A preparation method of composite high-strength polylactic acid gradient membrane material

A technology of polylactic acid and gradient film, which is applied in the direction of coating, etc., can solve the problems of poor biodegradability, etc., and achieve the effect of large cross-linking degree, increased hydrophobicity, and stronger impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

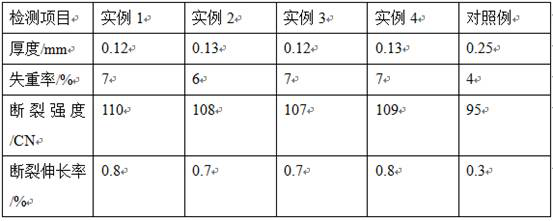

Examples

example 1

[0027]Add phosphogypsum whiskers and talc powder to the silane coupling agent, stir and mix, and place in a high-speed mixer for stirring and blending treatment. After blending for 25 minutes, let it stand to cool to room temperature, filter and collect the filter residue, and dry at 55°C After 6 hours, grind through a 200-mesh sieve to obtain inorganic reinforced particles; weigh xylitol, sebacic acid, glutamic acid and polycaprolactone respectively and place them in a three-necked flask, stir and mix and heat in an oil bath until the materials are melted Finally, pass nitrogen to remove the air, keep warm for 3 hours, let stand and cool to room temperature, collect the polymer and pour it into the mold, crosslink the reaction for 3 hours, and collect the crosslinked elastomer material; weigh 45 parts by weight Put epoxy silicone oil, 10 parts of toluene diisocyanate and 10 parts of cross-linked elastomer in a three-necked flask, stir and mix and keep warm for reaction, collec...

example 2

[0029] Add phosphogypsum whiskers and talc powder to the silane coupling agent, stir and mix, and place in a high-speed mixer for stirring and blending treatment. After blending for 26 minutes, let it stand and cool to room temperature, filter and collect the filter residue, and dry at 57°C After 7 hours, grind through a 200-mesh sieve to obtain inorganic reinforced particles; weigh xylitol, sebacic acid, glutamic acid and polycaprolactone respectively and place them in a three-necked flask, stir and mix and heat in an oil bath until the materials are melted Afterwards, ventilate nitrogen to remove the air, keep warm for 4 hours, let stand and cool to room temperature, collect the polymer and pour it into a mold, cross-link for 4 hours, and collect the cross-linked elastomer material; weigh 46 parts by weight Put epoxy silicone oil, 11 parts of toluene diisocyanate and 11 parts of cross-linked elastomer in a three-necked flask, stir and mix and keep warm for reaction, collect t...

example 3

[0031] Add phosphogypsum whiskers and talc powder to the silane coupling agent, stir and mix, and place in a high-speed mixer for stirring and blending treatment. After blending for 27 minutes, let it stand to cool to room temperature, filter and collect the filter residue, and dry at 59°C After 7 hours, grind through a 200-mesh sieve to obtain inorganic reinforced particles; weigh xylitol, sebacic acid, glutamic acid and polycaprolactone respectively and place them in a three-necked flask, stir and mix and heat in an oil bath until the materials are melted Finally, pass nitrogen to remove the air, keep warm for 4 hours, let it stand and cool to room temperature, collect the polymer and pour it into the mold, cross-linking reaction for 4 hours, and collect the cross-linked elastomer material; weigh 47 parts by weight Put epoxy silicone oil, 12 parts of toluene diisocyanate and 12 parts of cross-linked elastomer in a three-necked flask, stir and mix and keep warm for reaction, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com