A kind of epoxy resin composite shape-setting phase change material and its preparation method and application

A technology of shape-setting phase-change materials and epoxy resins, applied in the fields of application, heat exchange materials, chemical instruments and methods, etc., can solve problems such as overheating of pumping, less research on shape-setting phase-change materials, and affecting user pumping experience, etc. Achieve the effects of improving thermal conductivity, excellent solid-solid phase transition, and excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of EGDS / EP Composite Shaped Phase Change Material Particles

[0041]In a water bath at 65°C, add 16.26g of EGDS to a 100mL round bottom flask, and add 5mL of 0.5% sodium dodecylbenzenesulfonate (SBDS) ethanol solution to dissolve it evenly, then add 10g of epoxy The resin was stirred for 30 min. Based on the mass percentage of EP, add 3.3g curing agent at a mass ratio of 3:1, continue to stir for about 20 minutes until the mixture enters the gel-like solidified phase, then cast the mixture in a tin foil mold while it is hot, and transfer it after cooling. Put it on a watch glass and put it in a 50°C oven to cure for 48h. The solidified target product was cooled to room temperature to obtain an EGDS / EP composite shape-setting phase change material with a mass ratio of 55:45. The prepared material is crushed and passed through a 10-20 mesh screen to obtain 10-20 mesh particles of the EGDS / EP shaped phase change material.

[0042] Application of EGDS / EP comp...

Embodiment 2

[0044] Preparation of EGDS / EP / Ag Composite Shaped Phase Change Material Particles

[0045] In a water bath at 65°C, 16.26g of EGDS was added to a 100mL flask, and 5mL of SBDS ethanol solution with a mass fraction of 0.5% was added to dissolve it uniformly, and then 5wt% of silver powder was added based on the mass percentage of EGDS / EP. After it is dispersed evenly, add 10g of epoxy resin and stir for 30min. Based on the mass percentage of EP, add 3.3g curing agent at a mass ratio of 3:1, continue to stir for about 20 minutes until the mixture enters the gel-like solidified phase, then cast the mixture in a tin foil mold while it is hot, and transfer it after cooling. Put it on a watch glass and put it in a 50°C oven to cure for 48h. The solidified target product is cooled to room temperature to obtain a thermal conductivity-enhanced EGDS / EP / Ag composite shape-setting phase change material. The prepared material is crushed through 10-20 meshes to obtain 10-20 mesh particles ...

Embodiment 3

[0048] Preparation of EGDS / EP / MNWTs composite shape-setting phase change material composite shape-setting phase change material particles

[0049] The implementation method is the same as that of the specific embodiment 2, only the silver powder of the heat conducting material is replaced with multi-walled carbon nanotubes.

[0050] Application of EGDS / EP / MNWTs composite shape-setting phase-change material particles: the test method is the same as in Example 1; 10-20 mesh EGDS / EP / MNWTs composite shape-setting phase-change material particles can change the temperature of the first smoke at the filter end from the control sample The temperature of iQOS heat-not-burn cigarette products dropped from 54.7°C to 46°C, and the temperature of the smoke at the first filter end dropped by 8.8°C compared with that of iQOS supporting cigarettes.

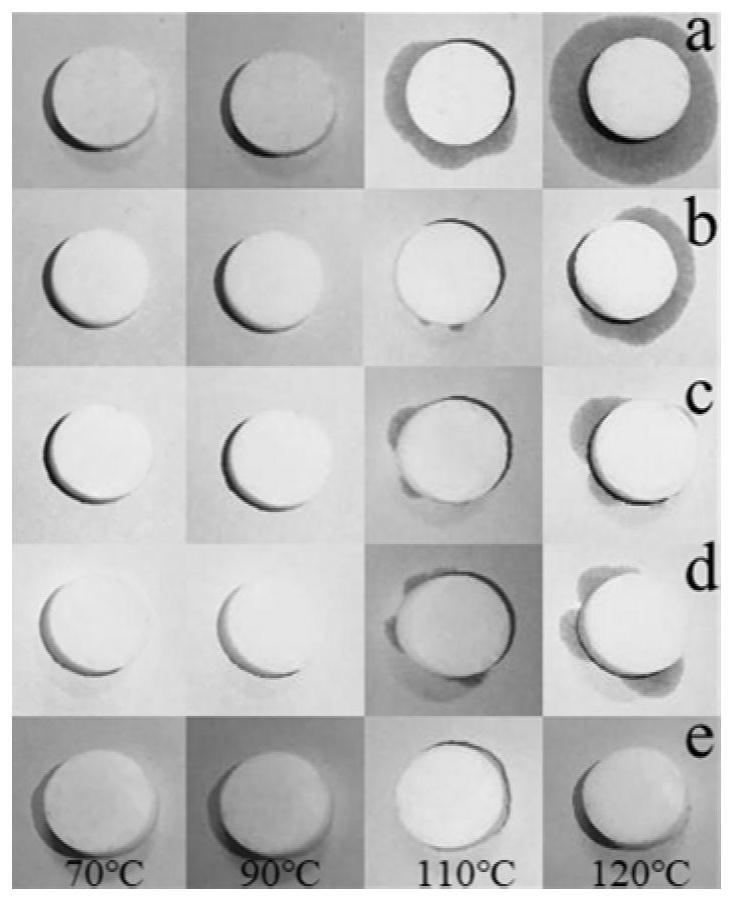

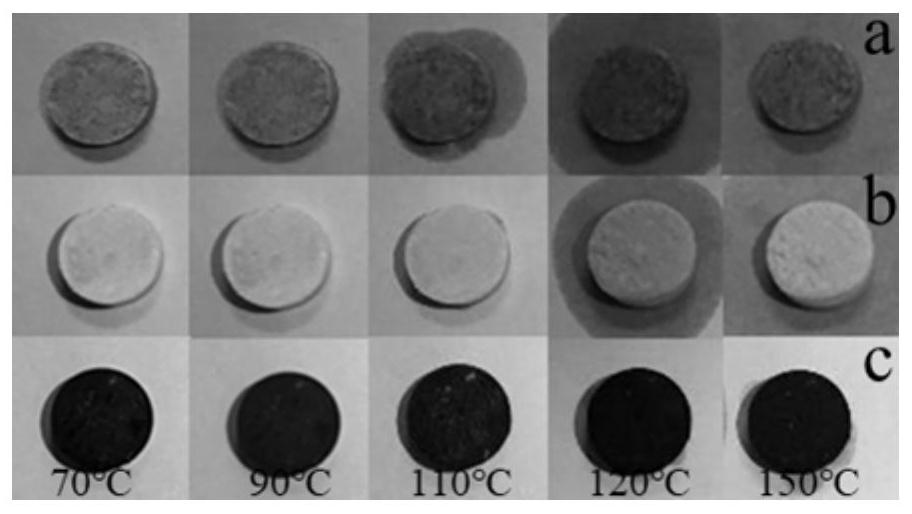

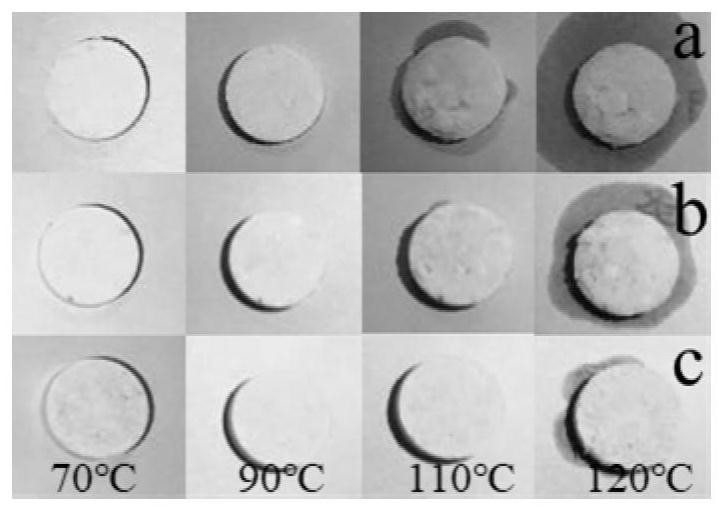

[0051] The leakage test of the present invention is as follows: figure 1 A photograph of an epoxy-based shape-setting phase-change material du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com