Small-sized packer capable of resisting high temperature and pressure

A small-sized, high-temperature-resistant technology, which is applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc. Weakening and failure of the sealing effect, enriching the potential of the international market, and maintaining the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

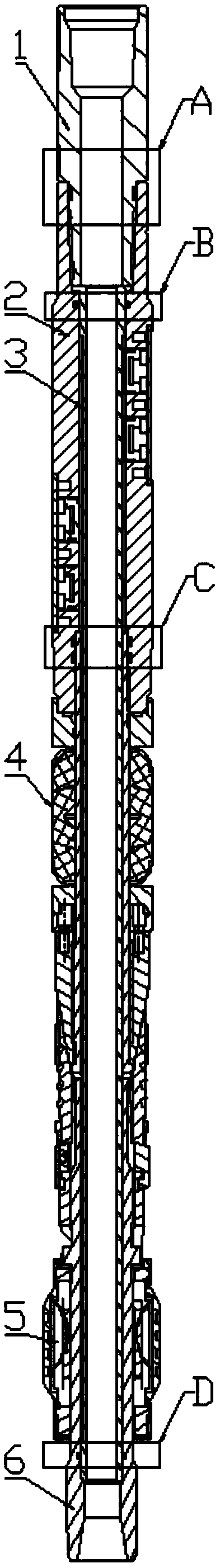

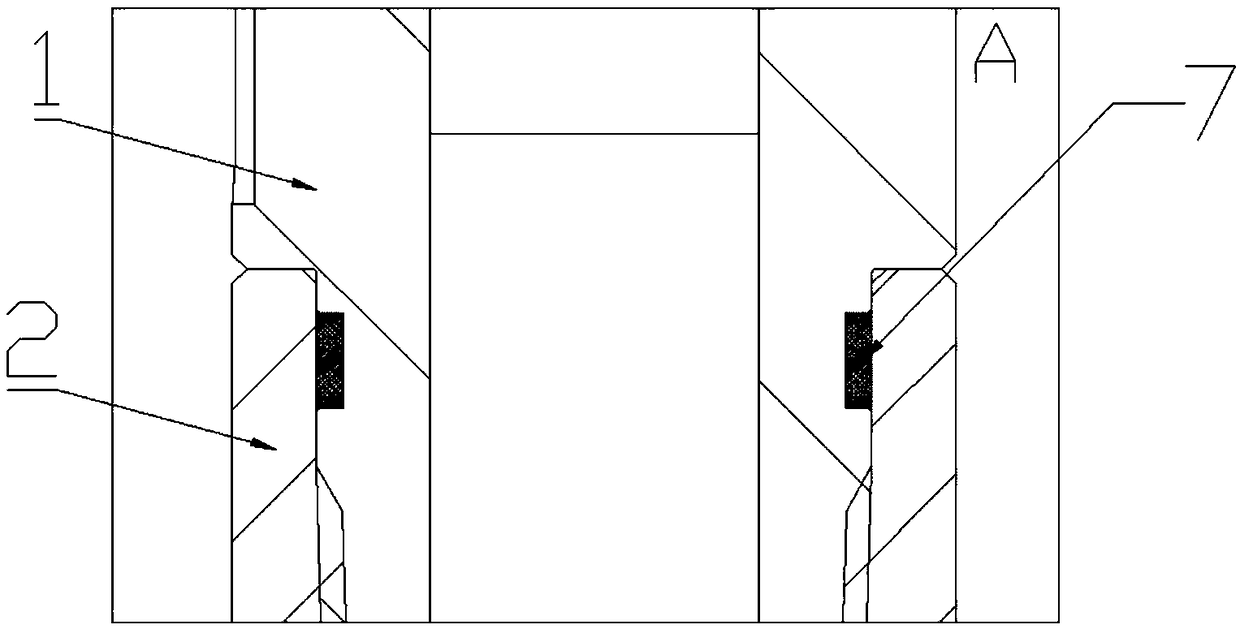

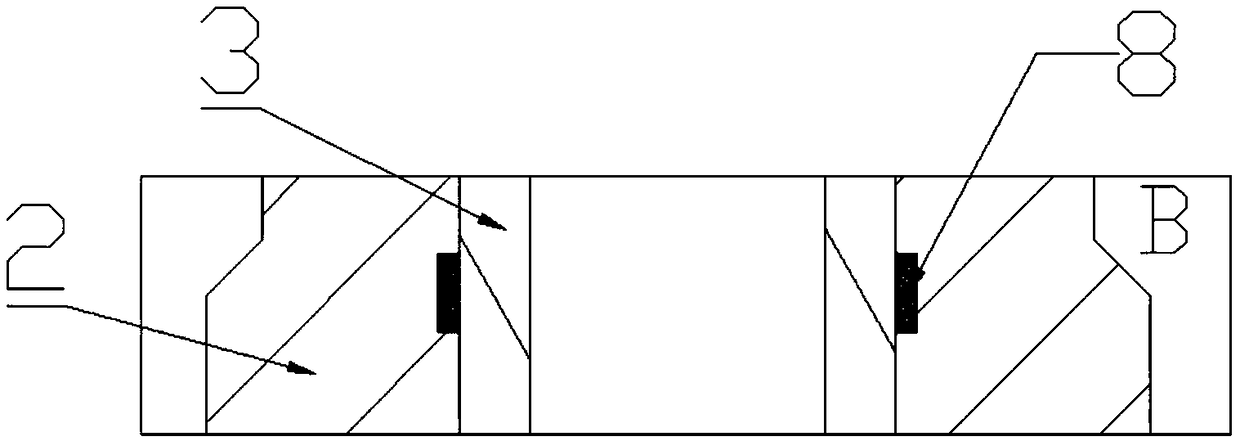

[0038] refer to Figure 1~6 , a small-sized packer resistant to high temperature and high pressure, including a volume tube 3 and an outer center tube 6 sleeved on one end of the volume tube 3; several parallel tubes are arranged between the volume tube 3 and the outer center tube 6 The first sealing assembly 10 provided; the first sealing assembly 10 includes at least two sealing rings 12 and one more retaining ring 11 than the sealing ring 12; the retaining ring 11 is formed with an oblique cut 19, so that the retaining ring 11 The ring 11 is cut off from the oblique cut 19; the acute angle formed between the plane where the oblique cut 19 is located and the bottom surface of the retaining ring 11 is 10-20°; both sides of the sealing ring 12 are engaged with the retaining ring 11.

[0039] In this embodiment, the structural composition, assembly relationship and setting principle of the small-sized packer are roughly the same as those of the existing packer. Since the impro...

Embodiment 2

[0057] Based on Example 1, with reference to Figure 7 and 10 , in order to avoid the more obvious risk of the rubber cartridge assembly being vulnerable to pressure due to the reduction in the thickness of the rubber cartridge assembly due to the smaller size of the packer, the following improvements have been made: the outer center pipe 6 is sleeved with The rubber cartridge assembly 4; the two ends of the rubber cartridge assembly 4 are provided with a protective bowl 13; the protective bowl 13 is a bowl-shaped structure with a through hole 17 in the middle formed by bending and pressing a steel wire irregularly; the protective The surface of the bowl 13 is provided with a rubber layer 18 .

[0058] Wherein, the rubber cartridge assembly 4 is usually made of high-temperature and high-pressure-resistant rubber, and contacts the inner wall of the casing 14 through its expansion and deformation during use, thereby completing the setting action of the packer. In the prior art...

Embodiment 3

[0067] Based on Example 2, refer to Figure 10 , in order to further improve the protective effect of the protective bowl on the rubber cartridge assembly, the following improvements are made: the protective bowl 13 includes a circular platform 16 and a conical platform 15 at the bottom of the circular platform 16, and the conical platform 15 The diameter of the upper surface is greater than the diameter of the lower surface of the conical frustum 15, the upper surface of the conical frustum 15 coincides with the bottom surface of the circular frustum 16, and the protective bowl 13 is provided with a The through hole 17 of the conical truncated 15, the conical truncated 16, the conical truncated 15 and the through hole 17 are concentric, and the circular truncated 16 and the conical truncated 15 are integrally structured. It is worth noting that, in this embodiment, for the convenience of description, the structures of the various parts of the protective bowl 13 are distinguis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com