Cast-in-place pile hole side wall reinforcing device

A technology of reinforcement device and cast-in-place pile, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of complicated pile foundation crossing stratum, waste of reinforcement materials, bad geological development, etc., so as to reduce the risk of hole collapse and reduce friction. The effect of drag loss and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

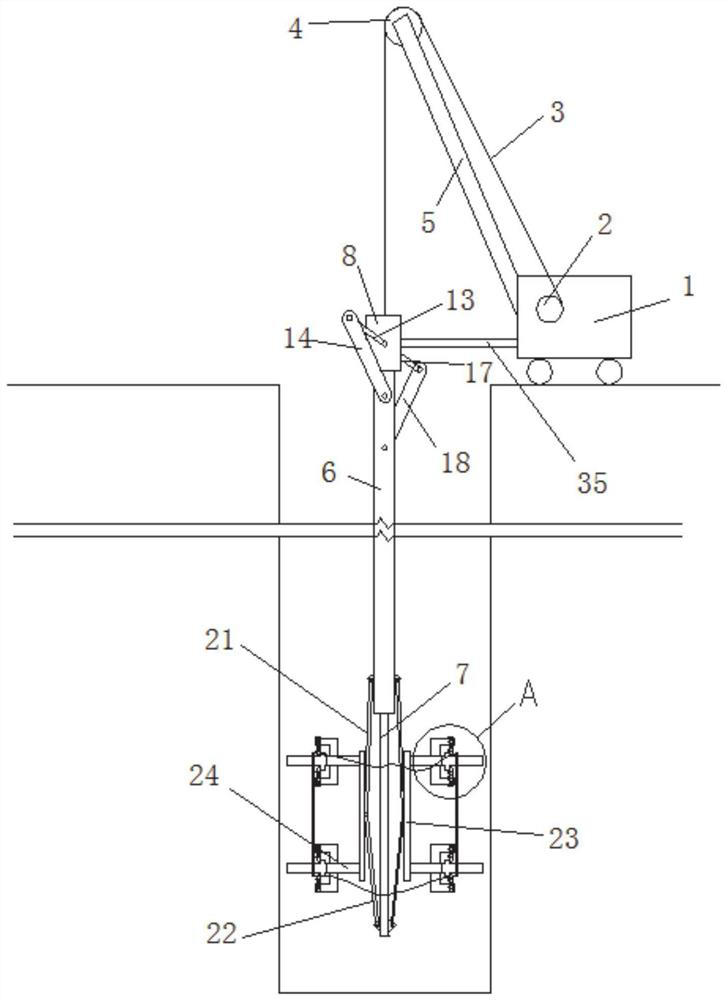

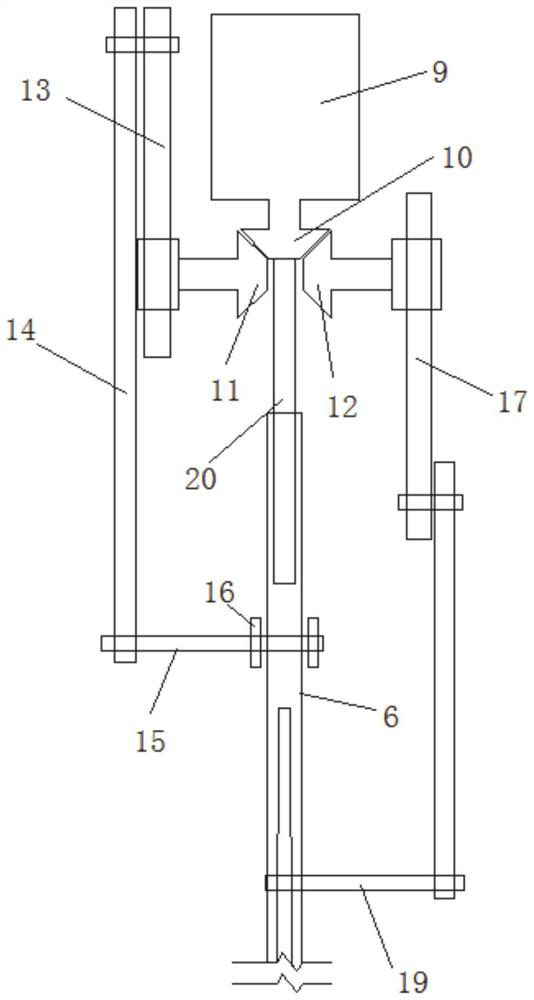

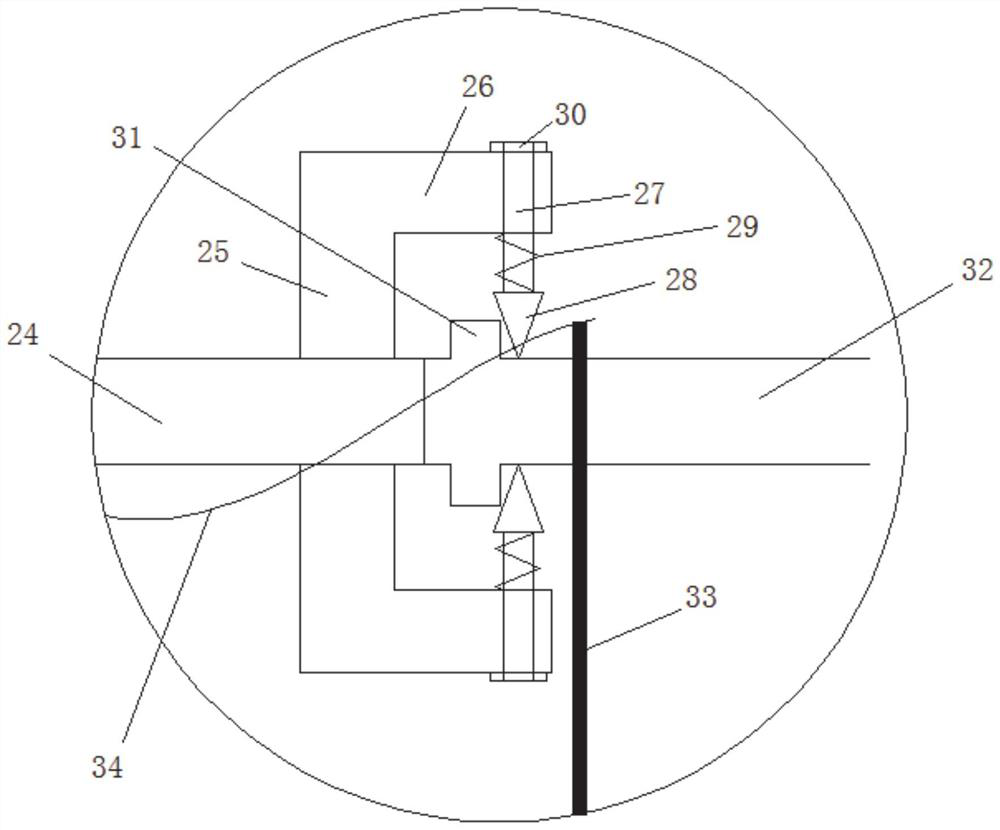

[0027] This embodiment provides a reinforcement device for the side wall of the cast-in-situ pile pile hole, such as Figure 1-Figure 3 As shown, it includes a lifting mechanism, and the lifting mechanism includes a trolley 1. The trolley adopts an existing trolley, and its specific structure is not described in detail here. The trolley 1 is equipped with a winch mechanism. Described winch mechanism adopts existing equipment and gets final product, comprises the reel 2 that is installed on the trolley, and described reel 2 is connected with motor, and motor can drive the rotation of reel, is wound with hoisting rope 3 on the reel, and described hoisting The movable end of the rope 3 is connected with the driving mechanism after bypassing the pulley 4, and the pulley 4 is connected to the end of the boom 5 in rotation, and the boom 5 is connected with the trolley 1.

[0028] The rotation of the motor can drive the reel 2 to rotate, and then drive the movable end of the hoisting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com