Novel horizontal directional drilling crossing percussive rotary drilling method

A technology of horizontal directional drilling and horizontal directional drilling rigs, which is applied in directional drilling, drilling equipment and methods, drilling tools, etc. It can solve the problems of increasing formation disturbance, prolonging the self-stabilization time of drilling, and the limited effect of mud stabilizing the hole wall. The effect of improving safety and stability, reducing the risk of pipeline settlement, and reducing the risk of hole collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

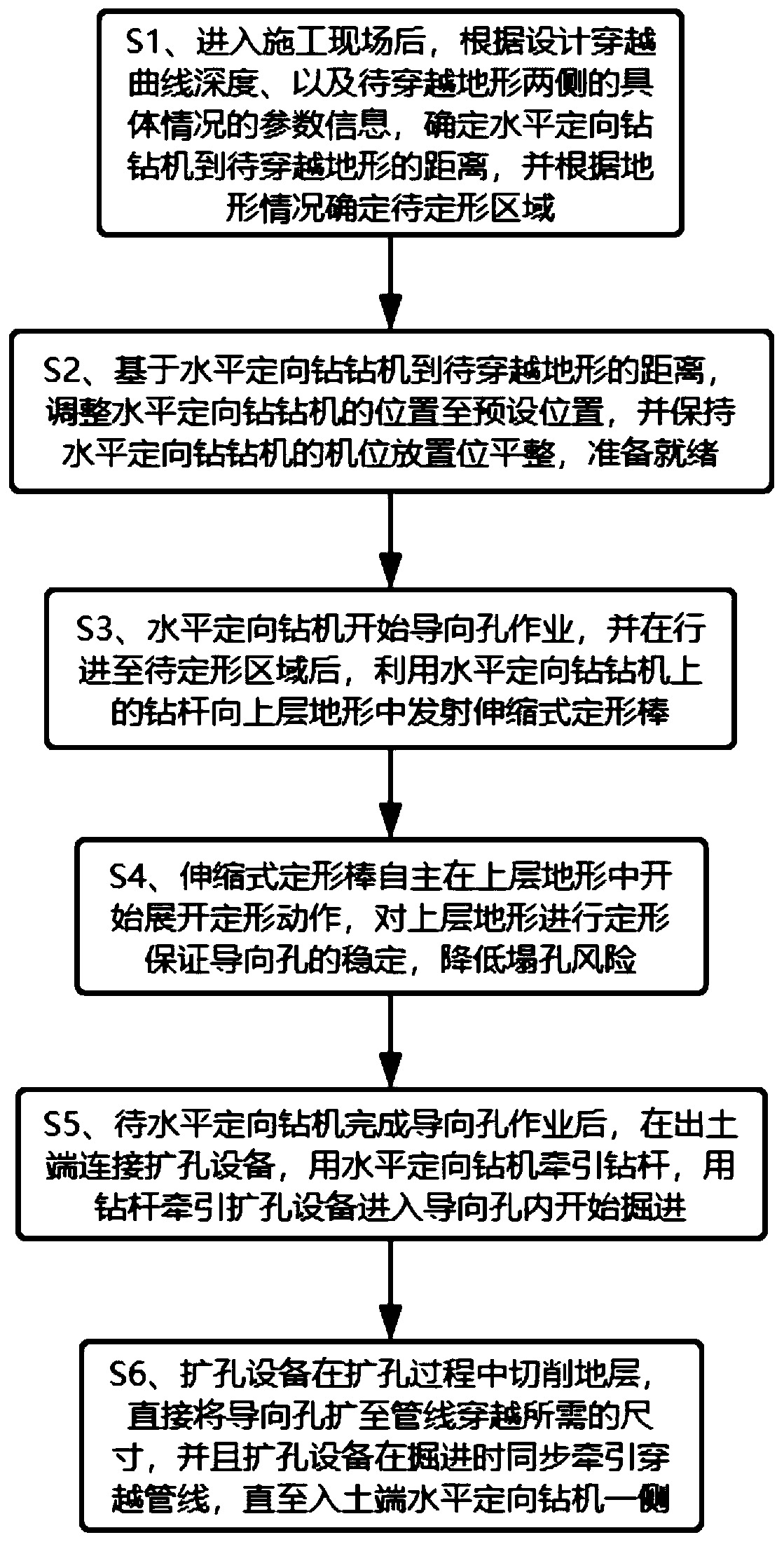

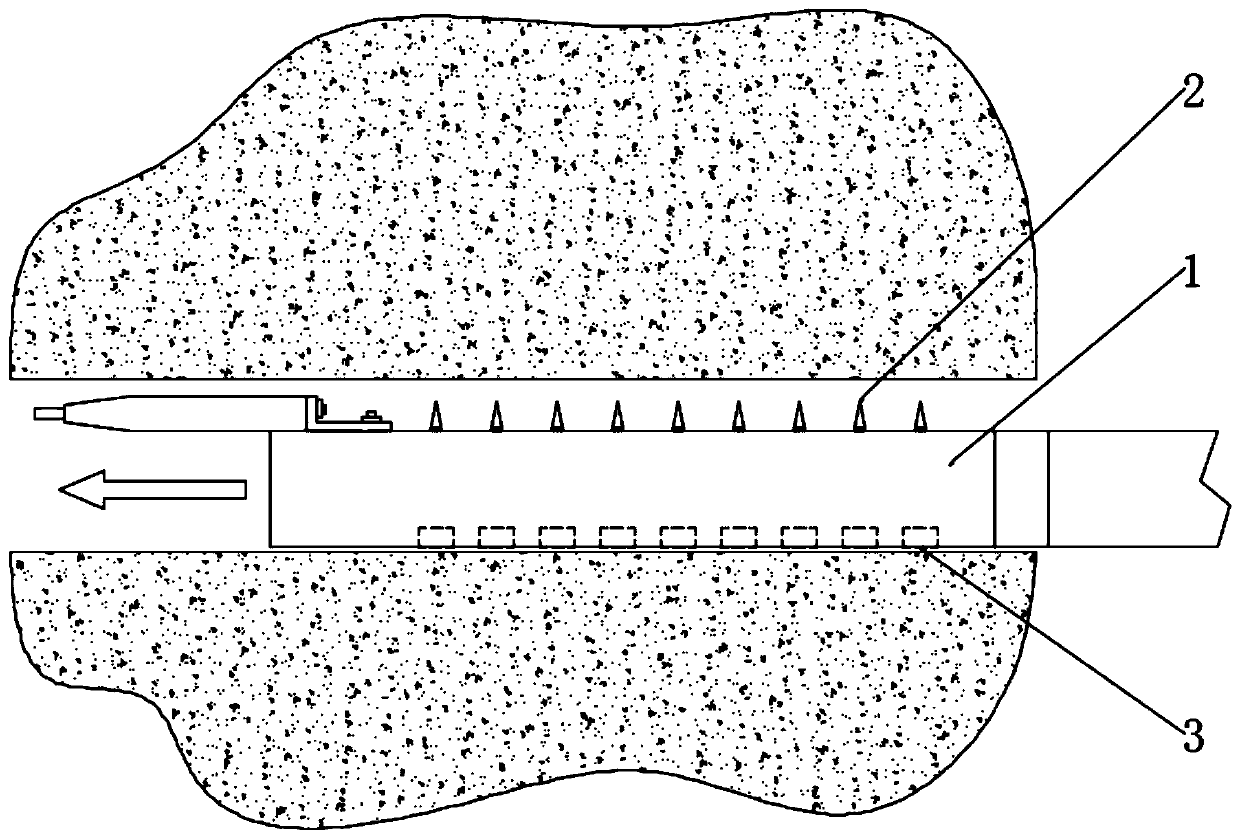

[0050] see Figure 1-2 , a novel horizontal directional drilling through percussion rotary drilling method, comprising the following steps:

[0051] S1. After entering the construction site, determine the distance from the horizontal directional drilling rig to the terrain to be crossed according to the depth of the designed crossing curve and the parameter information of the specific conditions on both sides of the terrain to be crossed, and determine the area to be shaped according to the terrain;

[0052] S2. Based on the distance from the horizontal directional drilling rig to the terrain to be traversed, adjust the position of the horizontal directional drilling rig to a preset position, and keep the position of the horizontal directional drilling rig flat and ready;

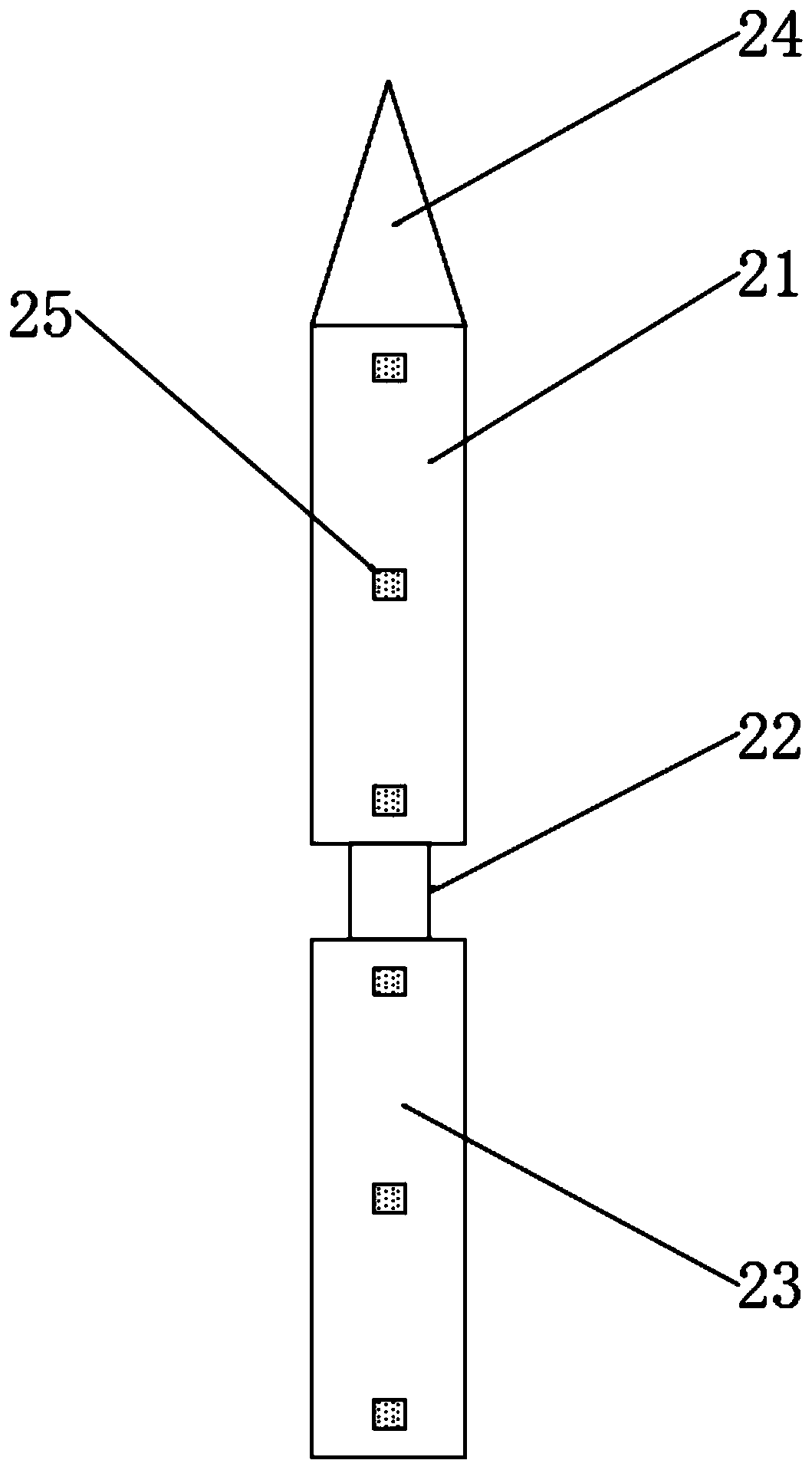

[0053] S3, the horizontal directional drilling machine starts the pilot hole operation, and after advancing to the area to be shaped, utilizes the drill pipe 1 on the horizontal directional drilling machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com