Bulge forming method and bulge forming apparatus

A technology of internal configuration and blank tube, which is applied in the field of extrusion forming and extrusion forming devices, can solve the problems of increased product deviation, difficult tube expansion forming, and reduced accuracy of tube expansion forming, and achieves the effect of simple structure and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

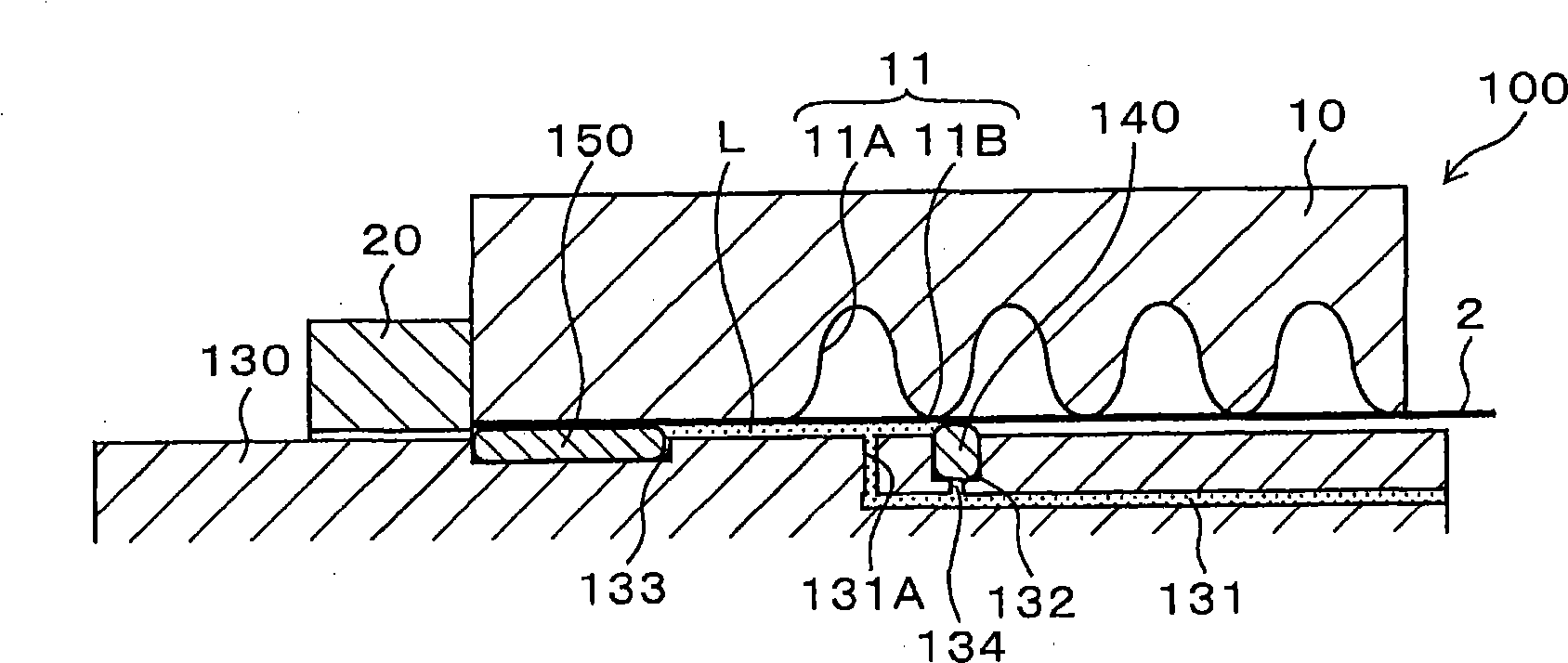

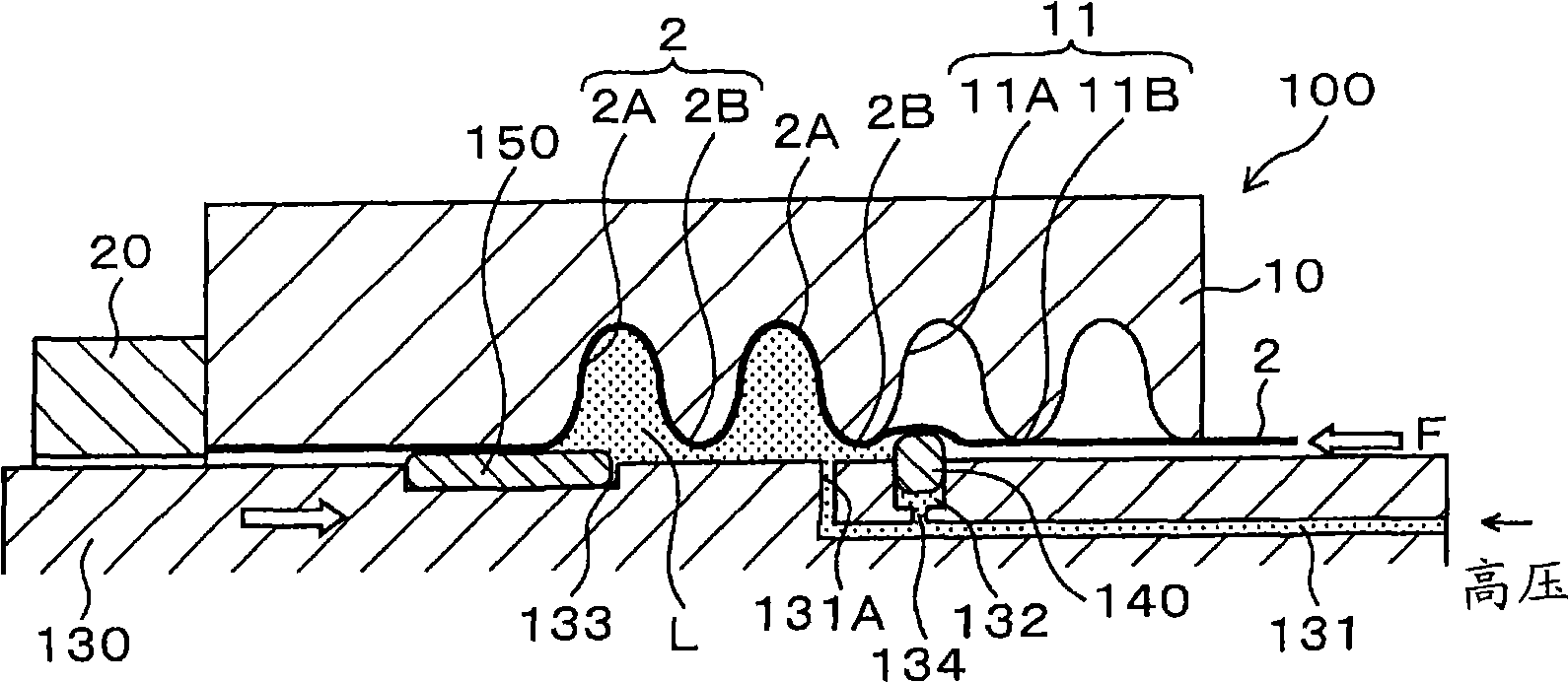

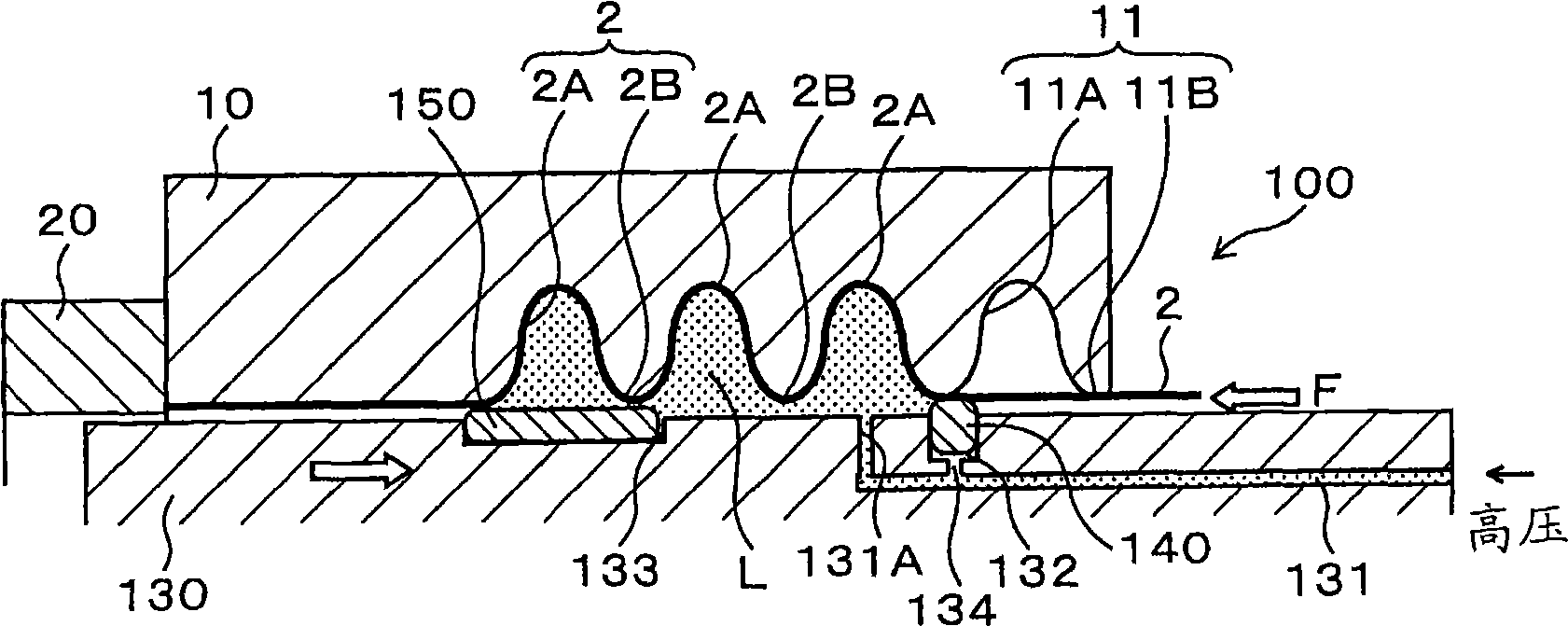

[0046] (1) Structure of the first embodiment

[0047] Next, a first embodiment of the present invention will be described with reference to the drawings. figure 1 It is a side sectional view showing a schematic structure of the extrusion molding apparatus 100 according to the first embodiment of the present invention. exist figure 1 The structure of the upper half of the extrusion forming device 100 is shown in . In addition, in this embodiment, for the Figure 7 The same components are denoted by the same symbols, and descriptions thereof are omitted.

[0048] A pressurized liquid supply channel 131 is formed inside the rod 130 , and the pressurized liquid L is supplied between the blank tube 2 and the rod 130 through the pressurized liquid supply port 131A therefrom. A pair of grooves 132, 133 are formed on the circumferential surface of the rod 130, and the pressure liquid supply port 131A is located between the pair of grooves. A pair of annular seal portions 140 , 1...

no. 2 approach

[0063] (1) Structure of the second embodiment

[0064] Next, a second embodiment of the present invention will be described with reference to the drawings. image 3 It is a side sectional view showing a schematic structure of the extrusion molding apparatus 200 according to the second embodiment of the present invention. Also, in the second embodiment, for the Figure 7 The same structural elements are marked with the same symbols, and their descriptions are omitted.

[0065]A rod 230 is arranged axially inside the blank tube 2 . The rod 230 is composed of a guide rod 235 fixed to the base tube 2 and a hollow rod 236 movably arranged around the guide rod 235 . The guide rod 235 has a large-diameter portion 235A and a small-diameter portion 235B smaller in diameter than the large-diameter portion 235A. The left end portion of the large-diameter portion 235A is fixed to the contact mold 20 . The small-diameter portion 235B is formed integrally with the right end portion of t...

no. 3 approach

[0079] Figure 5 A side sectional view showing a schematic structure of an extrusion molding device 300 according to a third embodiment of the present invention. In the third embodiment, the same reference numerals are assigned to the same components as those in the second embodiment, and descriptions of components having the same functions as those in the second embodiment are omitted. In the third embodiment, the pressure liquid supply port 231A is formed on the surface of the large-diameter portion 235A of the guide rod 235 instead of being formed on the surface of the small-diameter portion 235B of the guide rod 235 . Accordingly, the sealing portion 240 on the forming direction side at the start of forming the blank tube 2 can be brought into contact with the right end portion of the large diameter portion 235A. Therefore, the initial position of the sealing portion 240 on the side in the forming direction can be easily positioned at the start of forming the blank tube. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com