Dyeing method and dyeing device of gradient eyeglass

A dyeing method and technology of dyeing equipment, which are applied in the field of dyeing and dyeing equipment for gradient color lenses, can solve the problems of limited dyeing scale and low dyeing efficiency, and achieve the effects of improving dyeing efficiency, good dyeing effect, and reducing fixation instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

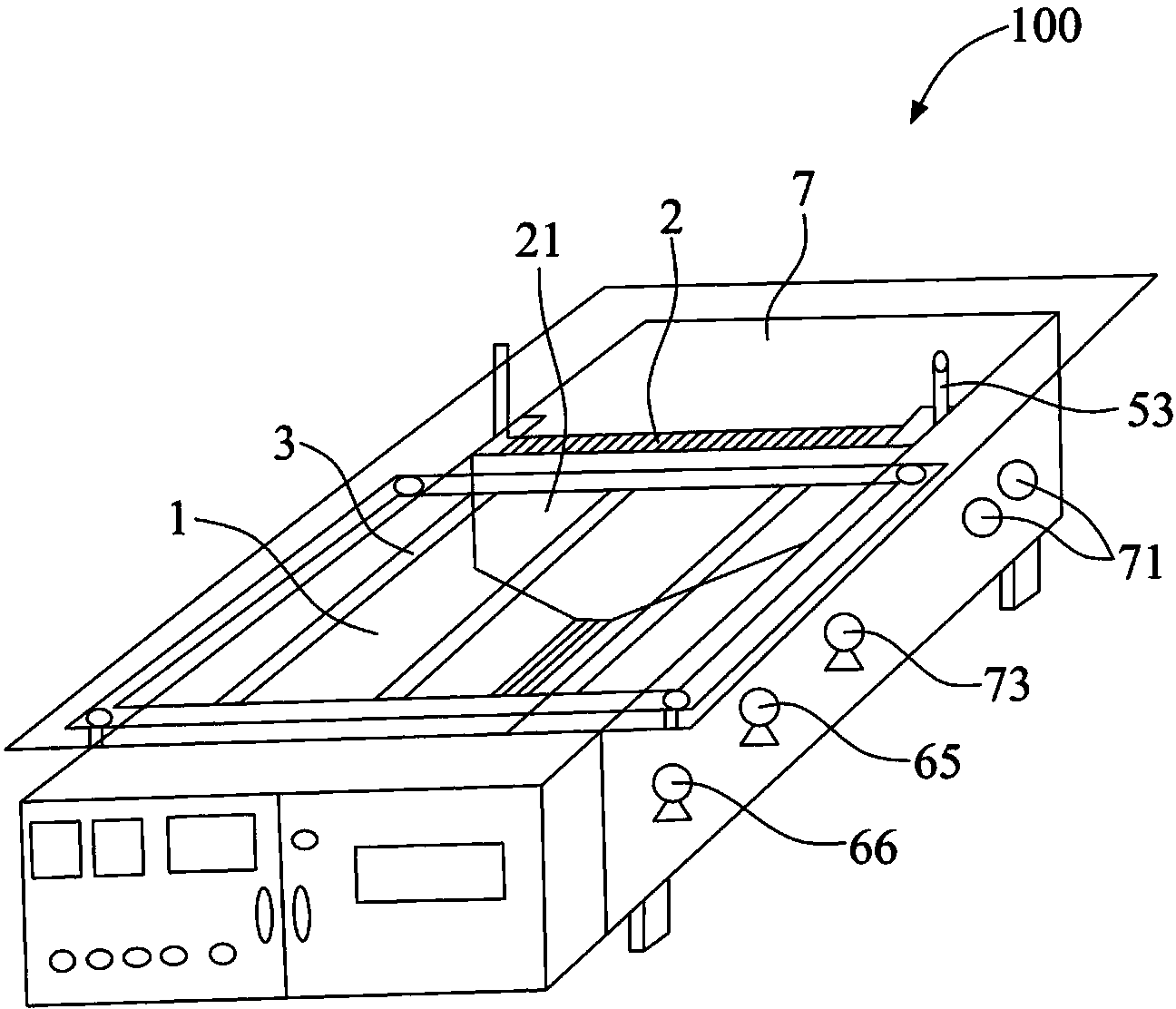

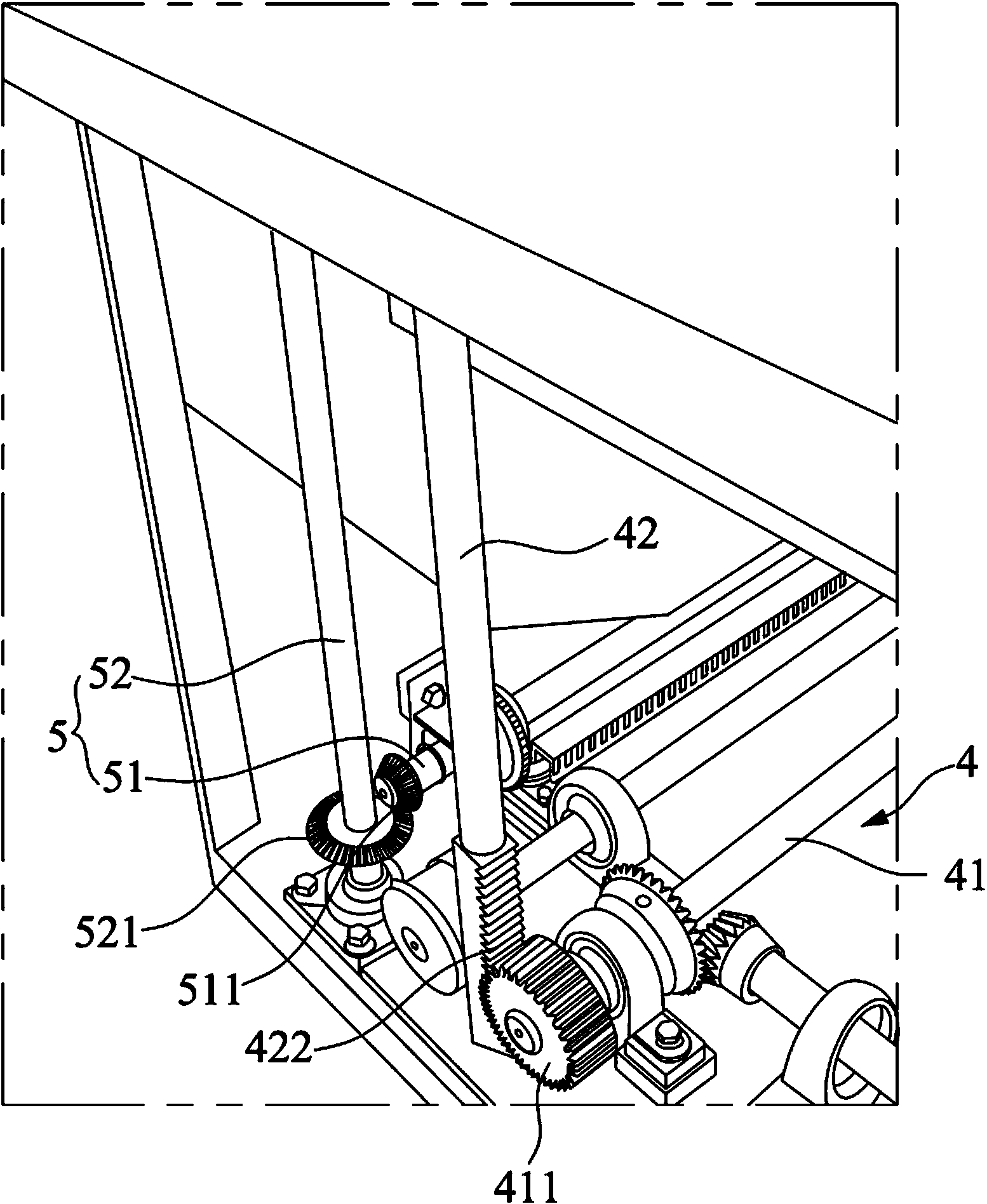

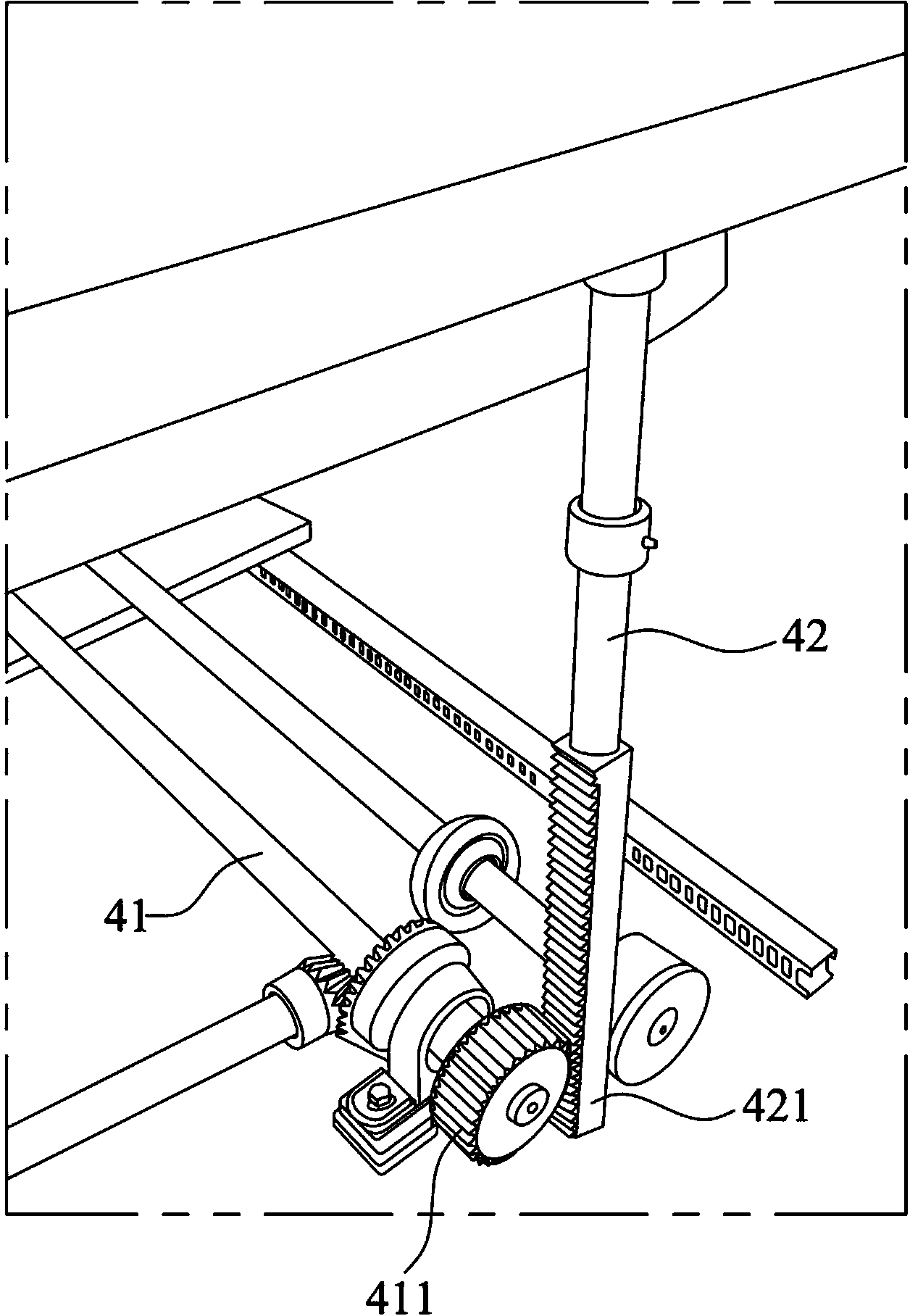

[0059] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific embodiments.

[0060] Such as figure 1 As shown, the dyeing method of a gradient lens according to the present invention includes the following steps:

[0061] ① Configure the dyeing solution according to the dyeing needs of the current lens 200, and make the dyeing solution reach the required temperature condition; specifically, in this step, the dyeing solution needs to be configured according to the material of the lens 200 that needs to be dyed and the required color requirements. , And at the same time determine the required temperature conditions, the temperature conditions are generally 60 ℃-80 ℃; of course, the dyeing solution can also be prepared according to actual needs, which are the conventional means of those skilled in the art, not here Explain one by one

[0062] ② Put the lens 200 into the dyeing solution, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com