Two-component split type composite FDY fiber and preparation method thereof

A composite fiber and two-component technology, applied in the field of fiber spinning, can solve the problems of poor dyeability and harsh dyeing conditions of PET

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Preparation of double-group lobed FDY fibers

[0043] Take 78 parts of polytrimethylene terephthalate chips and dry them at 140°C, put them into a polyester spinning screw extruder and melt them at 275°C; take 22 parts of polycaprolactam chips, dry them at 90°C and put them into polyamide spinning The screw extruder melts at 270°C;

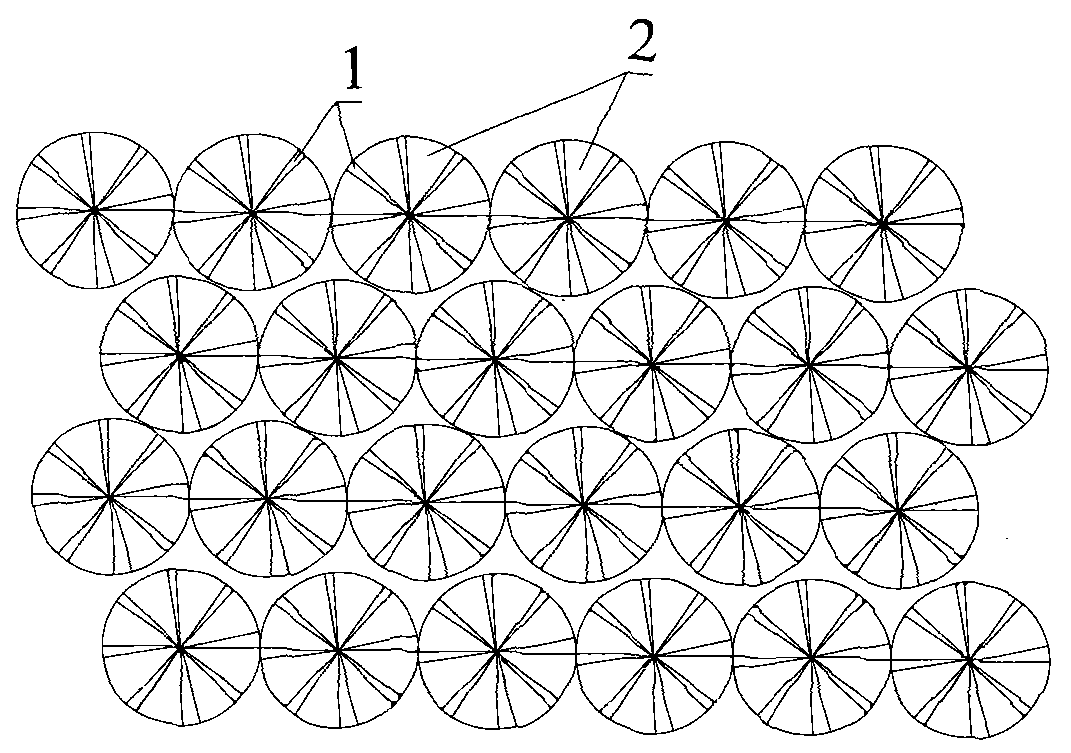

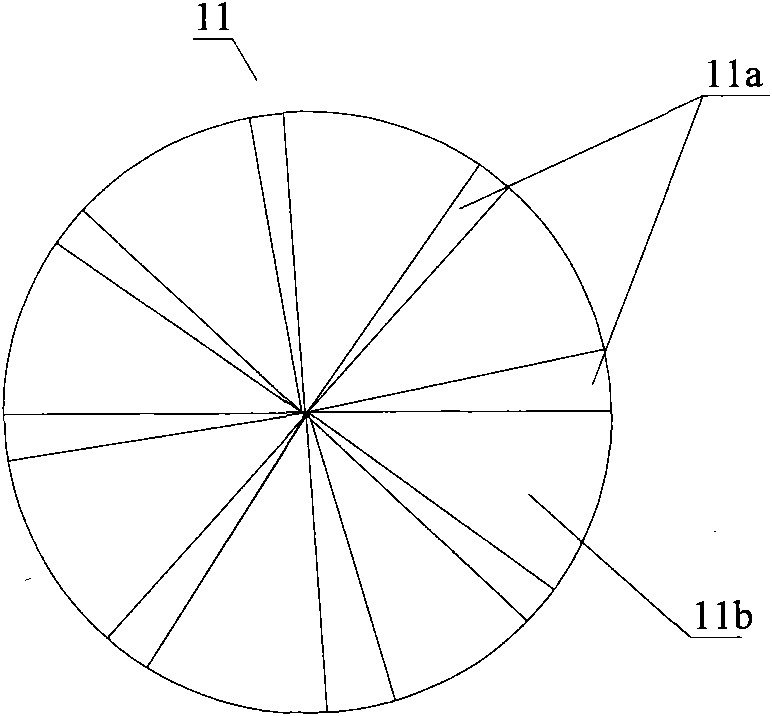

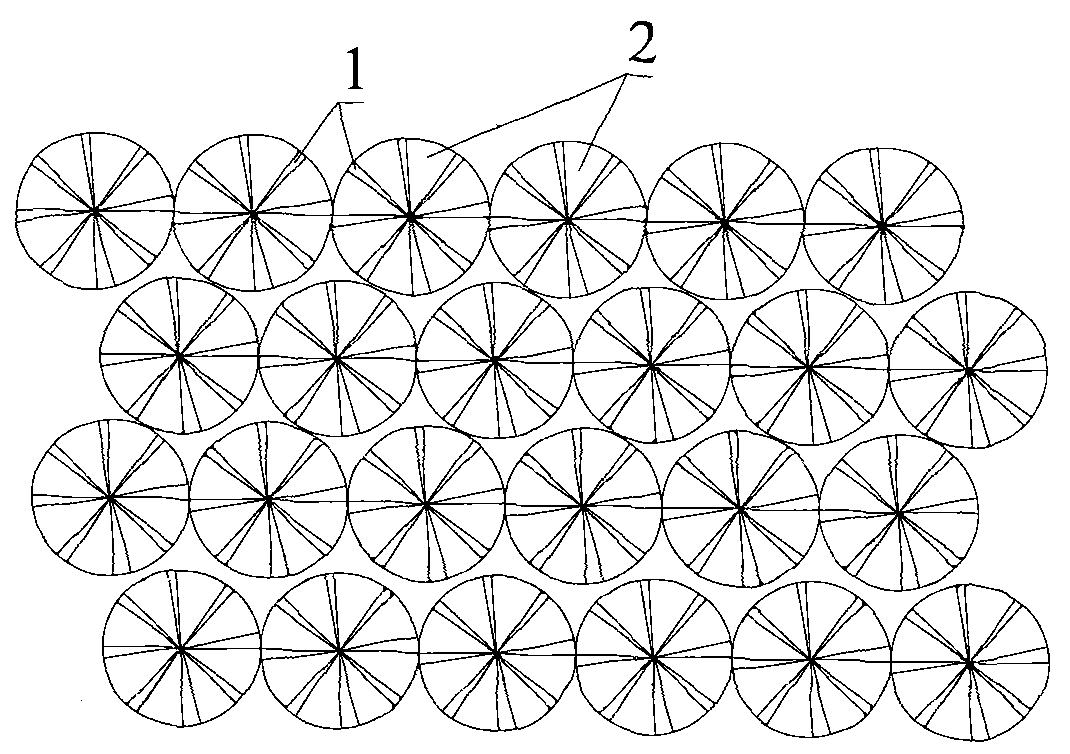

[0044] The melt of the two screw extruders was passed through as figure 2 The 8-split spinneret is extruded to obtain as-spun fibers. The following examples all use this spinneret to extrude to obtain 8-split as-spun fibers. The lobes between the fiber skeletons are composed of polycaprolactam, and the fiber lobes are polytrimethylene terephthalate;

[0045] Then, the as-spun fiber is cooled and shaped by ring blowing through a cooling blowing device, the cooling temperature is 23° C., and then oiled by an oil tanker on both sides. The oil agent is 10wt% siloxane emulsion, and the oil content of the fiber after oiling is 1.1 %, then ...

Embodiment 2 to Embodiment 4

[0049] 1. Preparation of double-group split-sheet FDY fibers

[0050] The concrete process parameter of this part operation among above-mentioned three embodiments sees Table 2:

[0051] Measure the performance of two-group split-sheet FDY fibers prepared in Examples 2 to 5, which are listed in Table 1.

[0052] 2. Preparation of two-component microfiber fabric

[0053] The process of this part of the above-mentioned three embodiments is all the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com