Low-deformation plate rolling machine

A plate rolling machine and low deformation technology, applied in the field of plate rolling machines, can solve the problems of unfavorable plate rolling machine sustainable development, reduction of plate forming quality, plate shape maintenance, etc., to achieve adjustability, improve shape setting effect, reduce The effect of deforming force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

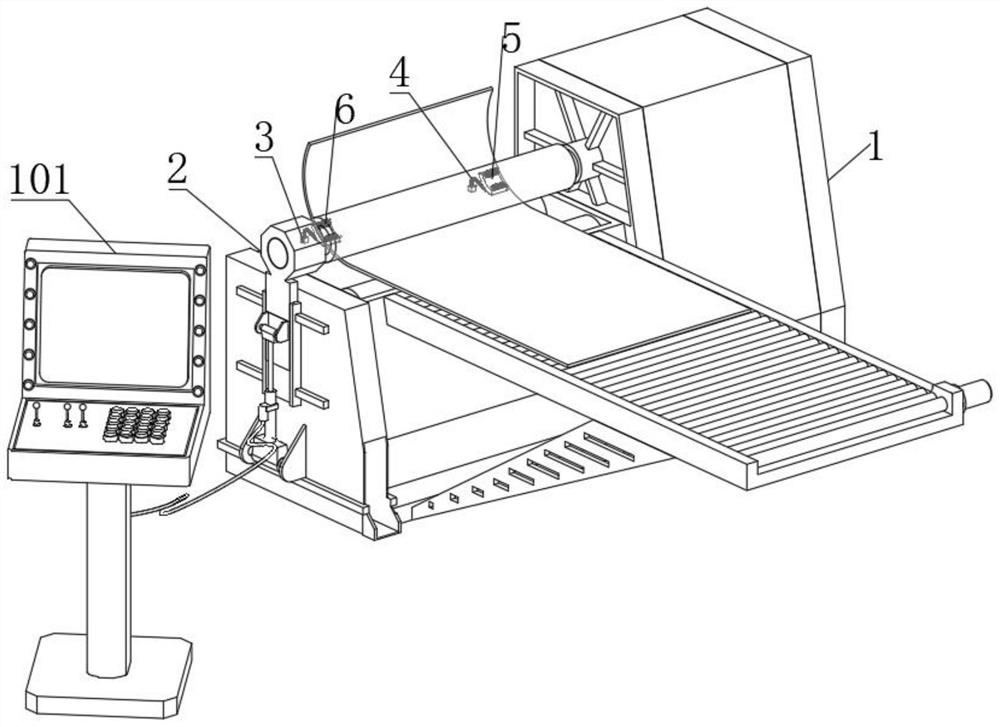

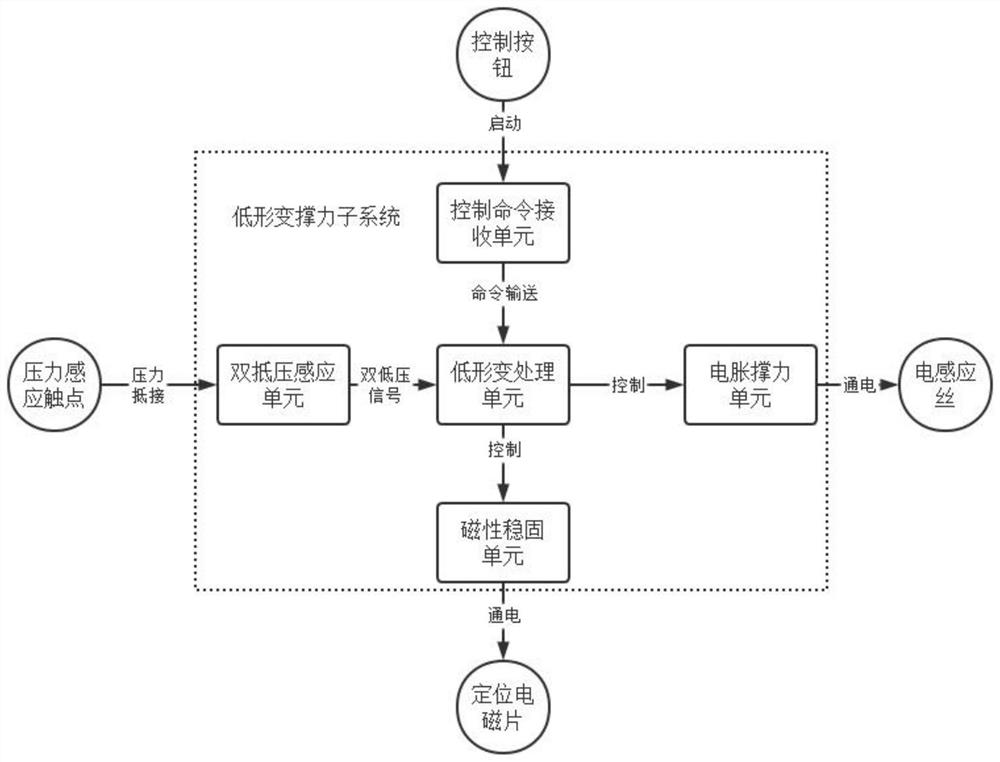

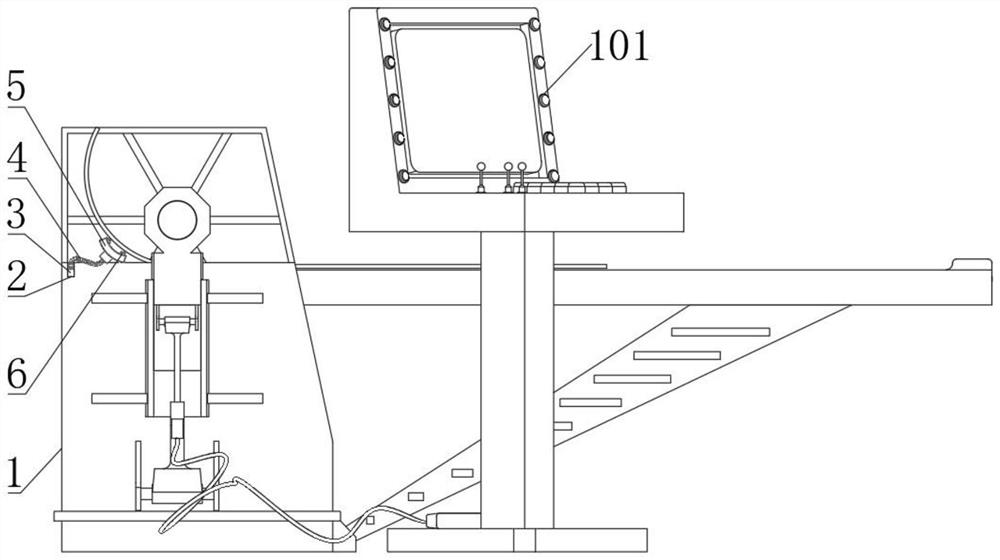

[0042] see Figure 1-9 , a low-deformation plate bending machine, comprising a plate bending machine body 1, a rear end of the plate bending machine body 1 is fixedly installed with a support rear plate 2, and the upper end of the support rear plate 2 is slidably connected with a pair of cavity conversion slides 3, The upper end of the cavity conversion slide 3 is fixedly connected with a gooseneck hollow tube 4, the right end of the gooseneck hollow tube 4 is fixedly connected with an isolation joint 501, the right end of the isolation joint 501 is fixedly connected with an arc-shaped isolation support plate 5, and the right end of the arc-shaped isolation support plate 5 is fixedly connected A pair of load-bearing grooves 502 are provided. The load-bearing elastic tubes 6 are rotatably connected in the load-bearing grooves 502. The outer ends of the load-bearing elastic tubes 6 are fixedly connected with a plurality of rolling bars 7 in a circular array. The rolling bars 7 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com