Pressure-balancing one-way valve for coiled-tubing layering fracturing

A layered fracturing and one-way valve technology, which is applied in the direction of wellbore/well valve device, wellbore/well components, sealing/isolation, etc., can solve the problem of unfavorable fracturing and acidification transformation, the passage inside the pipe cannot pass outside the pipe Simultaneously carry out sealing and other issues to achieve the effect of facilitating sandblasting and perforating and reverse circulation sand flushing to remove plugging, improving the effect of sealing and setting, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

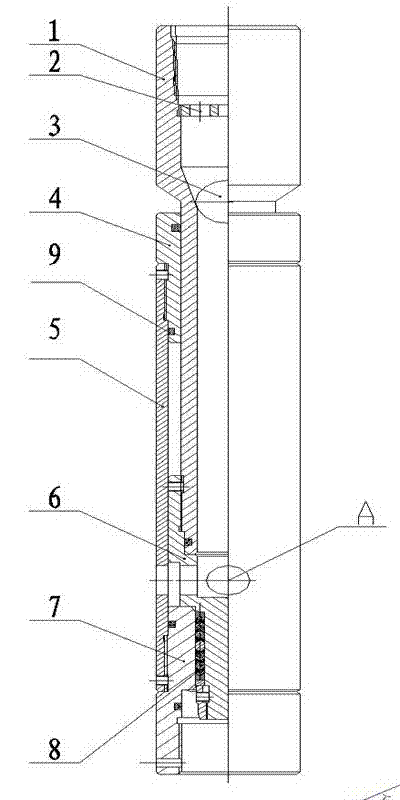

[0028] The structure and connection relationship of the present invention: the present invention is mainly composed of an upper joint 1, a retaining ring 2, a sealing ball 3, a limit connection sleeve 4, a body 5, a sealing head 6, a lower joint 7, and a sealing packing group 8. The present invention is connected in the following order from top to bottom: upper joint 1, retaining ring 2, sealing ball 3, limit connecting sleeve 4, body 5, sealing head 6, lower joint 7, sealing packing group 8; the upper joint 1. The upper end is a threaded buckle, which is used to connect the upper pipe string. There is a one-way valve structure formed by the sealing ball 3 and the retaining ring 2 in the center, and the lower end is connected to the sealing head 6; the limit connecting sleeve 4 is used to limit the upper joint 1 and the The sliding range of the sealing head 6; the main body 5 is connected under the limit connecting sleeve 4; the lower joint 7 is connected under the main body 5,...

Embodiment 2

[0030] Main application of the present invention: During the construction process, the device of the present invention has the following important functions: the pressure balance check valve for layered fracturing of the coiled tubing can be used to set the pressure balance check valve when the string is lowered to set the packer. Insert the sealing head 6 in the valve into the lower joint 7, so that the inside of the packer pipe is sealed, and the inner and outer passages of the upper and lower pipes of the packer are sealed off. When the packer needs to be unsealed, the pressure is balanced in one direction by lifting the pipe string The sealing head 6 in the valve is pulled out from the lower joint 7, so that the upper and lower pressures of the packer are balanced to facilitate unsealing.

[0031] The upper end of the upper joint 1 of the pressure balance check valve is connected to a sand blaster. When the sand blaster needs to perform sandblasting and perforation, the ret...

Embodiment 3

[0033] The best embodiment of the present invention is, with reference to the attached figure 1 , the present invention includes an upper joint, a limit connection sleeve, a body, a sealing head and a lower joint sequentially connected from top to bottom. There are a retaining ring and a sealing ball, the sealing ball is installed at the reduced diameter, the retaining ring is installed above the sealing ball, the lower end of the upper joint is fixedly connected to the sealing head and the sealing head is covered on the upper joint, and the limit connecting sleeve is placed on the On the above joint, the main body is set on the limit connection sleeve and the sealing head, the body is fixedly connected with the limit connection sleeve, there is a sliding gap between the sealing head and the limit connection sleeve, and the lower joint extends into the body The lower end is fixedly connected with the body. A sealing packing is also included, and the sealing packing is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com