Patents

Literature

52results about How to "Improve the setting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

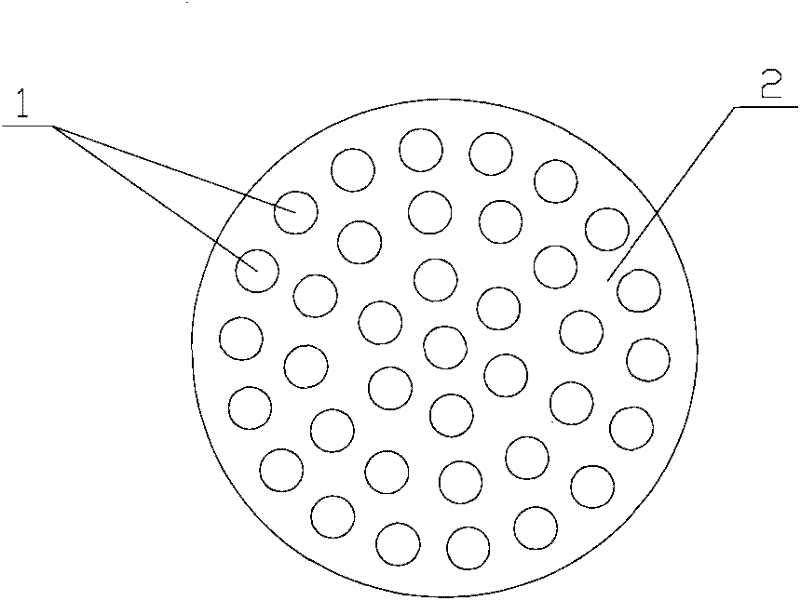

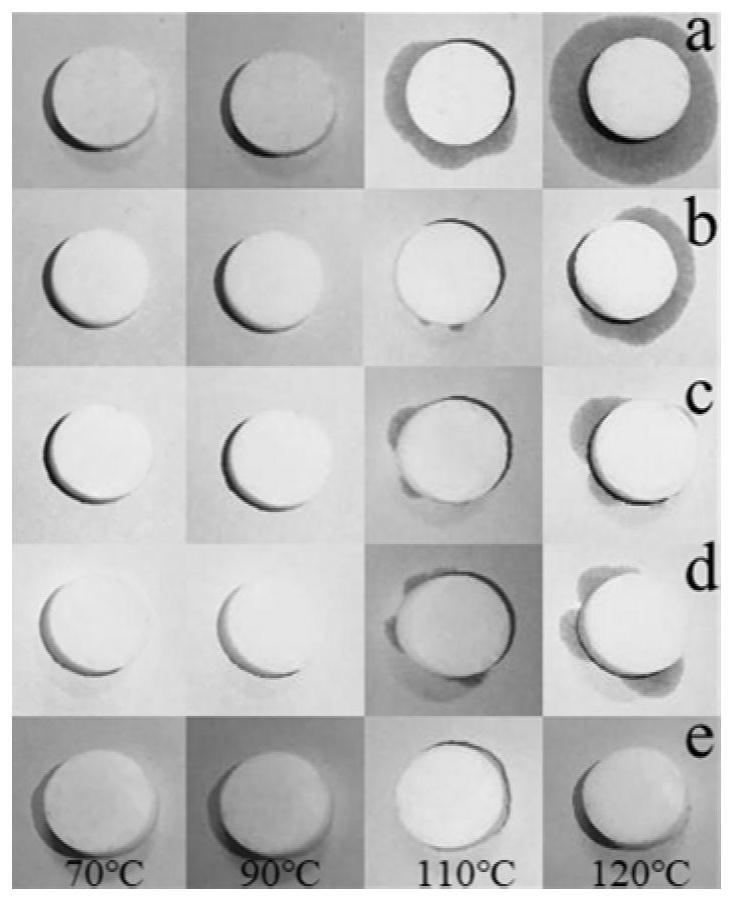

Island-fixed sea-island short fiber and its preparation method

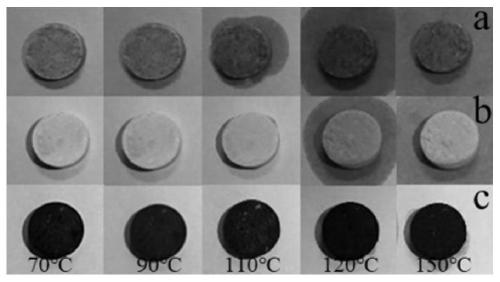

InactiveCN102260929ALoose molecular structureImprove the setting effectFilament/thread formingConjugated synthetic polymer artificial filamentsPolybutylene terephthalateMaterials science

The invention provides an island-fixed type sea-island short fiber, the island component of the island-fixed type sea-island short fiber is polybutylene terephthalate, and the sea component is alkali-soluble polyester. The present invention also provides a method for preparing the sea-island short fiber, comprising: melting the island component in a first screw extruder; melting the sea component in a second screw extruder; The molten body of the first screw extruder and the molten body of the second screw extruder are extruded through the spinning assembly to obtain nascent sea-island fibers; the nascent sea-island fibers are sequentially cooled, oiled, drawn, After crimping, loosening and setting, cut to obtain island-fixed short fibers. The PBT superfine fiber fabric prepared by adopting the island-fixing type sea-island short fiber provided by the invention has soft texture and good elasticity, and can be dyed under normal pressure conditions.

Owner:XIAMEN HONGXIN SPECIAL FIBER CO LTD

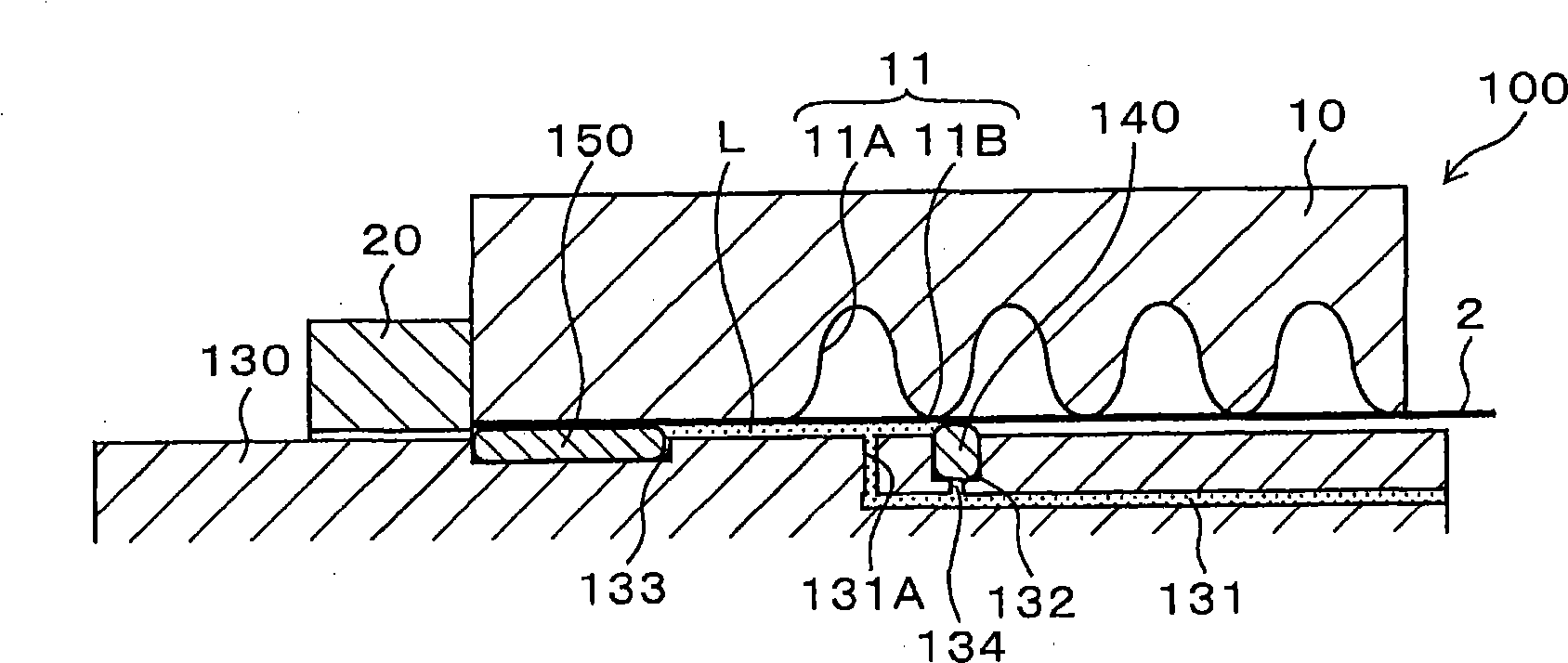

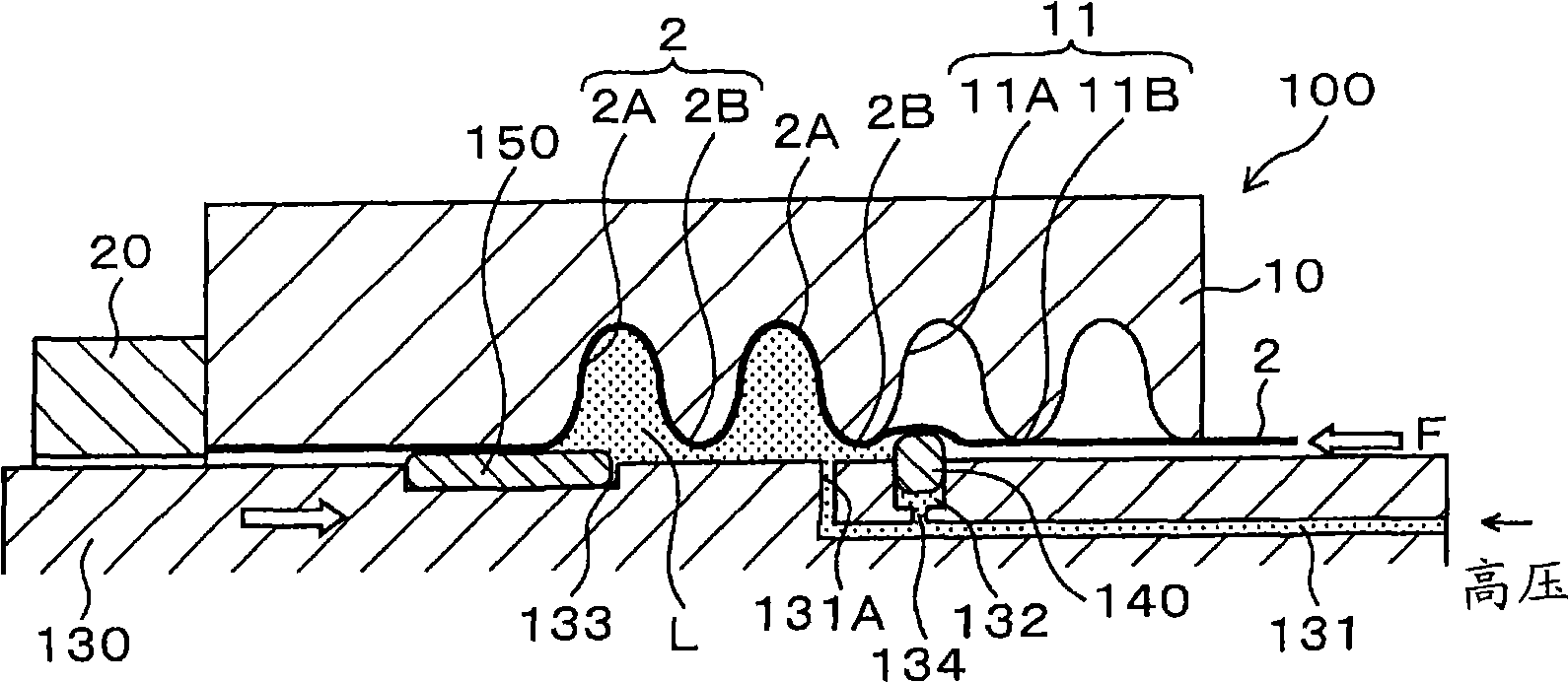

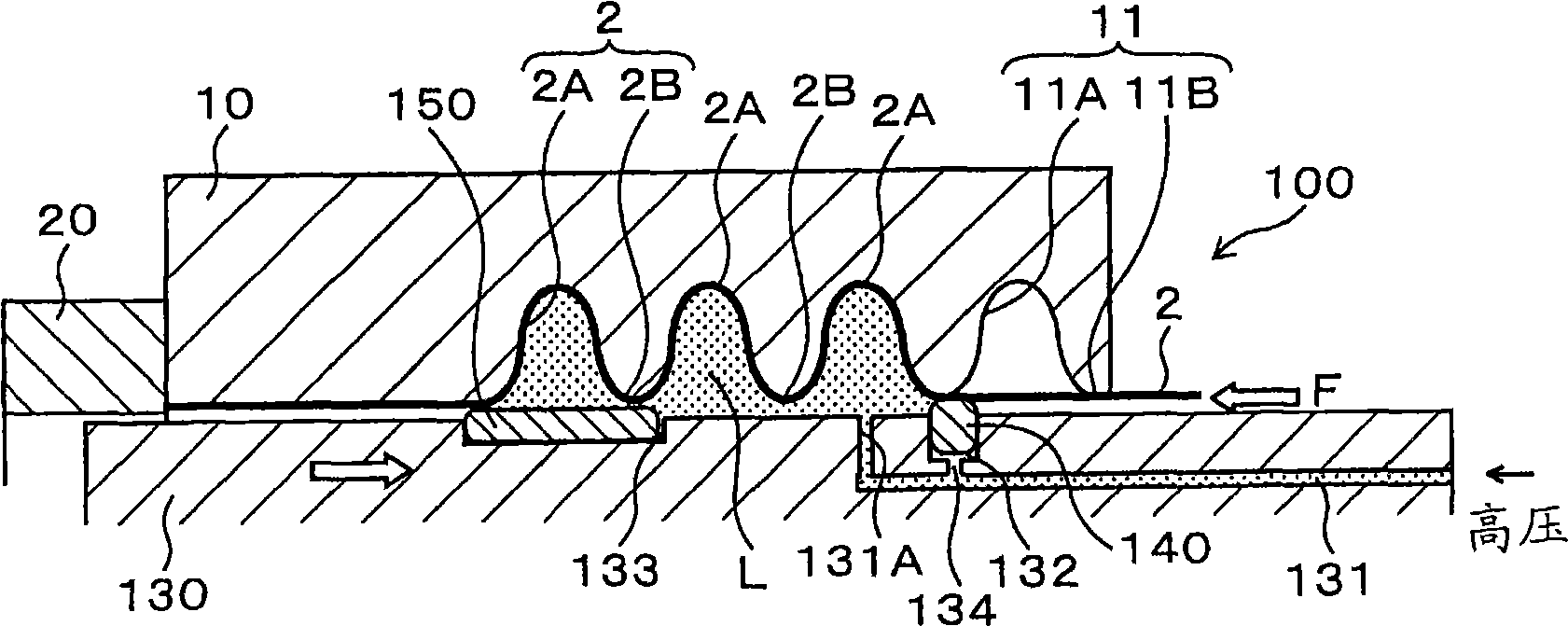

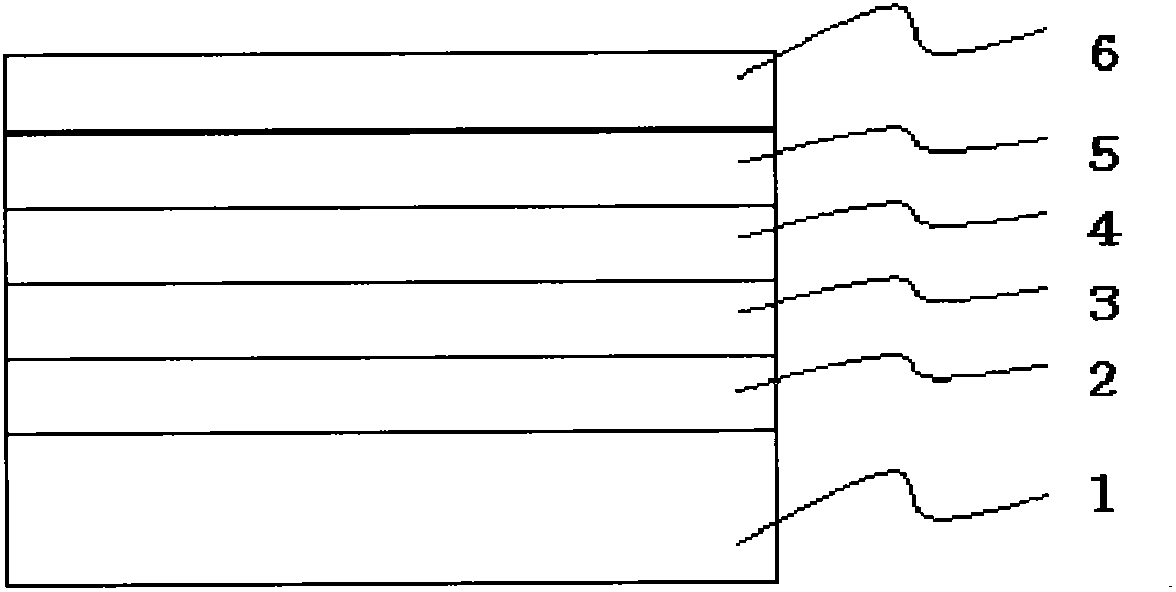

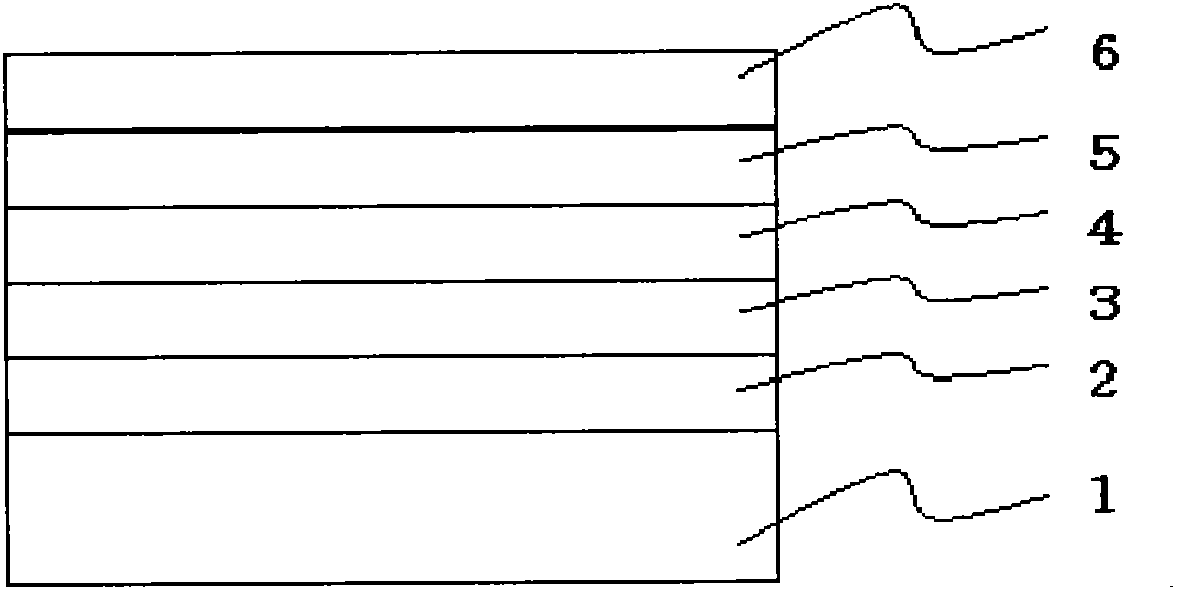

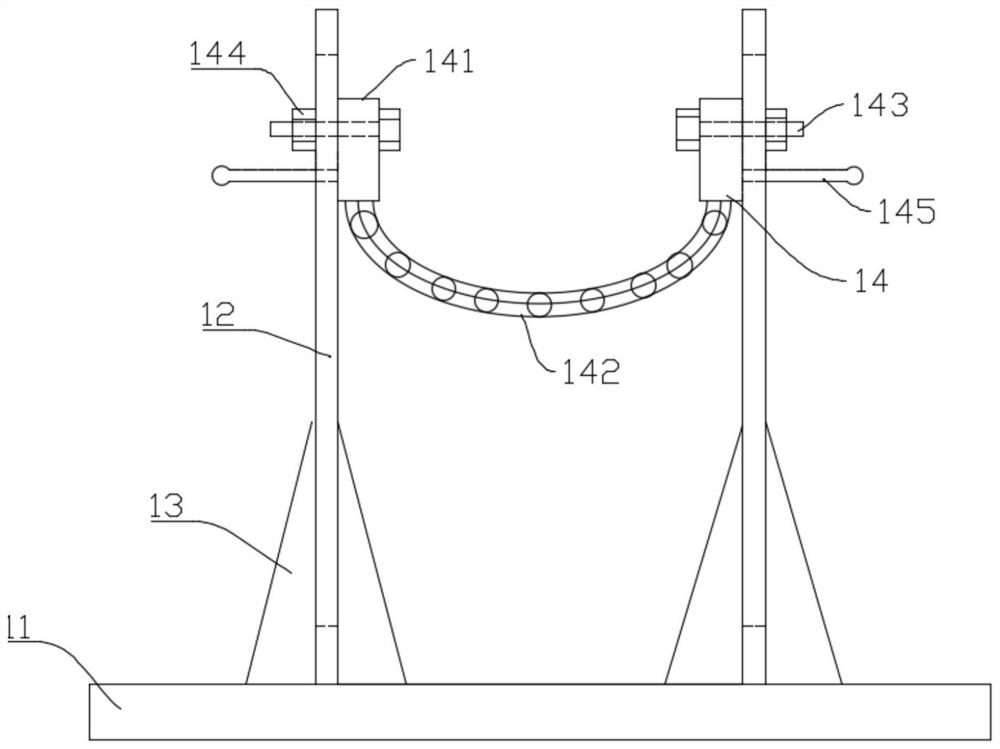

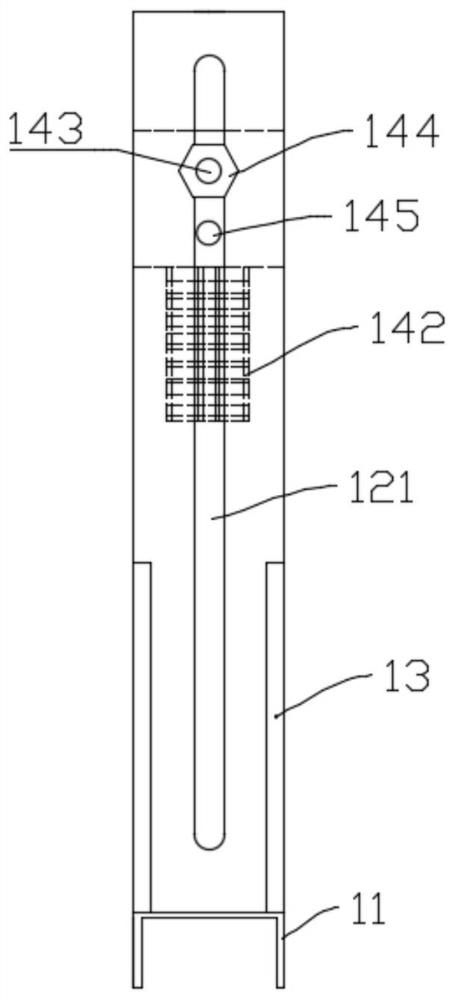

Bulge forming method and bulge forming apparatus

The invention provides a bulge forming method and bulge forming apparatus. The sealing portion (140) is in an anterior side of a forming direction is applied with liquid pressure of the pressurized liquid (L) in a direction from the rod (130) toward the raw material tube (2) so as to be followable to bulging of the raw material tube (2), which enables at least a part of the sealing portion (140) in close contact with the raw material tube (2) permanently. The distance between the sealing portions (140,150) is set to have a length of at least two crest portions of the inner surface shape (11) of the die (10), and a length in the axial direction of the sealing portion (150) in a posterior side of the forming direction is set to have a length of at least one crest portion of the inner surface shape (11) of the die (10). And thus the sealing portion (150) can always in close contact with any of the vale sections (2B) formed by the flat section of the raw material tube (2) and the raw material tube.

Owner:HONDA MOTOR CO LTD

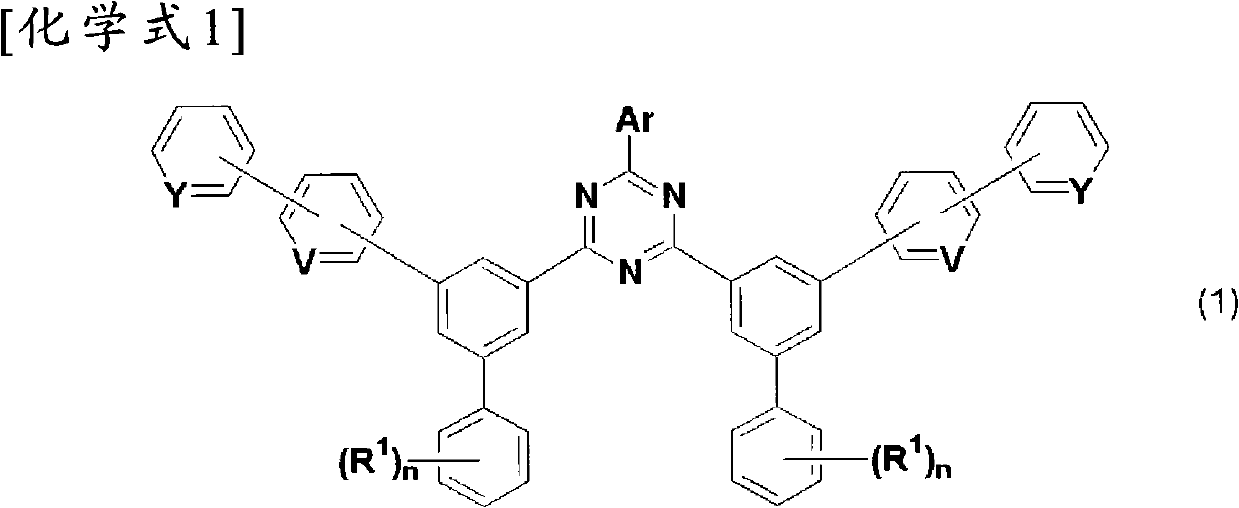

1,3,5-triazine derivatives, preparation method thereof, and organic electroluminescent device using them as constituents

ActiveCN102300859AImprove surface smoothnessImprove the setting effectOrganic chemistryElectroluminescent light sourcesArylHydrogen

A 1,3,5-triazine derivative represented by formula (1): wherein R 1 is hydrogen, C 1-4 alkyl group or substituted or unsubstituted phenyl group; n is an integer of 1-3, Ar is a substituted or unsubstituted aromatic hydrocarbon group, provided that Ar is different from two substituted quarterarylenyl groups bonded to the 1, 3 , 5-triazine ring; and V and Y are nitrogen or carbon, provided that a case where both of V and Y are carbon atoms is excluded. The organic electroluminescent device comprising the 1,3,5-triazine derivative as an electron transport material has a long lifetime.

Owner:TOSOH CORP +1

Two-component split type composite FDY fiber and preparation method thereof

InactiveCN101845685ALoose molecular structureEasy accessMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyamideMicrofiber

The invention provides a two-component split type composite FDY fiber which is characterized in that he two components in the two-component composite DTY fiber are a polyester component and a polyamide component, wherein the polyester component is selected from one or more of polytrimethylene terephthalate, polybutylene terephthalate and cation normal-pressure dyeable polyester. The invention also provides a preparation method for preparing the split type composite FDY fiber, which comprises the following steps: respectively melting the polyester component and the polyamide component, then carrying out extrusion molding through a spinneret plate, cooling, applying oil, drafting and winding to obtain the two-component split type composite FDY fiber. The composite FDY fiber and the two-component superfine fiber fabric which are prepared by the method have the characteristics of good dyeing property and soft texture.

Owner:XIAMEN HONGXIN SPECIAL FIBER CO LTD

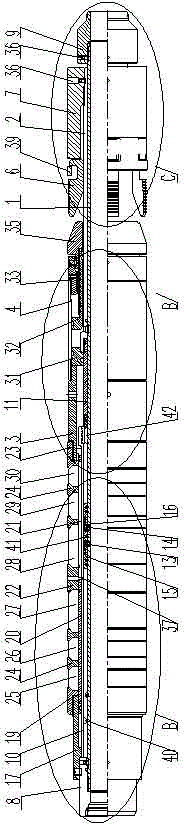

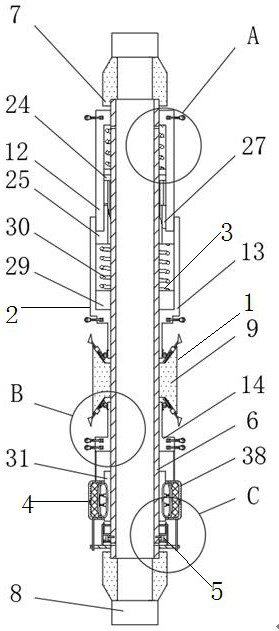

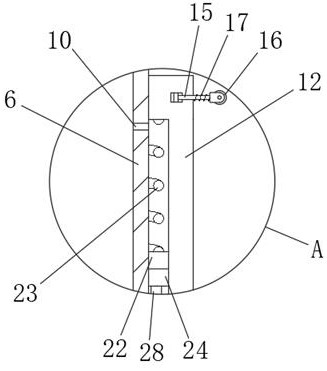

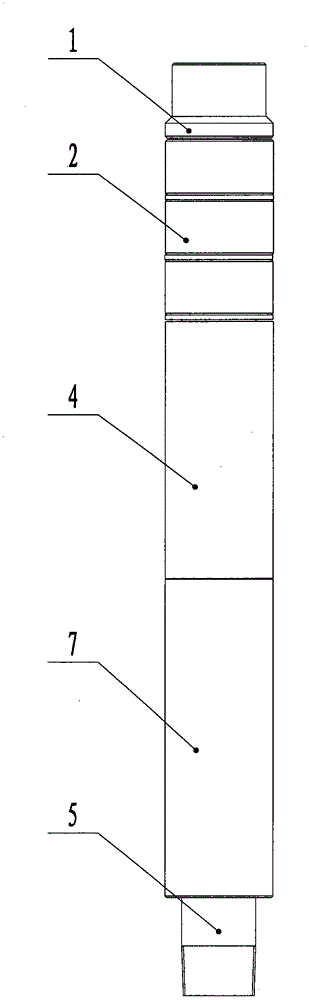

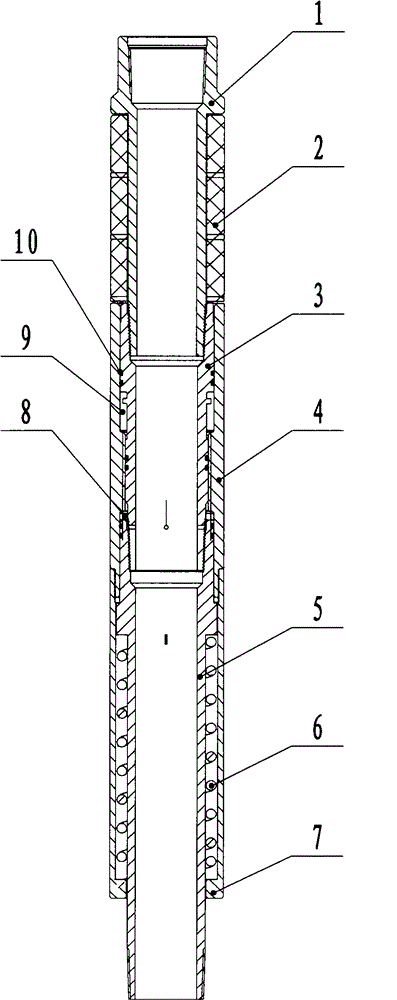

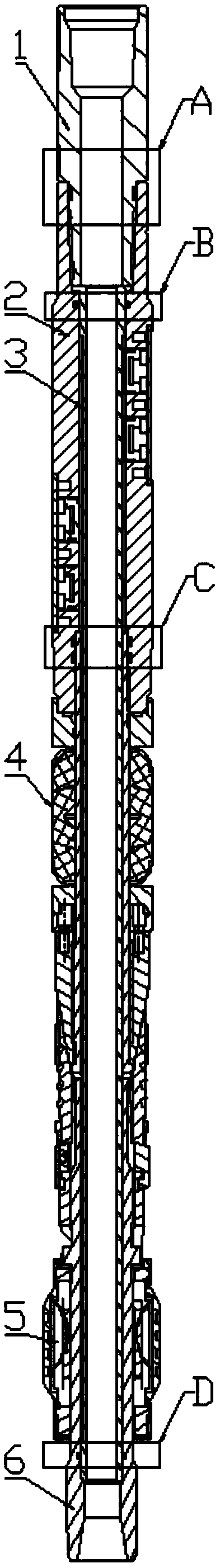

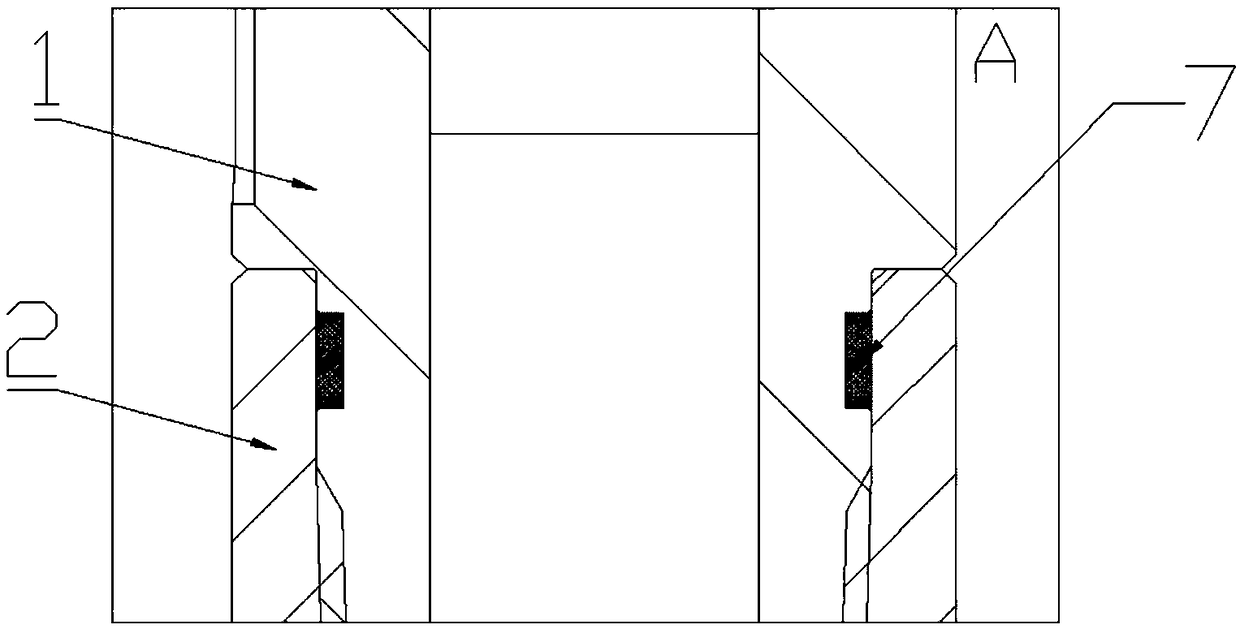

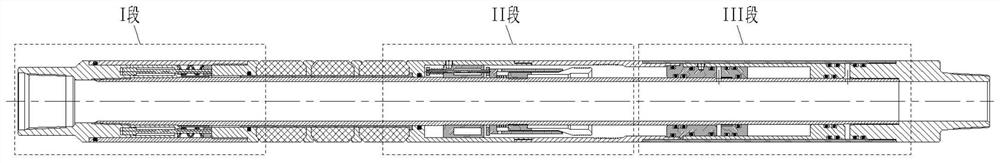

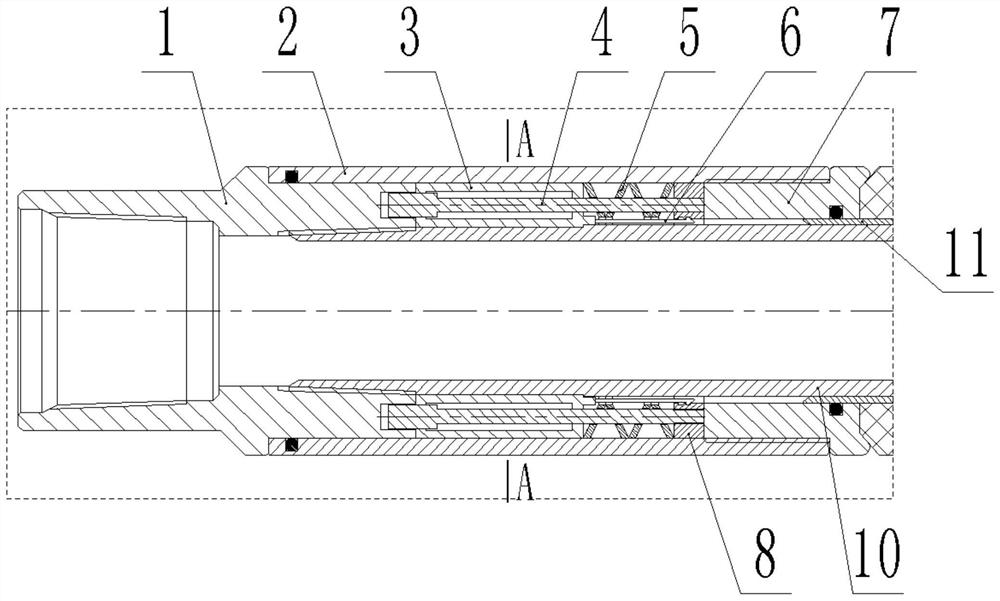

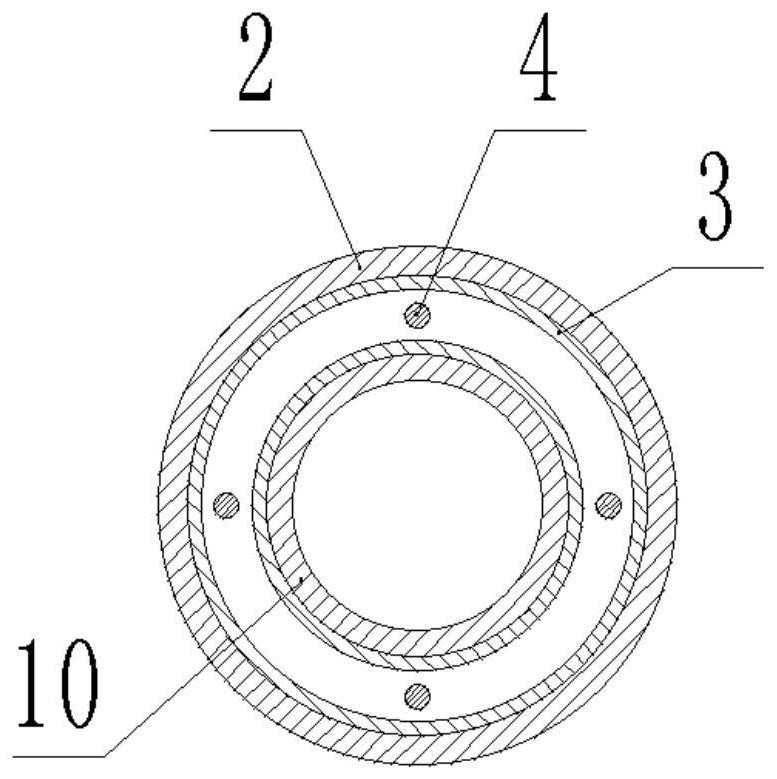

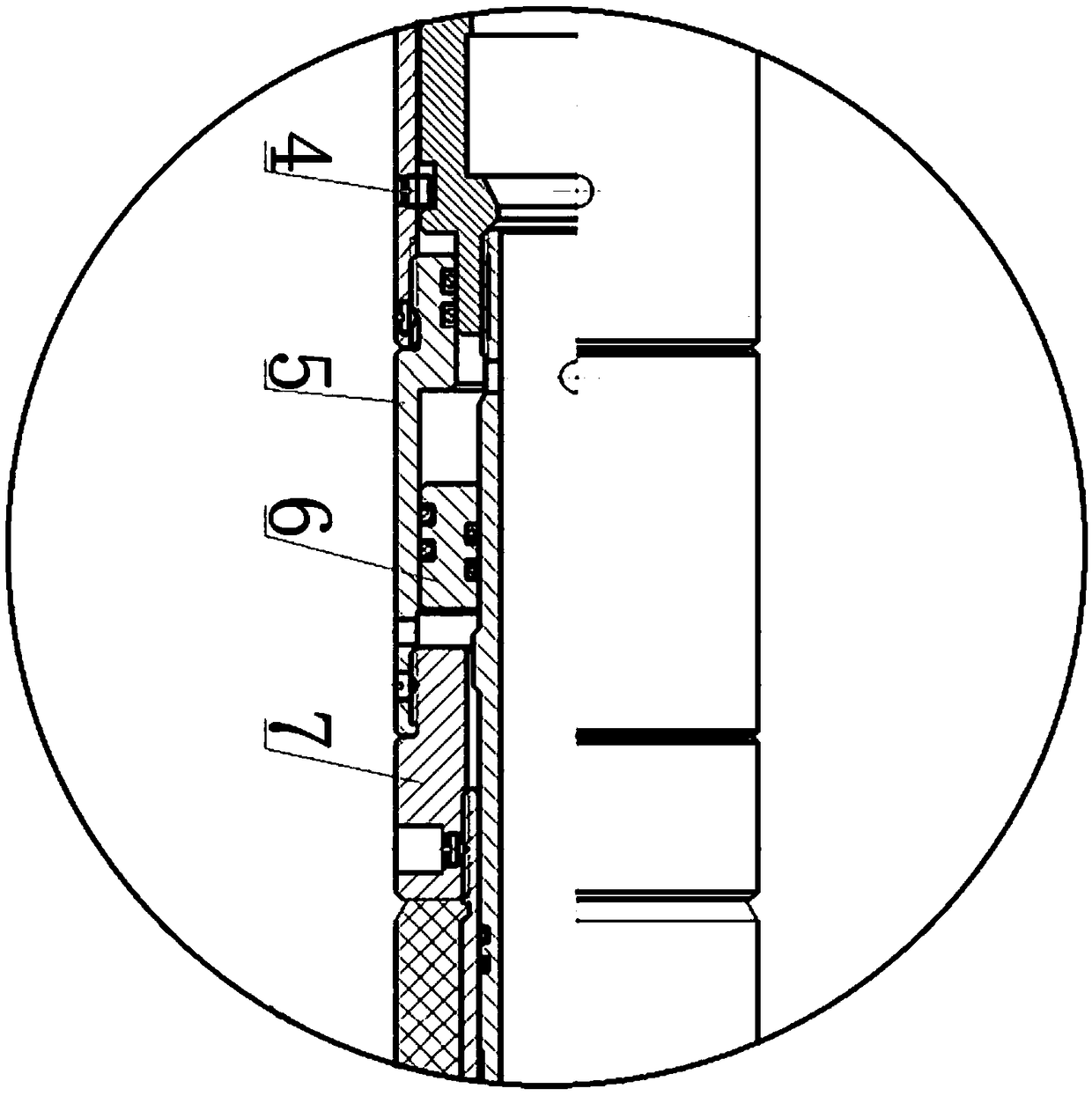

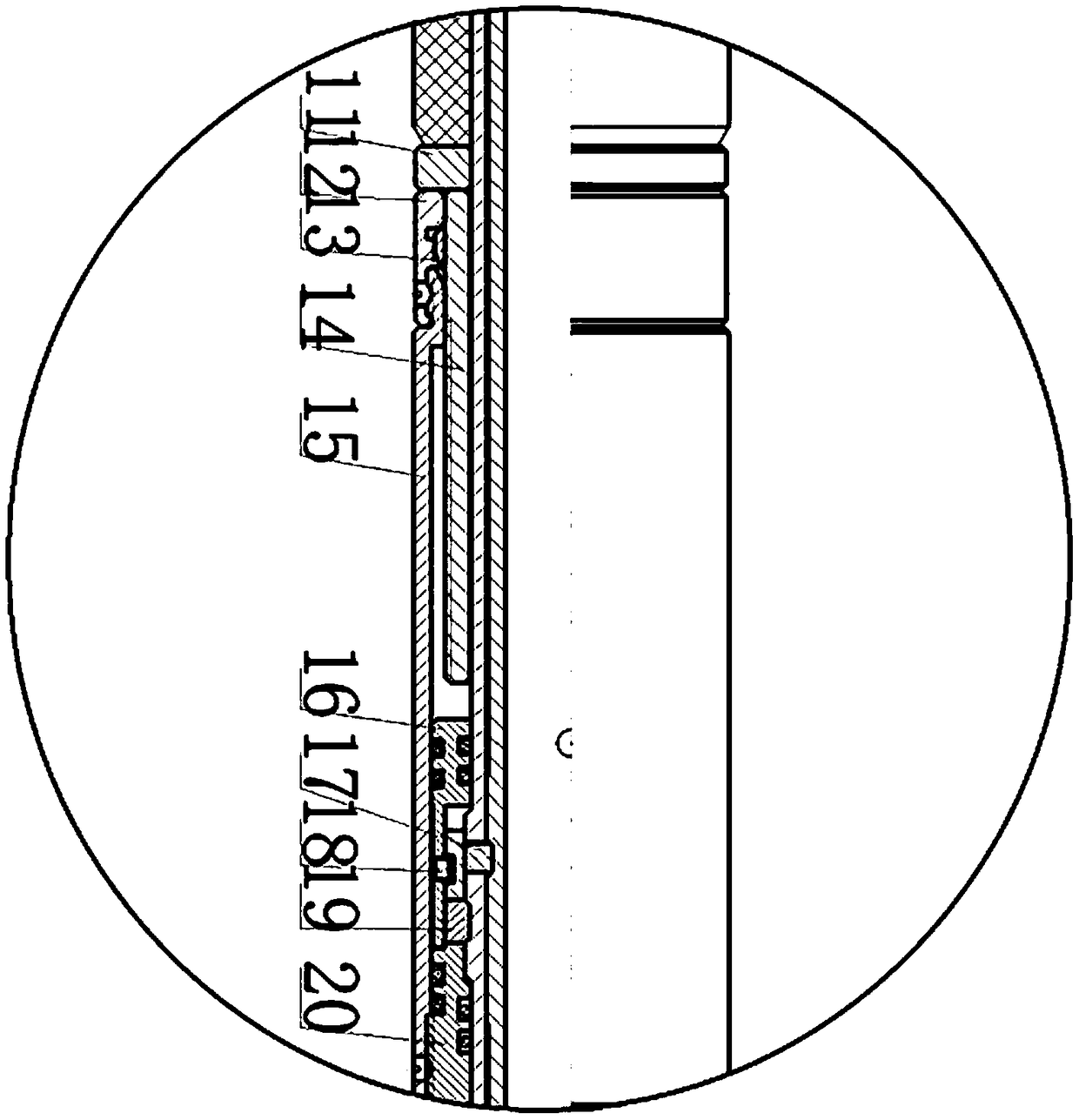

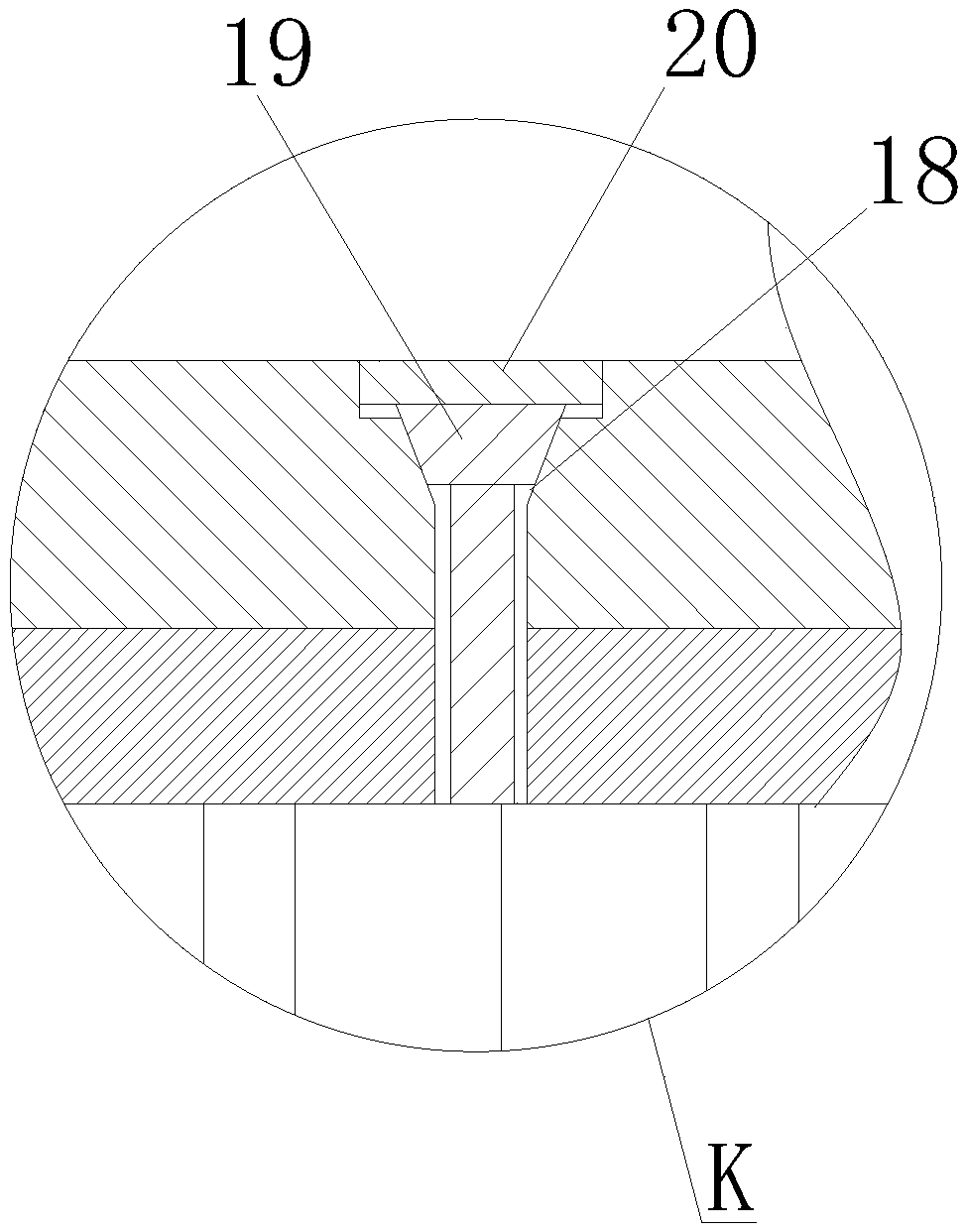

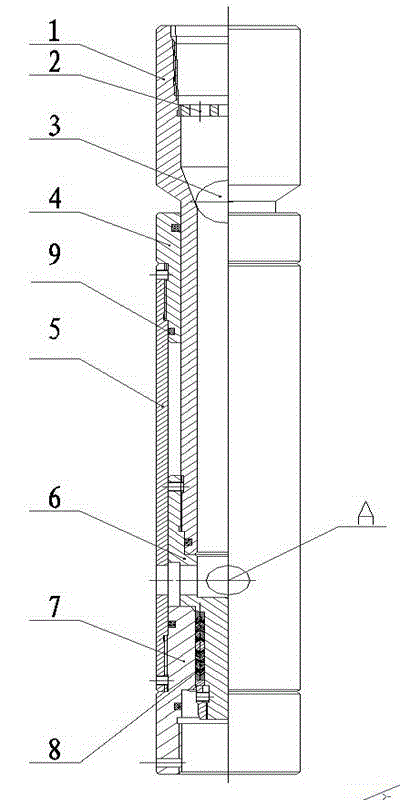

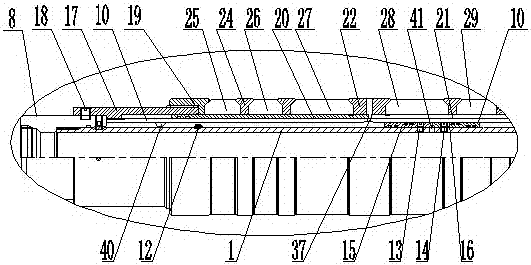

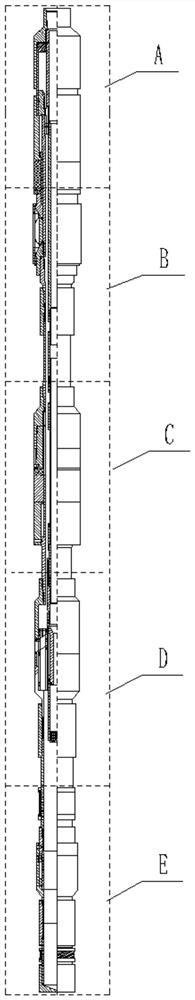

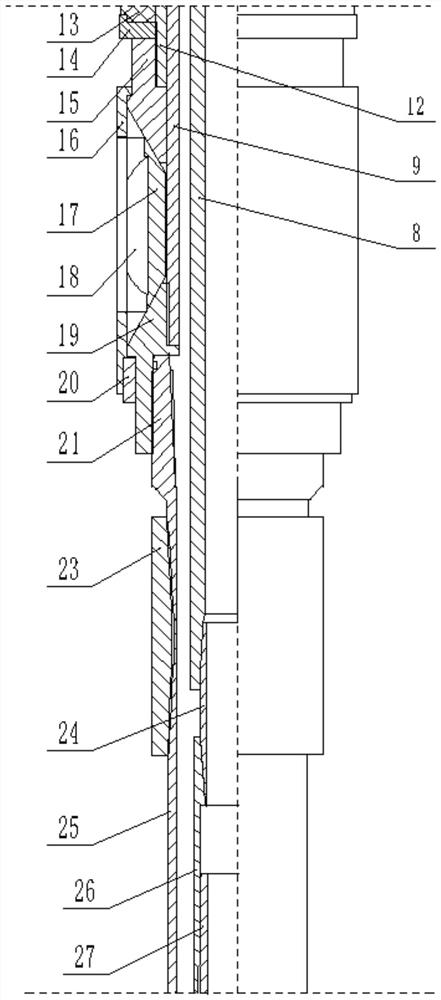

Self-seal-examining slip packer

InactiveCN104975820AThe sealing performance is safe and reliableGood setting effectSealing/packingEngineeringMechanical engineering

The invention relates to a self-seal-examining slip packer, and belongs to the field of oil-gas well operation downhole tools. The packer is composed of an inner center tube, an outer center tube, a slip and a slip sheath; an upper connector is installed at one end of the inner center tube through threads, a lower connector is installed at the other end of the inner center tube through threads, an inner piston sleeve, a releasing claw and the outer center tube are sequentially installed on the portion, between the upper connector and the lower connector, of the inner center tube, a balance connector is installed at one end of the inner piston sleeve through threads, an upper lining and a lower lining are sequentially installed on the portion, at the other end of the balance connector, of the inner piston sleeve, and a bypass connector is arranged between the upper lining and the lower lining; an upper guide ring is installed on the portion, at one side of the bypass connector, of the upper lining. Double packer element sealing is adopted in the packer in the setting process, sealing performance in the setting process is ensured, and the self-seal-examining slip packer is safer and more reliable, has the advantages of being easy and fast to operate and meets the requirement for blocking and partitioning an oil-string casing in oil field production.

Owner:荆州市赛瑞能源技术有限公司 +1

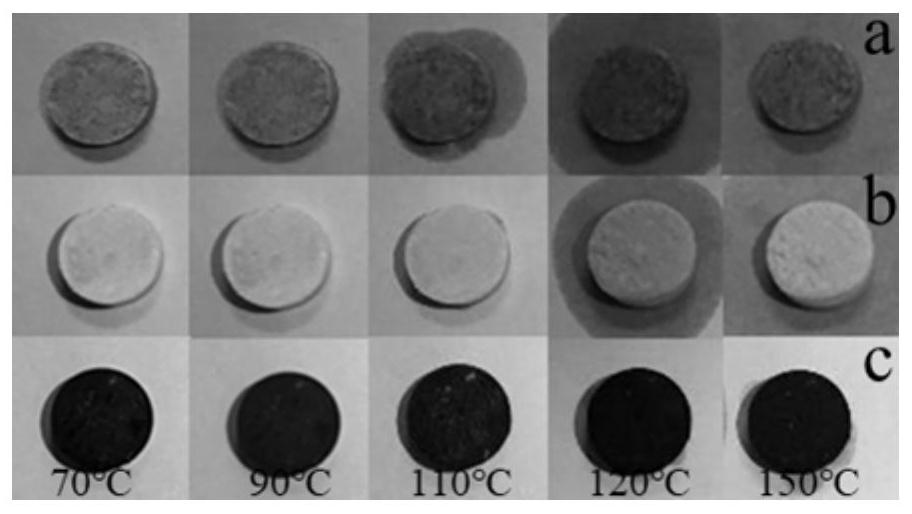

Epoxy resin composite shape-stabilized phase change material and preparation method and application thereof

ActiveCN111378250AImprove high temperature resistanceImprove thermal conductivityCigar manufactureHeat-exchange elementsFirming agentEpoxy resin composite

The invention discloses an epoxy resin-based composite shape-stabilized phase change material and a preparation method and application thereof. The epoxy resin-based composite shape-stabilized phase change material is prepared from 40-55% by mass of cured epoxy resin, 45-60% by mass of a phase change material and 0-10% by mass of a heat conduction material through a casting molding method, and a curing agent accounts for 33-36% of the cured epoxy resin. Due to good compatibility of the phase change material and epoxy resin and a polymer matrix with a three-dimensional cross-linked network structure formed after the epoxy resin is completely cured, the phase change material has the characteristics of excellent high-temperature resistance, solid-solid phase change and easiness in processingand preparation; the phase change material is converted from a crystalline state to an amorphous state, so that the material realizes the functions of heat absorption and energy storage; by adding theheat conduction material, the heat conduction property and the shape-stabilized property of the composite shape-stabilized phase change material are improved. The epoxy resin-based composite shape-stabilized phase change material is filled into an iQOS matched cigarette cooling section in the form of particles, so that the smoke temperature of the front one to three filter tip ends can be remarkably reduced.

Owner:NANTONG UNIVERSITY

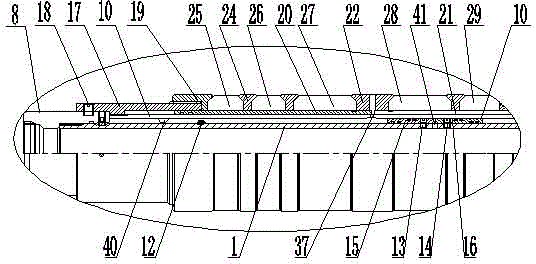

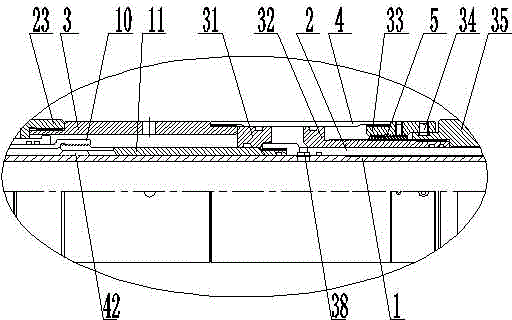

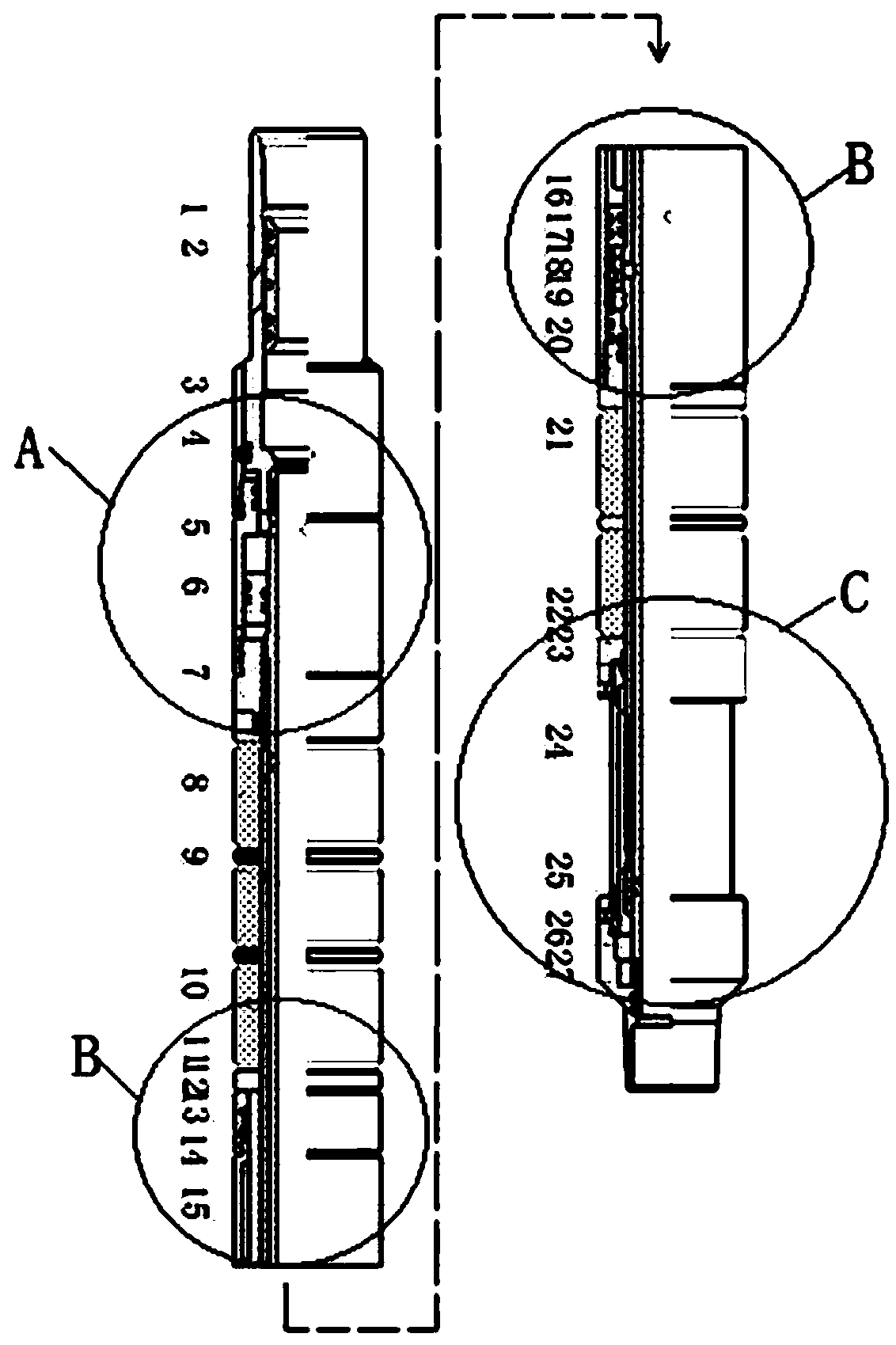

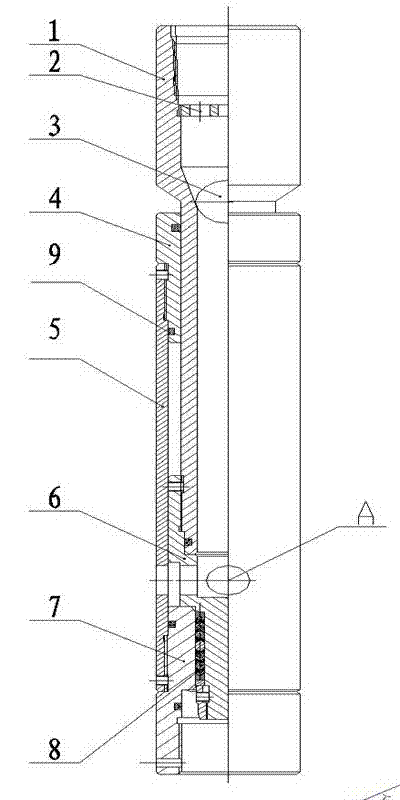

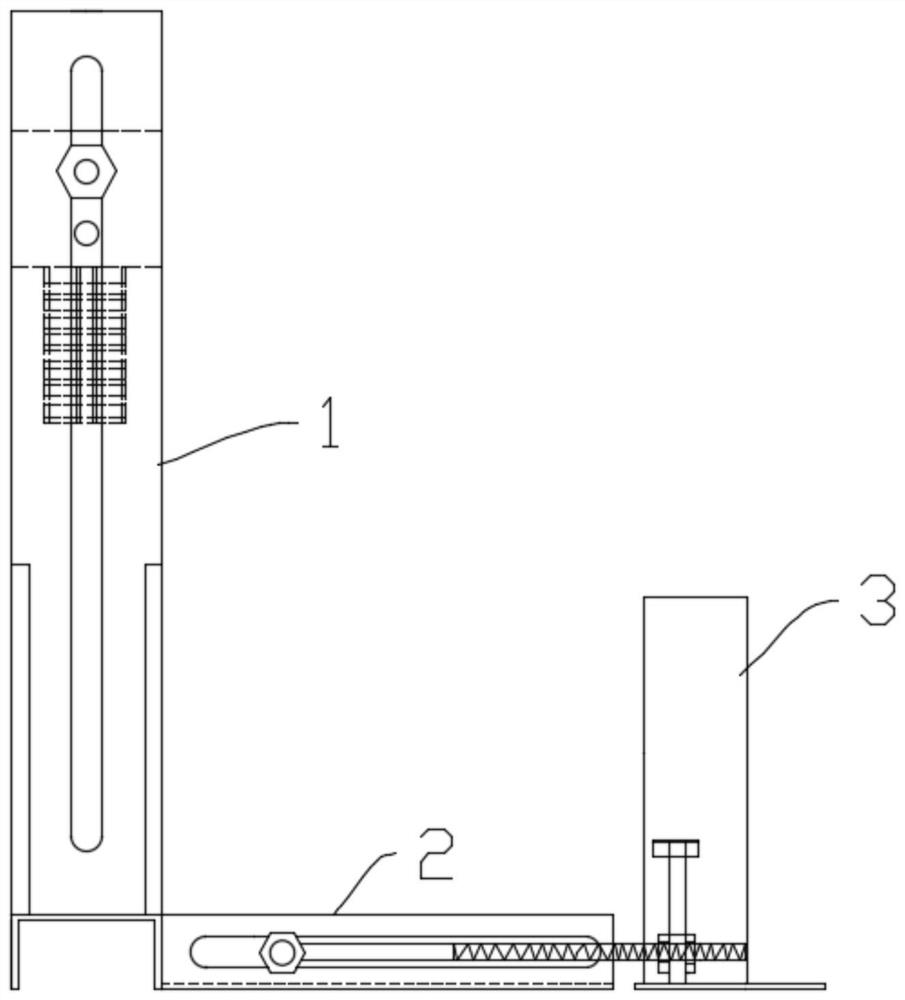

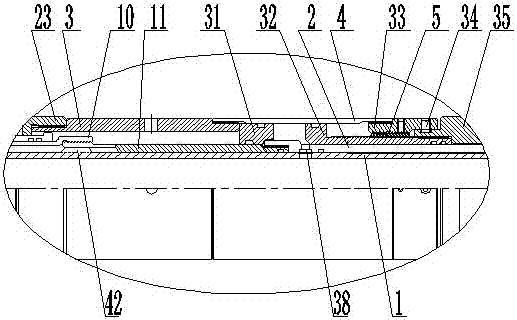

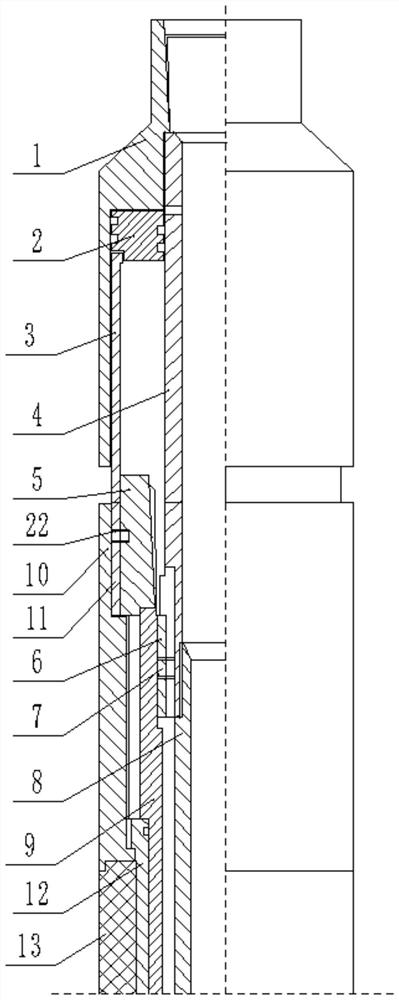

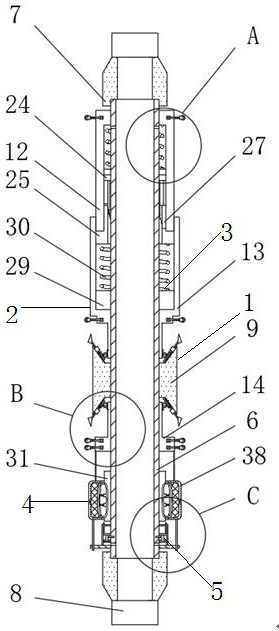

Combined integrated oilfield packer

InactiveCN112983336AImprove the setting effectEasy to operateDrilling rodsFlushingOil fieldStructural engineering

The invention provides a combined integrated oilfield packer, and relates to the technical field of oil and gas development. The combined integrated oilfield packer comprises a supporting assembly, a setting mechanism and an unsealing mechanism, wherein the supporting assembly comprises a central pipe, joints, a connecting ring, an adjusting cylinder, a first through hole and second through holes; the top end and the bottom end of the central pipe are fixedly connected with the joints; the outer side of the middle of the central pipe is fixedly connected with the adjusting cylinder; the second through holes are formed in the left side and the right side of the lower portion of the central pipe; the setting mechanism is matched with a centering mechanism and a rotating assembly to perform setting on the packer; and the unsealing mechanism is used for unsealing the packer. Oil liquid is injected into the central pipe, so that the oil liquid is pressed into the centering mechanism through the first through hole, and the centering mechanism is used for centering the packer; and meanwhile, the rotating assembly and the supporting assembly are matched with the centering mechanism to enable the setting mechanism to work, so that setting is completed, and the packer is convenient to center and set.

Owner:大安鸿源管业有限公司

Non-throttling Y344 type fracturing set packer

ActiveCN105625980AEasy to useEasy to controlFluid removalSealing/packingInteraction forcesEngineering

The invention discloses a non-throttling Y344 type fracturing set packer. The non-throttling Y344 type fracturing set packer comprises an upper connector, a rubber barrel, a slide block center pipe, a power slide block, a spring center pipe, a spring, a spring driving shell, a hydraulic cavity, an air cavity and a sealing ring. The inner diameter and the outer diameter of the sealed air cavity and the inner diameter and the outer diameter of the hydraulic cavity communicating with the center pipe are maintained to be the same so as to ensure that the area of the interaction force is the same. In the construction process, differential pressure exists between the air cavity and the hydraulic cavity and is a power source for achieving set packing of the rubber barrel. The set packing mode of the rubber barrel is only related to pressure inside a pipe column and not influenced by the differential pressure of the inside and the outside of the pipe column and the flow quantity and the flow velocity of liquid inside the pipe column, and set packing is achieved without sandblaster throttling. Therefore, the set packer can provide a possibility for large displacement sandblasting of the sandblaster. When the sandblasting amount of the maximum drift diameter of the set packer is achieved, due to the fact that the drift diameter is increased, the flow velocity of liquid containing sand inside a tool is decreased, and abrasion to an assembly in the pipe column is reduced; accordingly, the service lift of the tool is prolonged, the use security is improved, and the working efficiency and the construction quality are improved.

Owner:盐城市畅海精密机械有限公司

Low-deformation plate rolling machine

PendingCN114472626AEffective Surface PreservationImprove molding qualityClassical mechanicsEngineering

The invention belongs to the field of veneer reeling machines, and discloses a low-deformation veneer reeling machine which comprises a veneer reeling machine body, a supporting force rear plate is fixedly installed at the rear end of the veneer reeling machine body, a pair of cavity conversion sliding seats is slidably connected to the upper end of the supporting force rear plate, gooseneck hollow pipes are fixedly connected to the upper ends of the cavity conversion sliding seats, and the gooseneck hollow pipes are fixedly connected to the lower ends of the cavity conversion sliding seats. The right end of the gooseneck hollow pipe is fixedly connected with an isolation connector, the right end of the isolation connector is fixedly connected with an arc-shaped isolation supporting plate, and a pair of force bearing grooves are formed in the right end of the arc-shaped isolation supporting plate. Buffer and reverse acting force support is provided for a bent plate, the influence of deformation force of the plate and the pressure of a follow-up plate bending machine is reduced, the curved surface of the bent plate is effectively kept, the forming quality of the plate is improved, the bending precision of the plate is improved, and development of the plate bending machine body towards high-precision machining is facilitated.

Owner:HT METALFORMING EQUIP MFG

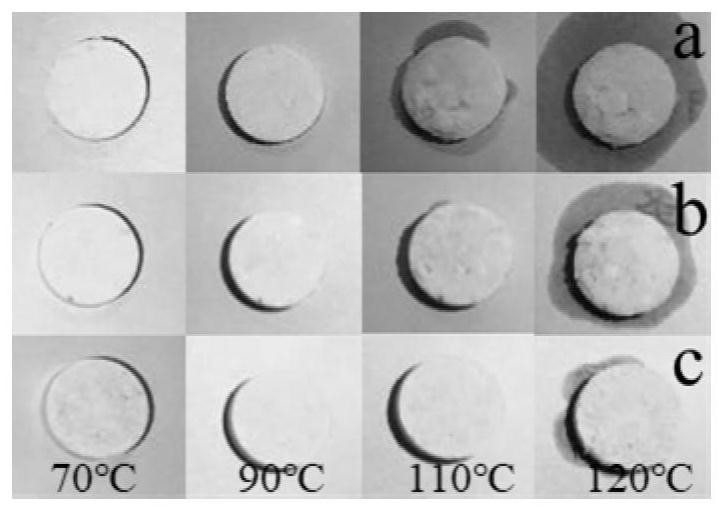

Small-sized packer capable of resisting high temperature and pressure

PendingCN109356547AImprove protectionAvoid rheologySealing/packingHigh pressureTemperature resistance

The invention relates to a small-sized packer capable of resisting the high temperature and pressure. The small-sized packer comprises a volume pipe and an outer central pipe which sleeves one end ofthe volume pipe;a plurality of first sealing assemblies which are mutually arranged in parallel are arranged between the volume pipe and the outer central pipe; each first sealing assembly comprises at least two sealing rings and blocking rings with the number being one more than the sealing rings; and the two sides of the sealing rings are clamped with the blocking rings correspondingly. The blocking rings made of materials with better high temperature resistance and rheological resistance effects are arranged on the two sides of the sealing rings, the sealing rings and the blocking rings canbe mutually matched with each other, good protection action can be provided for the sealing rings, the facts that the rheological phenomenon of the sealing rings due to softening under the tested high temperature and high pressure conditions, and the rheological sealing rings flow out from gaps between assemblies are avoided, thus sealing performance of thesealing rings is better, occurrence of the conditions of weakening and failure of the setting effect is avoided, and thus high temperature and high pressure resistance performance of the packer is ensured; and meanwhile a bevel cutting structure of the blocking rings is utilized, and thus the problem of difficult assembly caused by selection of blocking rings is solved.

Owner:成都托克密封件有限责任公司

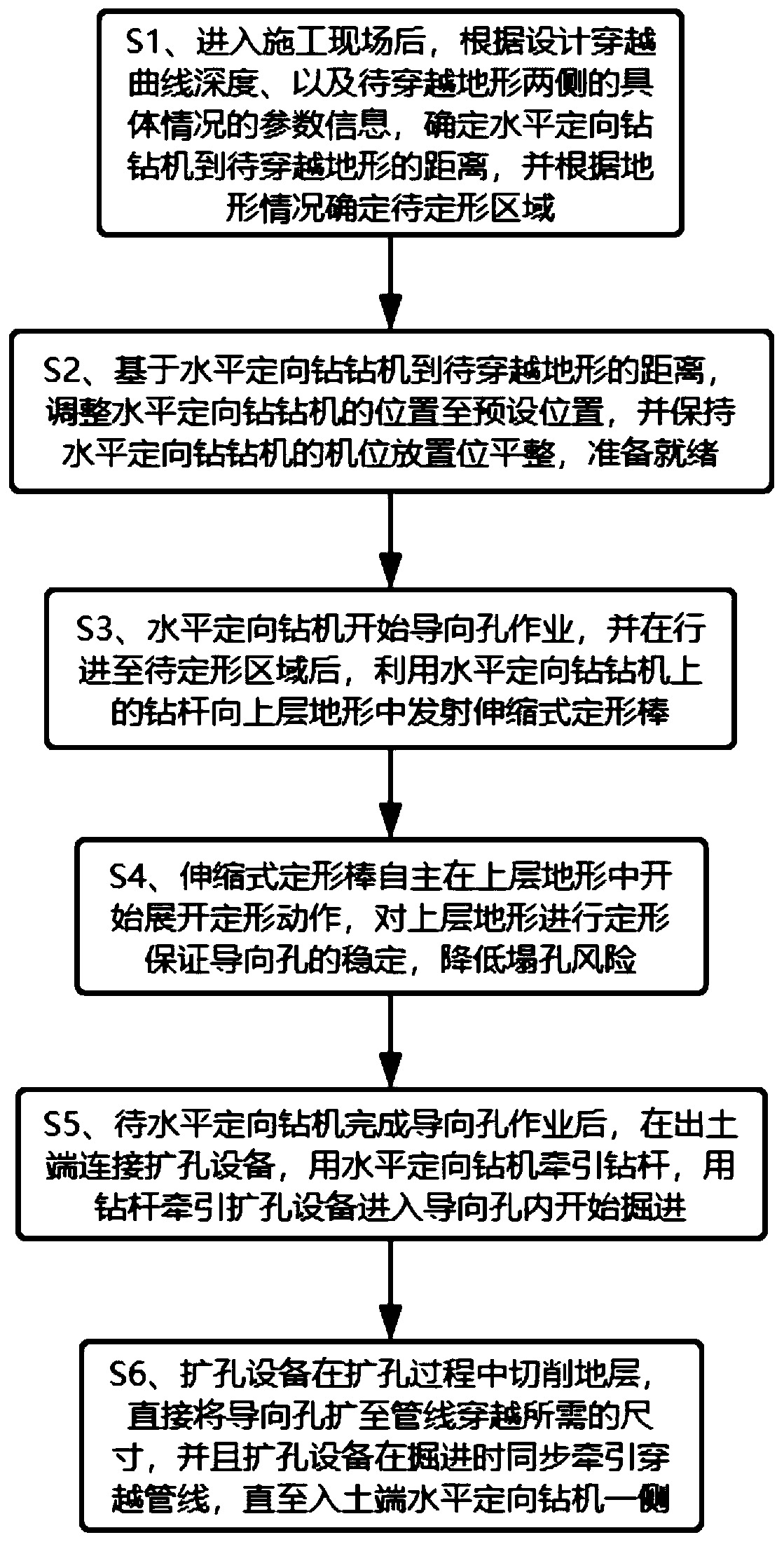

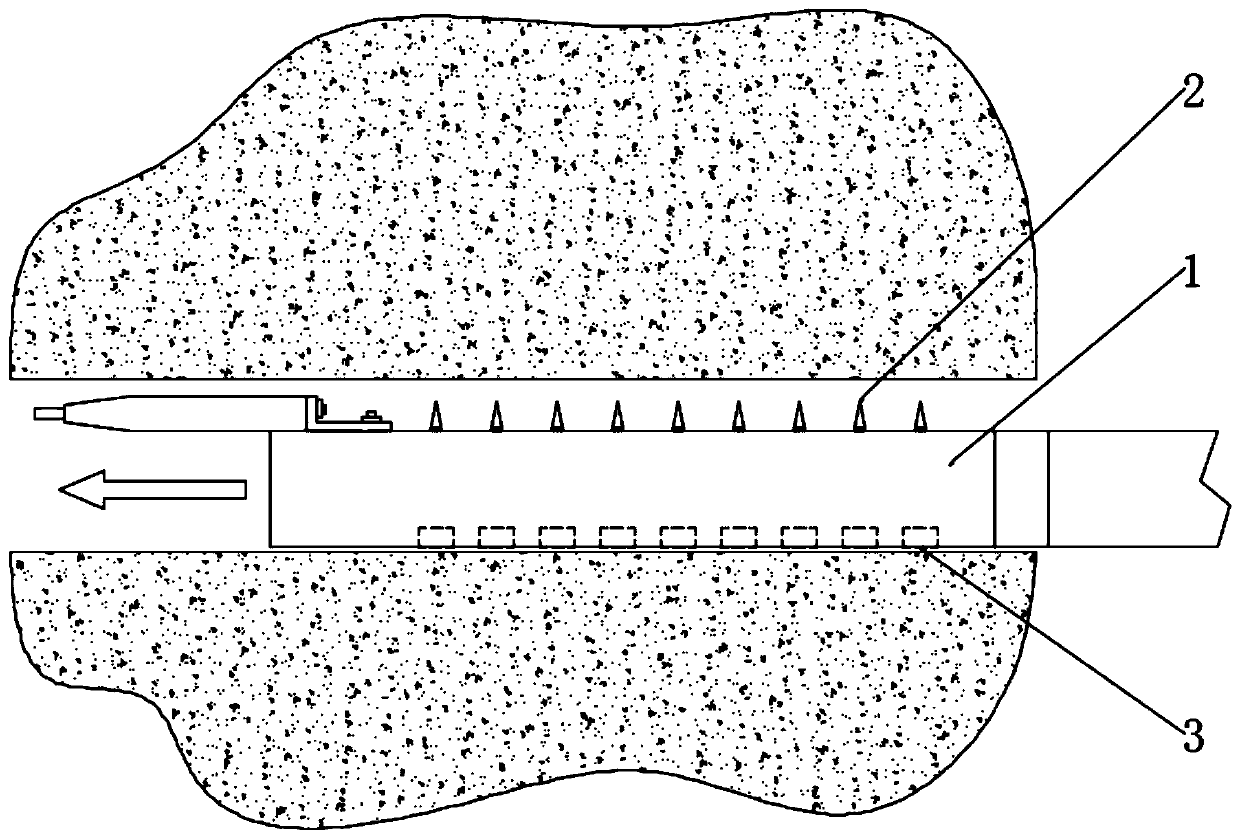

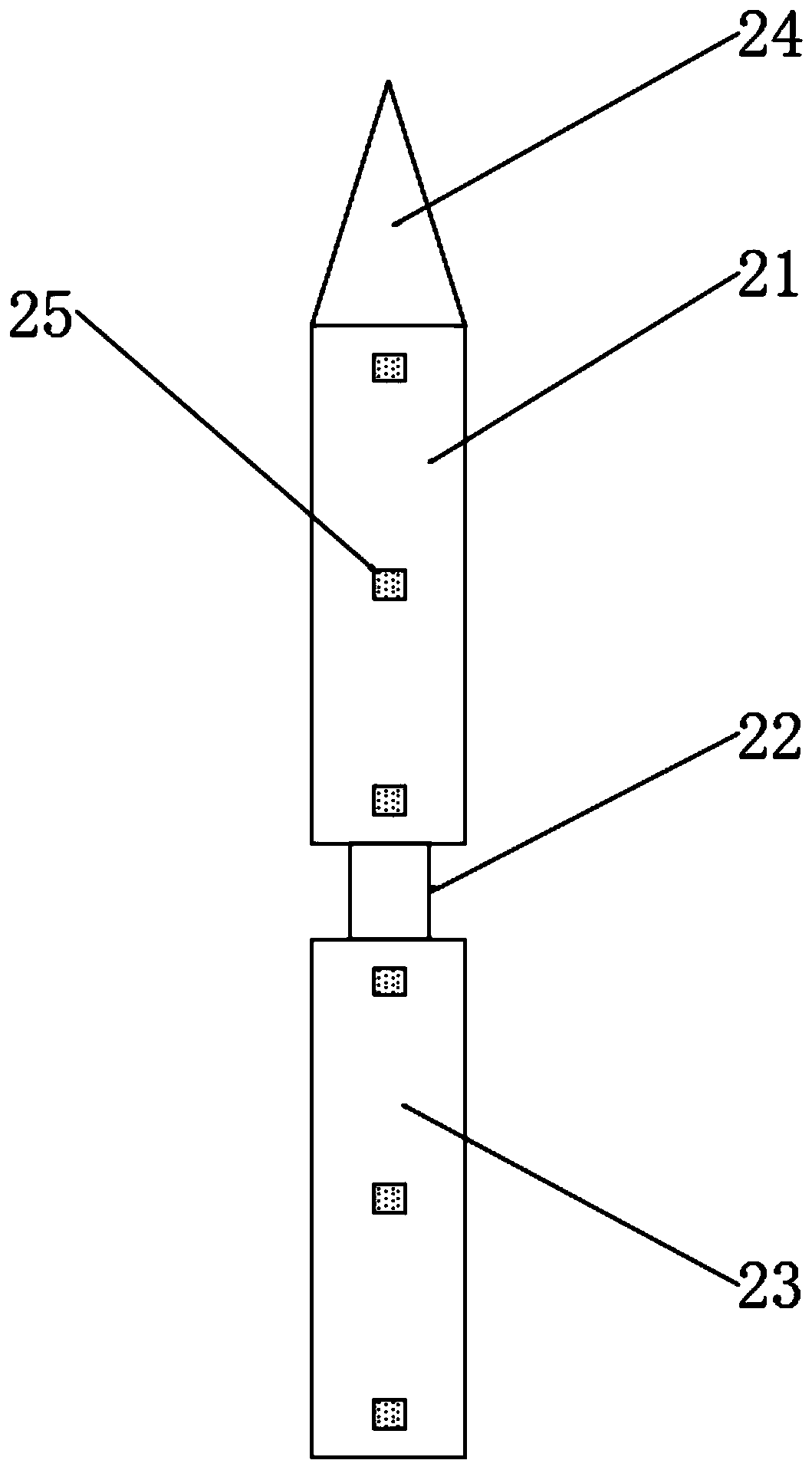

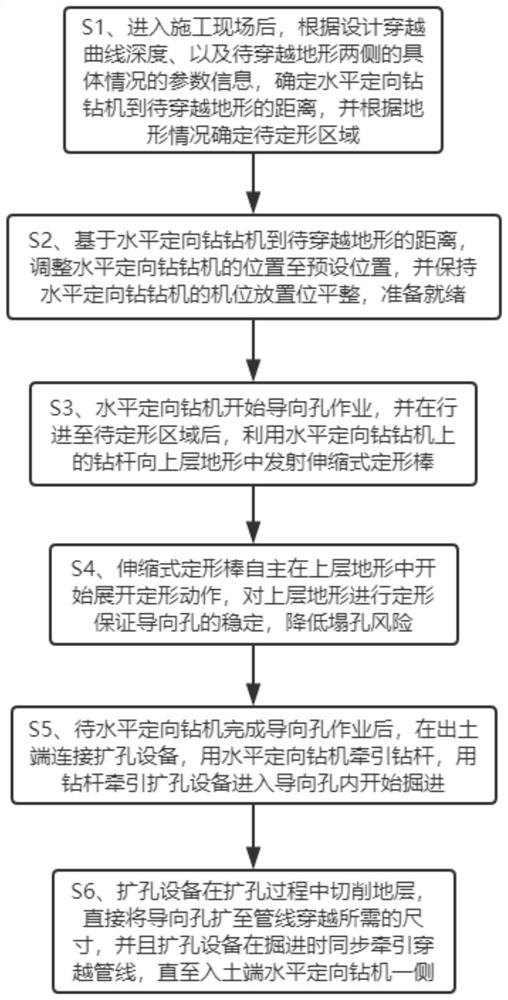

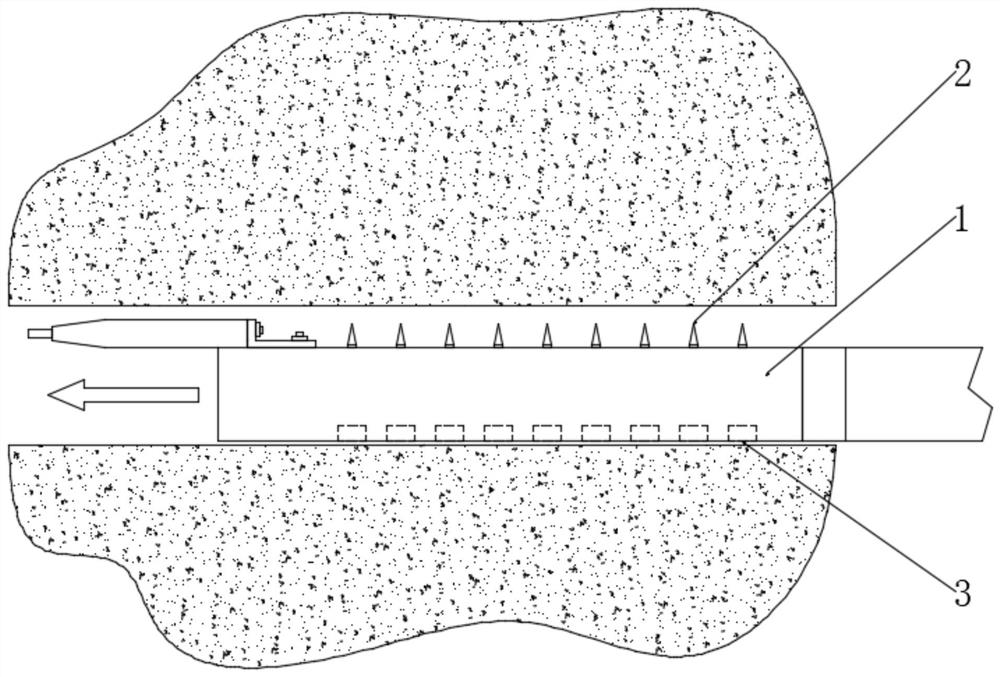

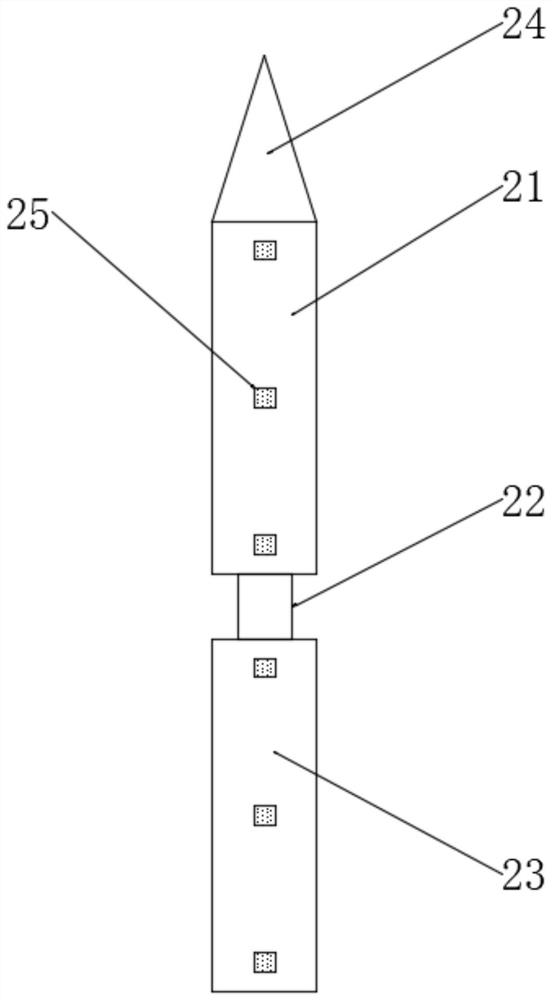

Novel horizontal directional drilling crossing percussive rotary drilling method

ActiveCN111520074AReduce the risk of hole collapseHigh gripEarth drilling toolsInsulationTerrainDrill hole

The invention discloses a novel horizontal directional drilling crossing percussive rotary drilling method, and belongs to the technical field of oil and gas pipeline horizontal directional drilling crossing and oil gas drilling and production. According to the novel horizontal directional drilling crossing percussive rotary drilling method, a loose stratum area can be determined after explorationand analysis of a crossing terrain, an existing drill rod is equipped with a corresponding number of retractable setting rods, after drilling to the loose stratum area, the retractable setting rods go deep into an upper terrain and trigger and unfold setting action by launching the retractable setting rods vertically upward, a plurality of setting triggering hands extend from the retractable setting rods to the surrounding area, the gripping force of the terrain is improved, effective connection of upper and lower areas of the loose stratum is realized, the stability of drill hole walls is improved, the risk of hole collapse is obviously reduced, the terrain strength near a pipeline is improved when the pipeline is reamed and dragged back, the risk of pipeline settlement is reduced, and the safety and stability of construction are greatly improved.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE +1

Oil field underground packer

The invention relates to an oil field underground packer, and relates to the technical field of oil field underground tools. The oil field underground packer comprises an upper connector, a central pipe, a liner pipe, a rubber sleeve component, an upper baffle ring, a lower baffle ring, a setting mechanism and a lower connector, wherein the upper end and the lower end of the central pipe are respectively in threaded connection with the upper connector and the lower connector; the liner pipe slidably sleeves the outer side of the central pipe; the rubber sleeve component sleeves the outer side of the liner pipe; an upper outer sleeve is in threaded connection with the outer side of the upper part of the upper baffle ring of a rubber sleeve; the upper outer sleeve is in sliding sealing fit with the upper connector; a snap spring sleeve is in threaded connection with the lower end of the lower baffle ring. annular spaces are reserved between the lower baffle ring and the central pipe and between the lower baffle ring and the central pipe; and snap spring claws, unlocking sleeves and unsealing mechanisms are arranged in the annular spaces. The invention provides the oil field underground packer capable of being set and unset repeatedly, which has the two advantages of good packing effect and large well washing channel section.

Owner:金亿中天科技开发有限公司

Double-rubber-barrel packer

The invention relates to a double-rubber-barrel packer. The double-rubber-barrel packer comprises an upper joint, a lower joint and a center tube, wherein the center tube is sleeved with an outer tube; the outer tube is sleeved with an upper rubber barrel and a lower rubber barrel, and the outer tube is sleeved with a lower cylinder sleeve between the upper rubber barrel and the lower rubber barrel; an upper compression sleeve for compressing the upper rubber barrel upwards and a lower piston for compressing the lower rubber barrel downwards are arranged between the lower cylinder sleeve and the outer tube; setting sealing liquid inlet holes are correspondingly formed in the positions, between the upper compression sleeve and the lower piston, of the center tube and the outer tube; the lower cylinder sleeve and the upper compression sleeve are correspondingly provided with locking structures which are locked in a matched mode, the lower cylinder sleeve is fixedly connected with the lower piston, a sleeve unsealing assembly is arranged on the position, on the upper side of the upper rubber barrel, of the outer tube, and the center tube is provided with a lifting and hanging structure which is matched with the sleeve unsealing assembly to drive the sleeve unsealing assembly to ascend to unseal the upper rubber barrel when the center tube is lifted; and an unsealing seat assemblyis arranged on the position, on the lower side of the lower rubber barrel, of the outer tube, when the central tube is lifted, the unsealing seat assembly can be driven downwards by a pipe column on the lower side of the lower joint to unseal the lower rubber barrel. The double-rubber-barrel packer has simple unsealing operation and good unsealing effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

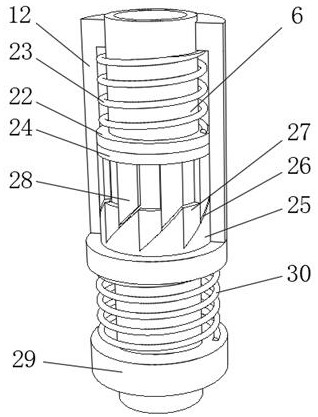

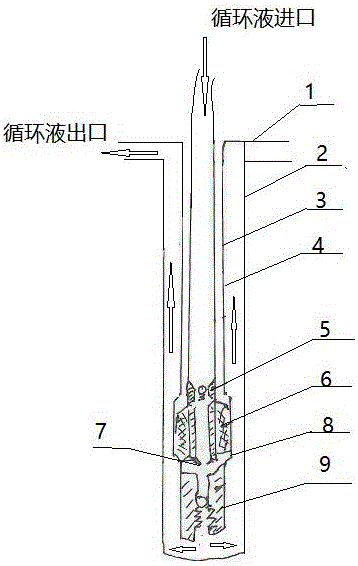

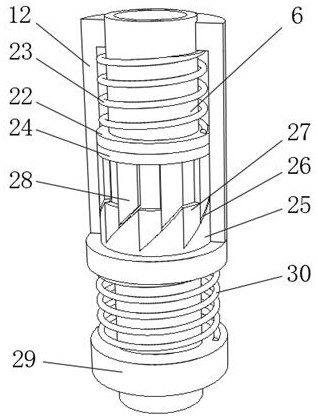

Pressure-balancing one-way valve for coiled-tubing layering fracturing

ActiveCN102926704AFunction as a one-way valveEasy to blast and perforateFlushingWell/borehole valve arrangementsUpper jointCoiled tubing

The invention discloses a pressure-balancing one-way valve for coiled-tubing layering fracturing. The pressure-balancing one-way valve comprises an upper joint, a limiting connecting sleeve, a body, a sealing head and a lower joint which are successively connected, wherein the inner part of the upper joint is of a hole-shrinkage cavity structure, a check ring and a sealing ball are mounted in a cavity in the upper part of the upper joint, the sealing ball is mounted at a hole shrinkage part, the check ring is mounted above the sealing ball, the lower end of the upper joint is fixedly connected with the sealing head and the sealing head is sleeved on the upper joint, the limiting connecting sleeve is sleeved on the upper joint, the body is sleeved on the limiting connecting sleeve and the sealing head and fixedly connected with the limiting connecting sleeve, a sliding gap is formed between the sealing head and the limiting connecting sleeve, and the lower joint stretches into the lower end of the body and is fixedly connected with the body. The pressure-balancing one-way valve for coiled-tubing layering fracturing has the characteristic of simple structure; and due to the adoption of the pressure-balancing one-way valve for coiled-tubing layering fracturing, the effects of packing and setting of an annular mechanical packer can be effectively improved, the setting and the packing are facilitated, and the abrasive perforating and the reverse-circulation sand-washing deblocking of a sand blower are facilitated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Continuous casing running operation circulation device and method

ActiveCN106223857AEnsure safetySatisfy the hollowed out stateDrilling machines and methodsWell drillingEngineering

The invention provides a continuous casing running operation circulation device which comprises a borehole and a casing. The casing, a special nipple and a float collar form a casing string, the lower ends of the special nipple and the float collar are sequentially connected, the casing string is positioned in the borehole, a continuous tube is arranged in the casing, a packer is connected at the lower end of the continuous tube and positioned in the special nipple, a one-way valve is arranged between the packer and the continuous tube, and an inner cavity of the special nipple is (good in smooth finish and sealing effect). When a pump is started to circulate on the ground, well drilling liquid reaches a well bottom through the continuous tube, the one-way valve and the packer and returns to a well mouth from an annular space between the borehole and the casing, so that underground circulation is finished, the device can realize halfway circulation, the inside of the casing cannot be completely filled with the well drilling liquid, and the actual load of the casing string cannot be increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

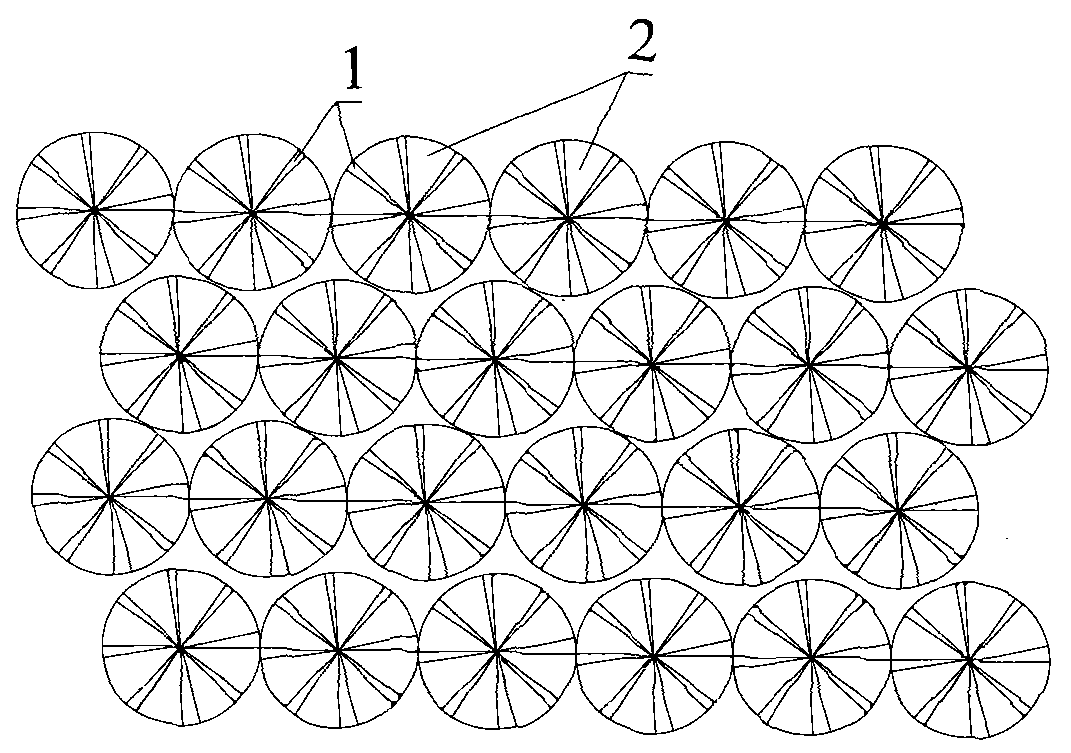

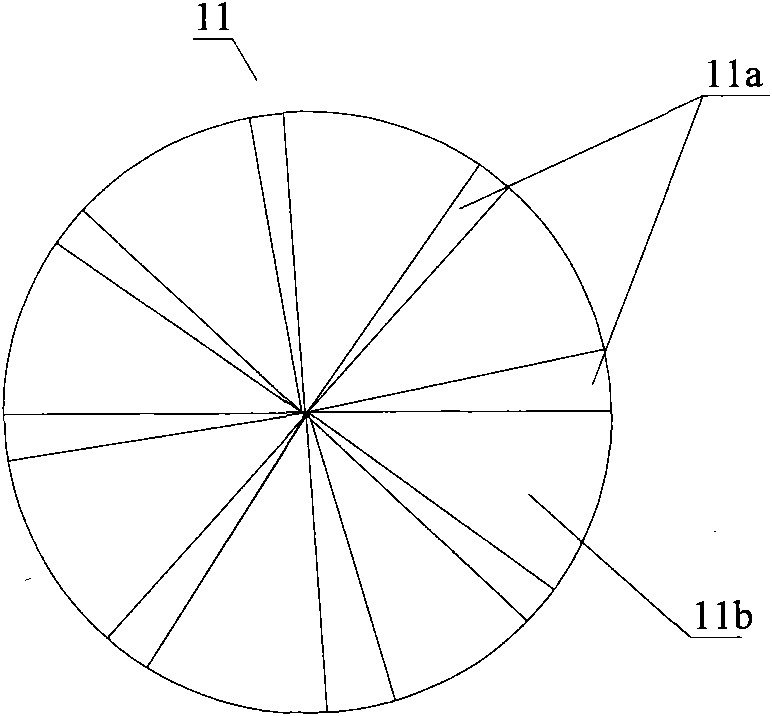

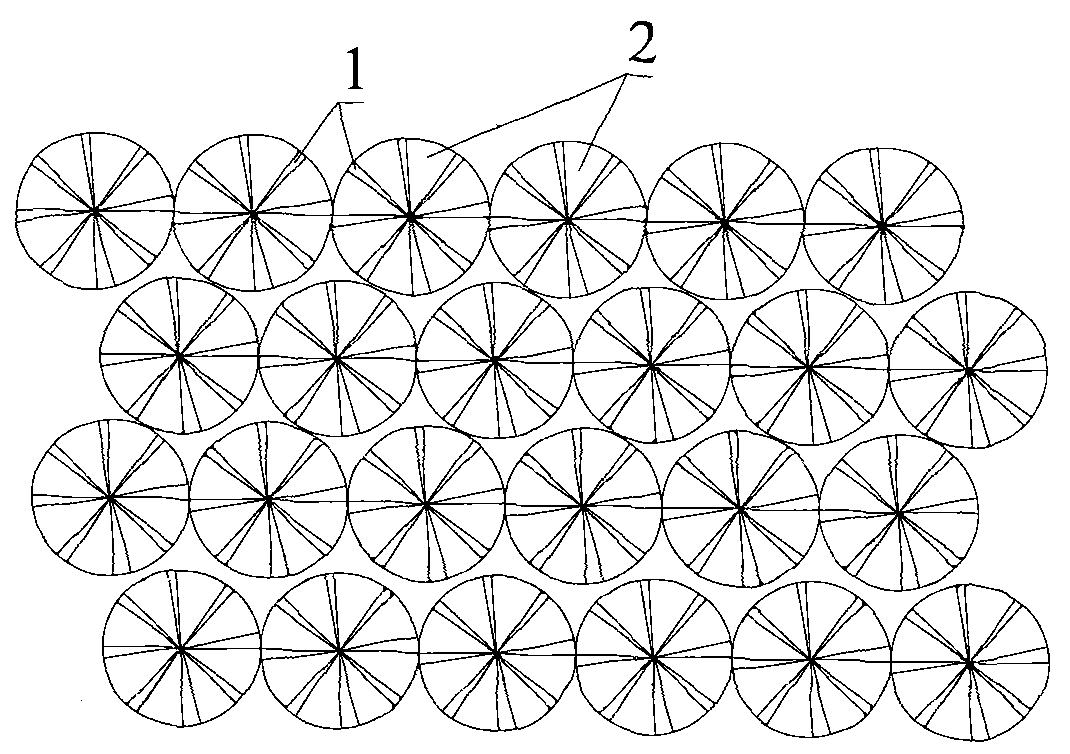

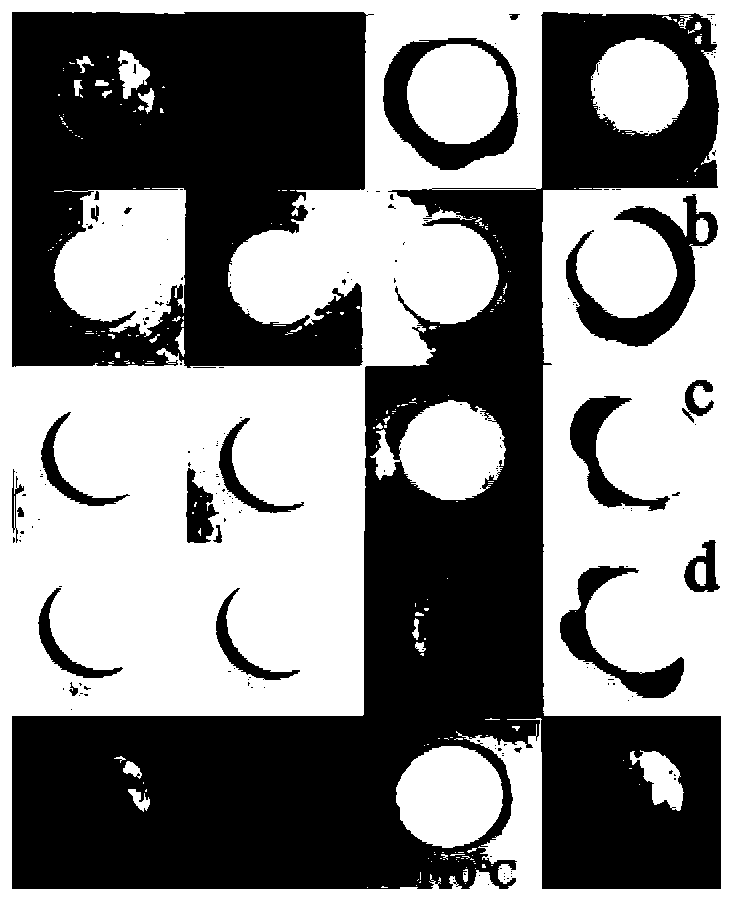

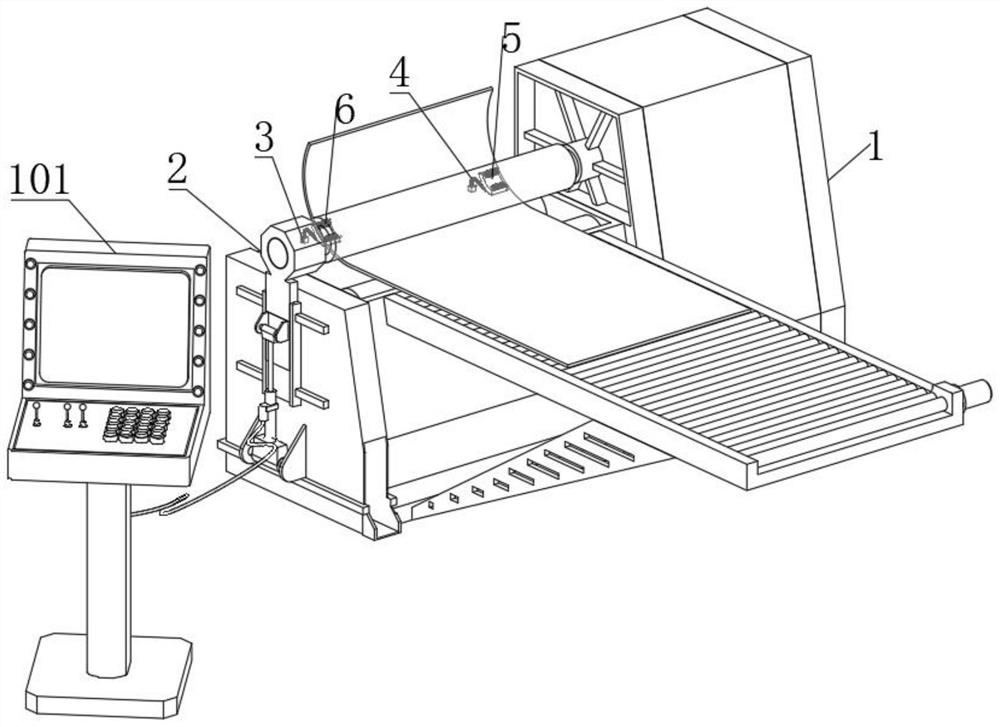

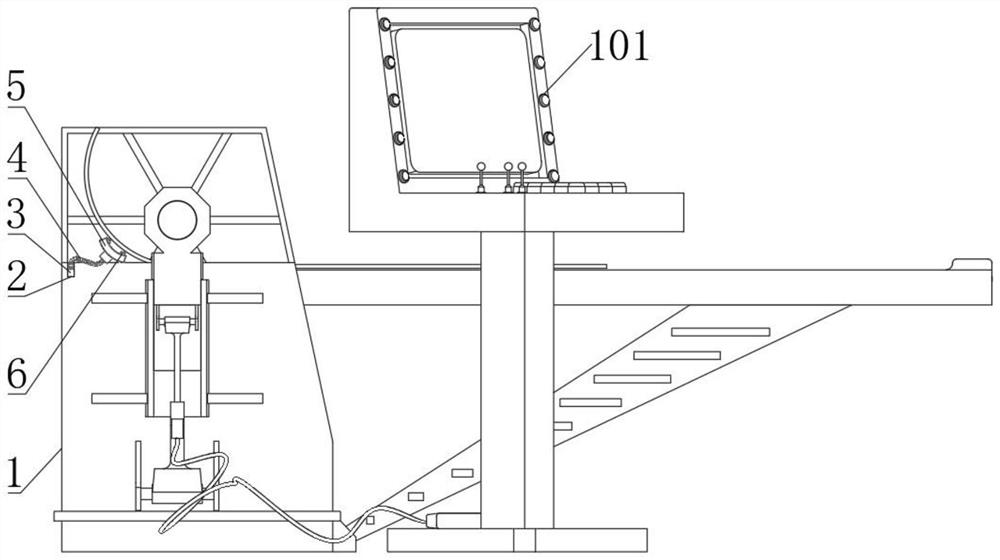

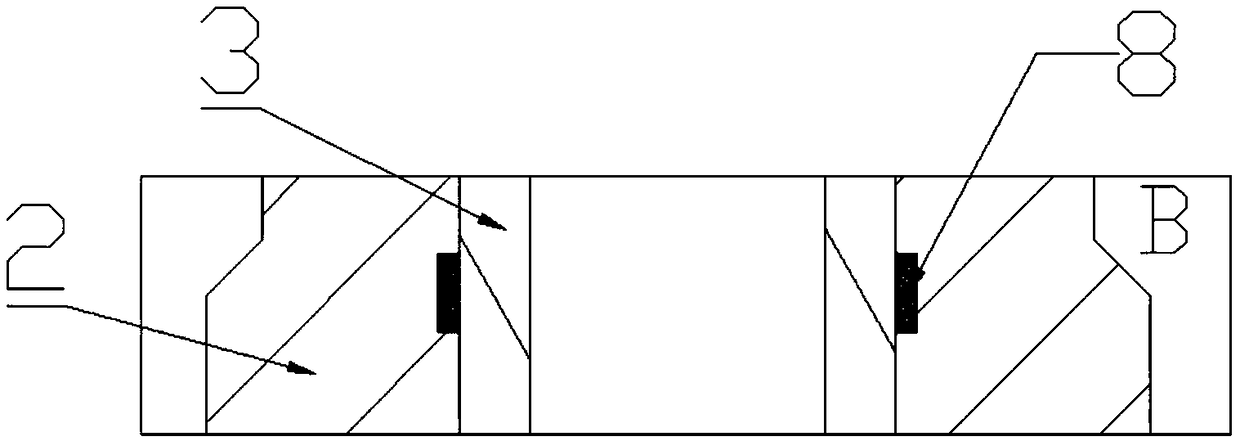

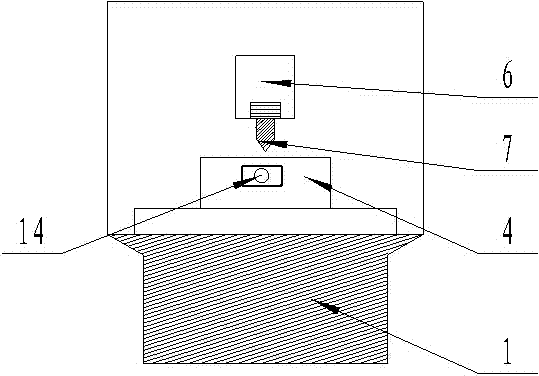

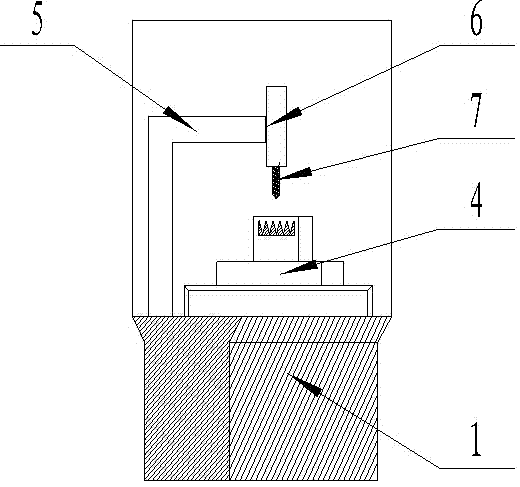

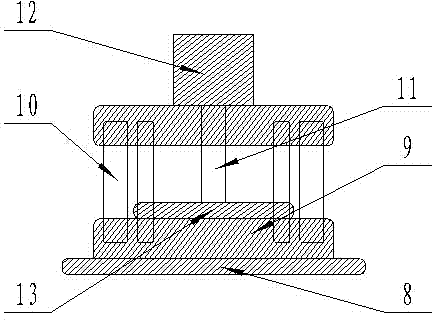

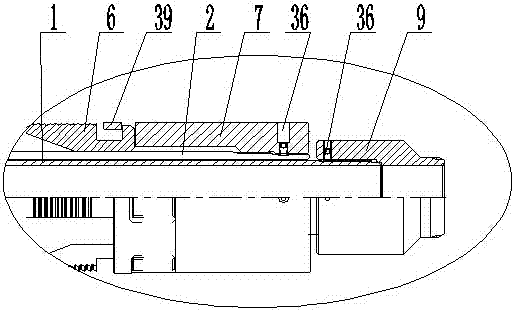

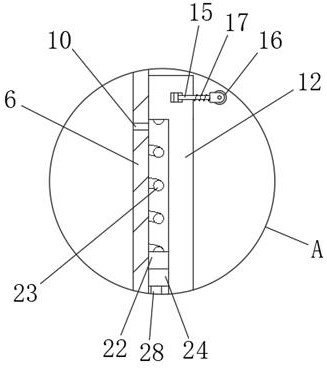

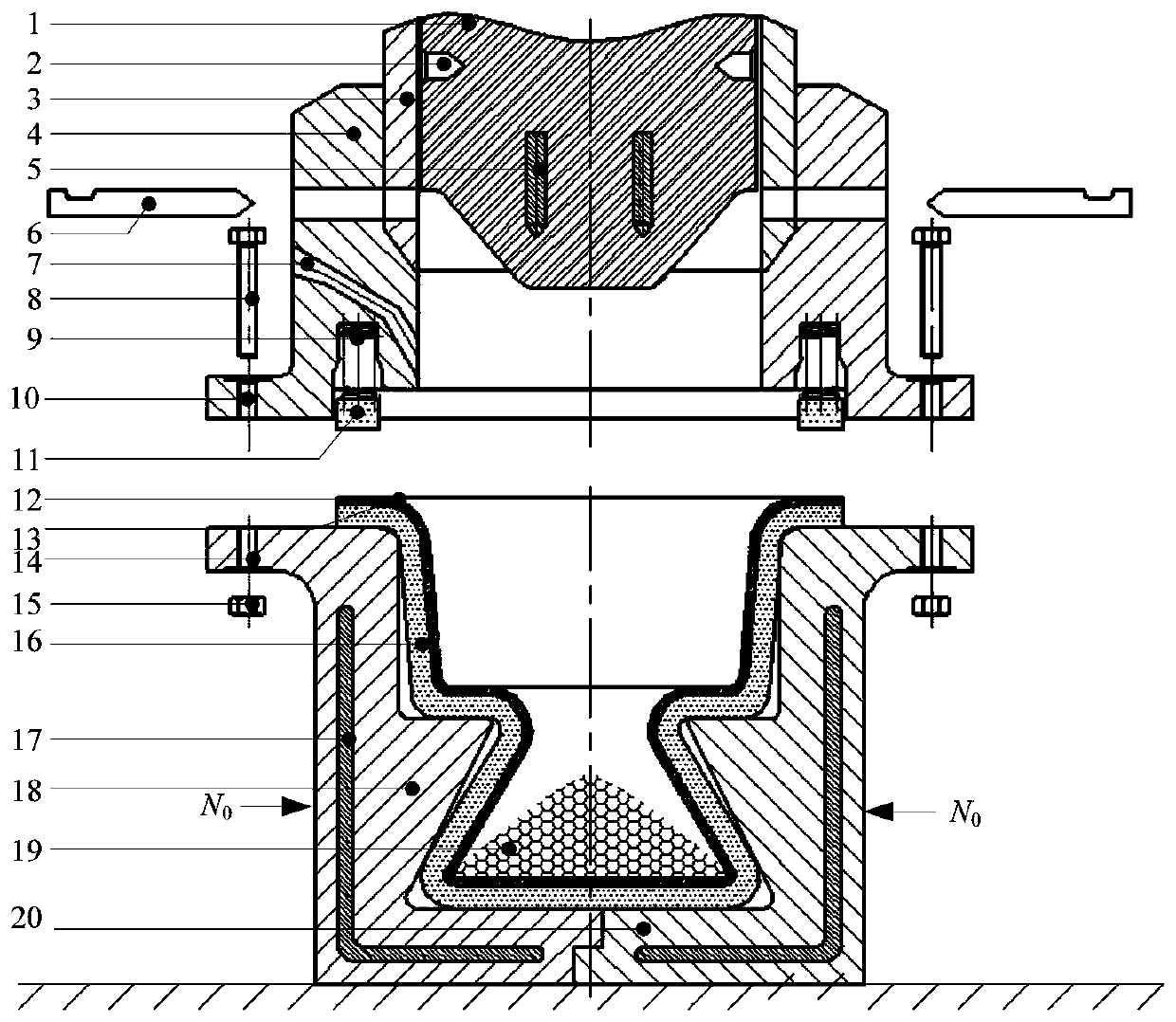

Efficient pneumatic jewel channel-setting device

The invention discloses an efficient pneumatic jewel channel-setting device. The efficient pneumatic jewel channel-setting device comprises a CNC numerical control machine for processing a jewel position hole and a jewel position channel and a channel-setting device body for channel setting of a jewel on the workpiece surface. The CNC numerical control machine comprises a machine base 1, an X driving shaft 2 and a Y driving shaft 3, a worktable 4 located on the upper surface of the machine base and driven by the X driving shaft 2 and the Y driving shaft 3 to perform horizontal displacement, a supporting column 5 fixedly installed on the machine base, a Z driving shaft 6 installed on the supporting column and a drill mouth 7 installed on the Z driving shaft and driven by the Z driving shaft to perform vertical movement, wherein the X driving shaft 2 and the Y driving shaft 3 are installed on the upper surface of the machine base. The channel-setting device body comprises a base 8, a lower die 9 installed on the base, a guide column 10 installed on the base, a column 11 installed on the base, an air cylinder 12 installed on the column and an upper die 13 driven by the air cylinder and performing vertical motion along the guide column. The efficient pneumatic jewel channel-setting device has the advantages of achieving full-automatic processing and channel setting and being high in working efficiency.

Owner:东莞市杰安腾精密五金制品有限公司

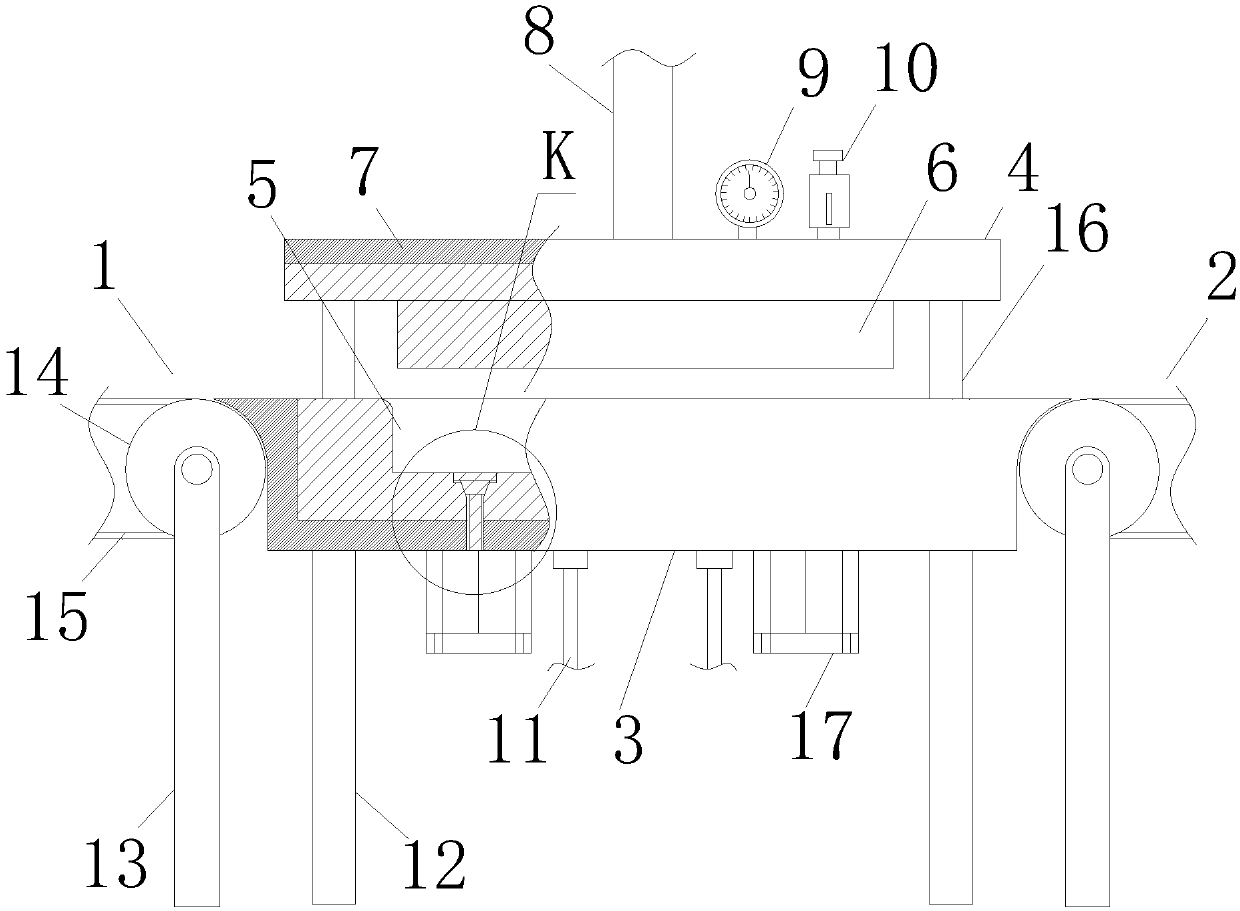

Pressing die for fiber-based cured plate

The invention discloses a pressing die for a fiber-based cured plate. The pressing die for the fiber-based cured plate comprises an input mechanism, wherein an output mechanism is arranged at the right side of the input mechanism; a lower bottom plate is arranged between the input mechanism and the output mechanism; an upper bottom plate is arranged above the lower bottom plate; the lower bottom plate is fixedly installed at the upper end of a support frame; a concave die is arranged on the upper surface of the lower bottom plate; a guide column is fixedly connected to the upper surface of thelower bottom plate; the upper bottom plate is slidably installed on the guide column; a convex die is arranged on the lower surface of the upper bottom plate; and the upper surface of the upper bottom plate is fixedly connected with the lower end of a hydraulic telescopic rod. The pressing die for the fiber-based cured plate is simple in structure, high in automation degree, high in pressing efficiency, and good in shaping effect.

Owner:GUANGDE TIANYUN NEW TECH

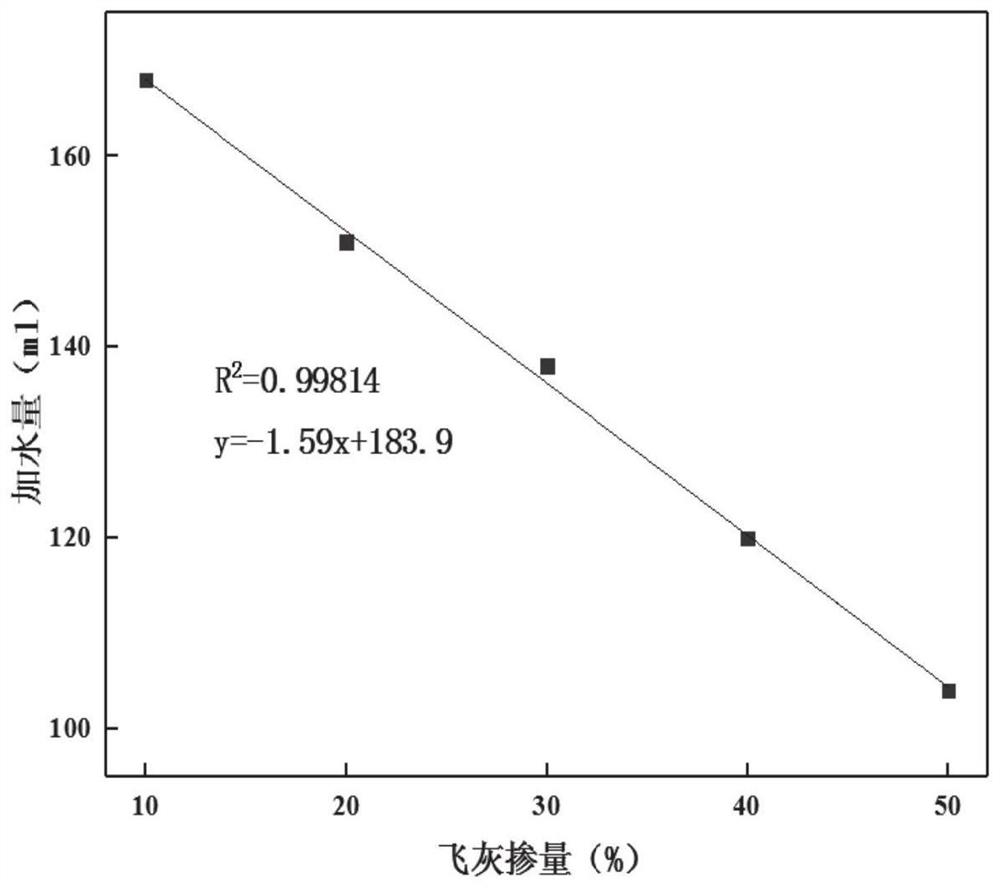

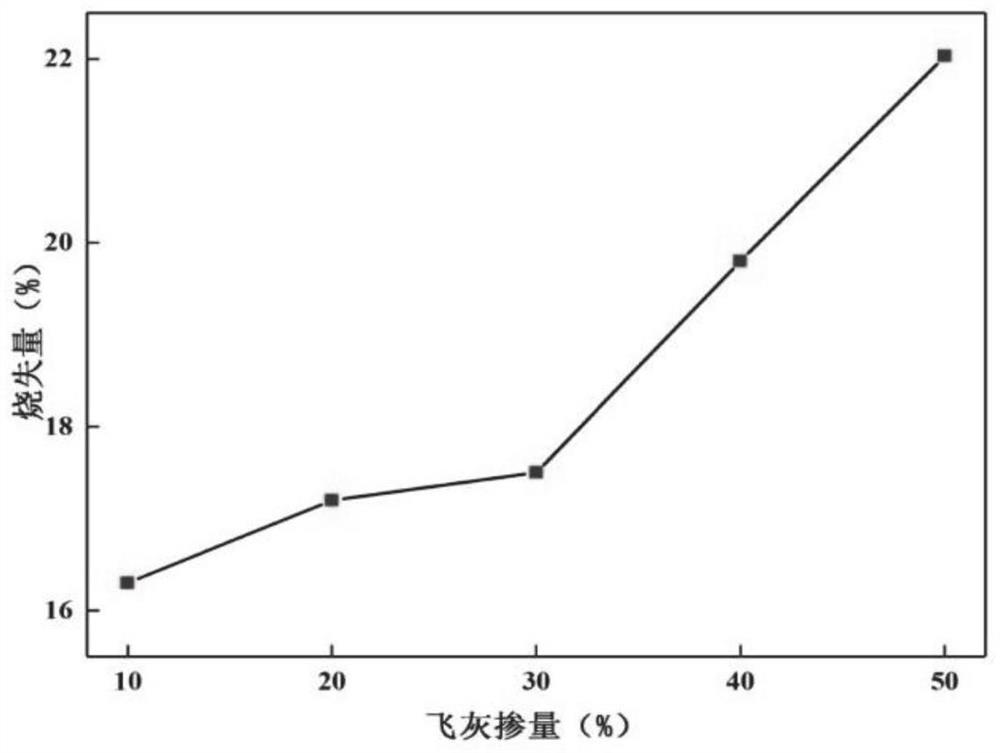

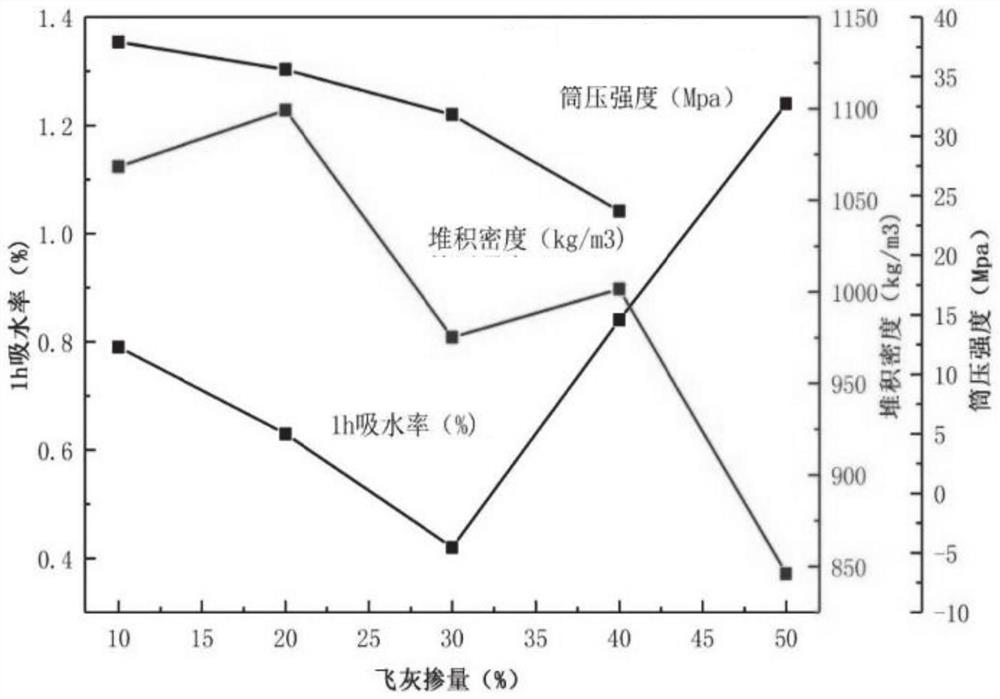

Phase-change ceramsite based on waste incineration fly ash as well as preparation method and application of phase-change ceramsite

PendingCN113372097AReduce disposal costsReduce demandCeramic materials productionCeramicwareSludgeExpanded clay aggregate

The invention relates to phase-change ceramsite based on waste incineration fly ash as well as a preparation method and application of the phase-change ceramsite. The phase-change ceramsite comprises fly ash ceramsite and a phase-change material; the fly ash ceramsite comprises the following raw materials in parts by weight: 15-45 parts of waste incineration fly ash, 25-45 parts of clay and 25-55 parts of municipal sludge, and the fly ash ceramsite has a capillary pore structure; and the phase-change material is loaded in the capillary pore structure of the fly ash ceramsite. The problem of preparing the phase-change ceramsite from waste incineration fly ash is solved, resources are effectively utilized, the waste incineration fly ash can be safely treated, and high-value utilization of the fly ash ceramsite is achieved.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

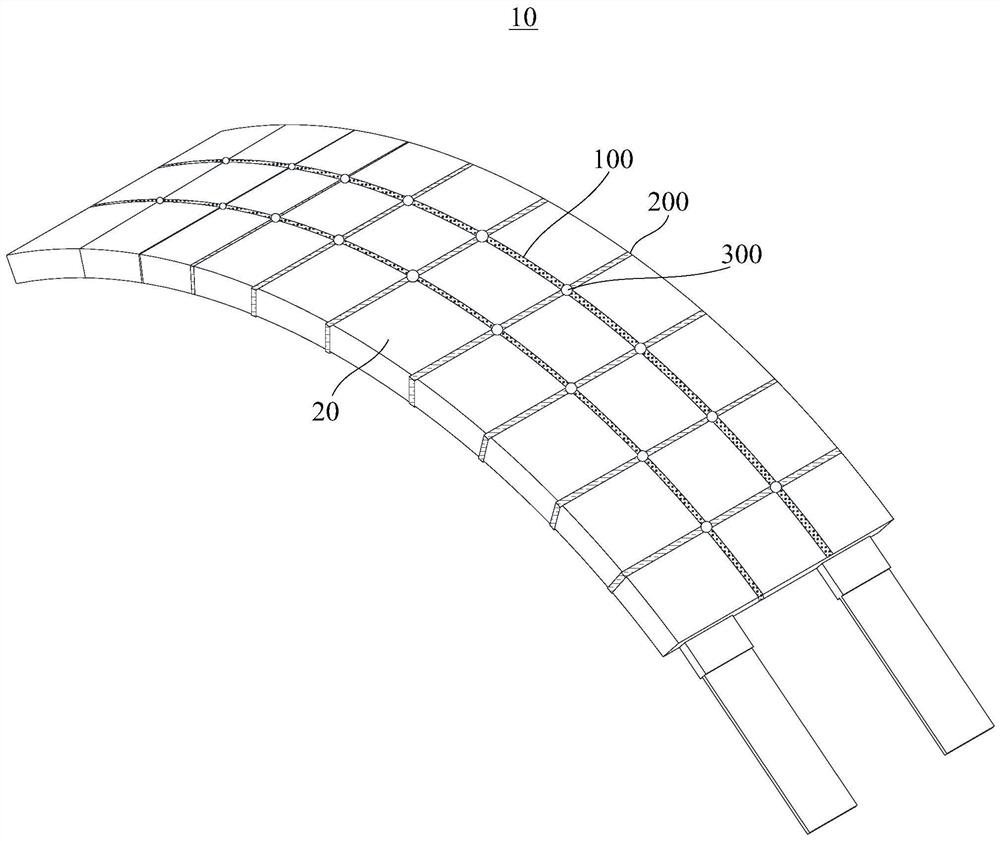

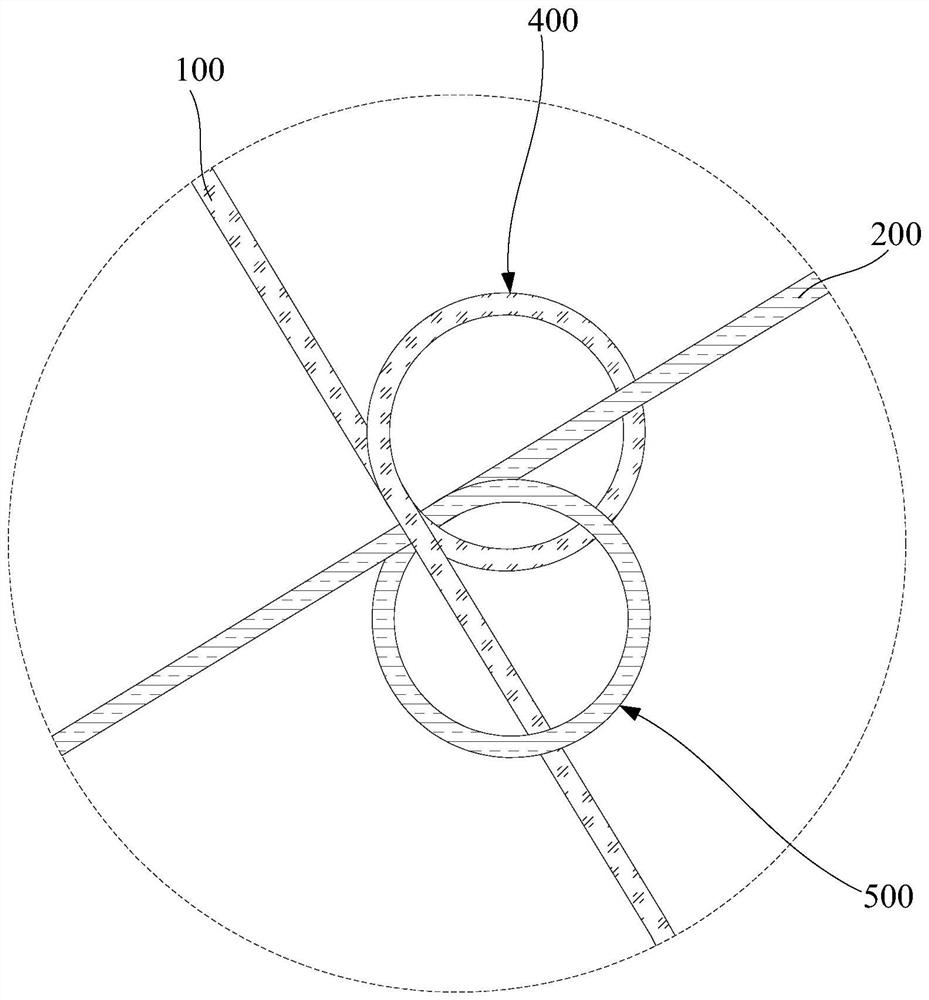

Arc-shaped battery cell with shaping structure and arc-shaped lithium battery

PendingCN113140779APrevent reboundImprove stabilityFinal product manufactureLi-accumulatorsEngineeringMechanical engineering

The invention provides an arc-shaped battery cell with a shaping structure and an arc-shaped lithium battery. The arc-shaped battery cell with the shaping structure comprises a first shaping part and a second shaping part, the first shaping part and the second shaping part are both wound on the surface of the arc-shaped battery cell, the extension direction of the first shaping part is parallel to the radian direction of the arc-shaped battery cell, and a preset included angle is formed between the extension direction of the second shaping part and the radian direction of the arc-shaped battery cell. The first shaping piece and the second shaping piece intersect to form an intersection node, and the first shaping piece and the second shaping piece are connected to the intersection node. The arc-shaped battery cell with the shaping structure is relatively good in shaping effect, high in stability and relatively strong in shaping durability.

Owner:HUIZHOU HENGTAI TECH

Pressure-balancing one-way valve for coiled-tubing layering fracturing

ActiveCN102926704BFunction as a one-way valveEasy to blast and perforateFlushingWell/borehole valve arrangementsUpper jointCoiled tubing

The invention discloses a pressure-balancing one-way valve for coiled-tubing layering fracturing. The pressure-balancing one-way valve comprises an upper joint, a limiting connecting sleeve, a body, a sealing head and a lower joint which are successively connected, wherein the inner part of the upper joint is of a hole-shrinkage cavity structure, a check ring and a sealing ball are mounted in a cavity in the upper part of the upper joint, the sealing ball is mounted at a hole shrinkage part, the check ring is mounted above the sealing ball, the lower end of the upper joint is fixedly connected with the sealing head and the sealing head is sleeved on the upper joint, the limiting connecting sleeve is sleeved on the upper joint, the body is sleeved on the limiting connecting sleeve and the sealing head and fixedly connected with the limiting connecting sleeve, a sliding gap is formed between the sealing head and the limiting connecting sleeve, and the lower joint stretches into the lower end of the body and is fixedly connected with the body. The pressure-balancing one-way valve for coiled-tubing layering fracturing has the characteristic of simple structure; and due to the adoption of the pressure-balancing one-way valve for coiled-tubing layering fracturing, the effects of packing and setting of an annular mechanical packer can be effectively improved, the setting and the packing are facilitated, and the abrasive perforating and the reverse-circulation sand-washing deblocking of a sand blower are facilitated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

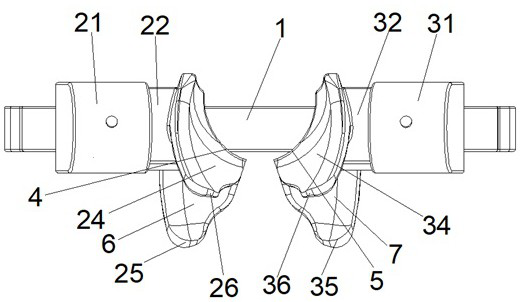

Gear shaft fixing and repairing device

The invention relates to a gear shaft fixing and repairing device, the device comprises a supporting frame, a positioning stop device and a connecting device, wherein the supporting frame comprises asupporting base, fixing support frames and supporting brackets, the fixing support frames are connected with the supporting base, the supporting brackets are arranged on the fixing support frames, thepositioning stop device comprises an adjustor, a base plate, a connecting block and a positioner, the adjustor and the positioner are both installed on the base plate, the connecting block is arranged between the adjustor and the positioner, the connecting device comprises an adjusting device, a positioning rod and a connecting rod, the adjusting device is connected with the supporting frame, thepositioning rod is arranged on the adjusting device, one end of the connecting rod is connected with the positioning rod, and the other end of the connecting rod is connected with the adjuster on thepositioning stop device. The gear shaft fixing and repairing device is high in adaptability, capable of achieving rapid positioning, convenient to adjust and use, good in fixing effect, capable of improving the gear shaft repairing operation efficiency and the site utilization rate, safe, reliable and capable of avoiding safety accidents caused by stability damage in the repairing operation process.

Owner:SGIS SONGSHAN CO LTD

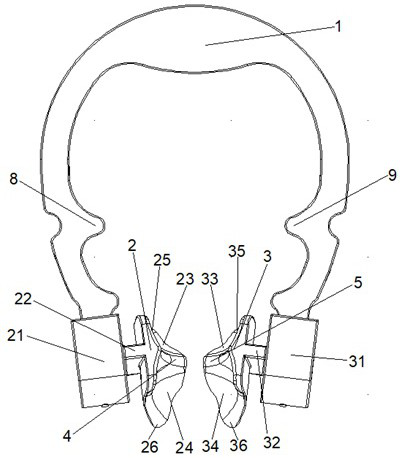

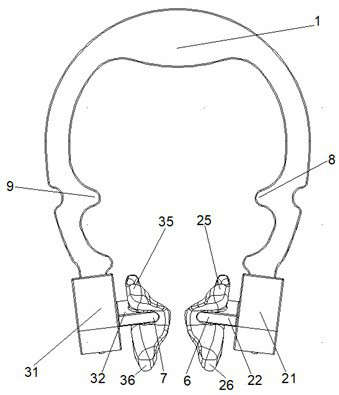

Self-adaptive forming sheet clamping ring

PendingCN114271965AIncrease clamping strengthPrevent collapseDental aidsTeeth cappingTooth fillingEngineering

The self-adaptive forming piece clamping ring comprises a ring body, the ring body is provided with an opening, the two ends of the opening are a first clamping end and a second clamping end, the first clamping end comprises a first fixing part and two first arc-shaped clamping faces, and the first fixing part is fixed to one side of the opening of the ring body; the second clamping end comprises a second fixing part and two second arc-shaped clamping surfaces, and the second fixing part is fixed on the other side of the opening of the ring body; a first elastic connecting part is arranged between the first fixing part and the two first arc-shaped clamping surfaces, one side of the first elastic connecting part is connected with the first fixing part, and the other side of the first elastic connecting part is connected with the two first arc-shaped clamping surfaces. The self-adaptive forming piece clamping ring can adaptively adjust the fitting state of each arc-shaped clamping surface and a tooth wall along with the tooth state to improve the fitting degree of the forming piece and the tooth, is firm in clamping, not easy to fall off, good in tooth filling effect, free from fighting for space with a clearance wedge, and convenient to use.

Owner:唐山恒新医疗器材有限公司

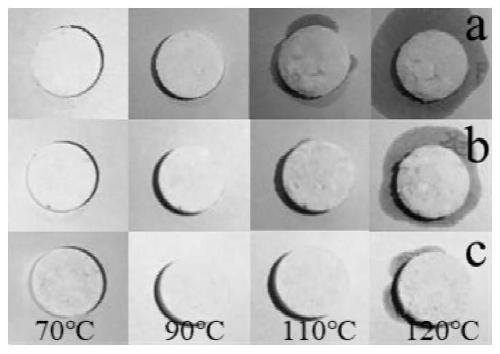

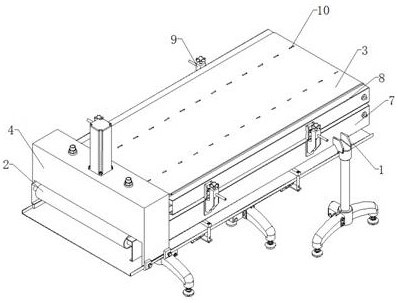

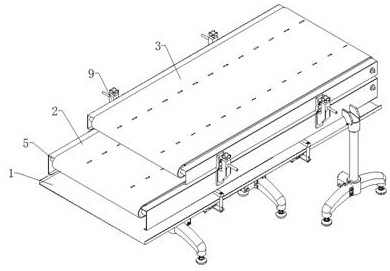

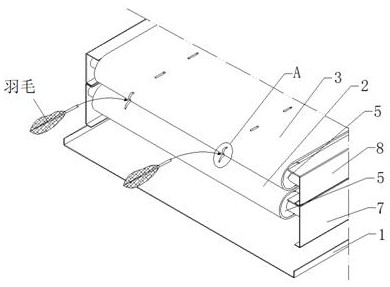

Feather shaping device for badminton production

ActiveCN112657148BAchieve initial shapeImprove the setting effectBall sportsStructural engineeringConveyor belt

The invention relates to a feather setting device for badminton production, which comprises a basic support mechanism, a lower conveyor belt, an upper conveyor belt and a pressing and setting mechanism. The lower conveyor belt and the upper conveyor belt are equipped with a conveying roller and a shaping heating plate. An auxiliary supporting mechanism is fixedly connected between the outer sides of the frame, and the auxiliary supporting mechanism includes a fixed support, an adjusting rod, an adjusting rod locking bolt, a supporting limit clip and a clamping fixing plate; the pressing and setting mechanism includes a pressing driving cylinder, Pressing plate, the top wall of the pressing plate is connected to the steam pipe, and the bottom wall of the pressing plate is provided with a semi-cylindrical channel and a steam nozzle; the lower conveyor belt and the upper conveyor belt are equidistantly arranged along the length direction of the feather stalk placement slots, and the upper and lower two are facing each other. Feather stalk placement grooves form a cylindrical hole-like cavity. The invention has simple structure and convenient operation, and realizes a feather shaping method for badminton production through the combination of one-time extrusion and second-time ironing, and effectively improves the overall quality and production efficiency of feather production.

Owner:WUWEI HONGXI SPORTS GOODS CO LTD

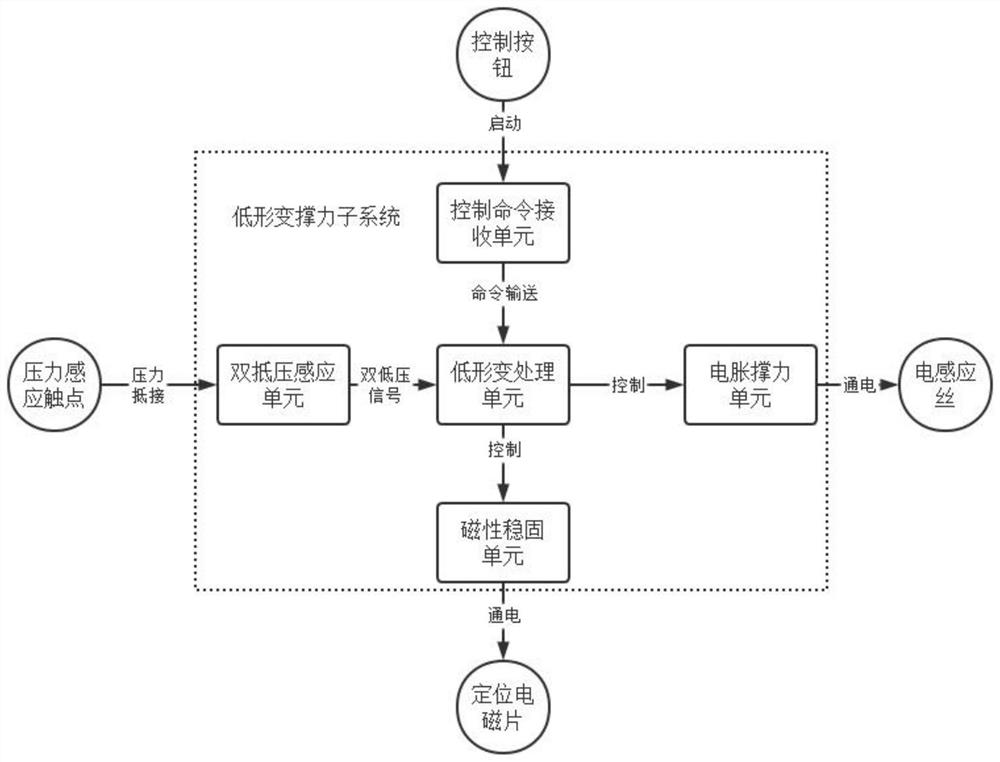

A self-testing slip packer

InactiveCN104975820BThe sealing performance is safe and reliableImprove the setting effectSealing/packingUpper jointThreaded pipe

The invention relates to a self-checking and sealing slip packer, which belongs to the field of downhole tools for oil and gas well operations. The packer is composed of an inner center pipe, an outer center pipe, slips and a slip sheath; one end of the inner center pipe is threaded with an upper joint, and the other end of the inner center pipe is threaded with a lower joint; the upper joint and the lower joint An inner piston sleeve, a release claw and an outer central tube are sequentially installed on the inner central tube between them; one end of the inner piston sleeve is threaded with a balance joint, and the inner piston sleeve at the other end of the balance joint is sequentially installed with an upper bushing and a lower bushing There is a bypass joint between the upper bushing and the lower bushing; the upper bushing on the side of the bypass joint is equipped with an upper guide ring, and the spacer is sealed with two sets of rubber tubes when setting to ensure that The sealing performance is safer and more reliable during setting, and has the characteristics of simple and fast operation; it meets the needs of sealing and separating oil layer casings in oilfield production.

Owner:荆州市赛瑞能源技术有限公司 +1

A kind of epoxy resin composite shape-setting phase change material and its preparation method and application

ActiveCN111378250BImprove high temperature resistanceImprove thermal conductivityCigar manufactureHeat-exchange elementsPolymer scienceFlue gas

The invention discloses an epoxy resin-based composite shape-setting phase change material and its preparation method and application; the epoxy resin-based composite shape-setting phase change material consists of 40-55% epoxy resin cured product, % phase change material and 0-10% thermal conductive material are prepared by casting molding method, and the curing agent accounts for 33-36% of the cured epoxy resin; due to the good compatibility between the phase change material and epoxy resin and the complete curing of epoxy resin The resulting polymer matrix with a three-dimensional crosslinked network structure makes it have excellent high temperature resistance, presents the characteristics of solid-solid phase transition and is easy to process and prepare; the phase change material changes from crystalline to amorphous phase The transformation enables the material to realize the function of absorbing heat and storing energy; the addition of heat-conducting materials improves the heat-conducting performance and shape-setting performance of the composite shape-setting phase change material. Epoxy resin-based composite shape-setting phase-change materials are filled into the cooling section of iQOS supporting cigarettes in the form of particles, which can significantly reduce the temperature of the smoke at the front one to three filter tip ends.

Owner:NANTONG UNIVERSITY

Correction process for adjusting heat treatment deformation of an arm lever portion

InactiveCN109201788APrevent overcorrectionEasy to operateShaping toolsHeat treatment bathsEngineeringMartensite

The invention discloses a correction process for adjusting heat treatment deformation of an arm lever portion. The correction process comprises the steps of: placing a deformed product in a containercontaining a cooling medium for cooling until the product reaches the martensite temperature and is cooled completely, taking out the product and air-drying the product for later use, putting the product into a salt bath furnace, starting the heat treatment, after the heated finished product is taken out the furnace, quickly putting the product into a press for correction; putting the corrected product into a material frame, and bringing the material frame vertically into a cold water tank; putting the product into the salt bath furnace again, starting the secondary heat treatment, after the heated finished product is taken out the furnace, quickly putting the product into a press for secondary correction; then vertically putting the corrected product into the cold water tank again, takingthe product out and drying the product to complete the correction work. The correction process can improve the overall correction quality and accuracy and improve work efficiency.

Owner:NANJING OURUI MACHINERY FORGING CO LTD

Upper-sealing and lower-mining integrated filling sand prevention pipe column

The invention discloses an upper-sealing and lower-mining integrated filling sand prevention pipe column and belongs to the technical field of oil exploitation. An upper packer, an interlayer connecting pipe, a lower packer, a special filling tool, a signal screen pipe, a safety joint, a sand filtering pipe and a blind plug are sequentially connected from top to bottom. The upper packer comprises an upper releasing joint, the upper releasing joint is internally provided with a releasing core pipe, a sealing piston is arranged in a sliding space, a pushing and pressing short section is further arranged in the sliding space, the outer wall of the pushing and pressing short section makes contact with the inner wall of the upper releasing joint, the end of the pushing and pressing short section is inserted into an installation gap in the sealing connecting sleeve, a first locking spring is arranged in the installation gap, the position, close to the end, of the outer wall of the releasing core pipe is connected with a releasing shear ring through a releasing shear pin, a releasing tail pipe is mounted in the releasing core pipe, and the tail end of the releasing tail pipe is connected with a compensator through a transition core pipe in an interlayer connecting pipe. The upper layer is plugged through the combination of the upper packer and the lower packer, so that the pipe column is well sealed and is long in service life.

Owner:王凯

A Combined Integrated Oilfield Packer

InactiveCN112983336BImprove the setting effectEasy to operateDrilling rodsFlushingOil fieldMechanical engineering

The invention provides a combined integrated oil field packer and relates to the technical field of oil and gas development. The combined integrated oilfield packer, the packer includes: a support assembly, the support assembly includes a central pipe, a joint, a connecting ring, an adjustment cylinder, a first through hole and a second through hole, the center pipe Both the top end and the bottom end are fixedly connected with joints, the outside of the middle part of the central tube is fixedly connected with an adjustment cylinder, and the left and right sides of the lower part of the central tube are provided with second through holes; the setting mechanism cooperates with the righting mechanism and the rotating assembly to set the packer; the unsealing mechanism is used for unsealing the packer. By injecting oil into the center pipe, the oil is pressed into the centralizing mechanism through the first through hole, and the centralizing mechanism straightens the packer. At the same time, the rotating component and the supporting component cooperate with the centralizing mechanism to make the setting mechanism work and complete the setting. The packer facilitates righting and setting.

Owner:大安鸿源管业有限公司

A method of horizontal directional drilling through percussion rotary drilling

ActiveCN111520074BImprove gripImprove stabilityEarth drilling toolsInsulationStructural engineeringHorizontal orientation

The invention discloses a horizontal directional drilling crossing impact rotary drilling method, which belongs to the technical field of oil gas pipeline horizontal directional drilling crossing and oil gas drilling and production. A horizontal directional drilling crossing impact rotary drilling method can realize the exploration and analysis of crossing terrain Finally, determine the loose stratum area, equip the existing drill pipe with a corresponding number of telescopic shaping rods, and launch the telescopic shaping rods vertically upwards after drilling to the loose stratum area, so that the telescopic shaping rods can penetrate into the upper layer The shape-setting action is triggered in the terrain, and multiple shape-setting tentacles are extended from the telescopic shaping rod to the surrounding area to improve the grip on the formation, so as to realize the effective connection of the upper and lower areas of the loose formation and improve the stability of the drilling hole wall It can significantly reduce the risk of hole collapse, and increase the strength of the formation near the pipeline when reaming and pulling back the pipeline, reduce the risk of pipeline settlement, and greatly improve the safety and stability of construction.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE +1

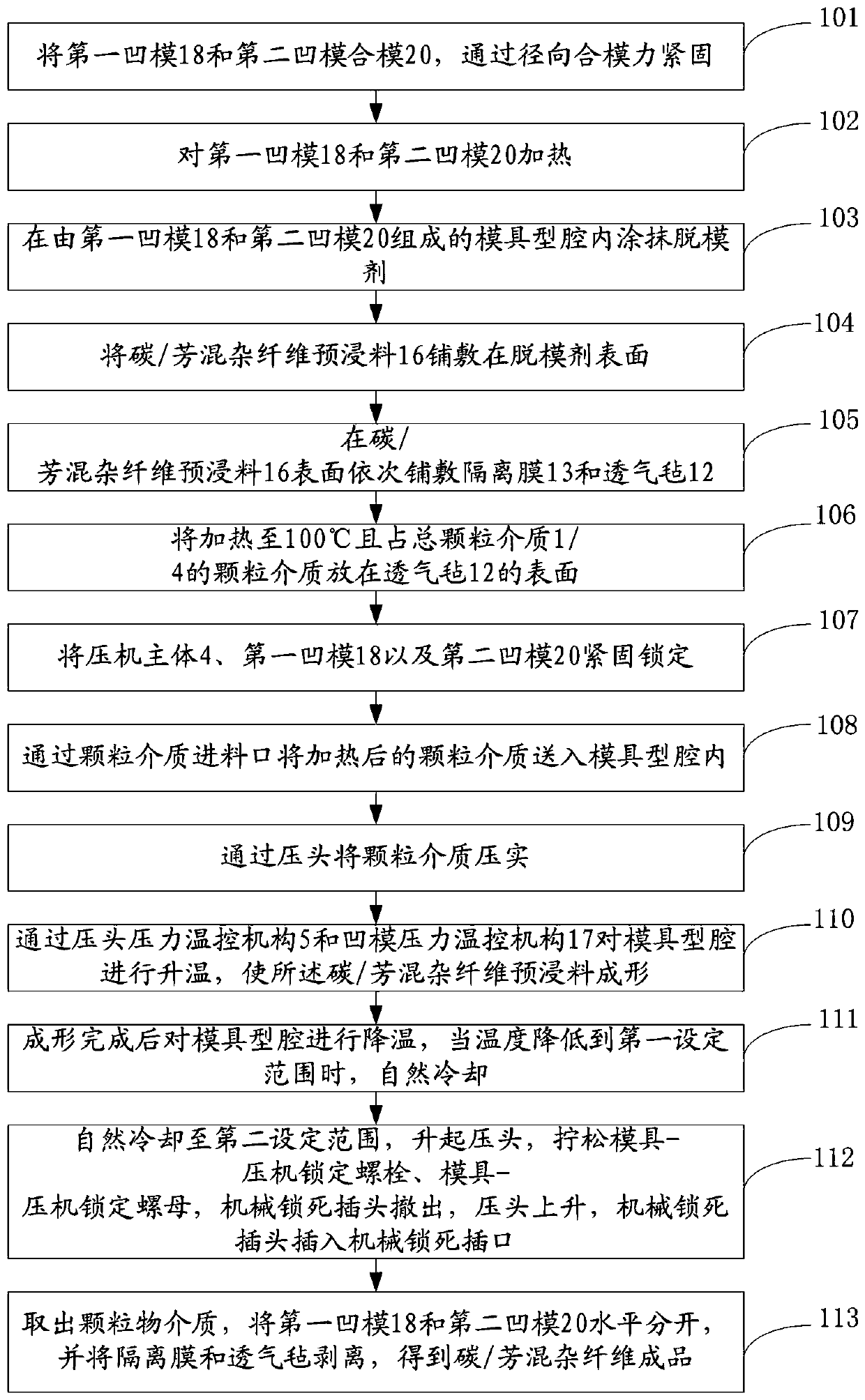

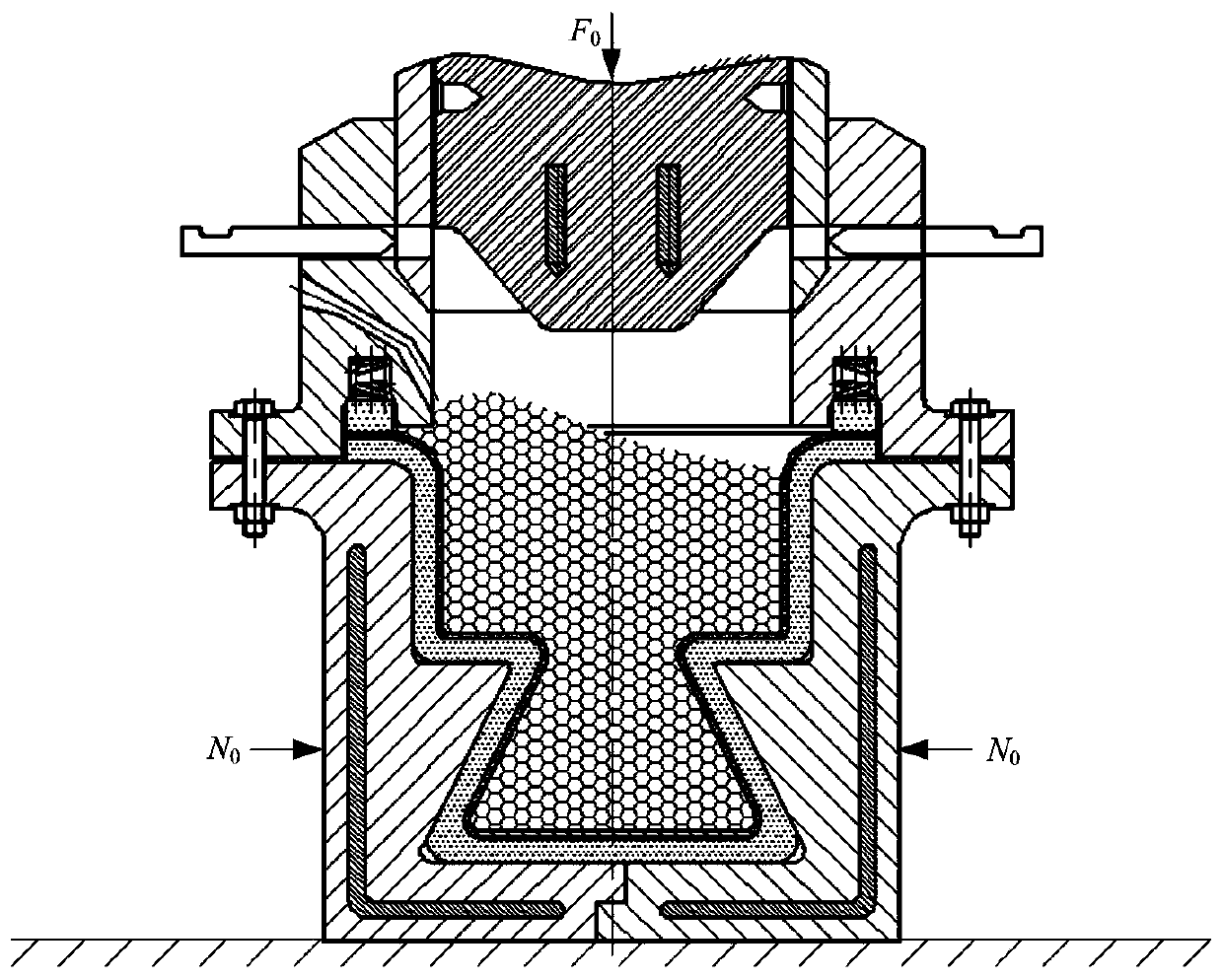

Device and method for preparing carbon fiber/aramid hybrid fiber composite material

The invention discloses a carbon fiber / aramid fiber hybrid fiber composite material preparation device and method. The method includes the steps that a first female die and a second female die are combined, fastened and heated; the interior of a die cavity composed of the first female die and the second female die is coated with a die releasing agent; carbon / aramid hybrid fiber prepreg is appliedto the surface of the die releasing agent; an isolating membrane and a ventilated felt are laid on the surface of the carbon / aramid hybrid fiber prepreg in sequence; a heated particle medium is fed into the die cavity; the particle medium is compacted; the die cavity is subjected to temperature rise; the die cavity is cooled and naturally cooled after forming is finished; the die cavity is naturally cooled to a second set range, and a pressure head is lifted; and the particle medium is taken out, the first female die is horizontally separated from the second female die, the isolating membraneand the ventilated felt are stripped off, and a carbon / aramid hybrid fiber finished product is obtained. By means of the method, the problem that the wettability between reinforced fibers and resins is insufficient can be solved, the good bonding degree between formed workpiece fibers and the resins is achieved, and the excellent mechanical property is formed.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com