Method for dyeing fabric or/and fabric fiber by using wood hydrothermal treatment waste liquid

A textile fiber and hydrothermal treatment technology, which is applied in the fields of dyeing, textiles and papermaking, etc., can solve the problems of difficult treatment of wood hydrothermal treatment waste liquid, etc., and achieve the effect of easy large-scale promotion and application, firm dyeing effect and good dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The water boiling of embodiment 1 timber handles waste liquid

[0053] (1) Put the eucalyptus board to be boiled into the wood cooking equipment wood cooking tank, and put distilled water into the wood cooking tank and submerge the eucalyptus board; (2) heat up until the water temperature reaches and maintains 80°C ( Usually can also be 60-100 ℃), carry out the poaching treatment of wood; (3) after 4.5h of poaching treatment, wood is taken out, and remaining solution is eucalyptus poaching treatment waste liquid, wherein, wood poaching time It is 1.5h / cm (usually the boiling time of wood can also be 1-2h / cm).

[0054] The boiling treatment waste liquid of embodiment 1A timber

[0055] Except also adding alkaline reagent sodium hydroxide when putting into water in the wood poaching container in step (1), all the other are identical with embodiment 1. Wherein, the mass ratio of sodium hydroxide to distilled water is 3:100 (usually also can be 0.5-8:100).

[0056] In th...

Embodiment 2

[0057] The steaming treatment waste liquid of embodiment 2 wood

[0058] (1) Palletize the wood and put it into the wood steaming kiln (steaming treatment device); (2) Close the wood steaming kiln, turn on the heater, and pass superheated steam into the steaming kiln; (3) Heating the wood inside the steaming treatment device (steaming kiln), the temperature in the temperature control device reaches and maintains at 90°C, and performs steaming treatment of the wood; (4) Performs steaming treatment under the condition of maintaining the temperature at 90°C After 6 hours, the wood was taken out, and the condensate left at the bottom of the steaming treatment was the eucalyptus wood steaming treatment waste liquid.

[0059] The purpose of boiling treatment and steaming treatment is to make the extract inside the wood discharge the wood conduit under the action of hot water / steam, so that the wood extract flows out.

[0060] In order to increase the content of extracts in wood hyd...

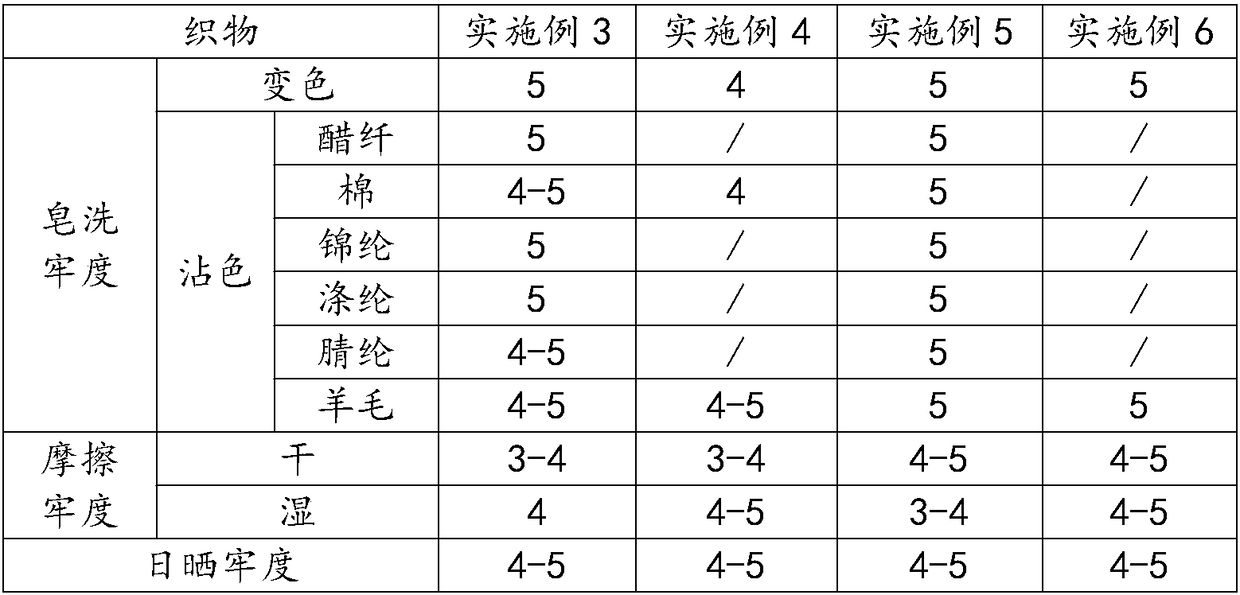

Embodiment 3

[0066] 1. Wood hydrothermal treatment waste liquid pretreatment

[0067] The eucalyptus steaming treatment waste liquid prepared in Example 2 was collected, filtered, and concentrated, the water was evaporated, and the eucalyptus hydrothermal treatment waste liquid was concentrated until the extract content reached 5%, and the hydrothermal treatment concentrated waste liquid was obtained. Standby, wherein, the extract content in the hydrothermally treated concentrated waste liquid is determined according to the method of the national standard GB / T 2677-4-1993 (Determination of the water extract content of papermaking raw materials).

[0068] In addition to the steamed waste liquid prepared in Example 2, the mixed solution of boiled waste liquid and steamed waste liquid is also applicable.

[0069] 2. Dyeing treatment

[0070] Put 10g of silk into 100ml of concentrated steaming waste liquid, wherein the ratio of the mass of fabric (silk) to the volume of waste liquid is 1:10 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com