Island-fixed sea-island short fiber and its preparation method

A short fiber and island technology, applied in the field of fiber spinning, can solve the problems of poor PET dyeability, hard fabrics, harsh dyeing conditions, etc., and achieve the effect of loose molecular structure, soft texture and good dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The embodiment of the invention discloses a preparation method of fixed island type sea-island fiber, including:

[0025] Melt the island component in the first screw extruder;

[0026] Melt the sea component in the second screw extruder;

[0027] Extruding the melt of the first screw extruder and the melt of the second screw extruder through a spinning assembly to obtain nascent sea-island fibers;

[0028] The nascent sea-island fibers are successively cooled, oiled, drawn, crimped, relaxed and shaped, and then cut to obtain fixed-island sea-island short fibers.

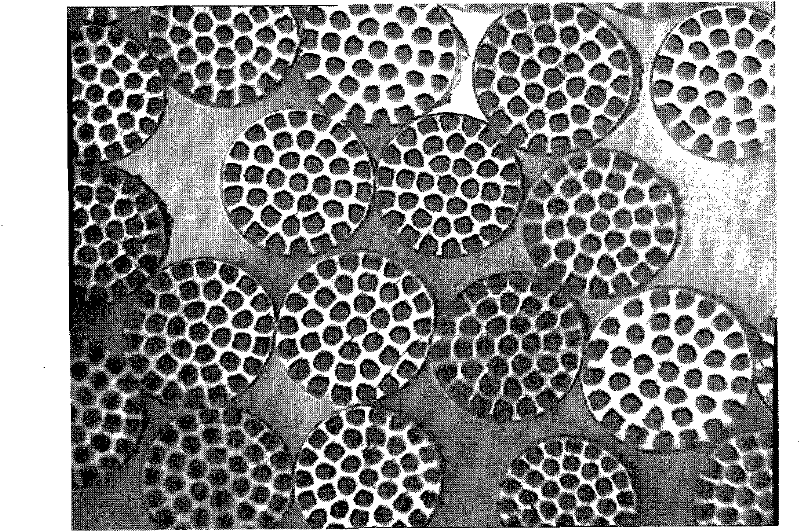

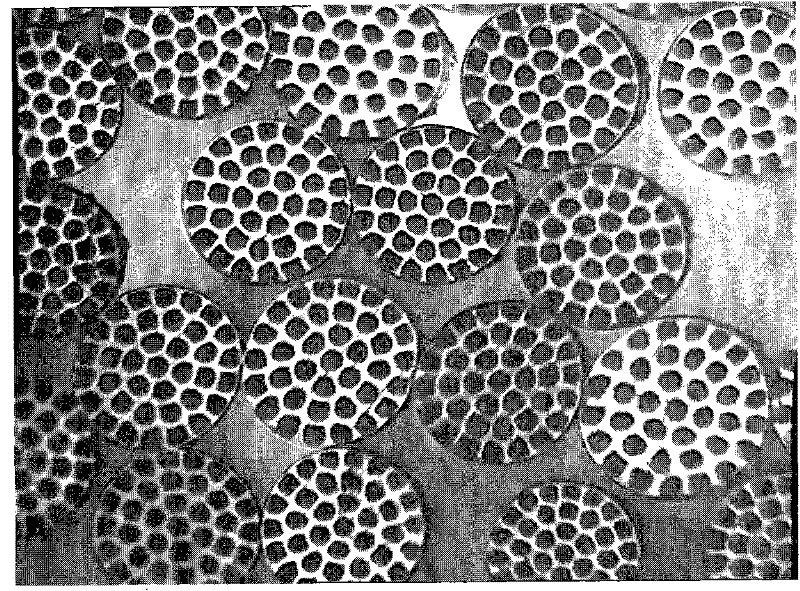

[0029] According to the present invention, the island component is PBT, and the PBT macromolecular segment has a longer flexible segment. Therefore, the fiber prepared from PBT has higher flexibility and elastic recovery rate, and has good dyeing properties. The sea component is an alkali-soluble polyester, preferably a copolyester of polyethylene terephthalate and a dicarboxylic acid (CoPET), and the dicarboxylic aci...

Embodiment 1

[0041] 1. Preparation of fixed island type island short fiber

[0042] After drying 78 parts of PBT chips at 145°C, they were put into the first screw extruder to melt at 260°C; 22 parts of CoPET chips were dried at 125°C and put into the second screw extruder to melt at 275°C.

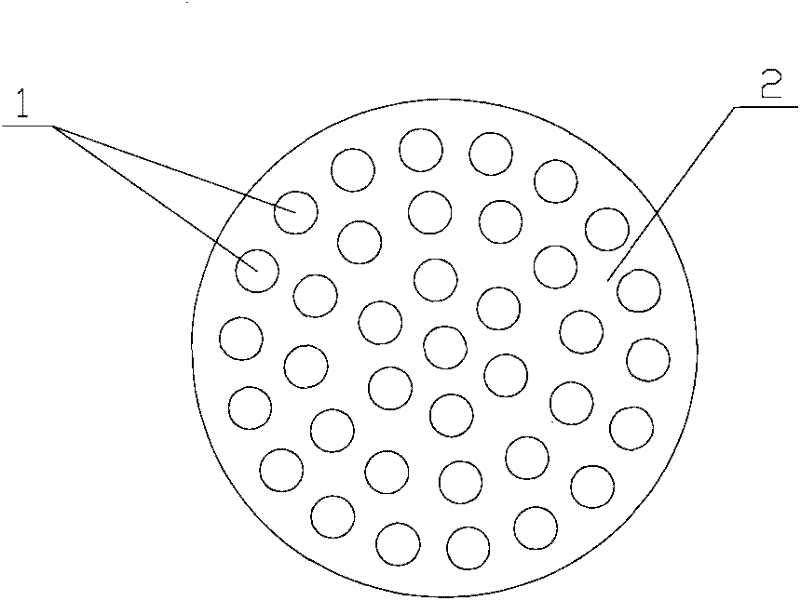

[0043] The melt of the two screw extruders figure 1 The spinneret shown is extruded to obtain primary sea-island fibers. The following embodiments are all used for extrusion molding with this spinneret at an extrusion pressure of 11Mpa to obtain primary sea-island fibers with an island number of 37. The primary sea-island fibers are formed from islands. The facies and the marine facies surrounding the island facies are composed of PBT and COPET in the marine facies;

[0044] Then, the nascent sea-island fiber is cooled and shaped by side blowing through a cooling and blowing device at a cooling temperature of 23°C, and then oiled by a double-sided tanker. The oiling agent is 4wt% silicone emulsion, and the o...

Embodiment 2 to Embodiment 4

[0049] 1. Preparation of fixed island type island short fiber

[0050] The above three examples all use PBT as the island phase and COPET as the sea phase. The specific process parameters are shown in Table 2, and the properties of the island-shaped sea-island short fibers prepared in Examples 2 to 5 are measured and listed in Table 1.

[0051] 2. Preparation of PBT ultrafine fiber non-woven fabric

[0052] This step of the above three embodiments is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com