Preparation method of nitrile-butadiene rubber blend, and nitrile-butadiene rubber blend and application thereof

A technology of nitrile rubber and blends, which is applied in the field of blend preparation, can solve the problems of reducing the content of mixed rubber raw rubber, increasing the Mooney viscosity of rubber materials, and losing the processing performance of rubber materials, so as to improve the durability Solvent properties, improved grip, and improved elongation

Inactive Publication Date: 2017-06-09

ZHUZHOU TIMES NEW MATERIALS TECH

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] But the modulus of elongation that these three kinds of methods improve is very limited, adopt high acrylonitrile content at the same time, increase the Mooney viscosity of sizing material and will lose the proc

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

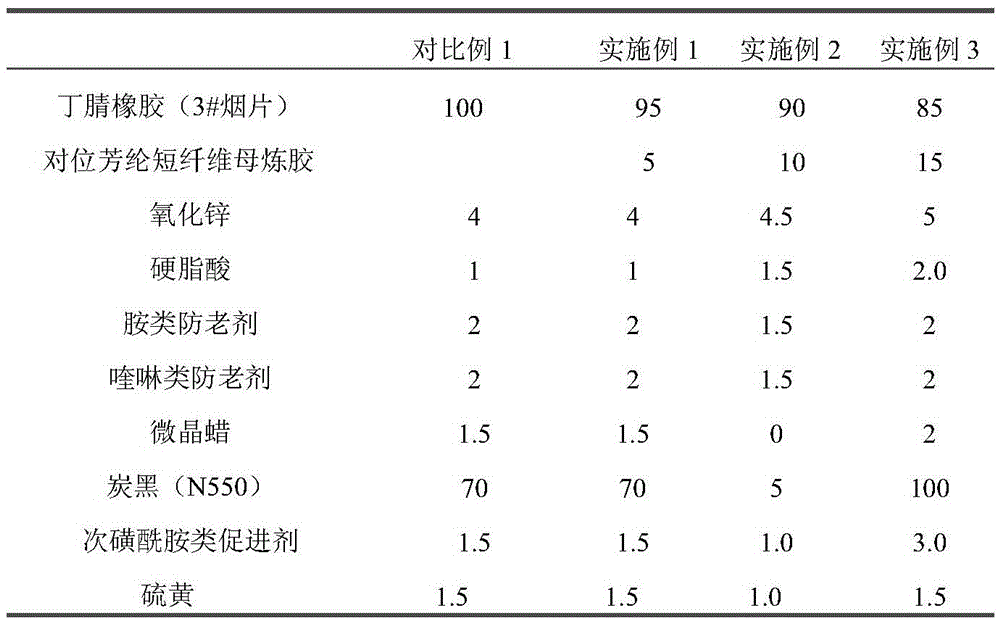

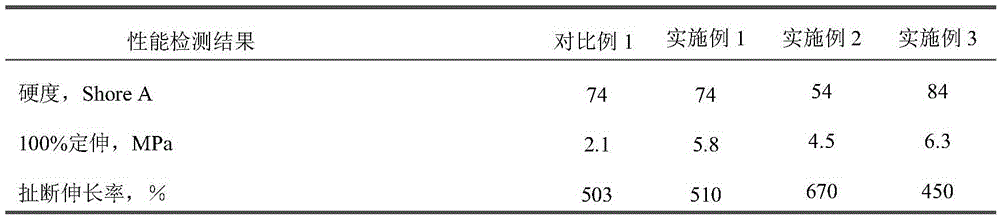

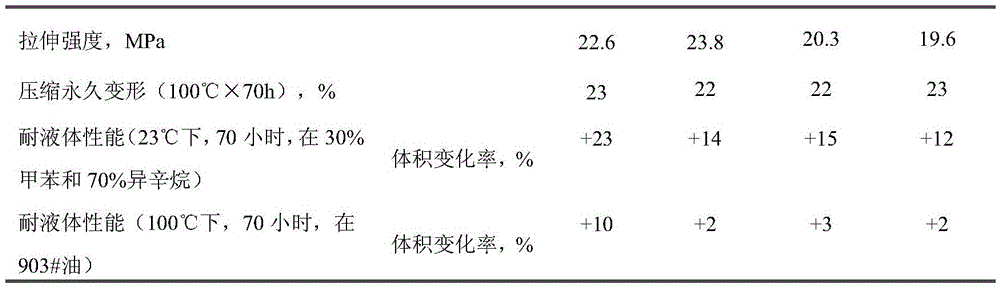

The invention relates to a preparation method of a nitrile-butadiene rubber blend. The preparation method comprises the following steps: 1) carrying out thin passing on a para-aramid short fiber master batch on an open mill, wherein the discharge batch is for later use; 2) sufficiently blending and mixing nitrile-butadiene rubber, the para-aramid short fiber master batch treated by the step 1), zinc oxide, carbon black and/or white carbon black in a Banbury mixer to obtain first compounded rubber; 3) carrying out thin passing on the first compounded rubber on an open mill until no yellow granular fibrous matters are visible, thereby obtaining second compounded rubber; 4) putting the second compounded rubber into a Banbury mixer, adding stearic acid, an anti-aging agent and a plasticizer, and sufficiently blending and mixing to obtain third compounded rubber; 5) adding a vulcanizing agent and an accelerator into the third compounded rubber at 50-100 DEG C, and blending until the vulcanizing agent is completely absorbed, thereby obtaining fourth compounded rubber; and 6) milling the fourth compounded rubber in an open mill, and discharging to obtain the nitrile-butadiene rubber blend. The invention also relates to a nitrile-butadiene rubber blend prepared by the method and application of the nitrile-butadiene rubber blend.

Description

technical field [0001] The invention relates to a preparation method, in particular to a preparation method of a blend. The invention also relates to the blends produced by this method, and their use. Background technique [0002] Among general-purpose rubbers, nitrile rubber has the best oil resistance, and is widely used in the automotive industry and petroleum industry to manufacture rubber seals, hoses, tapes, etc. Although nitrile rubber is a kind of polar rubber, the modulus of the rubber material is not high, and rubber products need higher modulus of rubber in order to improve the load-bearing capacity and solvent resistance of the product. [0003] There are generally three commonly used methods to improve the modulus of nitrile rubber. By increasing the content of acrylonitrile, increasing the Mooney viscosity of the compound and increasing the carbon black content of the compound, the modulus of the compound can be improved. [0004] But the modulus of elongatio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L9/02C08L77/10C08K13/02C08K3/22C08K3/04C08K3/36C08K5/09

Inventor 陈平李远黄自华姜其斌

Owner ZHUZHOU TIMES NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com