Non-throttling Y344 type fracturing set packer

A non-throttle, packer technology, applied in the directions of sealing/packing, production fluid, wellbore/well components, etc., can solve the problem of increasing the load of surface pump pressure equipment, limiting the sand blasting amount of the construction string, and intensifying sandblasting. The wear and tear of the orifice of the device can increase the pressure bearing capacity, the setting effect is good, and the setting effect is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

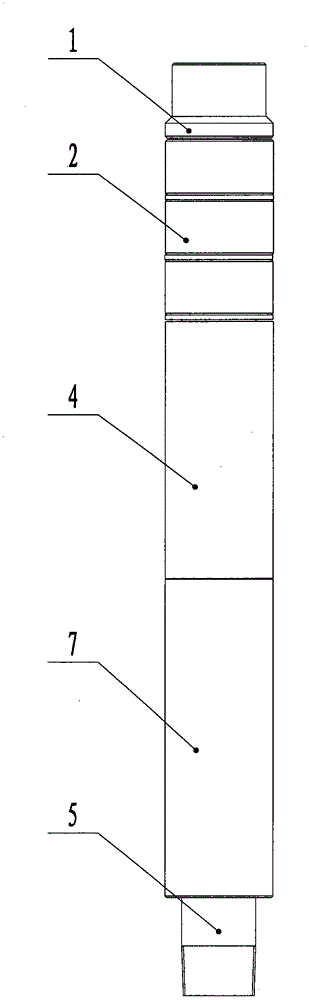

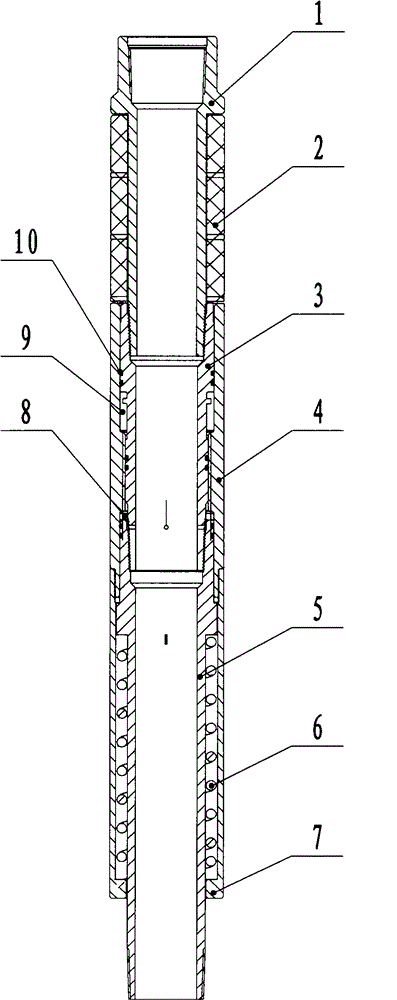

[0012] figure 1 , 2 Among them, it contains upper joint 1, rubber tube 2, slider center tube 3, power slider 4, spring center tube 5, spring 6, spring drive shell 7, hydraulic chamber 8, air chamber 9, sealing ring 10, upper joint 1 There are three sets of rubber tubes 2 and spacer rings in sequence, the end of which is connected with the slider center tube 3, the slider center tube 3 is equipped with a power slider 4, and the spring center tube 5 is connected below, and the slider center tube 5, the power slider The sealed cavity formed by the block 4 is called the air cavity 9, and the cavity formed by the power slider 4, the slider center tube 3, and the spring center tube 5 is the hydraulic cavity 8, and the power slider is connected to the spring drive shell, and the spring drive shell A spring 6 is arranged between 7 and the spring center tube 5, and three sets of sealing rings 10 are arranged between the slider center tube 3, the spring center tube 5, and the power sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com