Efficient pneumatic jewel channel-setting device

A high-efficiency, stone-positioning technology, applied in the field of high-efficiency pneumatic inlaying and inlaying devices, can solve the problems of low precision, inability to adapt to gems and zircons, and low efficiency, and achieve the effect of improving efficiency and precision and good effect of inlaying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

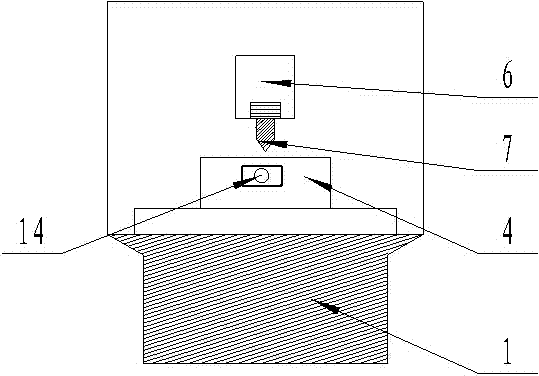

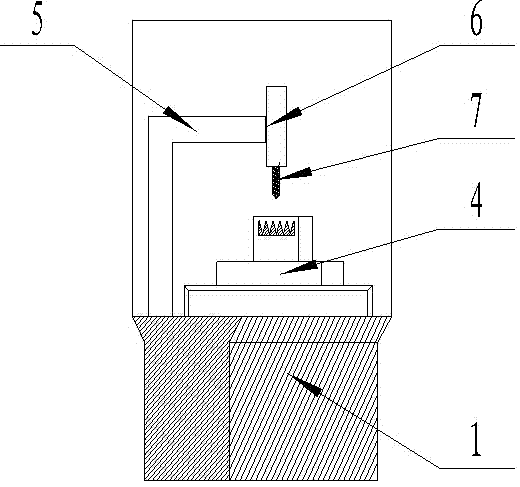

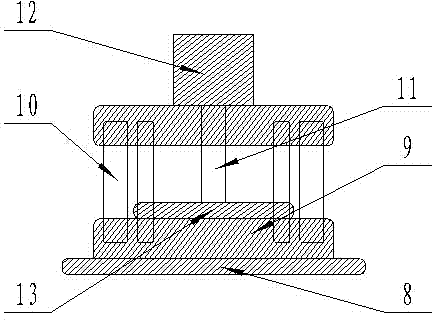

[0024] like Figure 1-3 As shown, a high-efficiency pneumatic setting stone device includes a CNC numerical control machine for processing stone holes and stone grooves and a pressing device for pressing gemstones on the surface of a workpiece; the CNC numerical control machine includes a machine base 1. X driving shaft 2 and Y driving shaft installed on the upper surface of the machine base 3. A workbench located on the upper surface of the machine base and driven by the X driving shaft and Y driving shaft for horizontal displacement 4. Fixedly installed on the machine base The pillar 5, the Z drive shaft 6 installed on the pillar and the drill bit 7 which is installed on the Z drive shaft and moves up and down under its drive; Die 9, the guide column 10 that is installed on the base, the column 11 that is installed on the base, the cylinder 12 that is installed on the column and the upper mold 13 that is driven by cylinder and moves up and down along the guide column is form...

Embodiment 2

[0031] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the X driving axis on the machine base is canceled on the CNC machine, the Y driving axis on the machine base and the A axis on the workbench are reserved, and the whole device is aimed at circular Or the cylindrical workpiece is processed with the stone hole and the stone groove, and the stone hole and the stone groove on the surface of the cylindrical or circular workpiece are processed through the rotation of the A axis and the up and down movement of the Y drive shaft. Other parts are identical with embodiment 1.

Embodiment 3

[0033] like Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the A-axis on the workbench is canceled on the CNC machine, and the X drive axis and Y drive axis on the machine base are reserved, and the whole device is used for stone-position holes for flat workpieces. For the processing of stone slots, the processing of stone slots and stone slots on the surface of the flat workpiece is realized by moving the X drive shaft and the Y drive shaft up and down, left and right. Other parts are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com