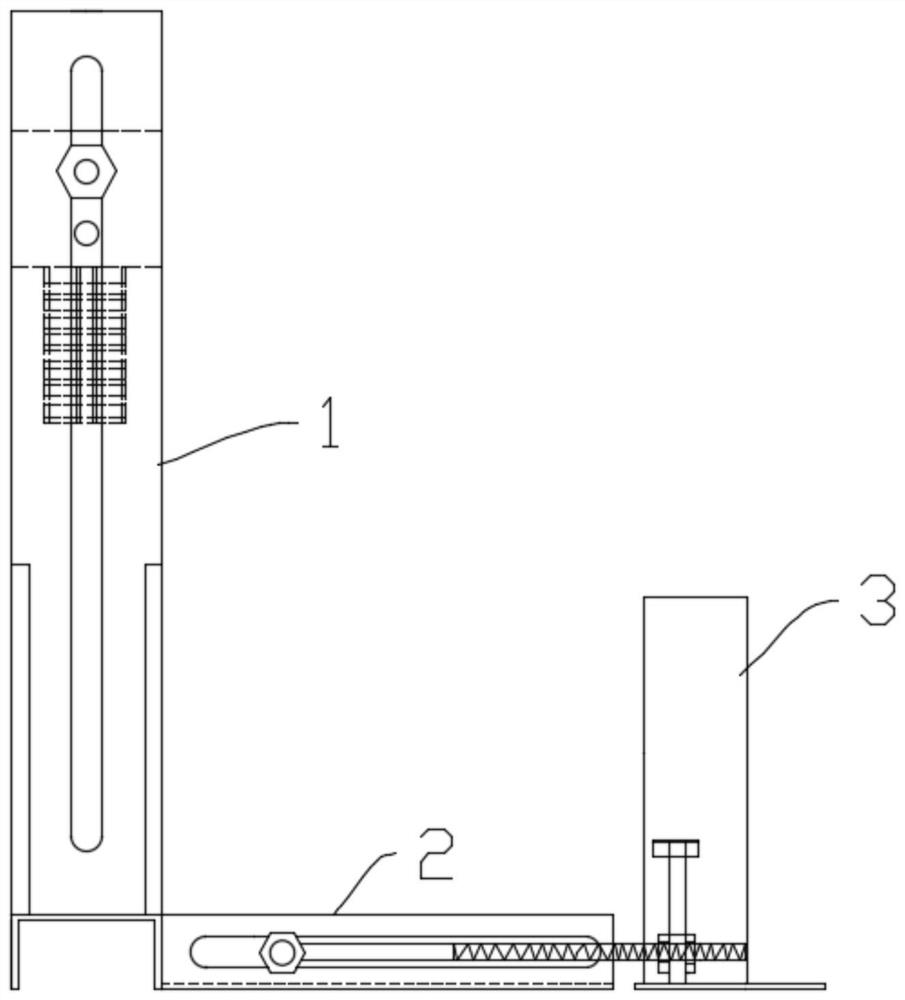

Gear shaft fixing and repairing device

A gear shaft and adjusting device technology, applied in the direction of workpiece clamping devices, workbenches, manufacturing tools, etc., can solve the problems of not spacious maintenance work platforms, poor stability of sleepers, and unguaranteed stability, so as to improve the utilization rate of the site, Easy to adjust and use, good setting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

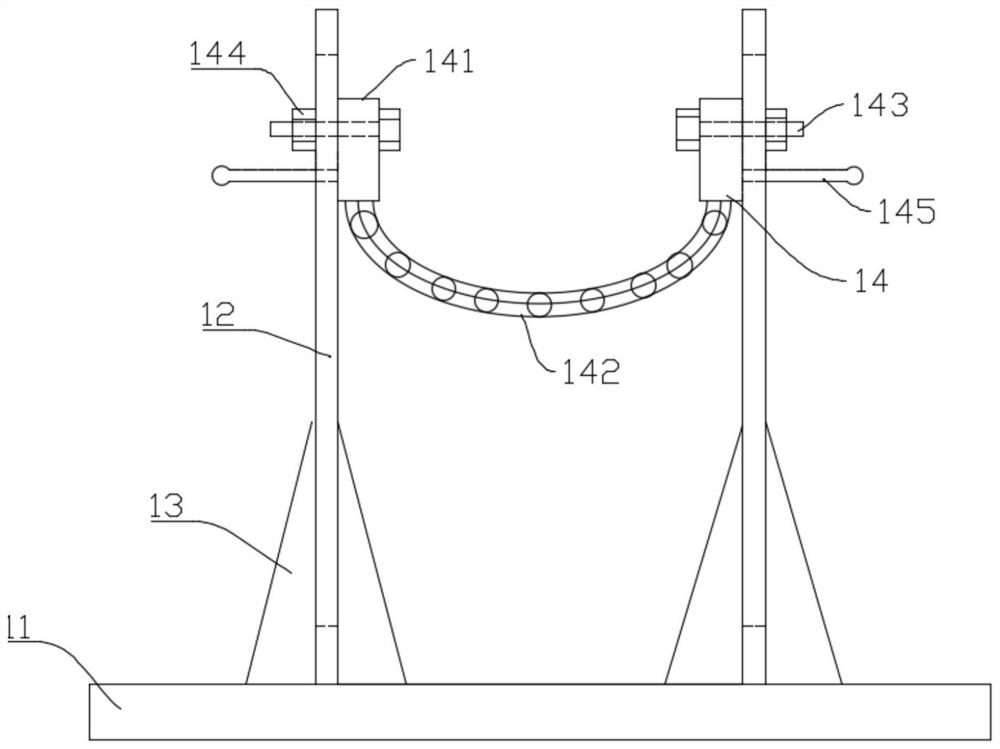

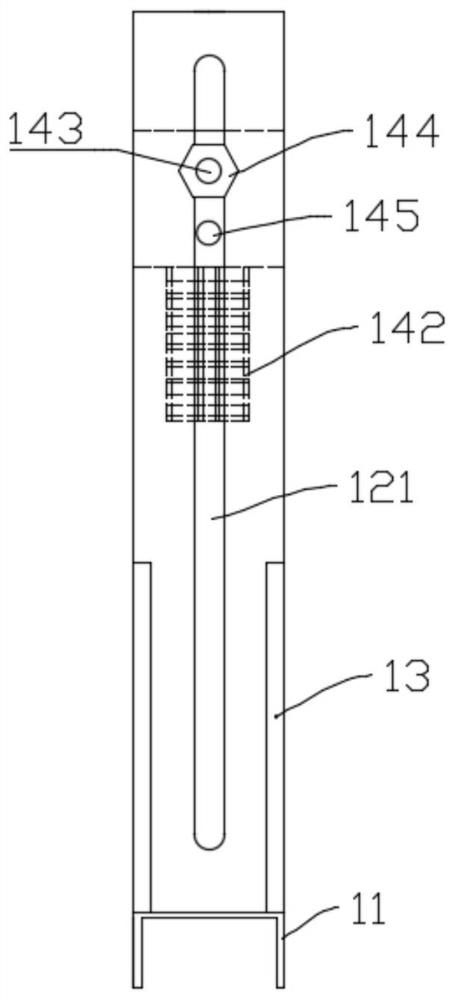

[0042] In this embodiment, the supporting foot 11 and the adjustment device 21 are preferably made of channel steel, and the fixed support frame 12, the triangular rib plate 13, the positioning block 141, the adjuster 31 and the backing plate 32 are all preferably made of steel plates, The connecting block 33 is preferably made of angle iron, and the supporting chain 142 is a double-row chain structure, the locator 34 is an arc-shaped plate structure, and the locator 34 and the backing plate 32 are all provided with a second rubber, which can effectively prevent gears from colliding with each other. Hard contact of locator 34 and backing plate 32. The supporting foot 11 and the fixed supporting frame 12 are preferably welded, the triangular rib plate 13 and the supporting foot 11 and the fixed supporting frame 12 are preferably welded, the positioning block 141 and the supporting chain 142 are preferably welded, and the handle 145 and the screw rod 143 are preferably welded wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com