Dyeing method of natural fiber

A natural fiber and dyeing method technology, applied in the field of natural fiber dyeing, can solve the problems of losing the main advantages of anhydrous supercritical carbon dioxide dyeing, weak interaction between natural plant dyes and cotton fibers, poor fastness, etc., and achieve good Social benefits, excellent reproducibility and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

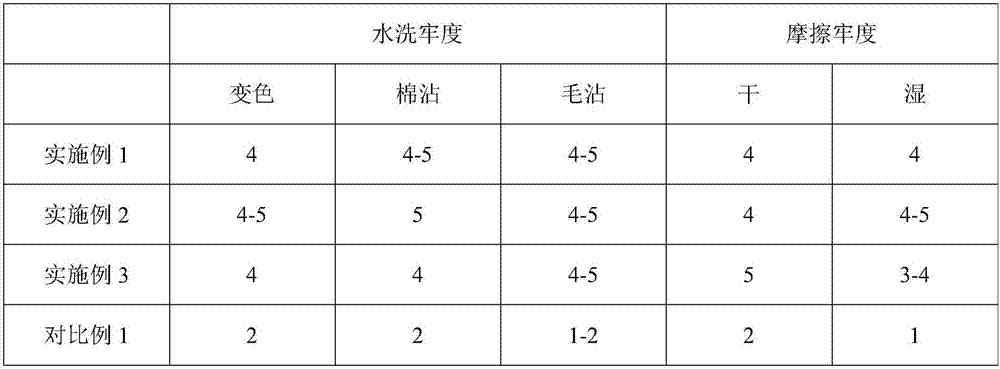

Examples

Embodiment 1

[0035] This embodiment discloses a method for dyeing natural fibers utilizing supercritical carbon dioxide fluid, and the specific steps are as follows:

[0036] Step 1. Extract 1g of natural plant dyes to 80 mesh in a fineness extractor, add liquid carbon dioxide and dimethylformamide into the supercritical carbon dioxide dyeing device, heat to 105°C, and keep for 30 minutes, then add natural fibers In the supercritical carbon dioxide dyeing device, dyeing is carried out at a temperature of 150° C. and a pressure of 25 MPa for 100 minutes. The mass ratio of the natural vegetable dye to the natural fiber is 1:10. Described fixing agent is 15g / L.

[0037] Step 2, controlling the supercritical carbon dioxide dyeing device to release the pressure, and recovering the carbon dioxide and the natural plant dye under the conditions of a temperature of 25-35° C. and a pressure of 4-6 MPa.

[0038] Step 3: Control the supercritical carbon dioxide dyeing device to release the pressure,...

Embodiment 2

[0043] This embodiment discloses a method for dyeing natural fibers utilizing supercritical carbon dioxide fluid, and the specific steps are as follows:

[0044] Step 1. Extract 1g of natural plant dyes to 100 mesh in a fineness extractor, add liquid carbon dioxide and ethylenediamine to the supercritical carbon dioxide dyeing device, heat to 125°C, and keep for 20 minutes, then add natural fibers to the supercritical carbon dioxide dyeing device. In the critical carbon dioxide dyeing device, dyeing is carried out under the conditions of a temperature of 130° C. and a pressure of 24 MPa, and is maintained for 90 minutes. The mass ratio of the natural vegetable dye to the natural fiber is 1:7. Described fixing agent is 12g / L.

[0045] Step 2, controlling the supercritical carbon dioxide dyeing device to release the pressure, and recovering the carbon dioxide and the natural plant dye under the conditions of a temperature of 25-35° C. and a pressure of 4-6 MPa.

[0046] Step 3...

Embodiment 3

[0050]This embodiment discloses a method for dyeing natural fibers utilizing supercritical carbon dioxide fluid, and the specific steps are as follows:

[0051] Step 1. Extract 1g of natural plant dyes to 100 mesh in a fineness extractor, add liquid carbon dioxide and diethylenetriamine into the supercritical carbon dioxide dyeing device, heat to 107°C, and keep for 30 minutes, then add natural fibers to the In the supercritical carbon dioxide dyeing device, the dyeing was carried out at a temperature of 140° C. and a pressure of 20 MPa, and was maintained for 110 minutes. The natural plant dye described in the present embodiment is turmeric dye, and described natural fiber is cotton fiber. The mass ratio of the natural vegetable dye to the natural fiber is 1:5. Described fixing agent is 10g / L.

[0052] Step 2, controlling the supercritical carbon dioxide dyeing device to release the pressure, and recovering the carbon dioxide and the natural plant dye under the conditions o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com