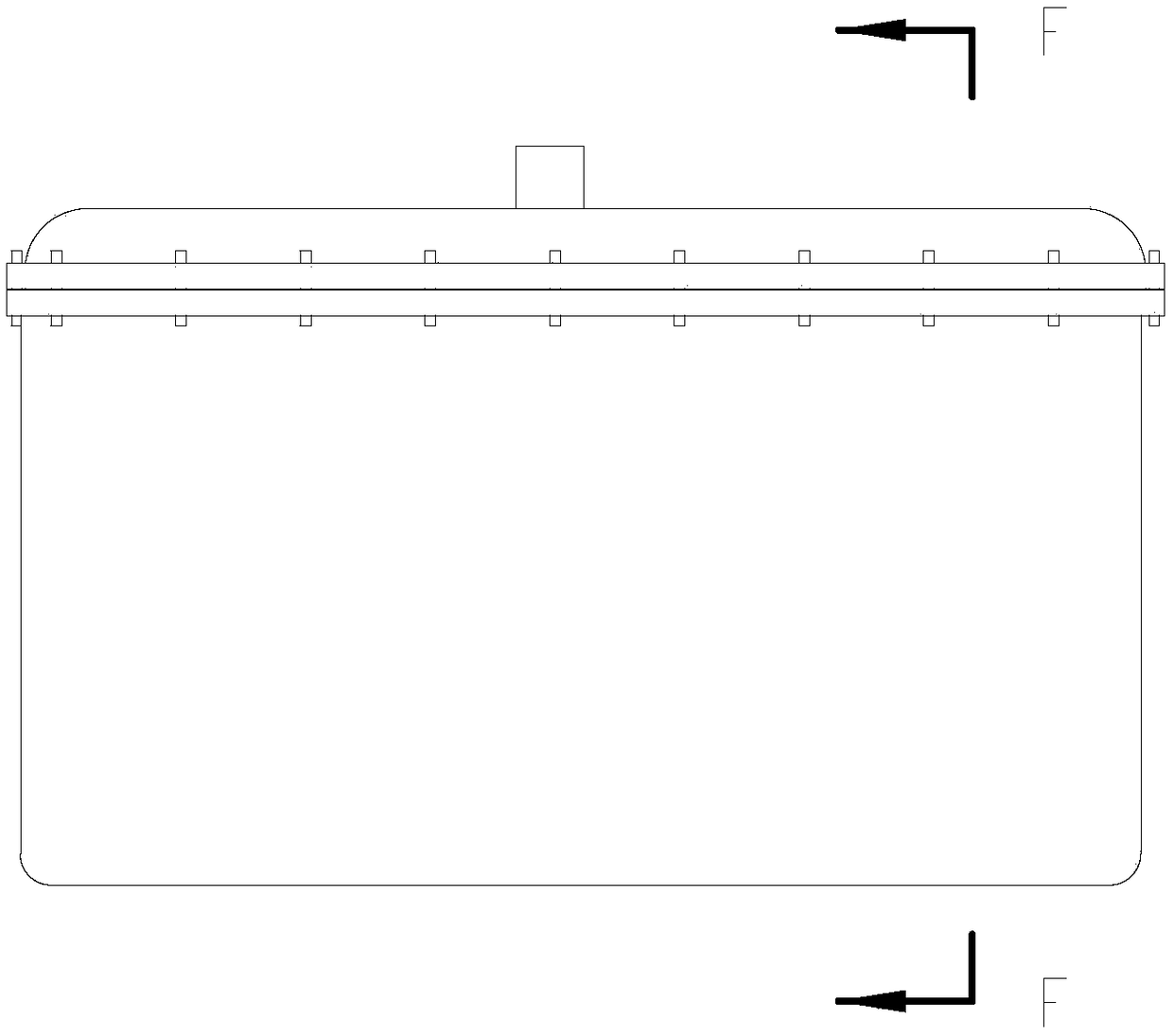

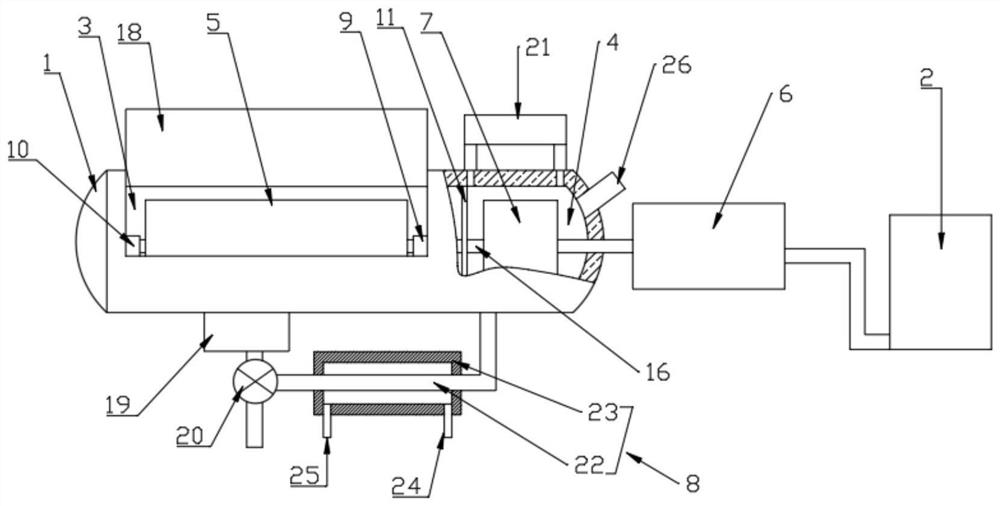

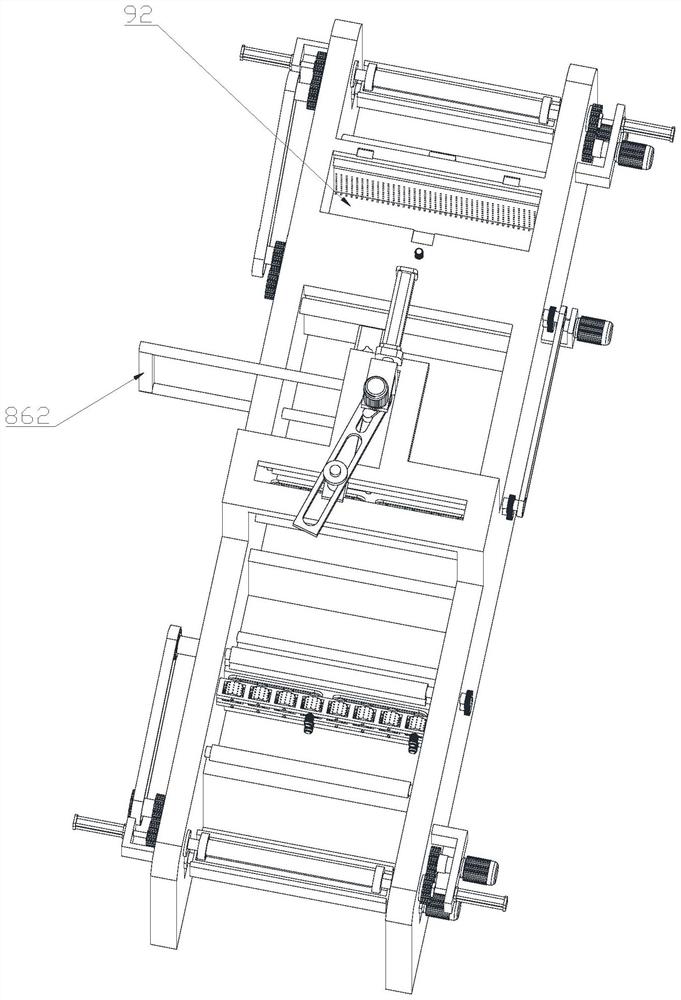

Vacuum dyeing device based on fast fabric printing and dyeing

ActiveCN109234949ANo creasesWith pre-dipped effectTextile treatment containersTextile treatment carriersMechanical engineeringWrinkle

The invention discloses a vacuum dyeing device based on fast fabric printing and dyeing. The device comprises a dip dyeing chamber, two dip-dyeing cloth rollers, a driving part and a plurality of driven rollers, wherein the dip dyeing chamber is provided with a sealing cover sealingly matched with the dip dyeing chamber; the two dip-dyeing cloth rollers capable of rotating forwardly and reverselyare arranged at an interval in the dip dyeing chamber; the driving part is used for driving the two dip-dyeing cloth rollers to synchronously rotate forwardly and reversely; the driven rollers are arranged between the two dip-dyeing cloth rollers in upper and lower rows. The vacuum dyeing device based on fast fabric printing and dyeing has the advantages that cloth does not have wrinkles, the situation that part of the cloth cannot be dyed or is dyed more lightly cannot occur, and the dyeing effect is improved; the structure has a pre-dip dyeing effect, thereby effectively reducing time required for dyeing of the cloth, and the work efficiency is high; the cloth is in a dyed state all the time when rolled to the dip-dyeing cloth rollers, thereby further improving the dyeing effect and dyeing efficiency.

Owner:SHAOXING UNIVERSITY

Dyeing method of natural fiber

The invention discloses a dyeing method of a natural fiber. The dyeing method comprises the following particular steps of firstly, adding natural vegetable dye, liquid carbon dioxide and a color fixing agent into a supercritical carbon dioxide dyeing device, heating, and maintaining for a certain time; afterwards, adding the natural fiber into the supercritical carbon dioxide dyeing device, dyeingat and under certain temperature and pressure, and maintaining for a certain time; next, relieving the pressure, cooling to a normal temperature and depressurizing to normal pressure to obtain a preliminarily dyed natural fiber; treating the preliminarily dyed natural fiber, afterwards, adding into the supercritical carbon dioxide dyeing device, dyeing at and under certain temperature and pressure, maintaining for a certain time, and then relieving the pressure to obtain a finished-product dyed natural fiber. The dyeing method, through a two-step dyeing method, is used for realizing printingand dyeing the natural fiber by natural dye, and further, does not need pretreatment, and the dyeing method has advantages of good environmental protection effect, water resource conservation, good color fixation effect and the like.

Owner:JIANGSU NEW REBA TECH CO LTD

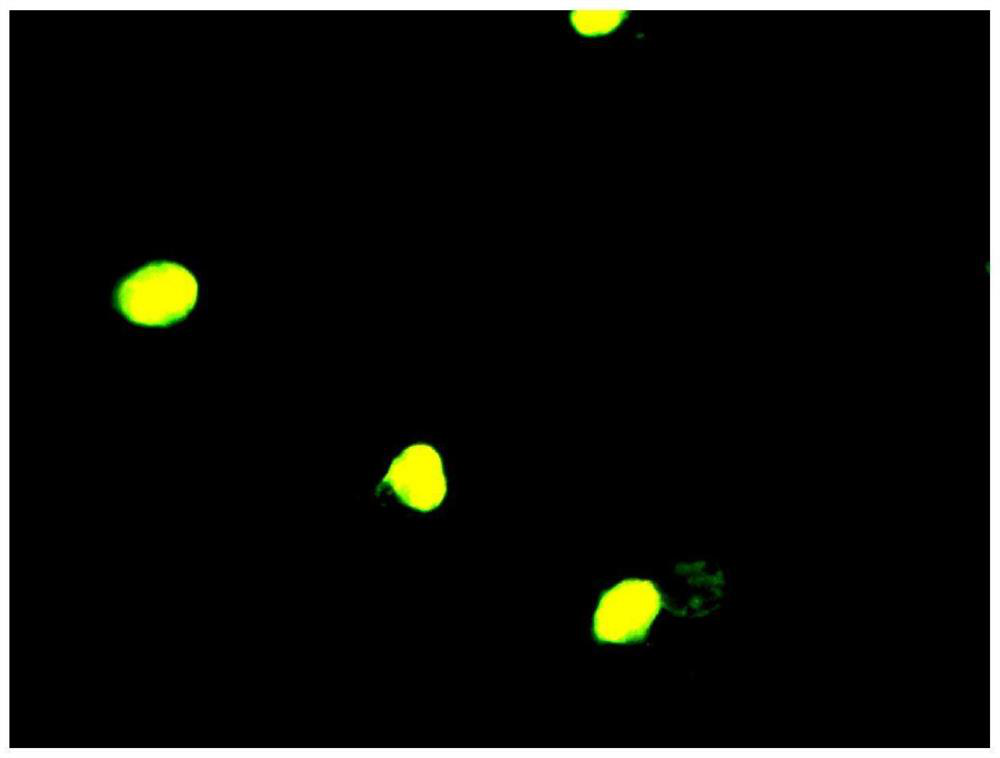

Gynecological fluorescent staining solution as well as preparation method and application thereof

PendingCN114563253ADyeing achievedClear ingredientsPreparing sample for investigationFluorescence/phosphorescenceFluorescent stainingDisodium phosphate

The invention discloses a gynecological fluorescent staining solution and a preparation method and application thereof.The gynecological fluorescent staining solution comprises acridine orange, sodium chloride, EDTA-Na, disodium hydrogen phosphate and citric acid, the components can be combined with different cell substances for staining, so that fluorescence of different colors is displayed under the action of exciting light, the components are clear after staining, and the staining effect is good. Different components present different colors and are easy to identify and distinguish. The preparation method of the gynecological fluorescent staining solution is simple, and the gynecological fluorescent staining solution can be prepared and used at any time and can also be stored and used after being prepared. According to the use method of the gynecological fluorescent staining solution, two nucleic acids, namely DNA and RNA, are mainly displayed, so that the fluorescent staining solution is obvious in luminescence. The use method is simple, observation and detection can be carried out through a fluorescence microscope after the gynecological fluorescent staining solution is dropwise added, the defects of a traditional saline smear method are overcome, and the detection rate is increased.

Owner:HANGZHOU XINLONG MEDICAL TREATMENT TECH CO LTD

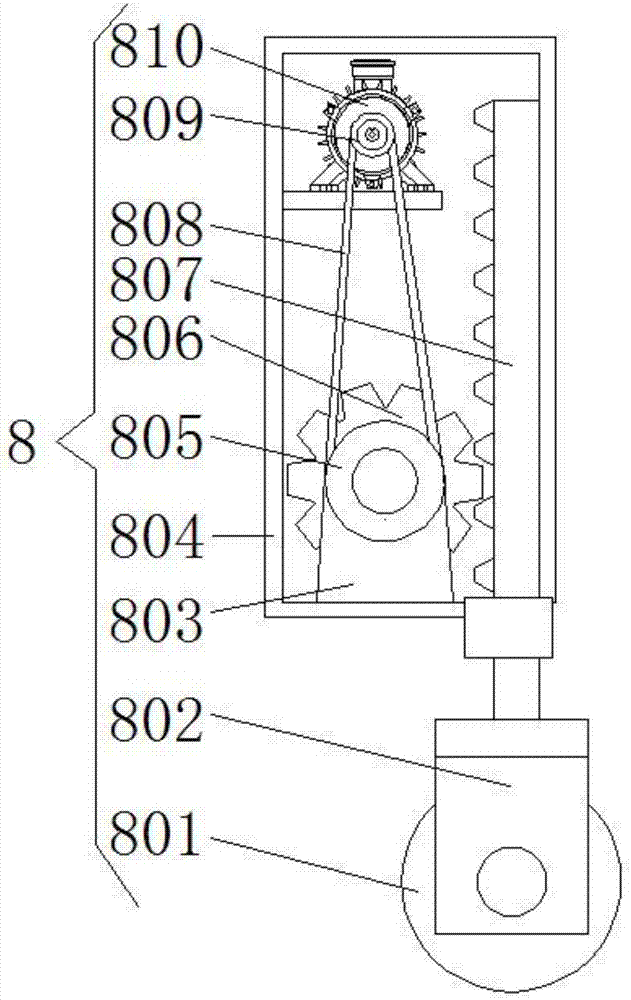

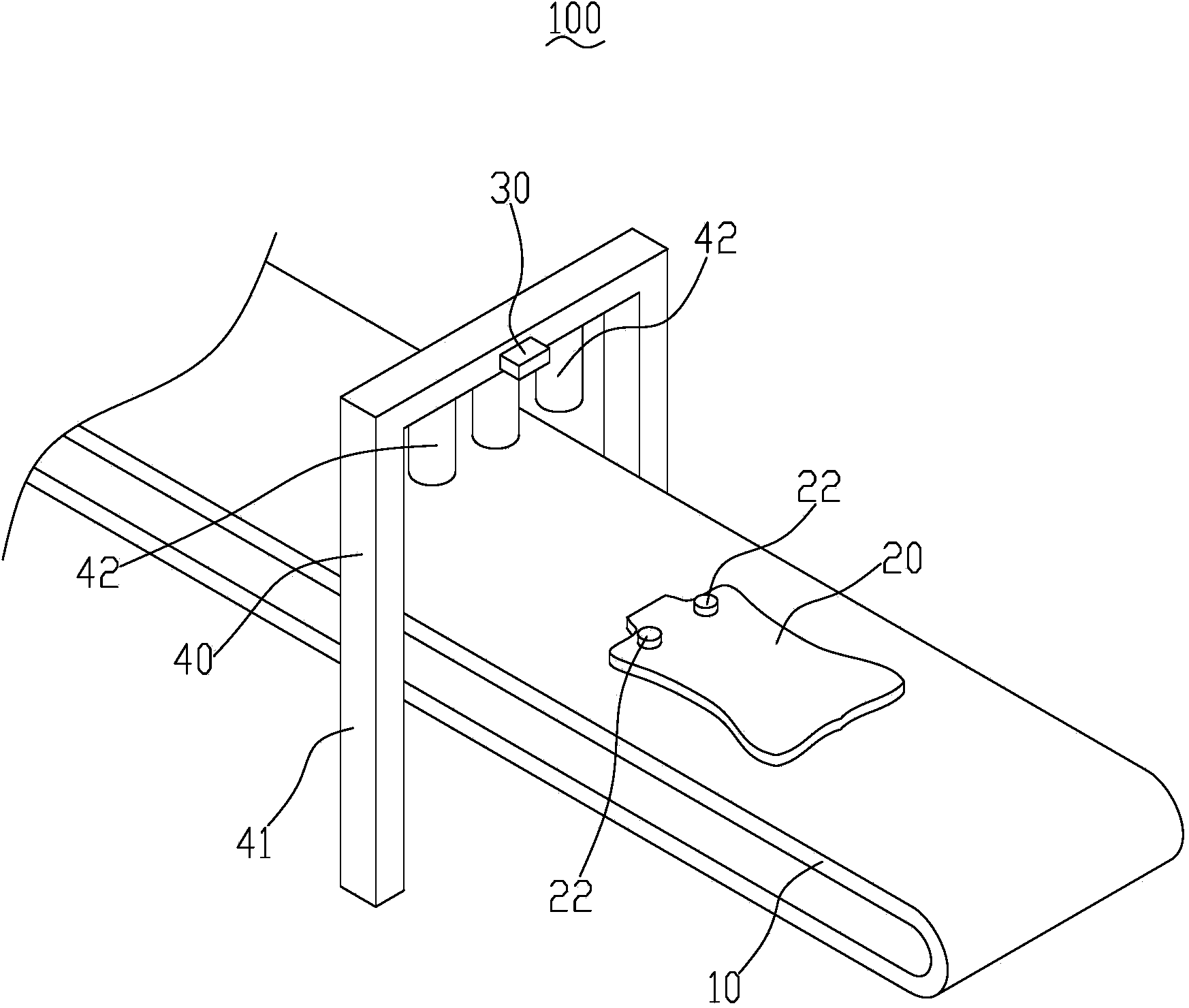

Automatic fur dyeing device

InactiveCN103642955ARealize automatic processingDyeing achievedLeather/skins/hides/pelt chemical treatment apparatusControl systemEngineering

The invention relates to an automatic fur dyeing device for spraying dye liquor on to-be-dyed fur. The device comprises a conveyer belt, a detector, a spraying mechanism and a dye program control system, wherein two detection marks are arranged on fur, and the detector is used for detecting the positions of the detection marks to judge the position of the fur on the conveyer belt and feeding the position information to the dye program control system. The dye program control system controls the spraying mechanism to spray the dye liquor required by dyeing on the fur according to predetermined patterns. The automatic fur dyeing device has the advantage of realizing automatic processing.

Owner:李世绪

Disperse dye polyster dyeing method using siloxane as medium

The invention discloses a disperse dye polyster dyeing method using siloxane as a medium, and belongs to the technical field of textile dyeing and finishing. The method comprises the following steps of (1) adding materials to be dyed, a prepared dye solution and dye accelerators into the dye medium to be dyed; (2) performing liquid removal, siloxane medium washing and drying after the dyeing so asto obtain a dyeing finished product. Compared with a patent CN103074781A, the method provided by the invention has the advantages that ordinary materials to be dyed is not needed to be pre-treated; during the dyeing, only a small number of nontoxic and harmless dye accelerators need to be added; the dyeing of the polyster fabric under the condition of normal pressure or micro pressure is realized, so that the dependence and requirements (high temperature and high pressure) on the equipment are reduced. In the subsequent washing, a water washing method is avoided; the siloxane medium is used;the zero sewage discharge is reached; the dyeing uniformity and color firmness of the disperse dye dyeing can be effectively improved; the siloxane medium obtained through dyeing, washing and drying can be cyclically used through recovery; the ecological dyeing of the disperse dye is really realized.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

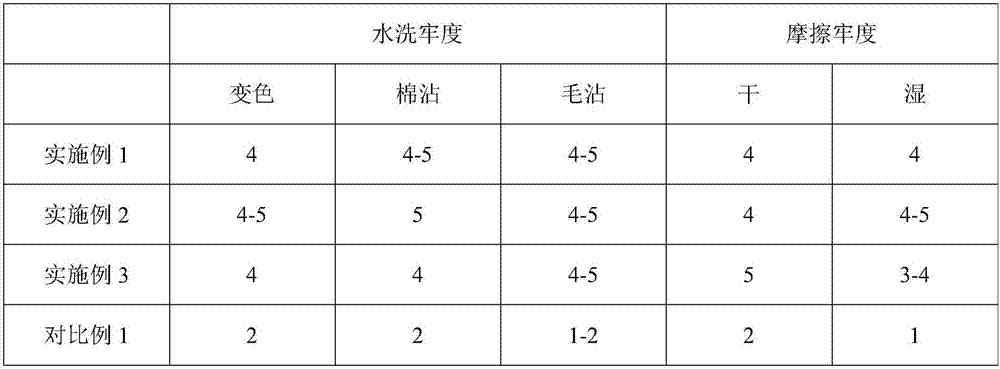

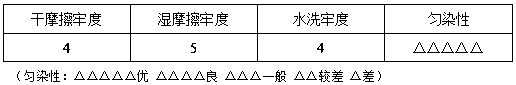

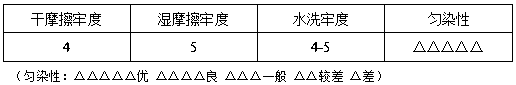

Alkaline silica sol color fixing agent and preparation method thereof

The invention discloses an alkaline silica soil color fixing agent and a preparation method thereof. The alkaline silica soil color fixing agent is prepared by mixing ethyl orthosilicate, water, alcohol, a catalyst and a silane coupling agent as raw materials in the molar ratio of 1:(30-40):(20-30):(0.3-0.7):(0.001-0.01) and then performing a sol-gel reaction. The preparation method comprises the following steps: mixing ethyl orthosilicate with an alcohol solvent, stirring evenly to obtain a solution A, evenly mixing the water with the catalyst to obtain a solution B, putting 30wt% of the solution A into a reactor, heating to the range of 30-60 DEG C, dropwise adding the solution b and the left 70wt% of the solution A to the reactor under the condition of stirring, performing reflux condensation at a temperature ranging from 30 to 60 DEG C, reacting for 30 minutes, next, dropwise adding the silicone coupling agent, further stirring for reacting for 0.5-3 hours, and aging for 8-12 hours, thereby completing the preparation of the alkaline silica soil color fixing agent; the alkaline silica soil color fixing agent has the advantages of safety and environmental pollution, good color fixing effect, small silica sol particle size, narrow distribution and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Solid wood coloring method

The invention discloses a solid wood coloring method and belongs to the field of wood coloring. The solid wood coloring method comprises the steps that a coloring solution is prepared, solid wood is soaked in the coloring solution, the colored solid wood is taken out and then stacked for 5-7 h at the normal temperature and normal pressure, the colored solid wood processed in the step (3) is driedtill the moisture content is 12% or below, the colored solid wood is conveyed into a drying kiln again and quickly heated to 70-80 DEG C by jetting high-temperature steam for 2-3 h, heat preservationis conducted for 5-6 h, then high-temperature drying is conducted, the maximum temperature is up to 110-115 DEG C and is maintained for 20-25 h, the moisture content of the solid wood is decreased to12% or below, and accordingly high-temperature quick drying of the colored solid wood is completed. According to the solid wood coloring method, the solid wood is colored through food colorants, so that the solid wood meets the national standard, the advantages of high coloring speed, high tinting strength and the like are achieved, and no harm is caused to human bodies.

Owner:NANJING FORESTRY UNIV

Printing and dyeing production process of dustproof yarn

InactiveCN110565399AEven and fine sprayGood adhesionMercerising of yarns/threads/filamentsFibre typesYarnPolyester

The invention discloses a printing and dyeing production process of dustproof yarn, relates to the field of textiles, and aims to achieve the purpose of improving the dyeing effect of the dustproof yarn. The process is technically characterized by comprising the steps of (1) preparation of a conductive fiber yarn core, wherein polyester fiber is provided, and the surface of the polyester fiber isplated with copper by means of a chemical plating method to serve as the conductive fiber yarn core; (2) coating of the fiber; (3) singeing; (4) mercerizing treatment; (5) prefabricating of a dyeing agent; (6) ionized adsorption, wherein skein is arranged in an ionization chamber and positively charged or grounded, the prepared dyeing agent is led into an electrostatic sprayer, and high-voltage negative electricity is connected with a metal current guide pipe on a nozzle of the electrostatic sprayer, so that the sprayed dyeing agent is adsorbed on the skein; (7) drying; (8) forming. By utilizing the printing and dyeing production process of the dustproof yarn for ionized adsorption of the dyeing agent, the adhesion effect is good, and no pollutant can be generated.

Owner:义乌市大利线带厂

Dyeing method of colorful echinopsis tubiflora

The invention relates to a dyeing method of colorful echinopsis tubiflora. The dyeing method comprises the following steps of: mixing plant-pigment stock solutions with different proportions, injecting the mixed plant-pigment stock solution into the epidermis and the root part of the echinopsis tubiflora by a syringe. The dyeing method has the advantages that the pigment stock solution prepared by utilizing natural plant dyes such as butterflybush flower, henna, tulip petals, peristrophe roxburghiana, dandelion, safflower and hematoxylon does not contain any chemical substances, so that the influence on the growth of the echinopsis tubiflora can be avoided while the echinopsis tubiflora is dyed; the plant-pigment stock solution is respectively injected into the root part and the epidermis of the echinopsis tubiflora, so that the plant-pigment stock solution can be better permeated into the internal tissues of the echinopsis tubiflora; by long-time continuous injection, the plant-pigment stock solution and the grown tissues of the echinopsis tubiflora are fused togehter.

Owner:邱泽文

Ink supplying and dyeing device for 3D printing color expression

ActiveCN110450410ADyeing achievedRealize full color 3D printingAdditive manufacturing apparatus3D object support structuresControl circuit3d printer

The invention discloses an ink supplying and dyeing device for 3D printing color expression. The ink supplying and dyeing device for 3D printing color expression comprises a bracket. One side of a speed adjusting section is divided into a plurality of flow guide blocks through grooves, and flow guide magnetic sheets are arranged at the tops of the flow guide blocks. The bracket is arranged beforea printing spray head of a 3D printer and used for carrying consumable items output by the 3D printer. A plurality of dyeing rollers are fixed in the mode of circularly surrounding the consumable items carried by the bracket. A control circuit is connected with a clutch and an electromagnet and controls movement of the clutch and the electromagnet. An ink supply pump is connected with an ink storage box, and when a control circuit controls the clutch to push the dyeing rollers to move towards the consumable items, the ink pump is controlled to pump ink in an ink supply area to be output from corresponding ink conveying pipes to the corresponding dying rollers to dye the consumable items. The ink supplying and dyeing device for 3D printing color expression solves the technical problem thatan existing FDM printer can not achieve full color printing.

Owner:深圳凯奇化工有限公司

Enzymatic method for dyeing cotton by using sargentgloryvine stem extract

The invention discloses an enzymatic method for dyeing cotton by using sargentgloryvine stem extract, and belongs to the field of textile dyeing. The method comprises the following steps of: extracting the sargentgloryvine stem extract, and dyeing the cotton at the temperature of 25 DEG C and the pH of 6.5 in a bath ratio of 10:1-30:1 by using 20 to 100g / L sargentgloryvine stem extract and 0.5 to 5U / mL tyrosinase as dye liquor to obtain enzymatically dyed cotton. The enzymatic method for dyeing the cotton by using the sargentgloryvine stem extract is simple and has the advantages of low energy consumption and environment friendliness, and the cotton can be dyed at room temperature.

Owner:SUZHOU UNIV

A kind of disperse dye polyester dyeing method using siloxane as medium

The invention discloses a method for dyeing polyester with disperse dyes using siloxane as a medium, and belongs to the technical field of textile dyeing and finishing. The dyeing method includes the following steps: (1) adding the dyed object, prepared dye solution and dyeing accelerator into the dyeing medium for dyeing; (2) deliquoring after dyeing, washing with siloxane medium, and drying to obtain the finished dyed product. Compared with the patent CN103074781A, this method does not need pretreatment for general dyed objects, and only needs to add a small amount of non-toxic dyeing accelerator when dyeing, which realizes the dyeing of polyester textiles under normal pressure or micro pressure conditions, thereby reducing the need for equipment. Dependencies and requirements (high temperature and pressure). Subsequent washing abandons the water washing method and uses siloxane medium to achieve zero discharge of sewage, and can effectively improve the uniformity and color fastness of disperse dyeing; and the siloxane medium obtained by dyeing, washing, and drying can be recycled. Using it, the ecological dyeing of disperse dyes is really realized.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

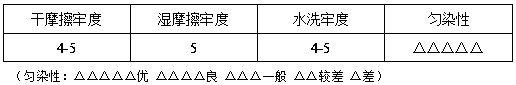

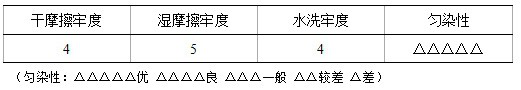

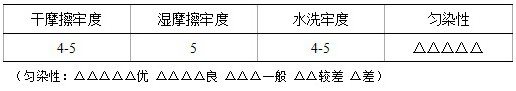

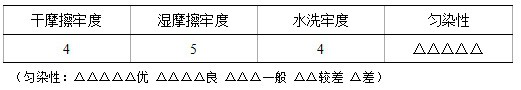

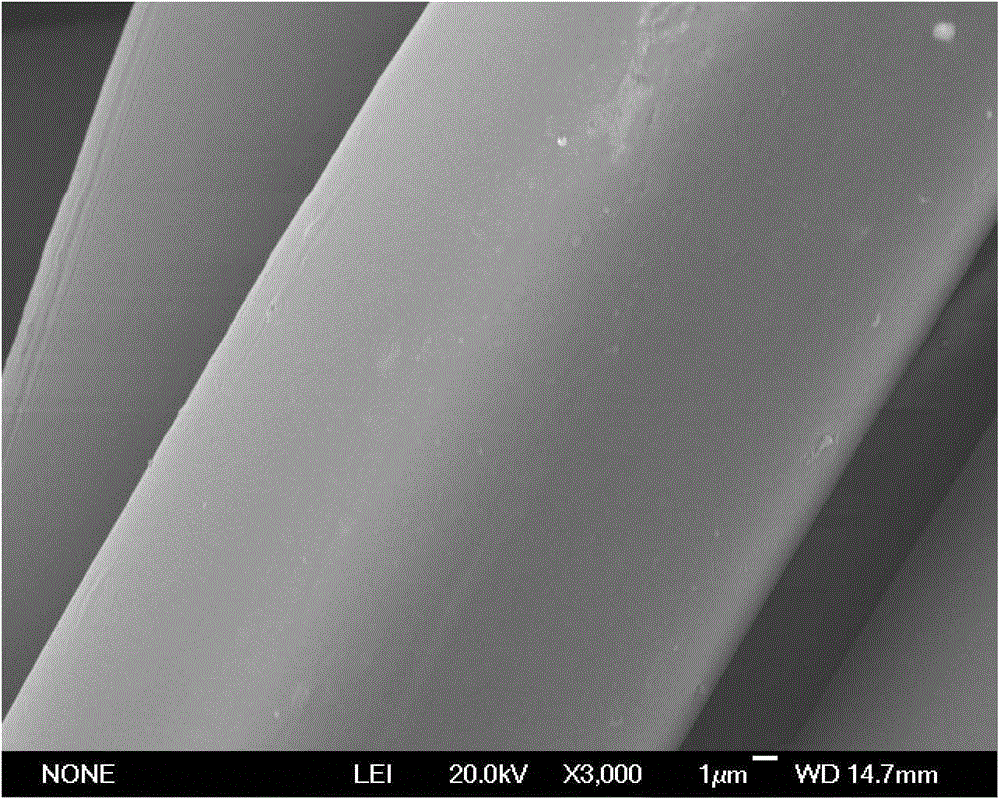

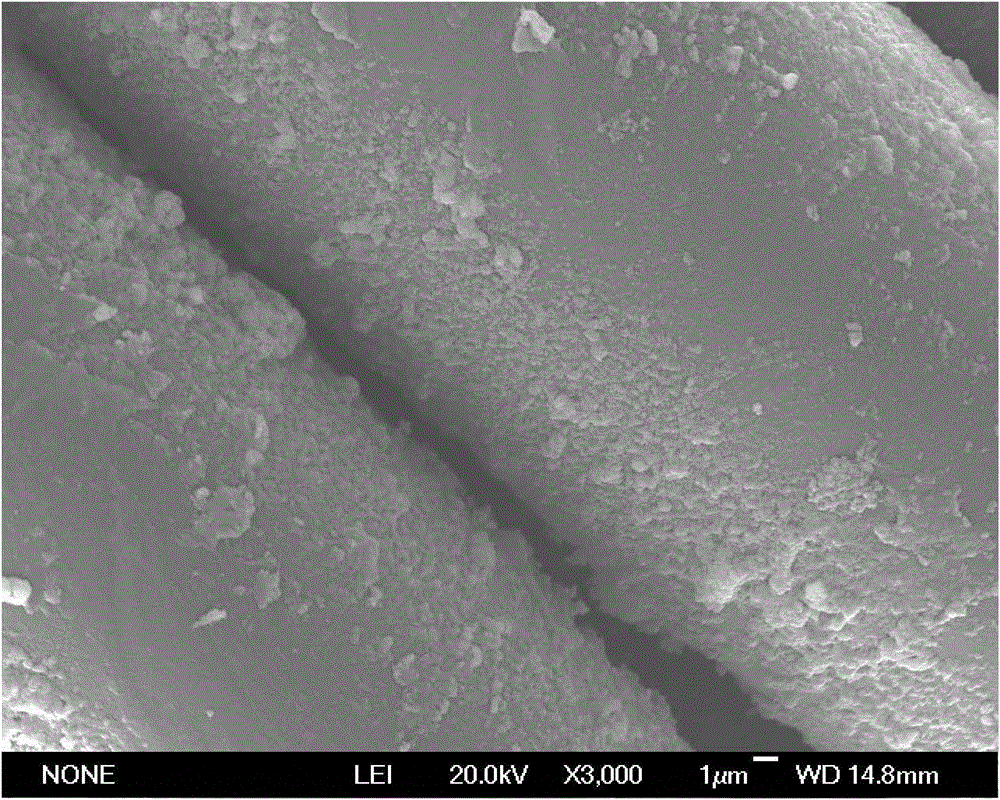

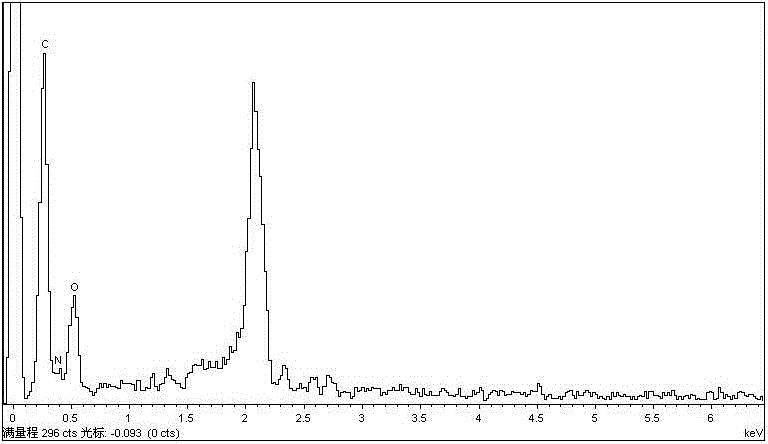

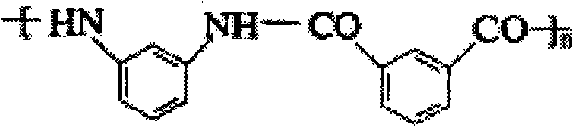

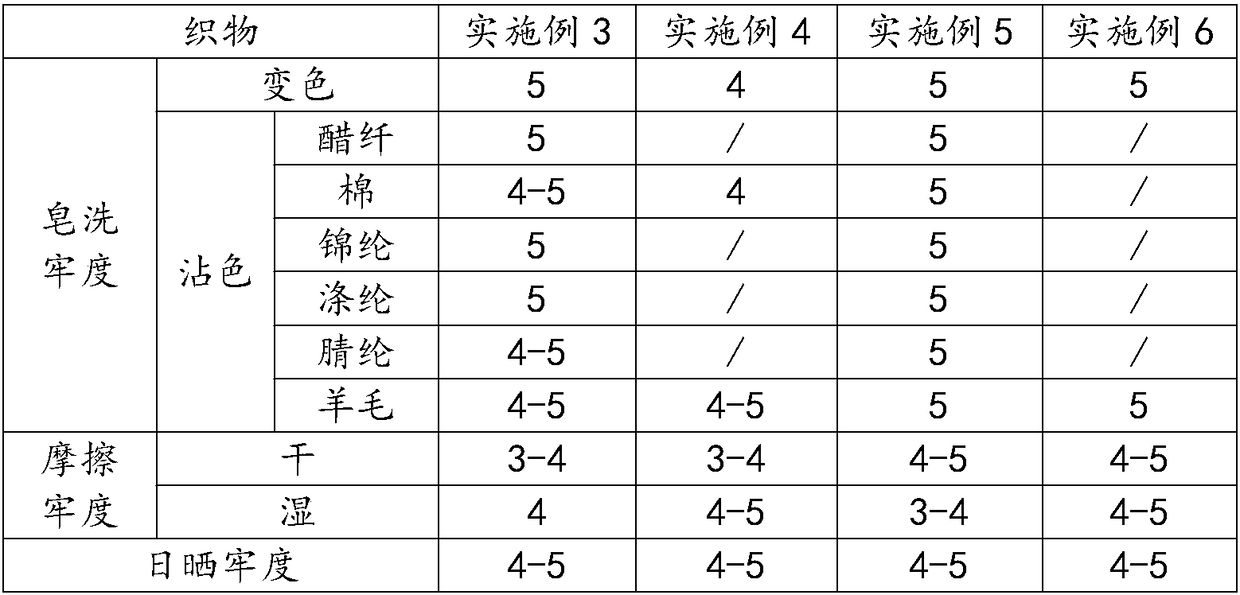

Modification of Nylon Swimsuit Fabric and Dyeing Composite Finishing Method

ActiveCN103757875BLittle impact on hand feelingWide spectral response rangeFibre typesDyeing processSulfonatePre treatment

The invention discloses a modifying and dyeing composite finishing method for brocade ammonia swimming wear fabric. The modifying and dyeing composite finishing method is specifically implemented according to the following steps: step 1) performing pretreatment on the brocade ammonia swimming wear fabric by using a sodium hydroxide solution, then sequentially soaking in an ethanol solution, washing with deionized water, and finally drying to obtain the clean brocade ammonia swimming wear fabric; step 2) preparing a composite finishing solution containing tetrabutyl titanate, ethanol, silver nitrate, sodium dodecyl sulfonate, an acid dye and a water repellent agent, namely AG-7620, and performing modifying and dyeing composite finishing on the brocade ammonia swimming wear fabric obtained in the step 1) in a hydrothermal environment; step 3) preparing a washing solution, washing the modified and dyed brocade ammonia swimming wear fabric obtained in the step 2) with the washing solution, and finally drying the modified and dyed brocade ammonia swimming wear fabric. According to the modifying and dyeing composite finishing method for the brocade ammonia swimming wear fabric, disclosed by the invention, the modification and the dyeing can be simultaneously performed on the brocade ammonia swimming wear fabric.

Owner:HOSA IND FUJIAN

A textile dyeing device capable of saving dye

InactiveCN107488959BSaving dyeRealize deliveryLiquid/gas/vapor removalTextile treatment machine arrangementsStructural engineeringTextile dyeing

The invention discloses a textile dyeing device capable of saving dyes. The textile dyeing device comprises a box body, a dye box is fixedly connected between two opposite sides of the inner wall of the box body through a supporting plate, the two opposite sides of the inner wall of the box body are fixedly connected with a fixing device through fixing blocks, one side of the top of the supporting plate is fixedly connected with a pressing device, a leaky bucket is fixedly connected between two opposite sides of the inner wall of the box body, the bottom of the leaky bucket communicates with a first dye tube, one end of the first dye tube communicates with a water pump, the outlet end of the water pump is connected with a spray dyeing tube through a second dye tube, the two opposite sides of the inner wall of the box boy are fixedly connected with a pair of cushioning devices, the centers of the cushioning devices are rotatably connected with pressed roller wheels, and a drying device is fixedly connected between the two opposite sides of the inner wall of the box body through a fixing plate. The invention relates to the technical field of textile processing. The textile dyeing device capable of saving the dyes improves the dyeing efficiency, shortens the drying time, saves the dyes, reduces the labor intensity and improves the work efficiency.

Owner:李文艳

Three-color cloth dyeing method

The invention discloses a dyeing method of three-cloth cloth. Dispersed dyes are firstly applied to carry out dyeing on terylene and modified terylene, then cationic dyes are added to carry out dyeing for the second time on the modified terylene on the basis of separating dyes, and finally reactive dyes are applied to carry out dyeing on the cotton fibers, so that dyeing of woven cloth which is formed by combined interweaving of the three fibers including modified terylene, terylene and cotton can be realized. According to the invention, a technical problem of how to carry out dyeing on the woven cloth which is formed by combined interweaving of the three fibers including modified terylene, terylene and cotton can be solved.

Owner:浙江灏宇科技有限公司

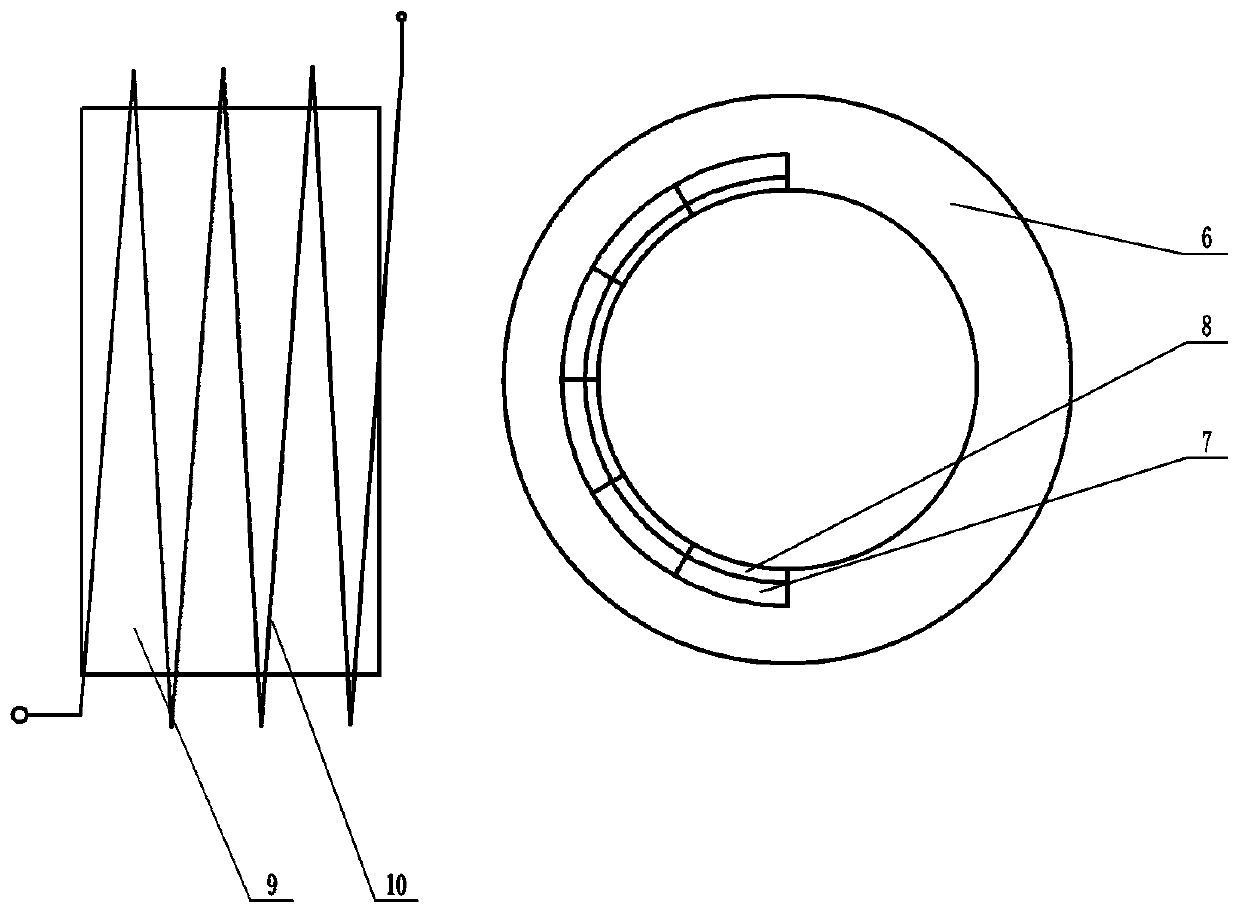

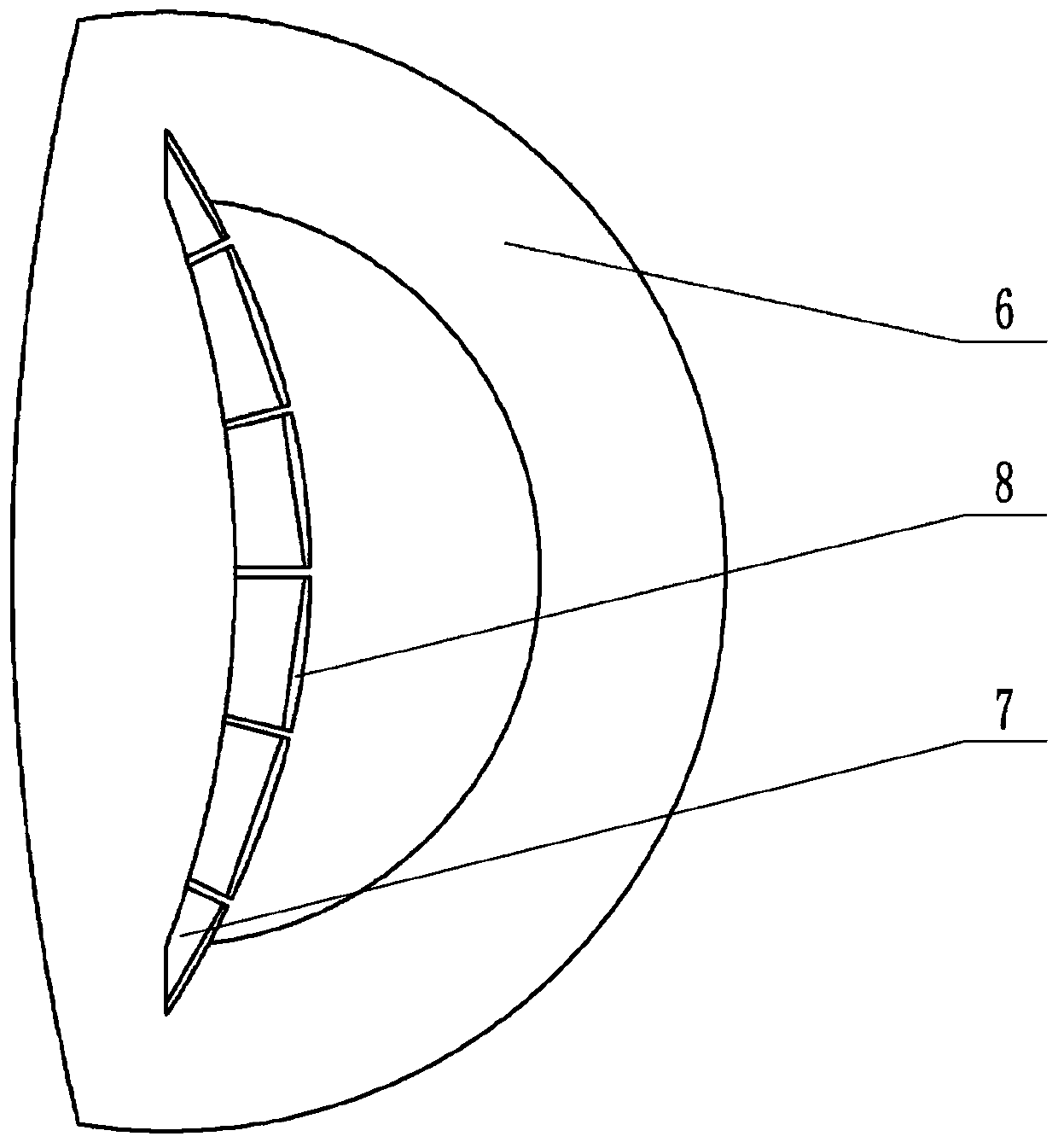

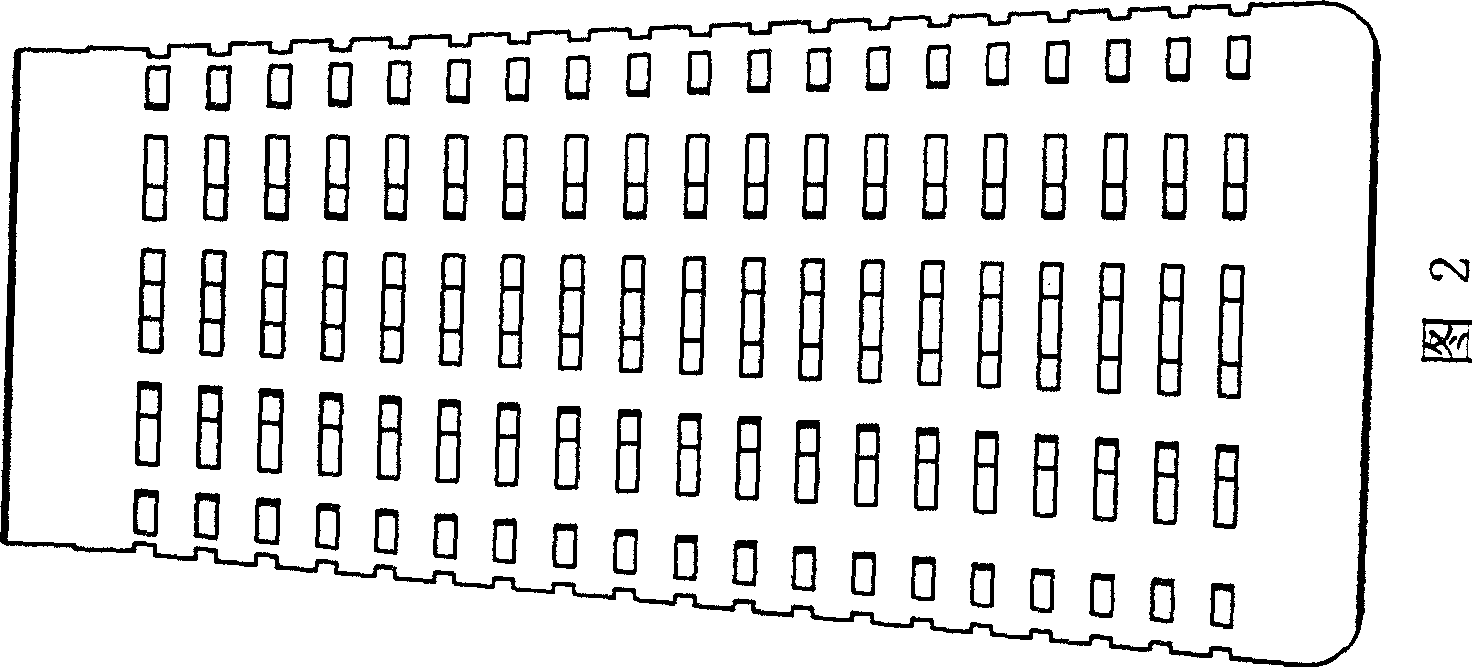

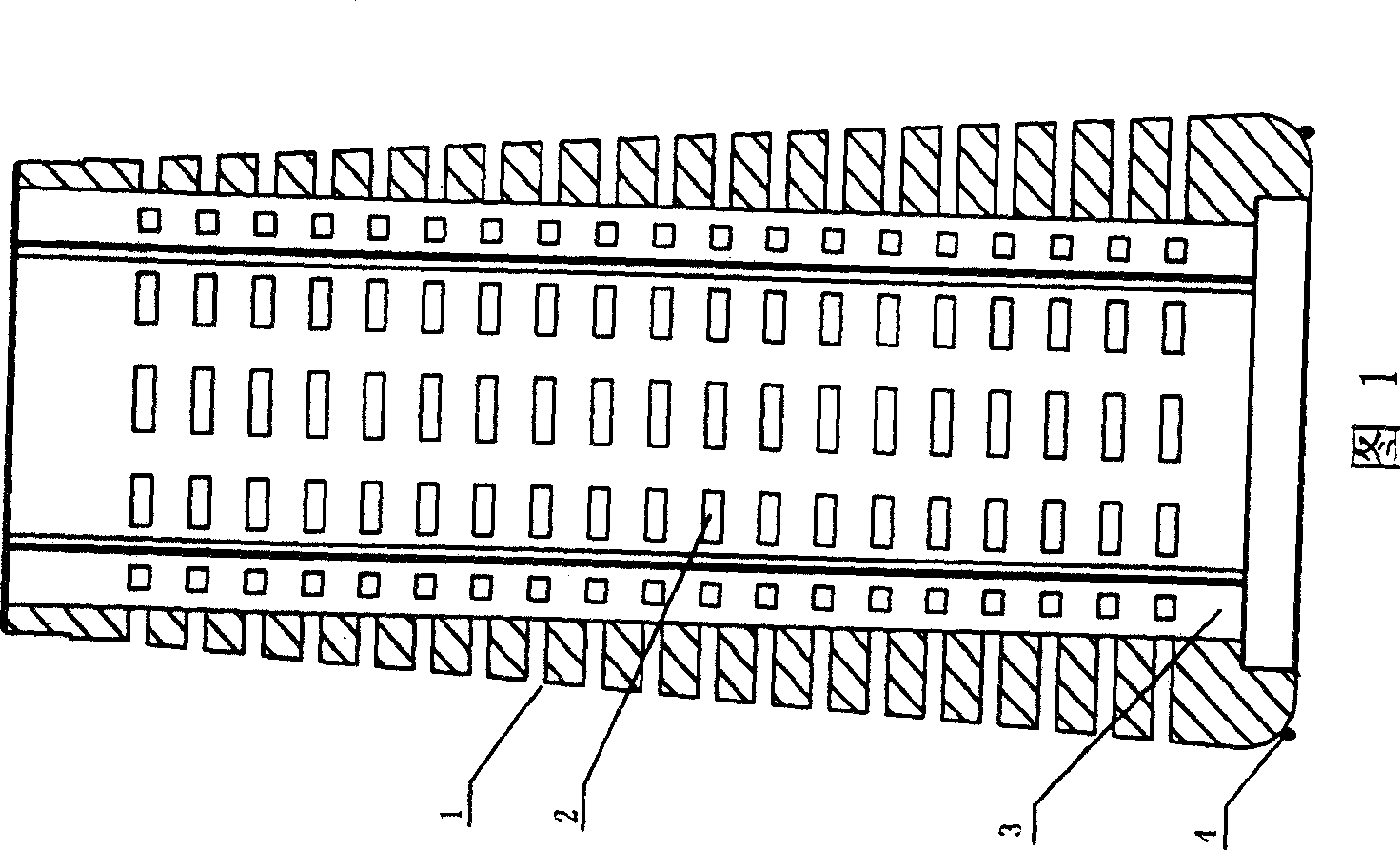

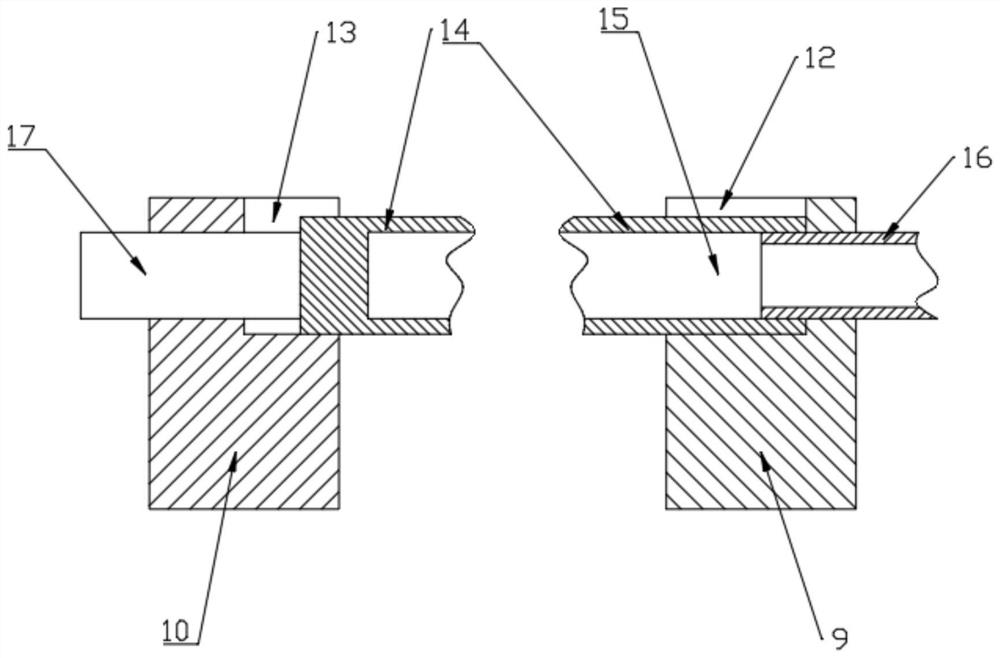

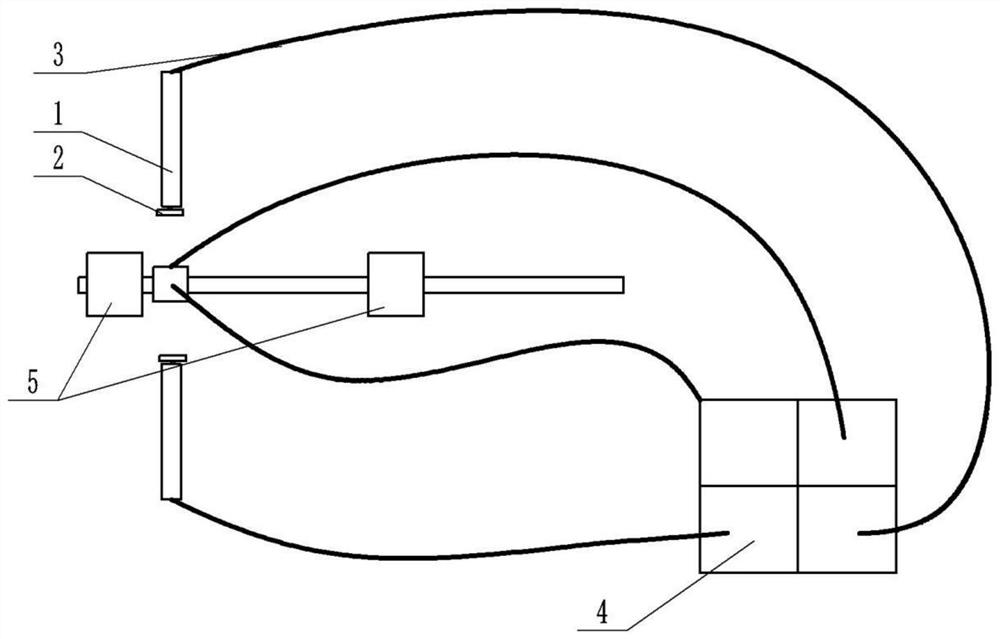

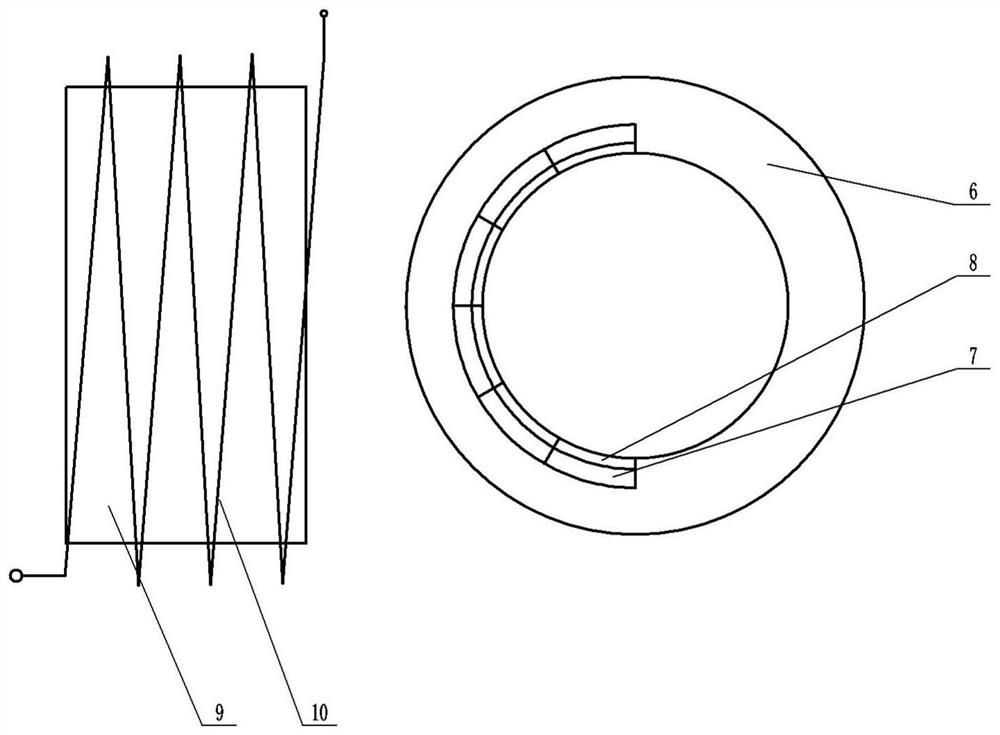

Novel yarn dyeing flow process and canister for dyeing

ActiveCN100467700CDyeing achievedIncrease productivityTextile treatment containersLiquid/gas/vapor textile treatmentYarnDying processes

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

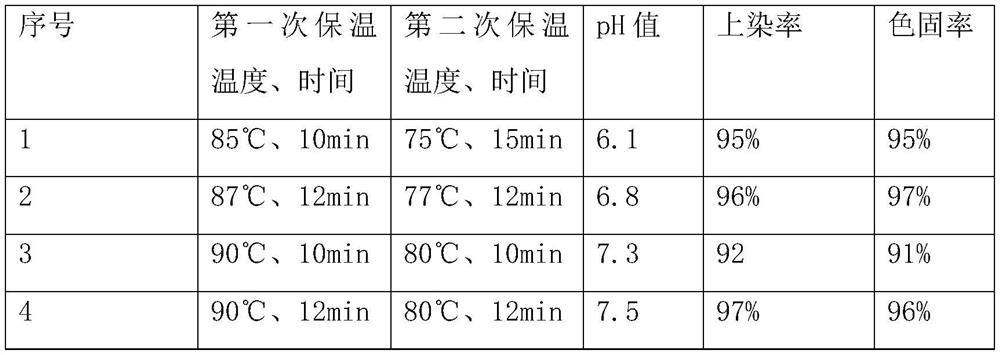

Normal-pressure dyeing method of meta-aramid yarn

The invention relates to a normal-pressure dyeing method of a meta-aramid yarn, belonging to the technical field of textile printing and dyeing. The method comprises the following steps: coarsening the meta-aramid yarn, wherein the coarsening process is as follows: acid or alkali is 10-20 g / L, a penetrant is no more than 2 g / L, the bath ratio is 1:10-20, the temperature is 90-100 DEG C, and the time is 20-30 min; then, washing with water to obtain the meta-aramid yarn with a coarsened fiber surface; activating the meta-aramid yarn with coarsened fiber surface, wherein the activating process of the meta-aramid yarn with a coarsened fiber surface is as follows: a cation modifier is 10-20 g / L, the bath ratio is 1:20-30, the temperature is 60-90 DEG C, and the time is 30-40 min; and finally, dyeing the meta-aramid yarn, i.e. dyeing the meta-aramid yarn to be dyed under the normal pressure to obtain a colored meta-aramid yarn. The invention is beneficial to saving energy, avoids damage to fibers, has no stringent requirements on the dyeing device and facilitates the operation. Besides, the invention realizes that the fabric subjected to subsequent processing can be provided with required patterns in accordance with the weaving process.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

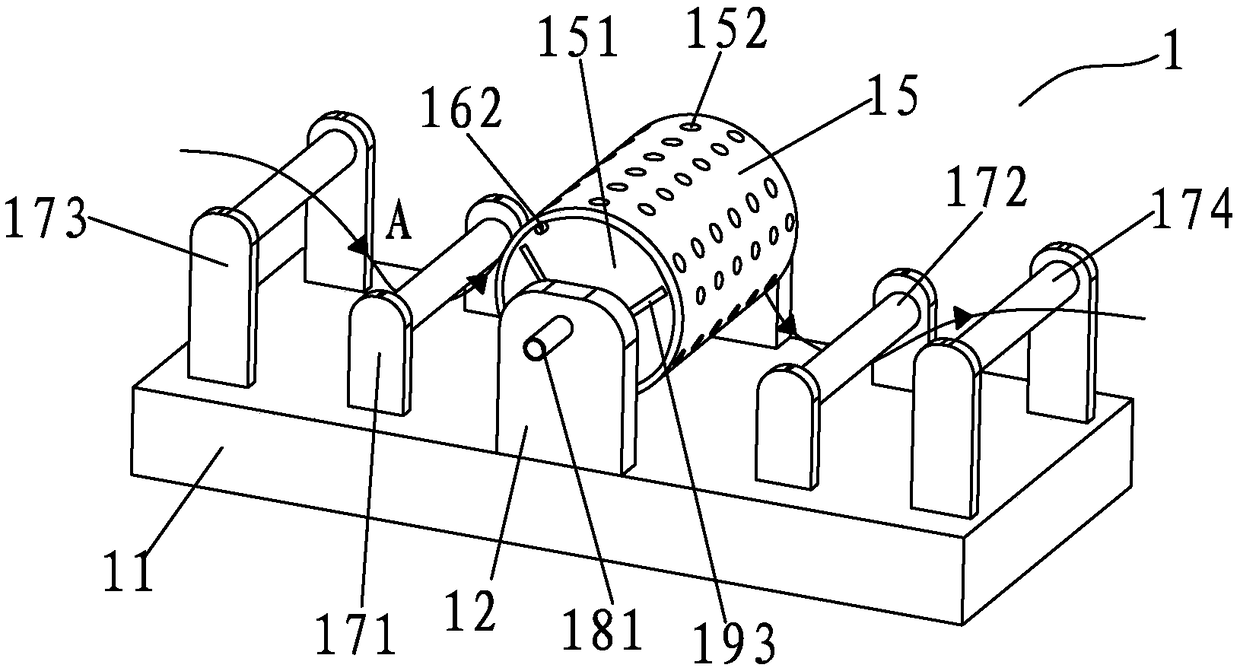

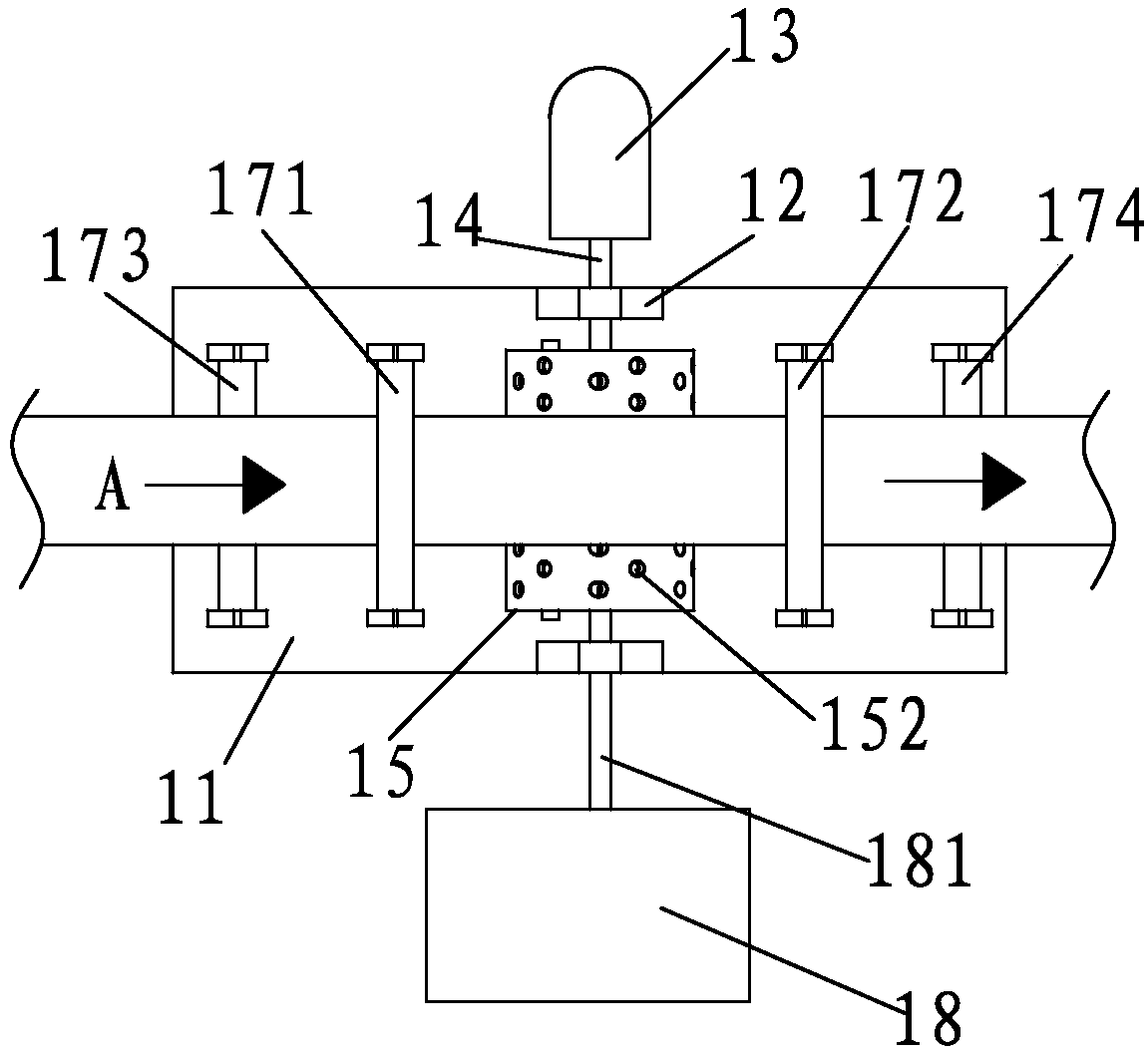

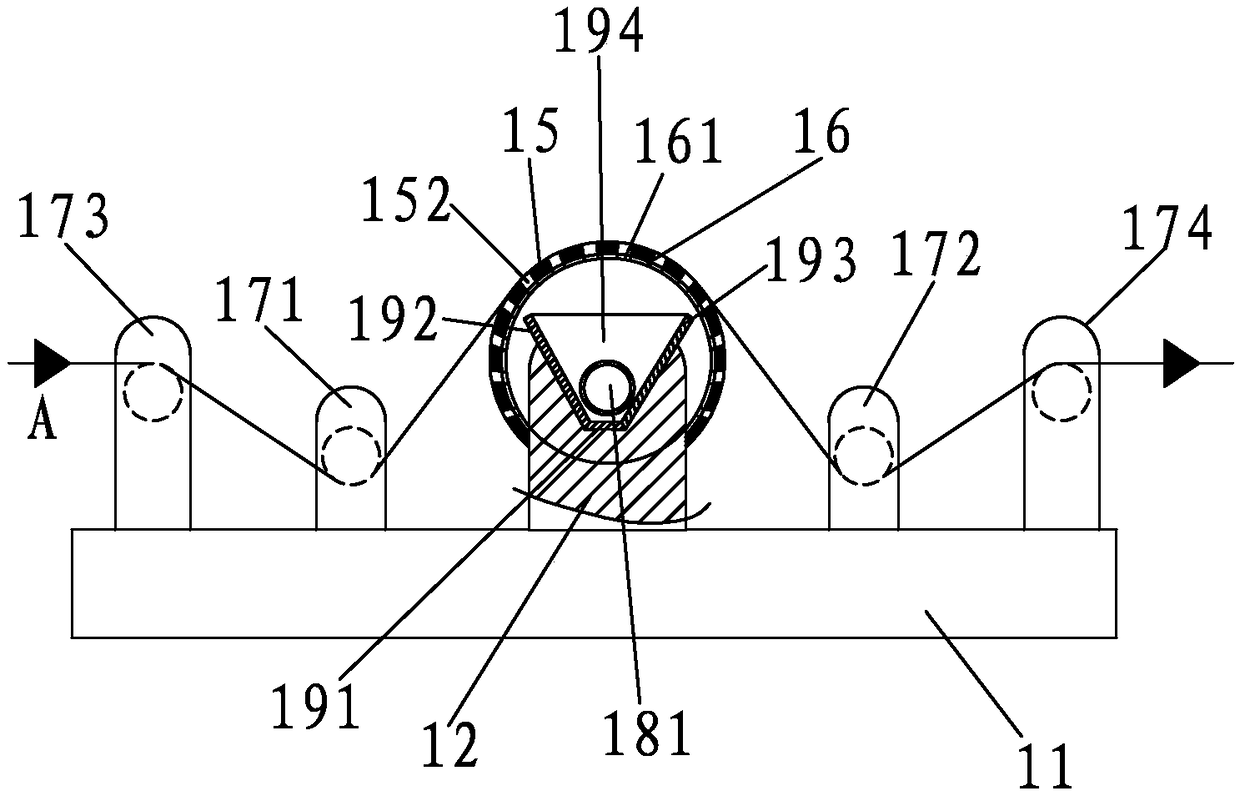

Dyeing system and dyeing method

PendingCN114016231AImprove efficiencyEasy to cleanTextile treatment containersTextile treatment machine arrangementsChemistryWoven fabric

The invention provides a dyeing system which comprises a dyeing tank and a mixing barrel which are connected, the dyeing tank is horizontally arranged, a mounting hole plate is arranged in the dyeing tank and divides the dyeing tank into a first cavity and a second cavity, and a positioning assembly for positioning a cloth roll is arranged in the first cavity; a booster pump is arranged between the mixing barrel and the second cavity, the booster pump pumps liquid in the mixing barrel and then pumps the liquid into a first heat exchanger arranged in the second cavity, and the first heat exchanger guides the liquid into the cloth roll; and a circulation assembly forming circulation with the first cavity and the second cavity is further arranged outside the dyeing tank, a second heat exchanger is arranged in the circulation assembly, and liquid in the first cavity enters the circulation assembly, then is heated by the second heat exchanger, enters the first heat exchanger and then enters the cloth roll. According to the dyeing system, the non-woven fabric can be dyed only through one-time operation, the efficiency is high, meanwhile, the dyeing rate of the dyed non-woven fabric can reach 90% or above, and the color fixation rate can reach 90% or above.

Owner:YICHANG XINLONG SANITARY MATERIALS CO LTD

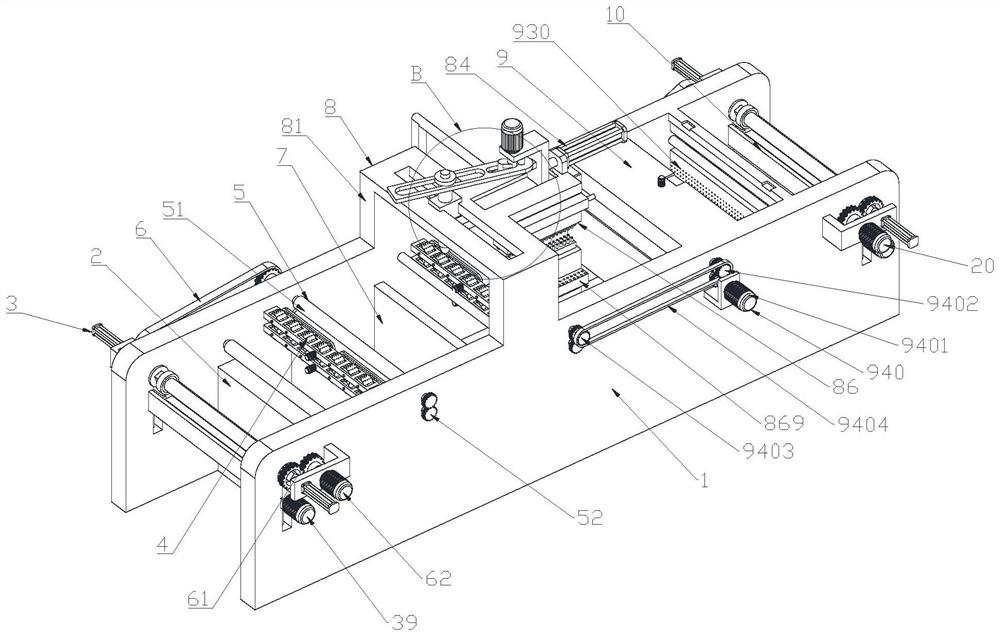

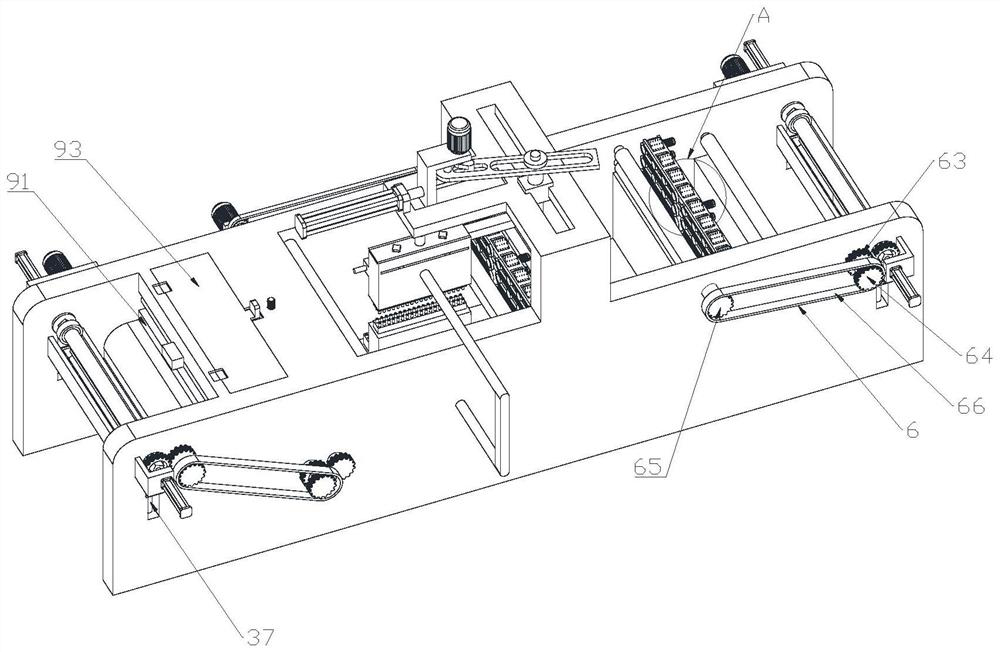

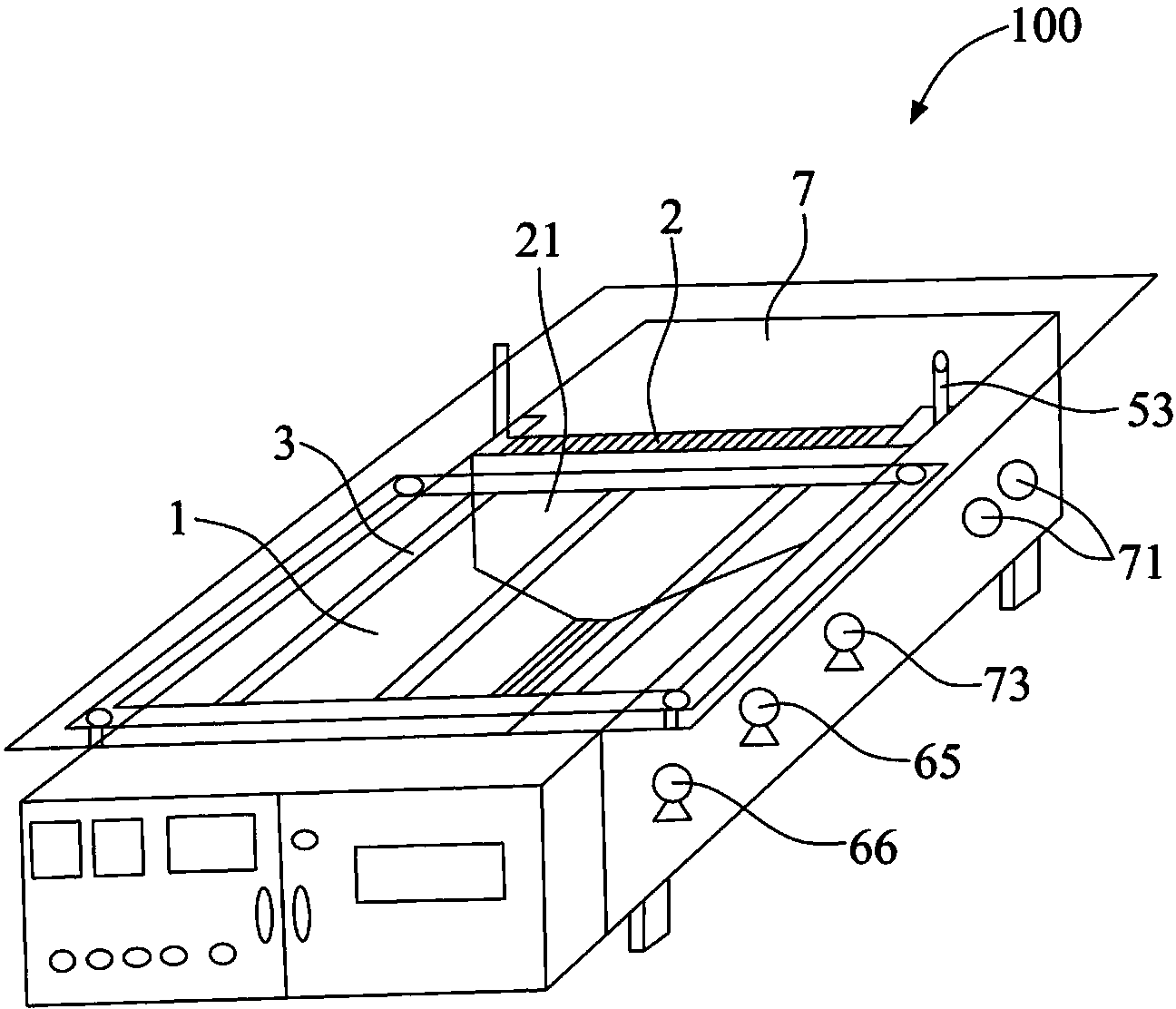

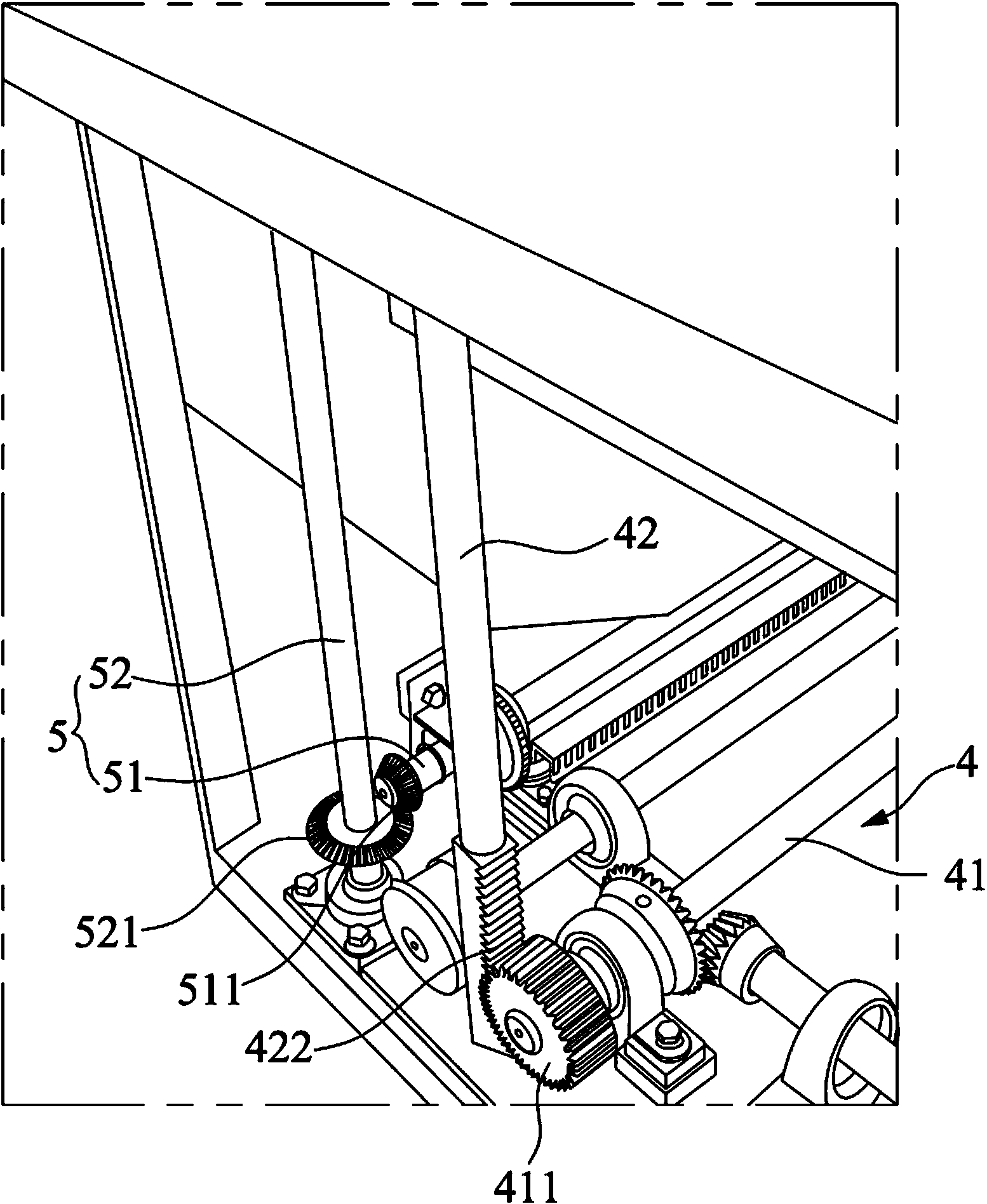

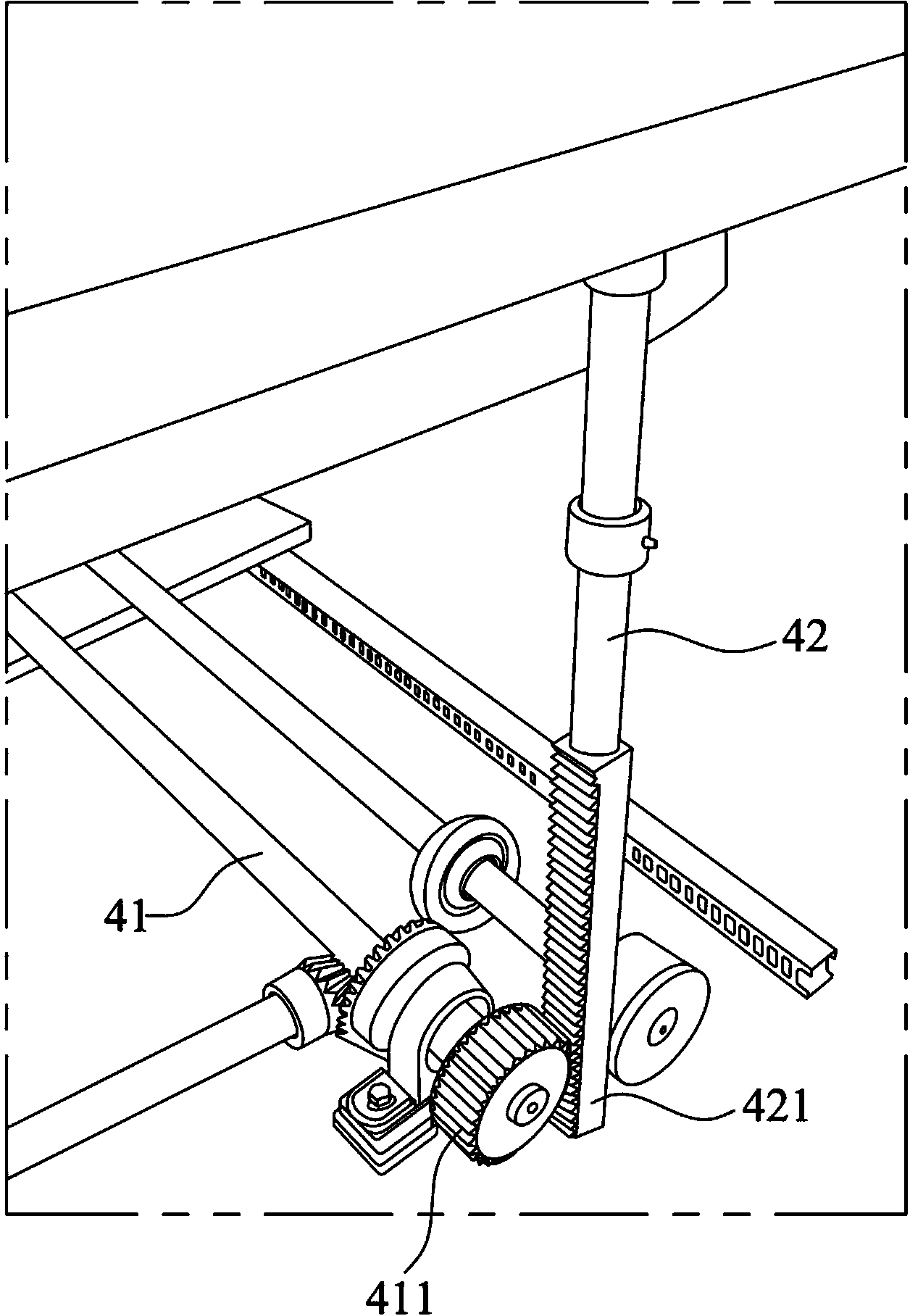

Efficient water-saving polyester dyeing device and dyeing process thereof

ActiveCN113981636AControl depthDyeing achievedLiquid/gas/vapor treatment machines driving mechanismsSucessive textile treatmentsPolyesterWater saving

The invention discloses an efficient water-saving polyester dyeing device, the dyeing device comprises symmetrically distributed platform supports, and is characterized in that a collecting tank for collecting wastewater is arranged between the platform supports, a dyeing tank is arranged in the collecting tank, one end of the collecting tank is provided with a release device for releasing polyester fabric, the other end is provided with a winding device for winding the polyester fabric, the side, close to the releasing device, of the dyeing pool is provided with a flattening device for flattening the fabric, a first transmission device for transmitting the fabric is arranged between the flattening device and the dyeing pool, a first driving is arranged on the platform supports, and the first transmission device and the release device are synchronously driven by the first driving device. According to the dyeing device, the first driving device controls the first transmission device and the releasing device to rotate synchronously, the polyester fabric is conveyed into the dyeing pool to be soaked, dyeing of the polyester fabric is achieved, and the color depth of the fabric is controlled by controlling different dyeing time.

Owner:浙江赛芙纺织品有限公司

Method for dyeing fabric or/and fabric fiber by using wood hydrothermal treatment waste liquid

The invention discloses a method for dyeing a fabric or / and fabric fiber by using a wood hydrothermal treatment waste liquid and belongs to the field of wood processing. The method for dyeing the fabric or / and fabric fiber by using the wood hydrothermal treatment waste liquid comprises the following steps: collecting a waste liquid generated from wood hydrothermal treatment; putting the fabric or / and fabric fiber into the waste liquid, heating to 50-100 DEG C, and keeping the temperature for 0.5-2 hours. By adopting the method, the waste liquid generated in wood hydrothermal treatment is sufficiently utilized, and the process is simple and convenient; meanwhile, coloring groups in the wood hydrothermal treatment waste liquid are reacted with amino on the fabric fiber, so that a solid and long-lasting dyeing effect on the fabric or / and fabric fiber can be achieved.

Owner:BEIJING FORESTRY UNIVERSITY

Ink supply and dyeing device for 3D printing color expression

ActiveCN110450410BDyeing achievedRealize full color 3D printingAdditive manufacturing apparatus3D object support structuresComputer printingColor printing

The invention discloses an ink supply and dyeing device for 3D printing color expression, which includes a frame. A groove divides one side of the speed regulating section into a number of guide blocks. The top of the guide block is provided with a guide magnetic sheet; the support A rack is placed in front of the printing nozzle of the 3D printer and is used to carry the consumables output by the 3D printer; a number of dyeing rollers are fixed circumferentially around the consumables carried by the bracket; the control circuit is connected to and controls the clutch and the electromagnet respectively. Movement; the ink supply pump is connected to the ink storage box, and is used to control the ink supply pump to pump the ink in the ink supply area when the control circuit controls the clutch to push the dyeing roller to move toward the consumables. The corresponding ink tube is output to the corresponding dyeing roller to realize dyeing of consumables. The invention solves the technical problem that existing FDM printers cannot realize full-color printing.

Owner:深圳凯奇化工有限公司

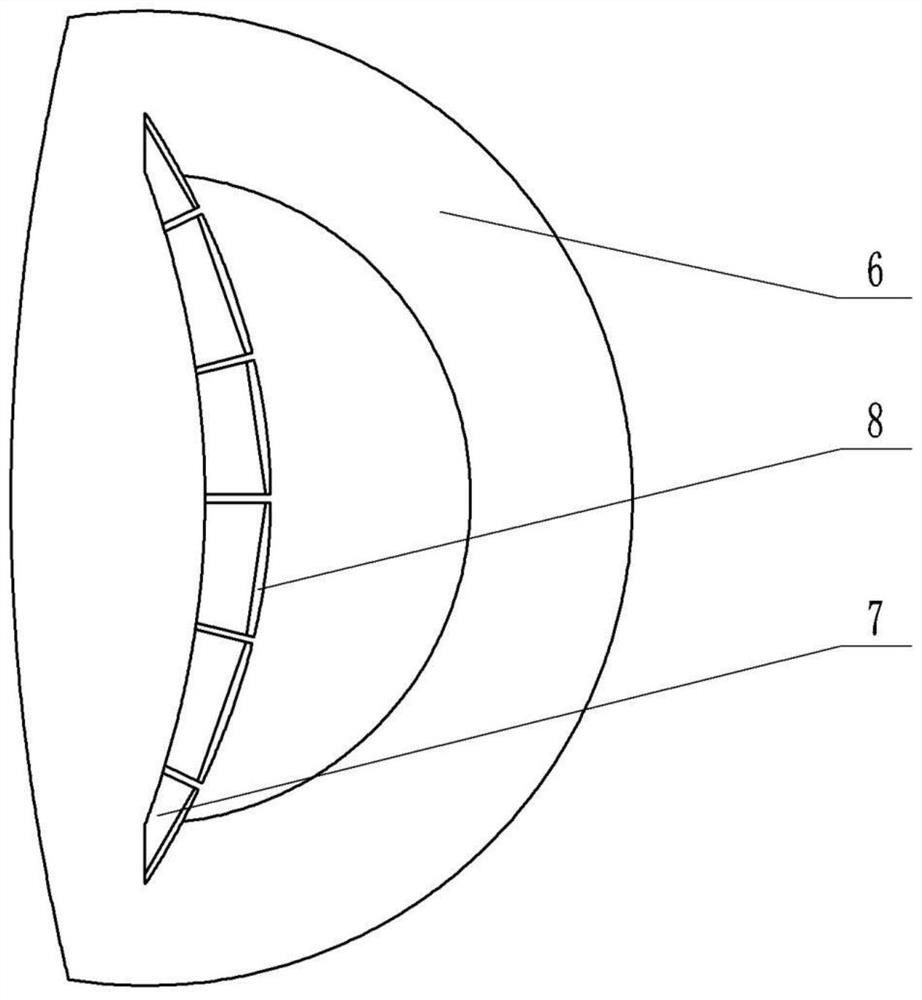

Dyeing method and dyeing device of gradient eyeglass

ActiveCN102645682BDyeing achievedReduce the situation of fixed instabilityLiquid surface applicatorsCoatingsControl systemFixed frame

The invention discloses a dyeing method and a dyeing device of gradient eyeglass. The dyeing method comprises the following steps of: 1, configuring dyeing solution according to the dyeing requirement of present eyeglass, and enabling the dyeing resolution to reach a desired temperature condition; 2, putting the eyeglass into the dyeing resolution, and descending the liquid level of the dyeing solution at the speed of 5-40mm / min; 3, keeping the liquid level of the dyeing resolution when the dyeing of the gradient section of the eyeglass is accomplished; after one dyeing process is completed, resetting the eyeglass, and resetting the liquid level of the dyeing resolution for dyeing of next process. The dyeing device comprises a dyeing groove, a baffle plate, an eyeglass fixing frame, an eyeglass elevating mechanism, a baffle plate elevating mechanism and a control system. Compared with the prior art, the eyeglass does not need to be lifted repeatedly in different sections in one dyeing process, so that the dyeing efficiency is improved; and due to the mode that the liquid level is descended gradually is adopted, the eyeglass can be dyed in gradient in deed, so that the function of good dyeing effect is achieved.

Owner:XIAMEN YARUI OPTICAL

A kind of dyeing method of modified wood

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com