Landfill leachate treatment method for garbage transfer station

A technology of landfill leachate and waste transfer station, which is applied in the field of landfill leachate treatment in waste transfer stations, which can solve problems such as potential safety hazards, large amount of concentrated water, secondary pollution of waste gas, etc., and achieve the effect of avoiding cost waste and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

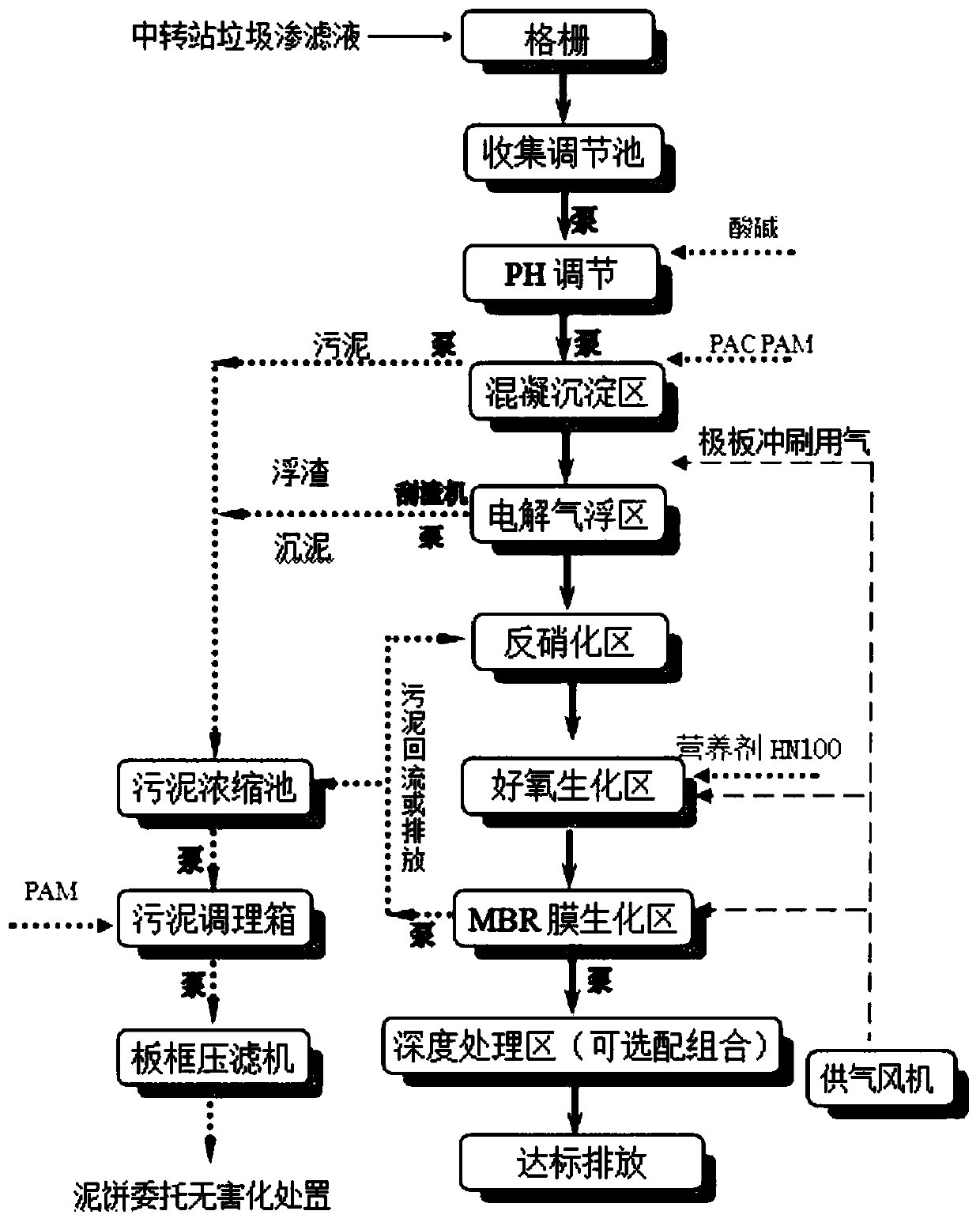

[0065] Step 1: First filter the landfill leachate through the grid, and then pass it into the collection and adjustment tank, control the hydraulic retention time of the material to 6h, adjust the water quality, and obtain the primary mixed solution; then adjust the PH, and lift the primary mixed solution through the pump Enter the pH adjustment tank, under the automatic control of the pH online controller, add alkaline chemicals to adjust the pH value, adjust the pH of the primary mixed solution to 8; after pH adjustment, pass the primary mixed solution into the coagulation tank, and add PAC , PAM coagulant agent, after coagulation for 10 minutes, easy-to-precipitate flocs are formed to obtain a mud-water mixture; the mud-water mixture enters the sedimentation tank for mud-water separation to remove precipitated particles, impurities and heavy metal pollutants. After separation, a supernatant is obtained, and the separation produces The sludge and scum are discharged into the ...

Embodiment 2

[0075] Step 1: First filter the landfill leachate through the grid, and then pass it into the collection and adjustment tank, control the hydraulic retention time of the material to 8h, adjust the water quality, and obtain the primary mixed solution; then adjust the PH, and lift the primary mixed solution through the pump Enter the pH adjustment tank, under the automatic control of the pH online controller, add alkaline chemicals to adjust the pH value, adjust the pH of the primary mixed solution to 8.5; after pH adjustment, pass the primary mixed solution into the coagulation tank, and add PAC , PAM coagulant agent, after coagulation for 13 minutes, easy-to-precipitate flocs are formed to obtain a mud-water mixture; the mud-water mixture enters the sedimentation tank for mud-water separation to remove precipitated particles, impurities and heavy metal pollutants. After separation, a supernatant is obtained, and the separation produces The sludge and scum are discharged into th...

Embodiment 3

[0084] Step 1: First filter the landfill leachate through the grid, and then pass it into the collection and adjustment tank, control the hydraulic retention time of the material to 10h, adjust the water quality, and obtain the primary mixed solution; then adjust the PH, and lift the primary mixed solution through the pump Enter the pH adjustment tank, under the automatic control of the pH online controller, add alkaline chemicals to adjust the pH value, adjust the pH of the primary mixed solution to 9; after pH adjustment, pass the primary mixed solution into the coagulation tank, and add PAC , PAM coagulant agent, after coagulation for 15 minutes, easy-to-precipitate flocs are formed to obtain a mud-water mixture; the mud-water mixture enters the sedimentation tank for mud-water separation to remove precipitated particles, impurities and heavy metal pollutants. After separation, a supernatant is obtained, and the separation produces The sludge and scum are discharged into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com