Continuous casing running operation circulation device and method

A technology of circulation device and casing, applied in drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve problems such as no effective technical countermeasures, non-existence, etc., and achieve enhanced sealing, good effect, and sealing powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

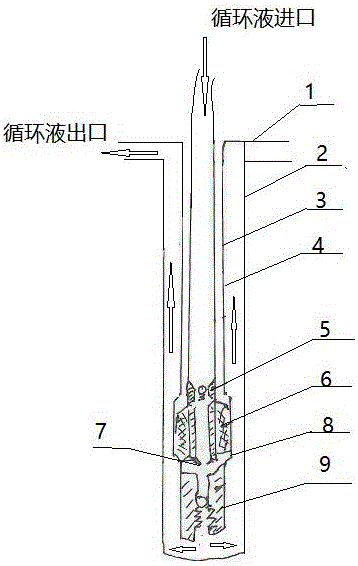

[0033] In order to overcome problems such as wellbore necking, block loss, and lost circulation, when the drilling fluid needs to be circulated, the actual hollowing out of the casing string does not exist, and the load of the casing string will be greater than the maximum load of the drilling rig. The present invention provides such as figure 1 Shown is a continuous circulation device and method for casing running operation. In the process of hollowing out and running the casing, the present invention can circulate halfway, but will not completely fill the inside of the casing with drilling fluid. The casing can be circulated while running downhole without increasing the actual load of the casing string.

[0034] A continuous circulation device for casing operation, including a wellbore 2 and a casing 3, the casing 3 is connected with the lower end of the special nipple 8 and the floating hoop 9 to form a casing string, and the casing string is located in the well Inside the ...

Embodiment 2

[0038] Based on Embodiment 1, in this embodiment, the lower end of the packer 6 is provided with a nozzle 7 .

[0039] The packer 6 is a rubber bucket packer.

[0040] The internal diameter of the special short joint 8 is 2 mm larger than that of the conventional casing, and its smoothness reaches 7.

[0041] The characteristic short joint 8 has a length of 1-1.5m.

[0042] The casing 3 has an outer diameter of 244.5 mm; the continuous tube 4 has an outer diameter of 62 mm.

[0043] The packer 6 adopted in the present invention is a rubber barrel type, and the rubber barrel type packer 6 can effectively perform setting, has good setting effect and strong sealing performance. The special pup 8 also used is to grind and polish the inner wall of the conventional pup, so that the glossiness of the inner wall of the pup reaches 7, so that when the packer 6 is set, the surface tension of the pup prepared in this way becomes larger and equal to The sealability of the contact surfa...

Embodiment 3

[0046] Based on the above-mentioned embodiments, this embodiment provides a continuous cycle method for running casing operations, and the specific steps are:

[0047] Step 1 Run the casing 3, the special nipple 8 and the floating hoop 9 into the wellbore 2 in order to form a string of casings, and place the casing 3 on the wellhead 1;

[0048] Step 2 Connect coiled tubing 4, one-way valve 5 and packer 6 in sequence, fill the connected coiled tubing 4 with circulating fluid, and run it into casing 3 at wellhead 1;

[0049] Step 3: Lower the packer 6 in step 2 to the special sub-joint 8 in step 1 and start the pump cycle;

[0050] Step 4 After completing the circulation, close the circulation pump, and lift the coiled tubing 4 out of the wellhead 1;

[0051] Step 5 After the cycle is completed, continue to run casing 3;

[0052] Step 6 In the subsequent casing running 3 process, when the cycle is performed, the above steps are repeated until the operation is completed.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com