Phase-change ceramsite based on waste incineration fly ash as well as preparation method and application of phase-change ceramsite

A waste incineration fly ash and ceramsite technology, applied in applications, ceramic products, and other household appliances, can solve the problems of difficulty in large-scale promotion and application and high disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Step 1: The raw materials are pulverized separately with a pulverizer or a ball mill, and passed through a 100-mesh sieve for later use;

[0063] Step 2: Mix waste incineration fly ash, clay and dried municipal sludge according to a certain mass ratio to form a mixture. The mass ratio of each component is respectively: 30 parts of waste incineration fly ash, 30 parts of clay, and 40 parts of dried sludge.

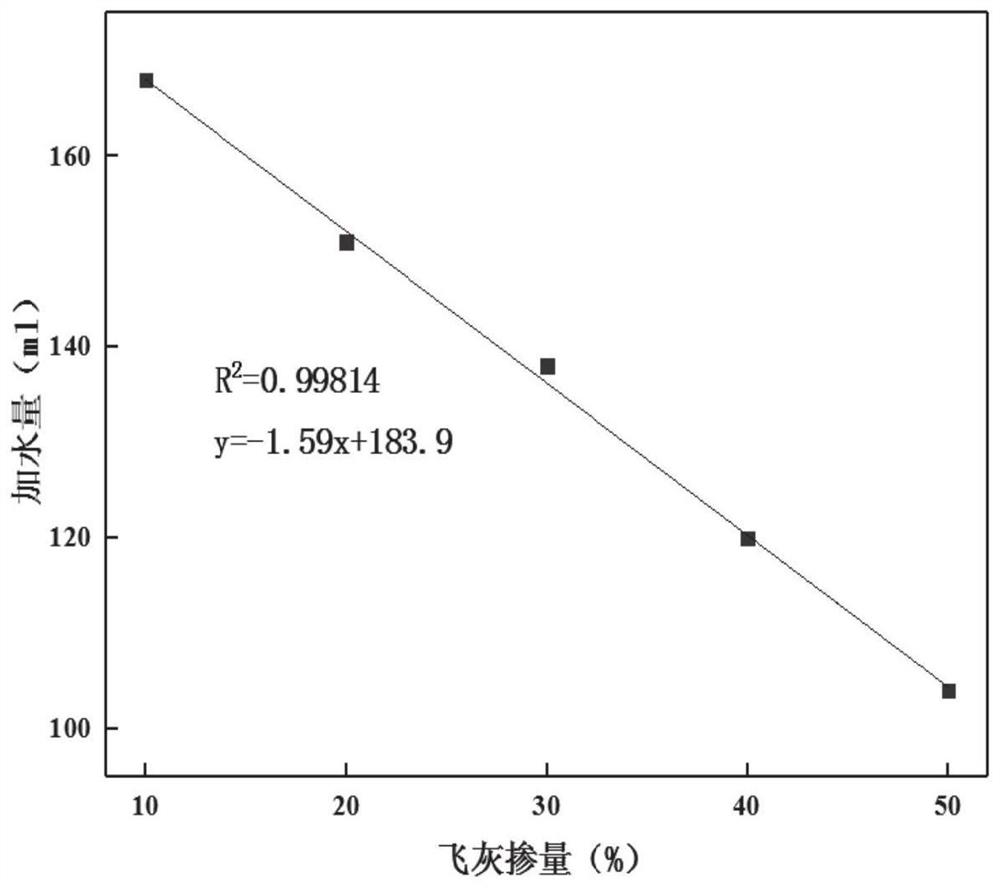

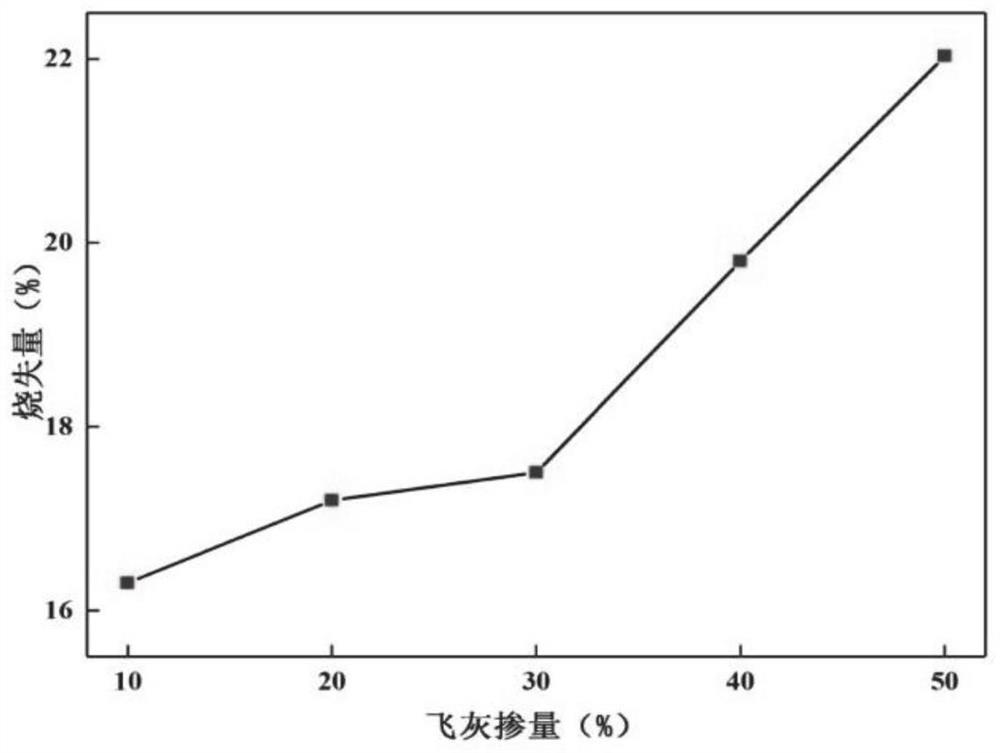

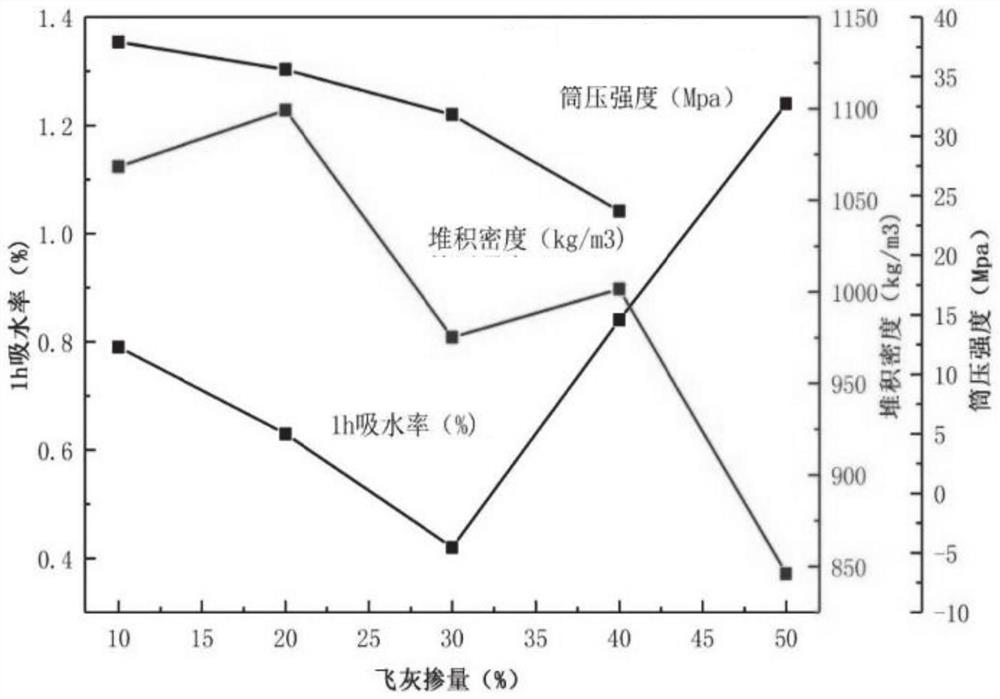

[0064] Step 3: Take an appropriate amount of water and add it to the mixture and stir evenly to make it into a ball; then granulate so that the diameter of the ceramsite is about 10-20mm; Put the container in full bloom, heat and dry it in an oven at 105°C for 4 hours, and then sinter in a muffle furnace at a temperature of 1150°C for 20-30 minutes. After sintering, cool naturally to obtain fly ash ceramsite.

[0065] (2) Preparation of phase change energy storage ceramsite:

[0066] Using paraffin as phase change material and fly ash ceramsite as carrier, phase ch...

Embodiment 2

[0069] The difference from Example 1 is 40 parts of waste incineration fly ash, 30 parts of clay, and 30 parts of dried sludge.

[0070] The phase transition temperature is 40-60°C, and the phase transition enthalpy is above 80J / g.

Embodiment 3

[0072] The difference from Example 1 is 20 parts of waste incineration fly ash, 30 parts of clay, and 50 parts of dried sludge.

[0073] The phase transition temperature is 40-60°C, and the phase transition enthalpy is above 80J / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com