Patents

Literature

47results about How to "Achieve dyeing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

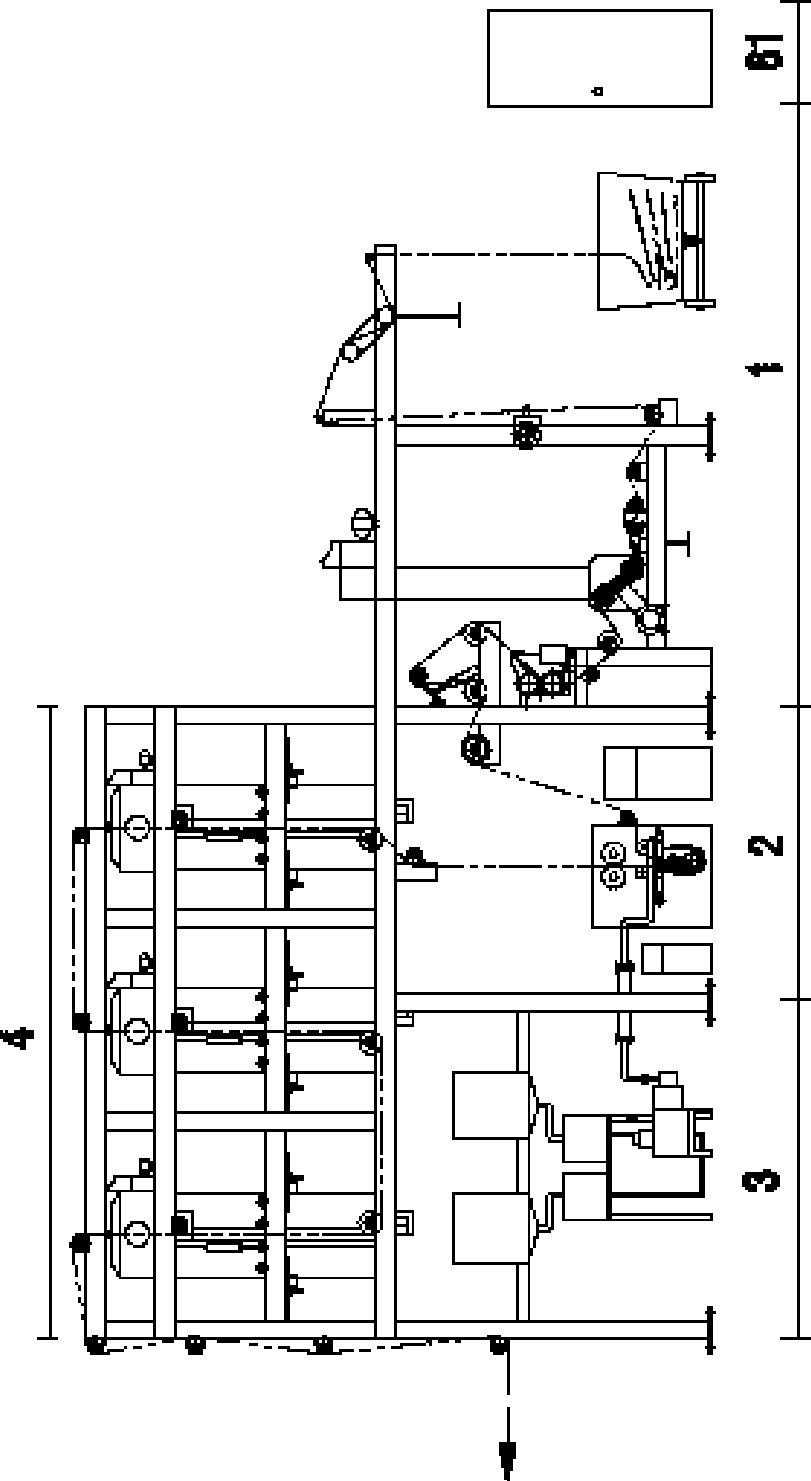

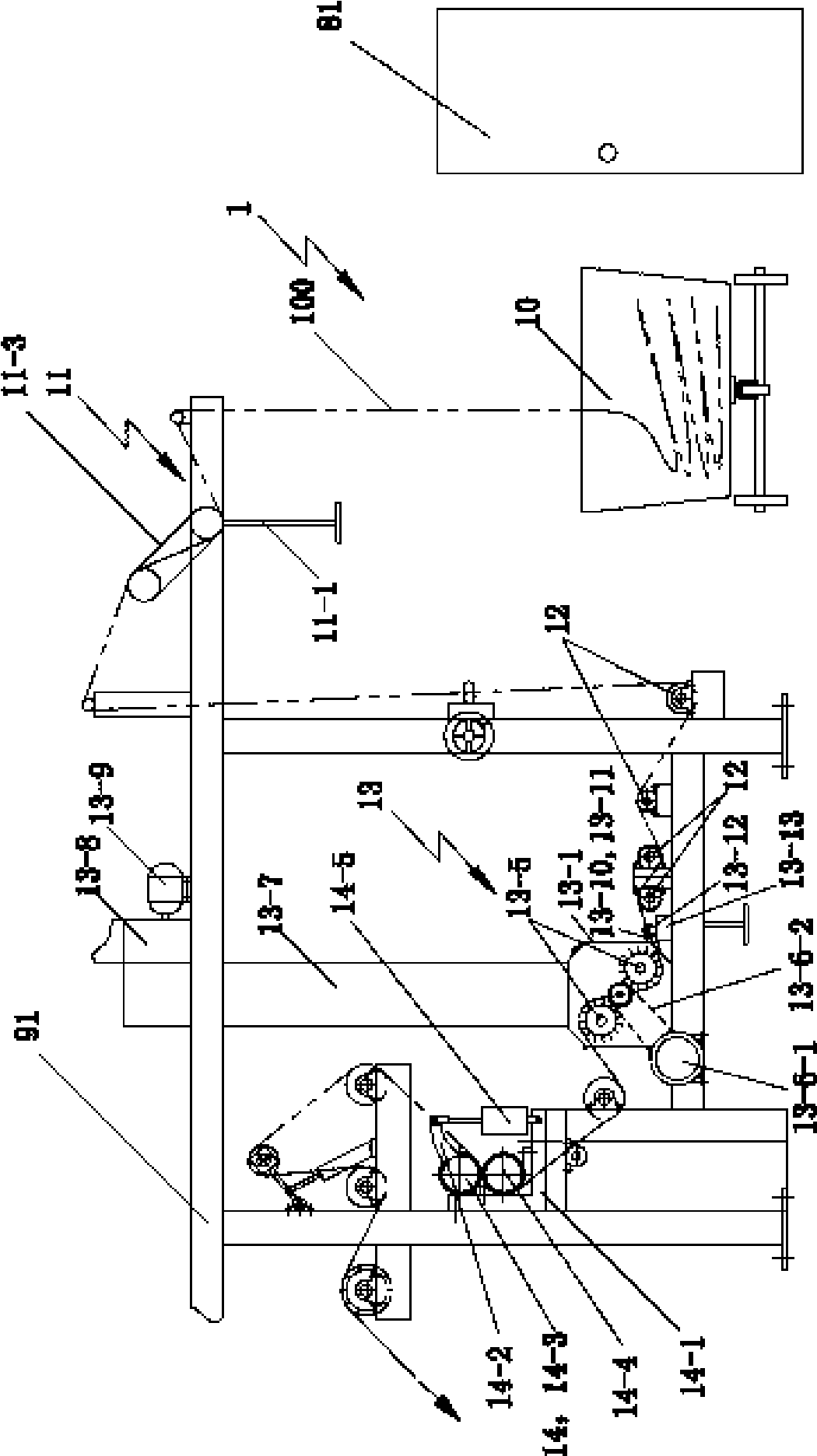

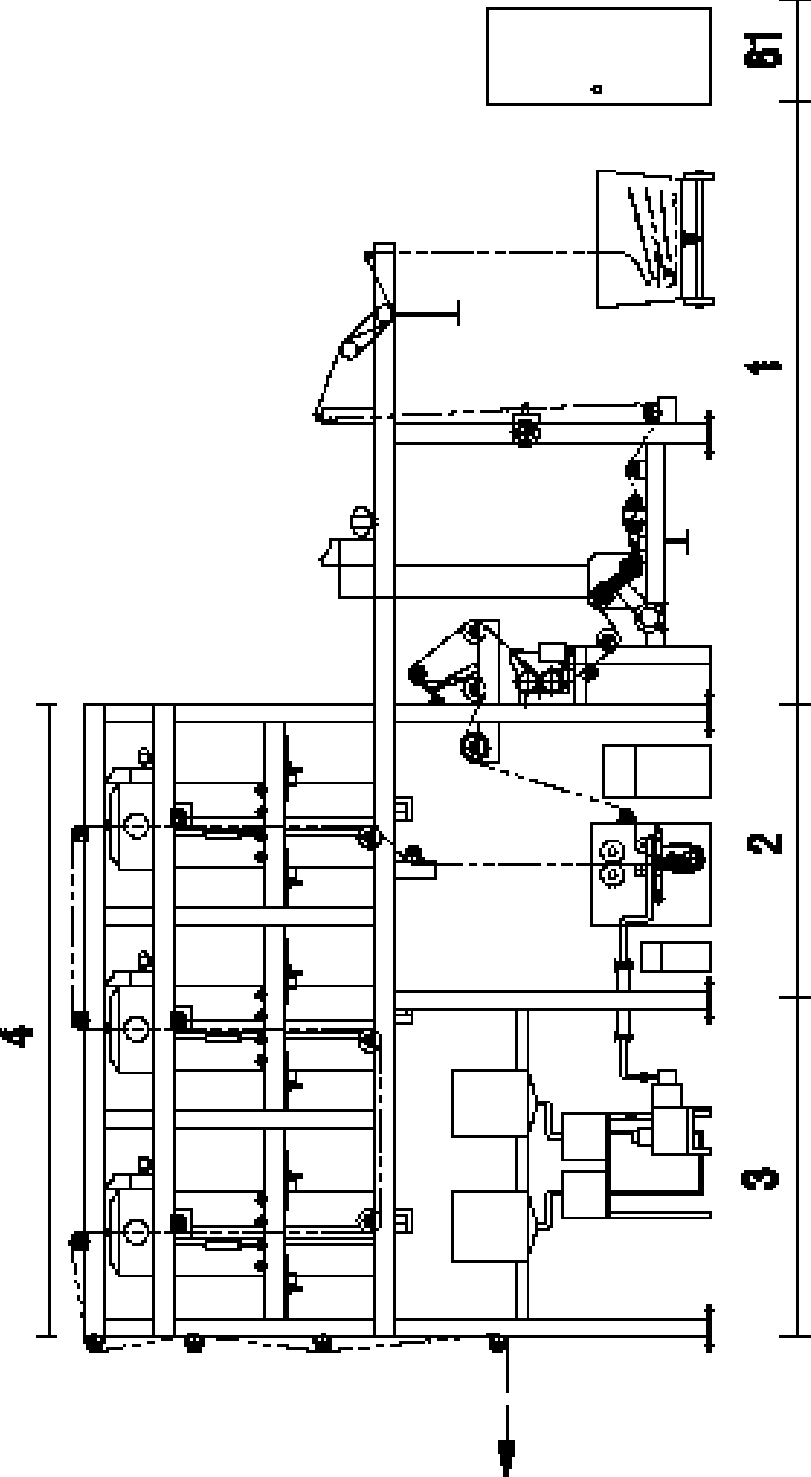

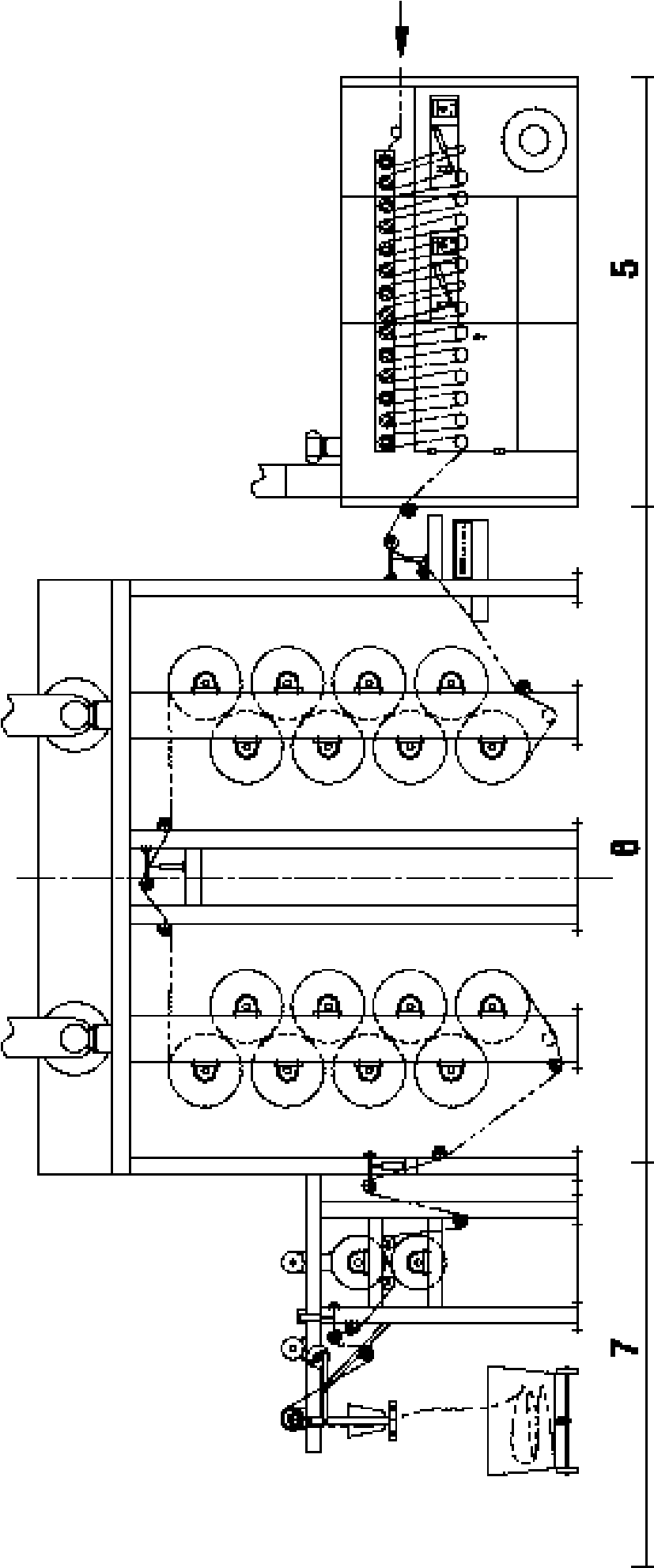

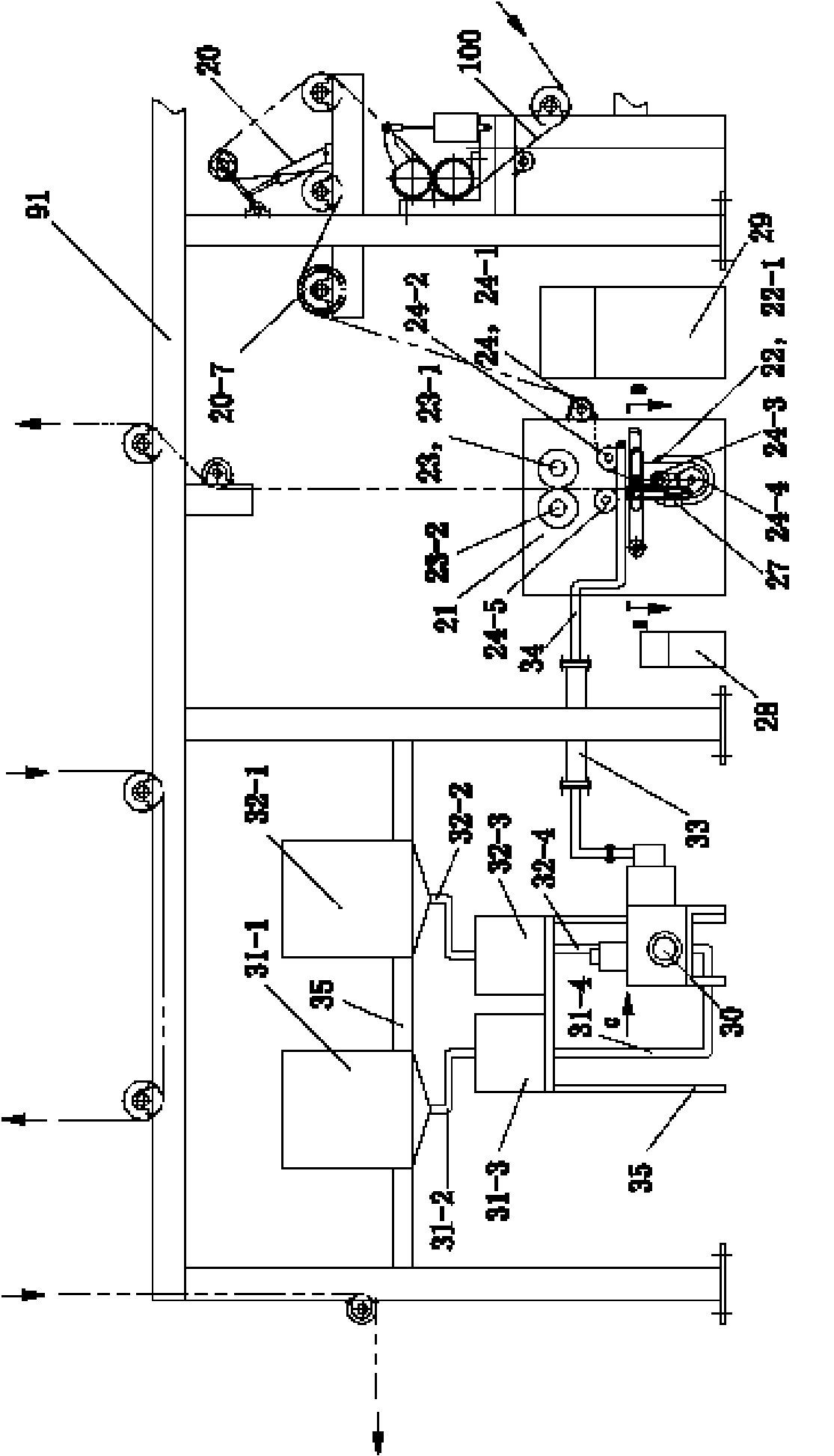

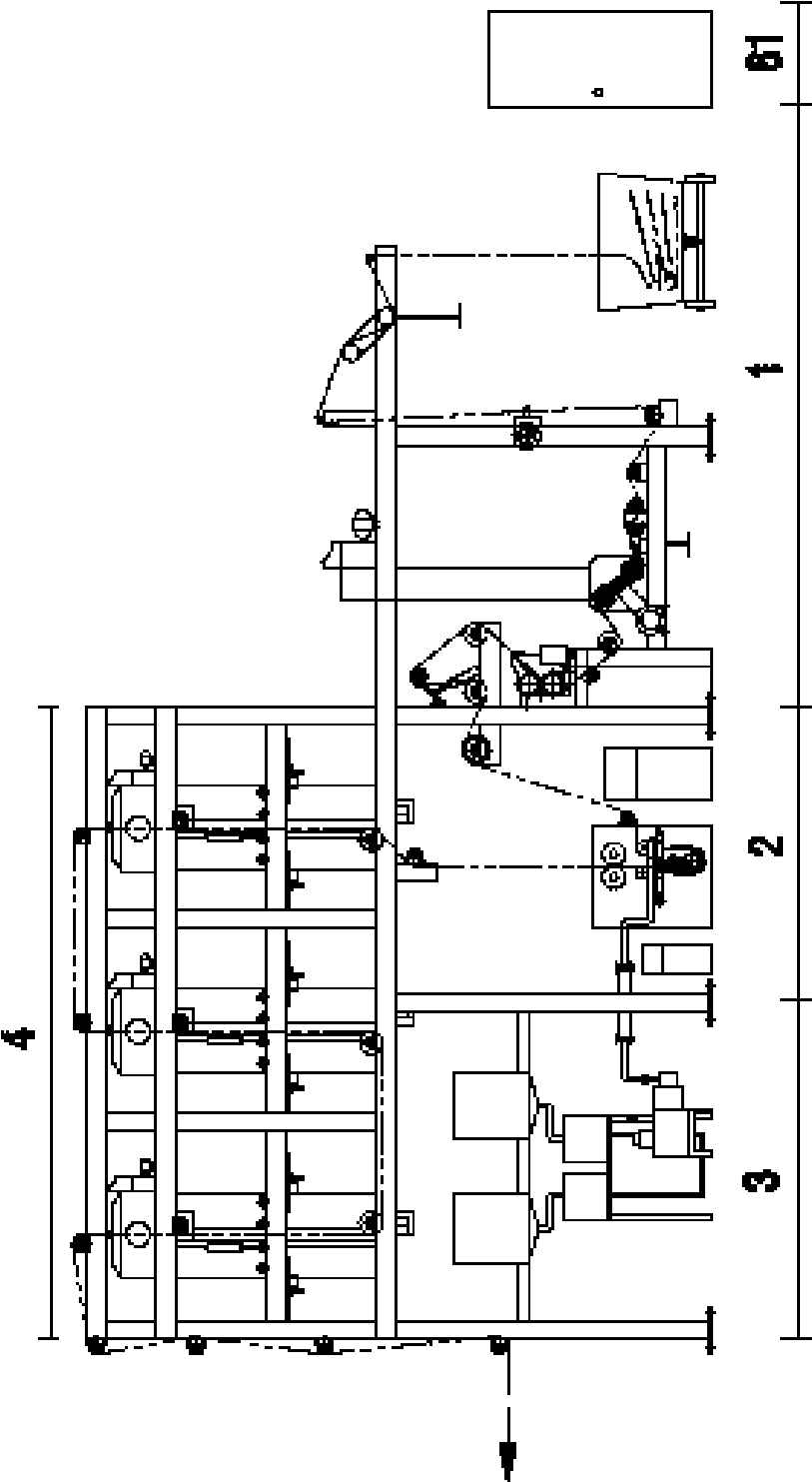

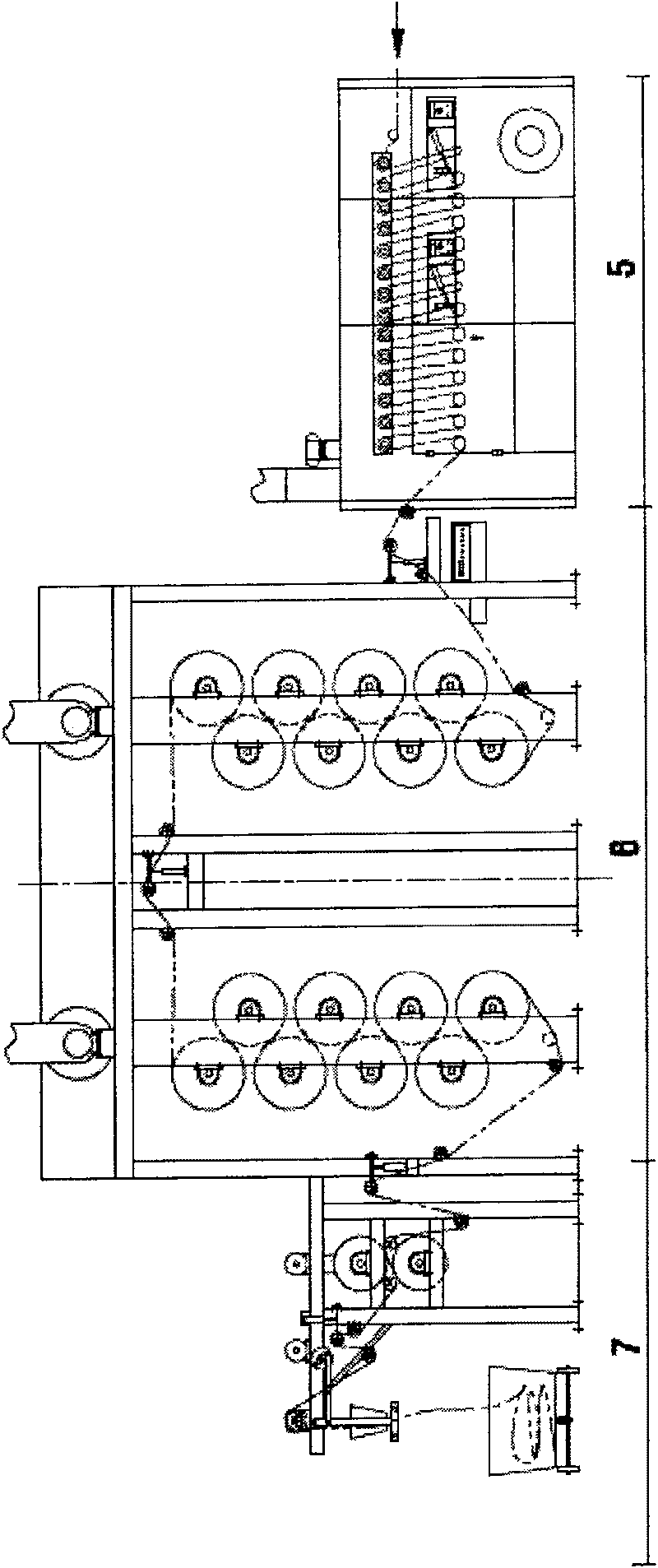

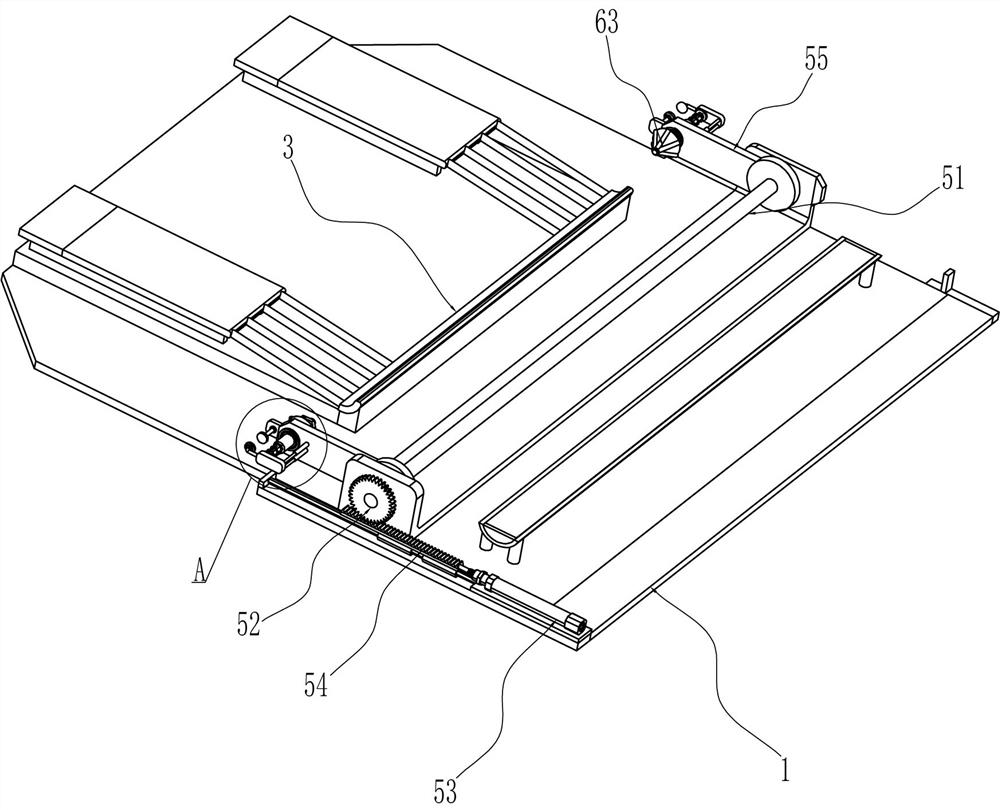

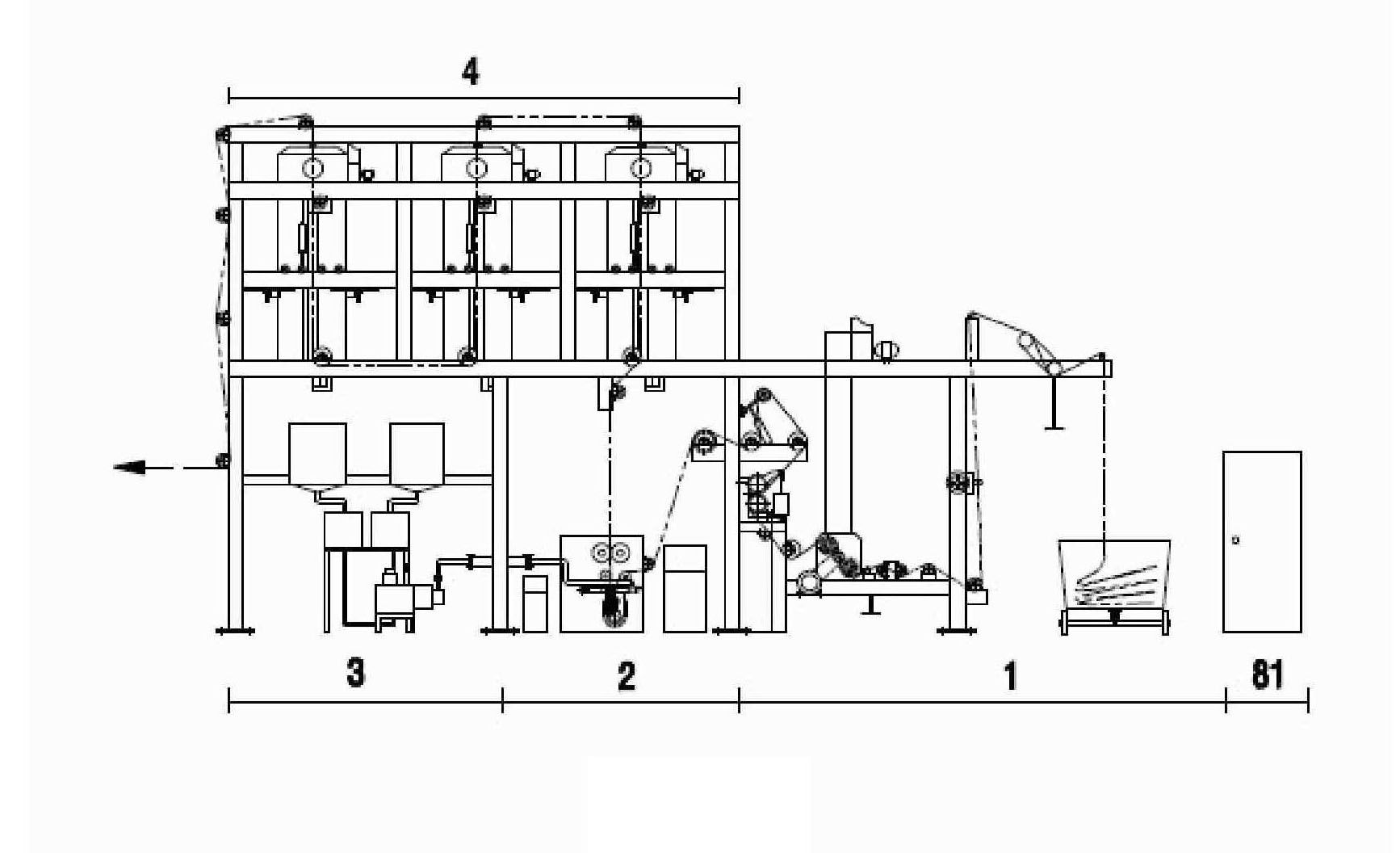

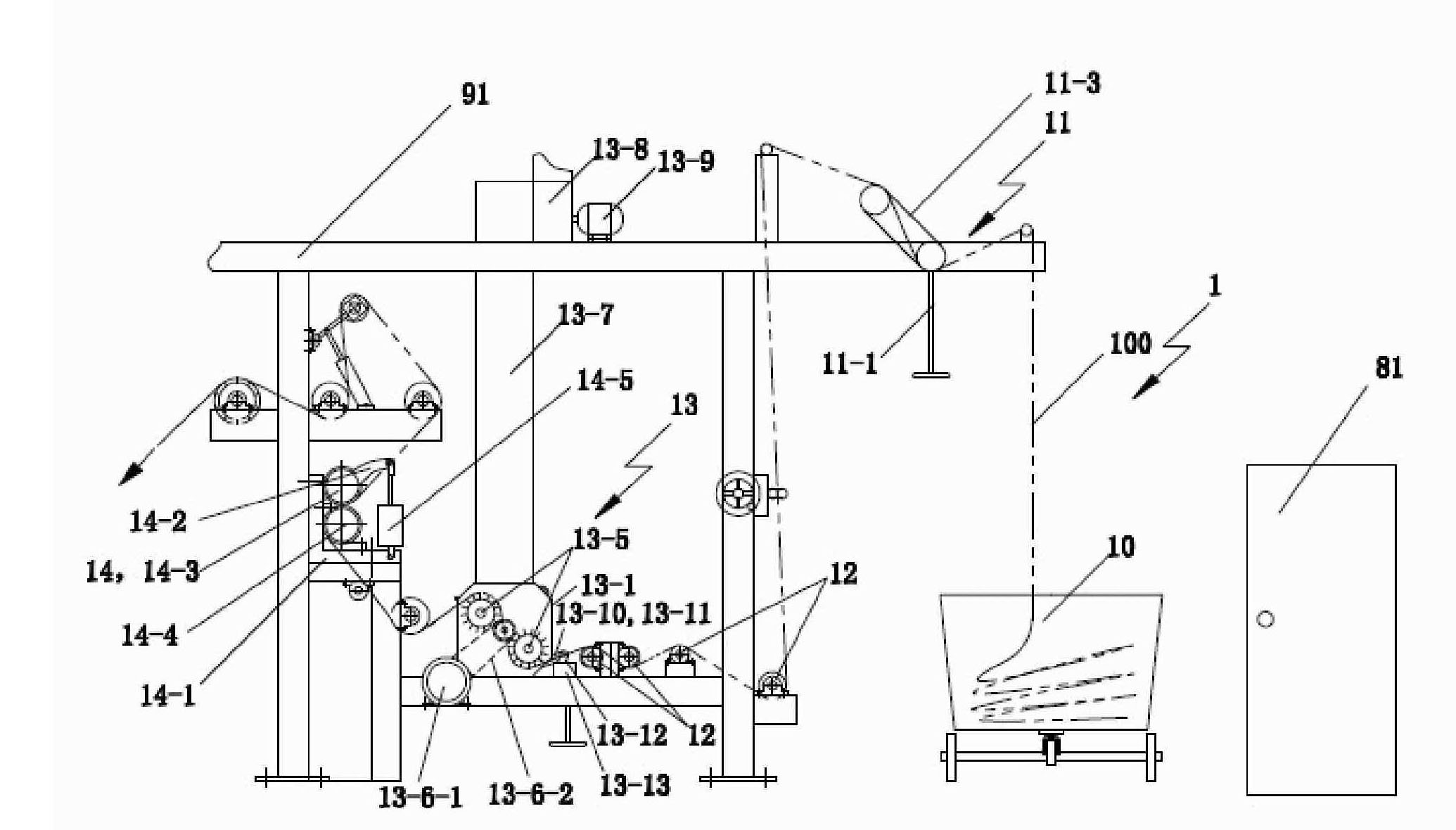

Continuous pigment dyeing pad dyer

InactiveCN101487175AOptimize layoutGuaranteed uptimeSucessive textile treatmentsDrying solid materials with heatEngineeringHot blast

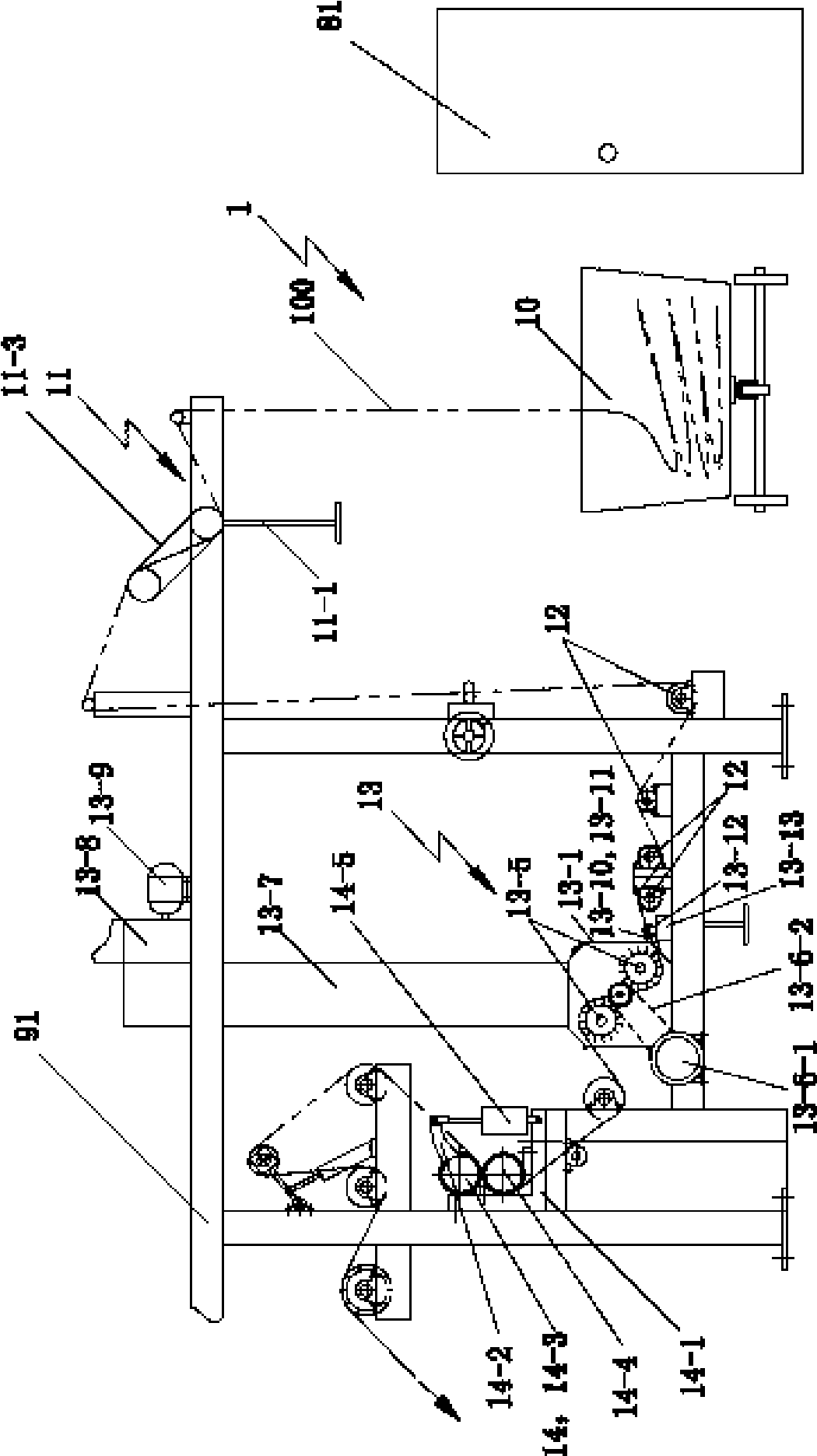

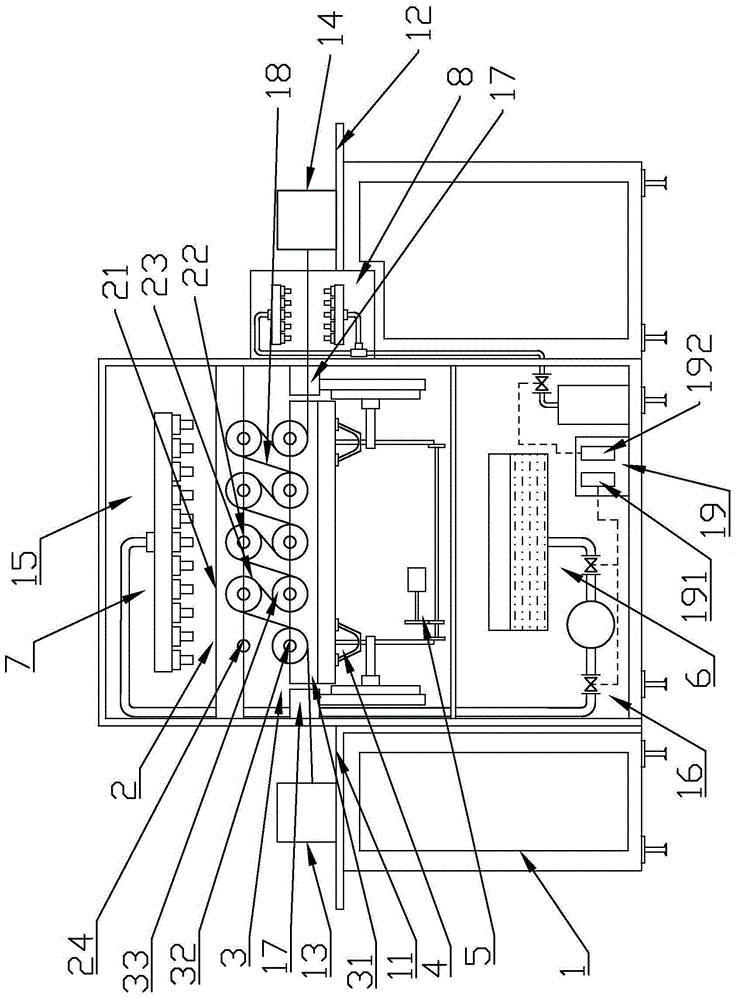

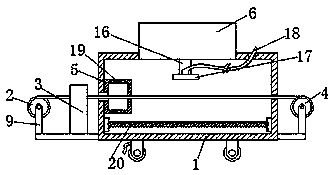

The invention relates to a continuous paint dyeing padding machine. The padding machine comprises a device which brushes hair and collects dusts for the textile, a traction binding vehicle which can obstruct the tensile force of the textile, a padding device, an infrared pre-baking device, a hot-blast pre-baking device, a steam drying device and a fabric outlet disposing device, and all devices are sequentially arranged. All components of the dyeing padding machine are reasonably configured; and when in use, the energy resource is saved, the process is simple and the dyeing effect is good.

Owner:常州市东高染整有限公司

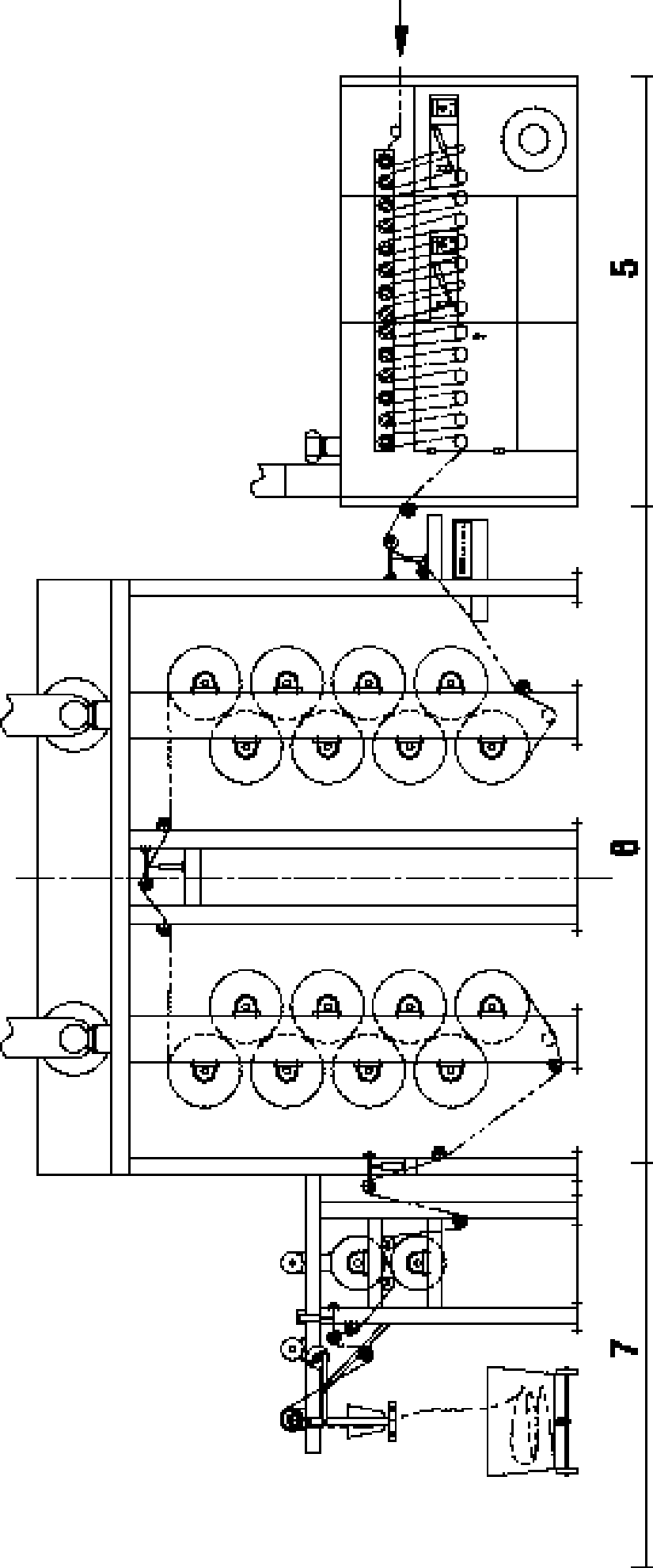

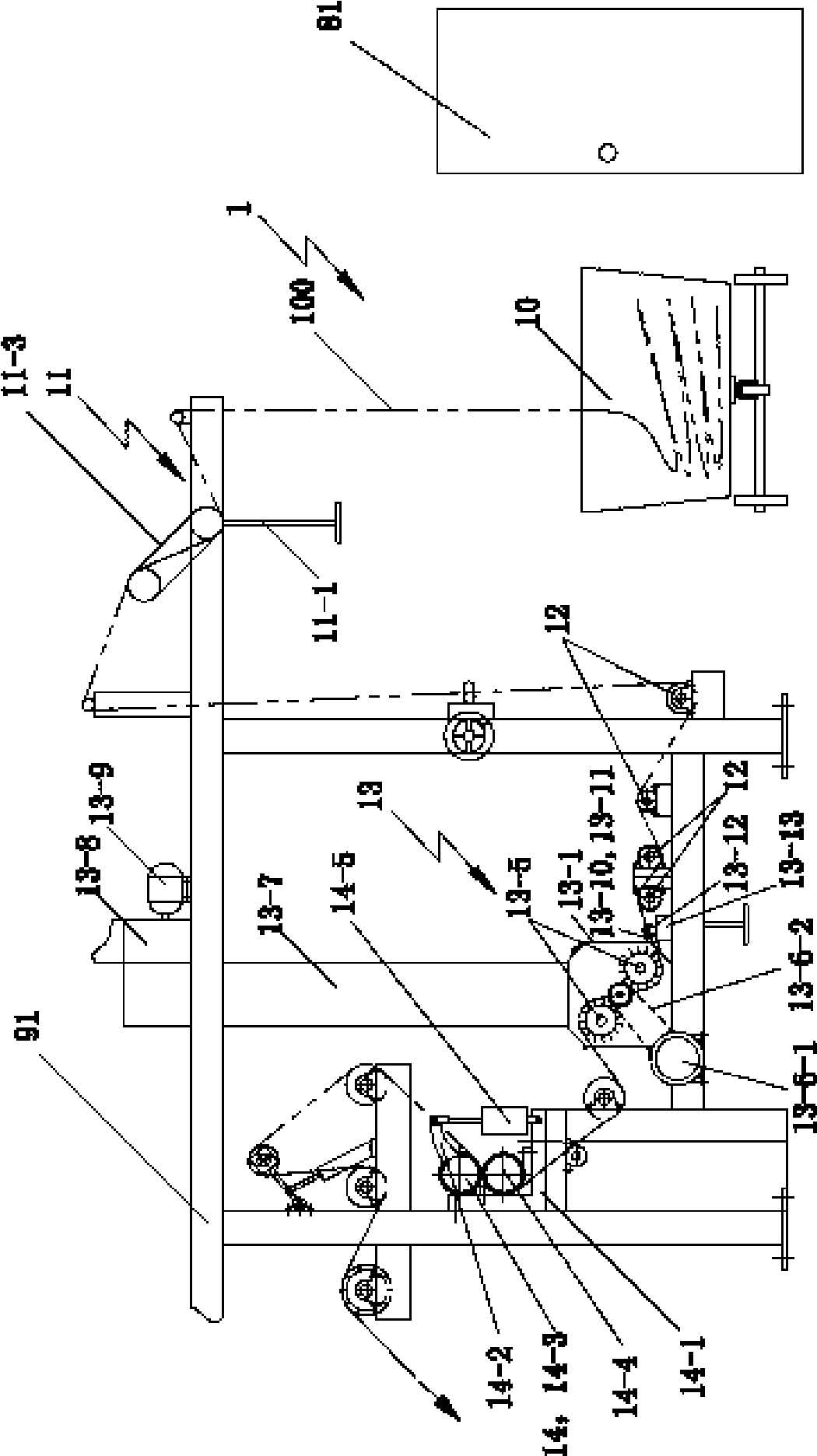

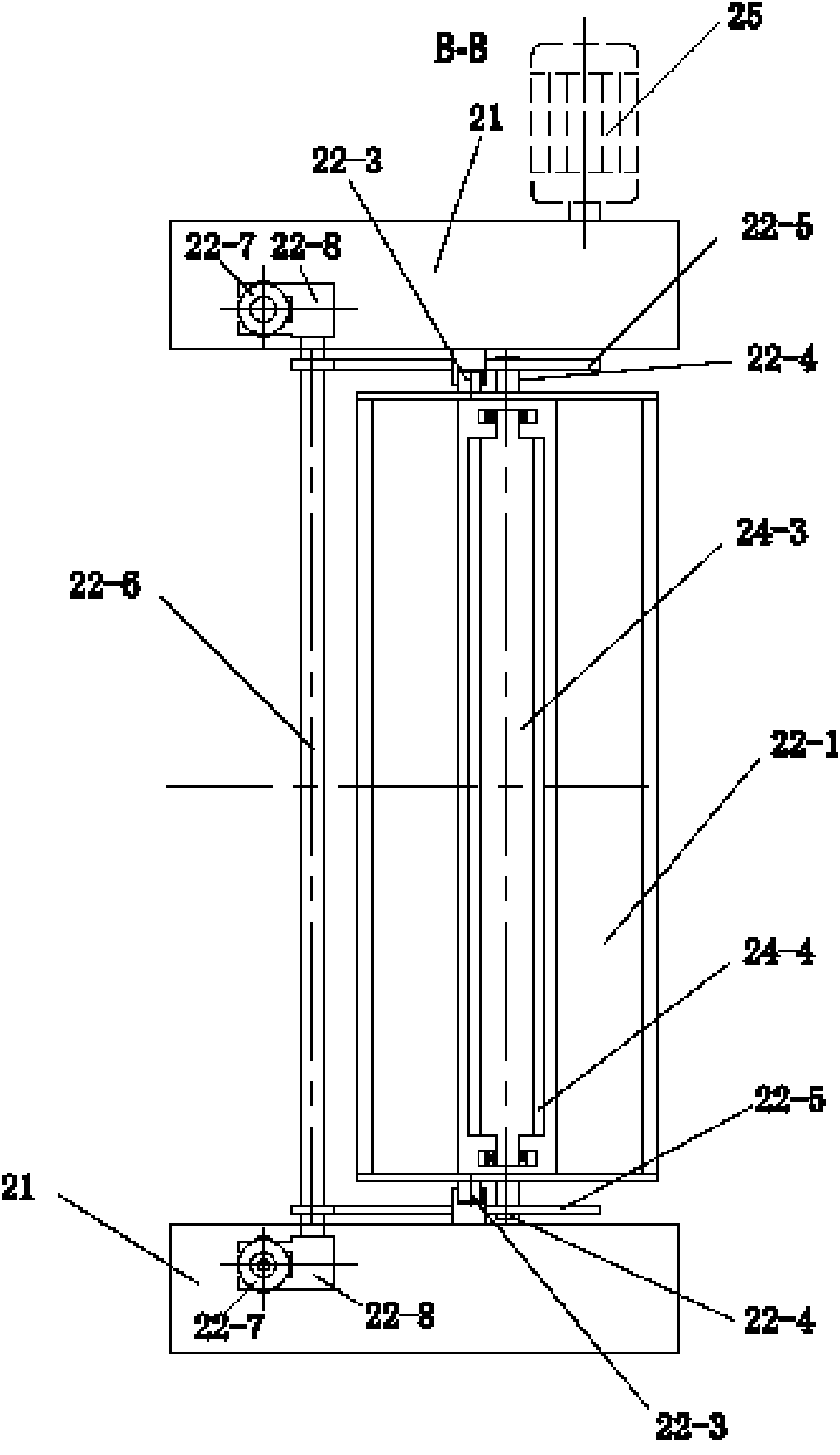

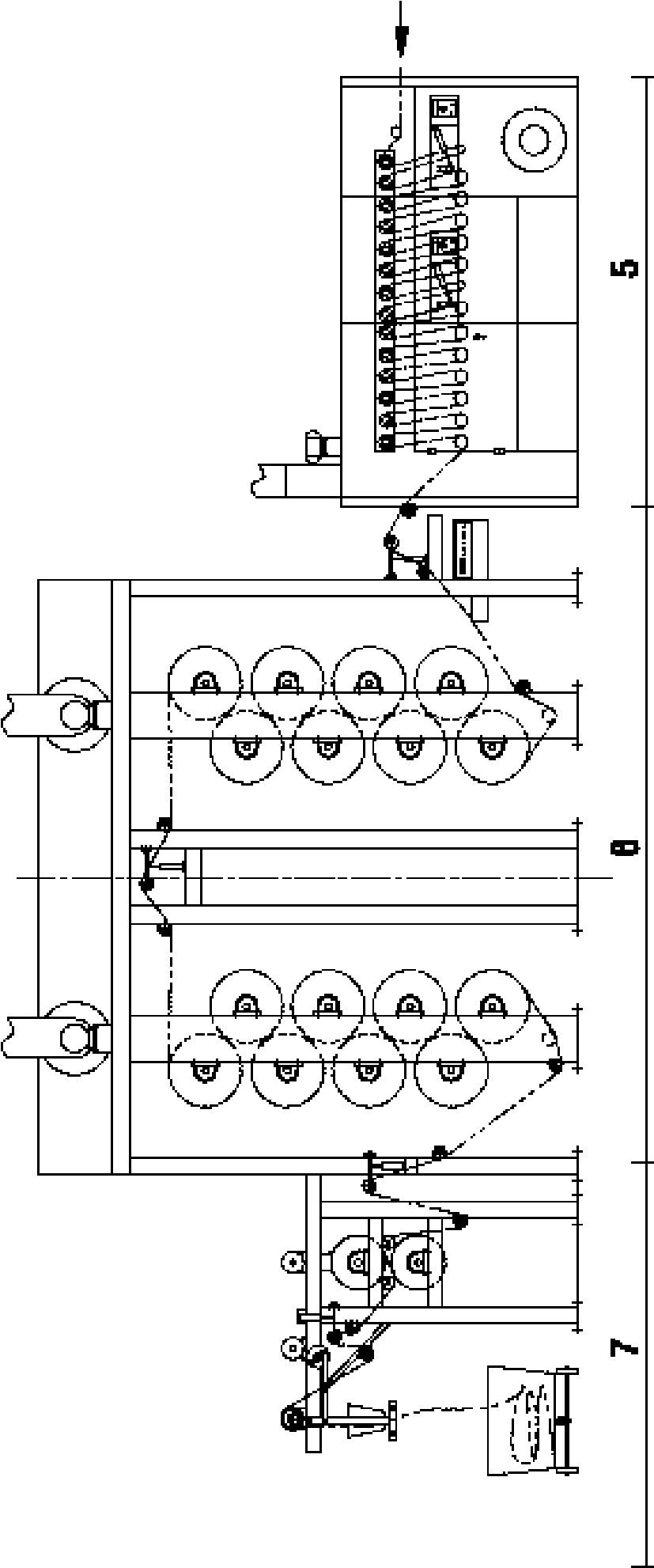

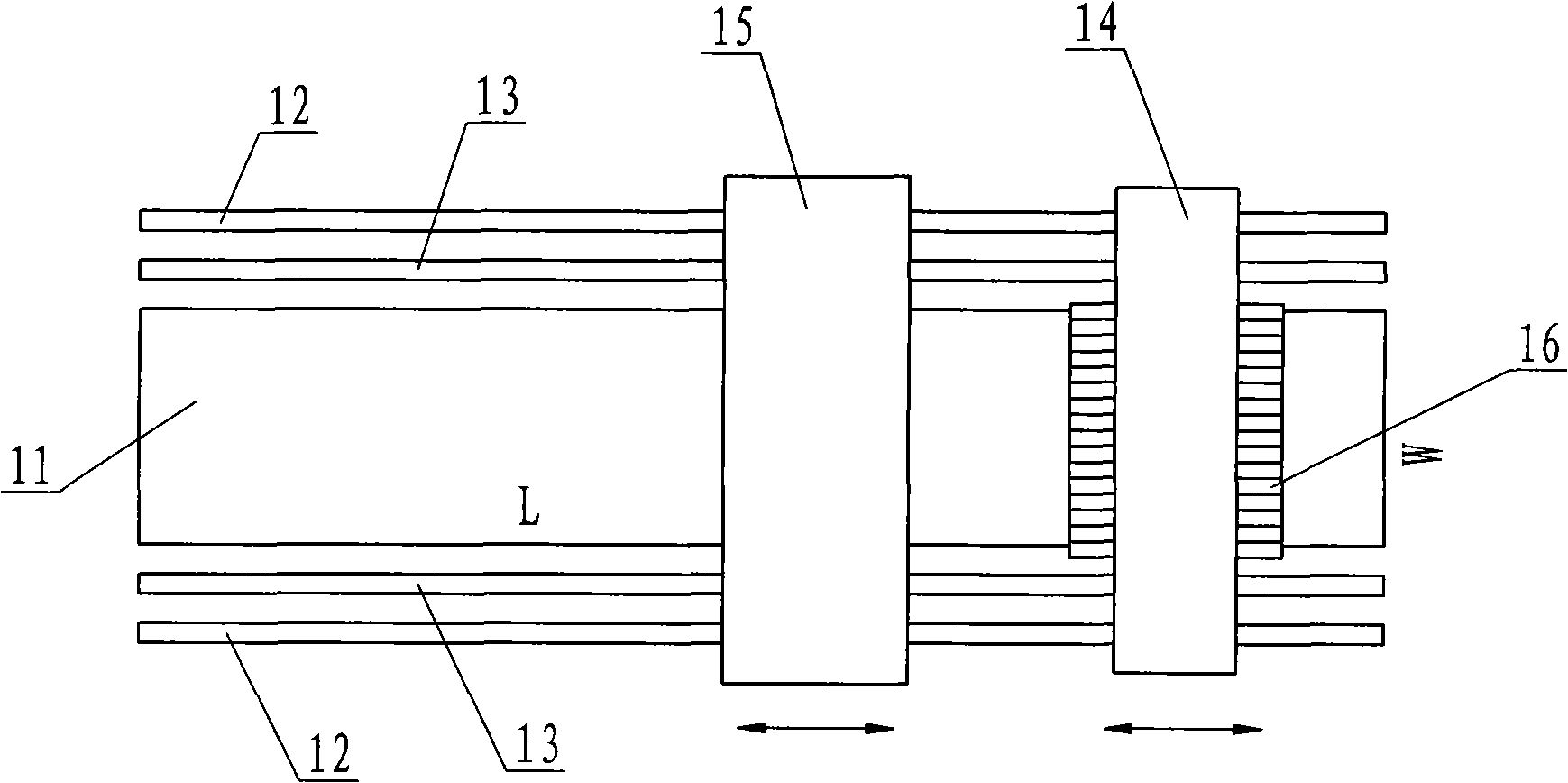

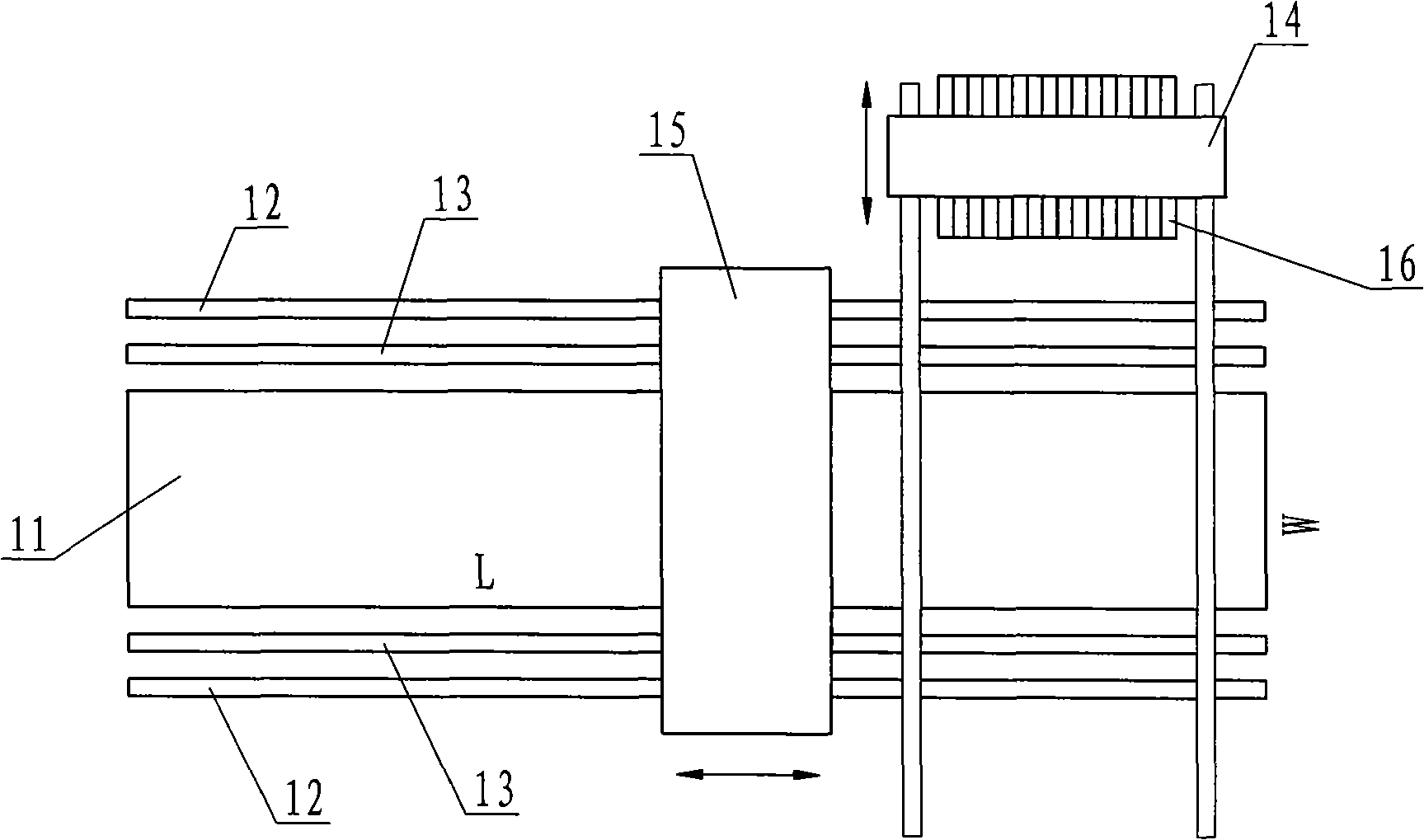

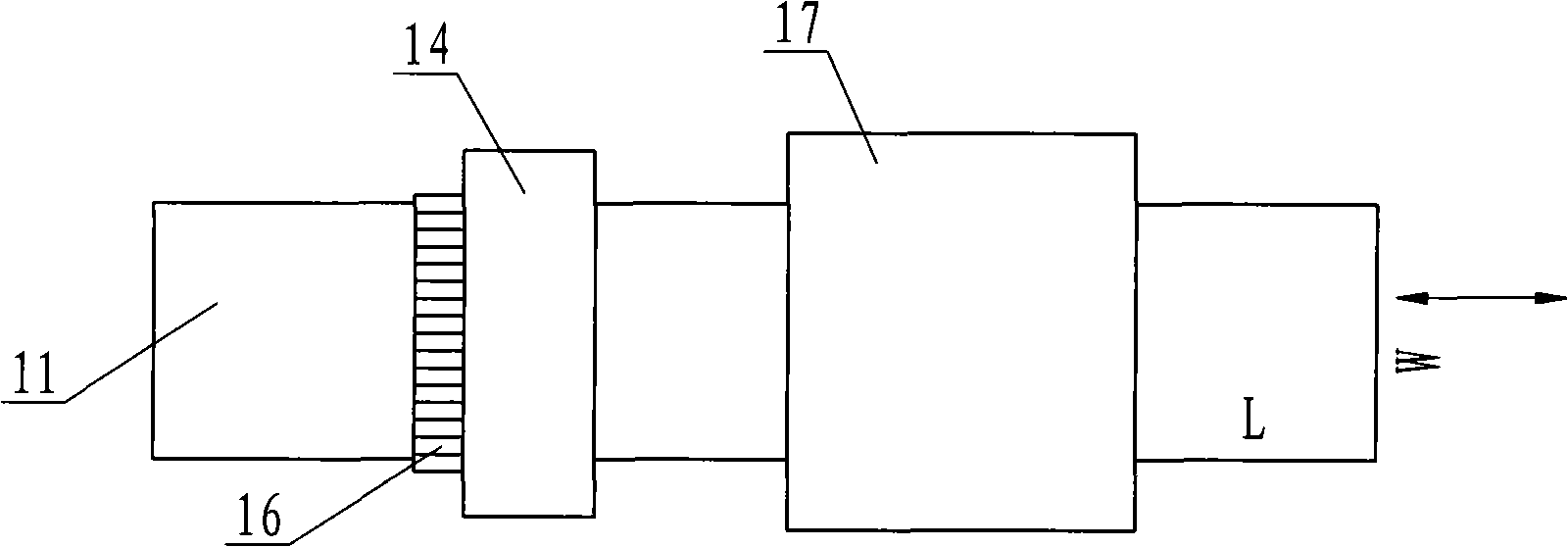

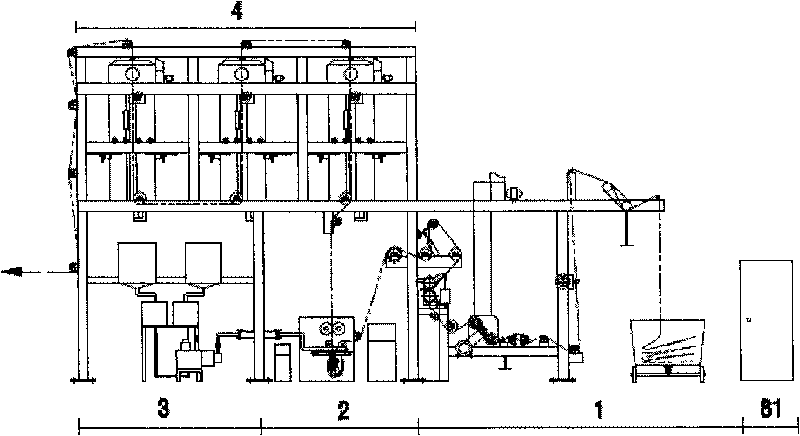

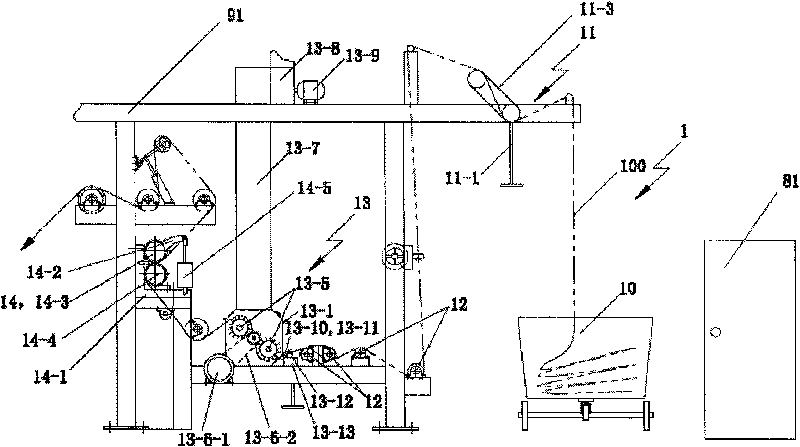

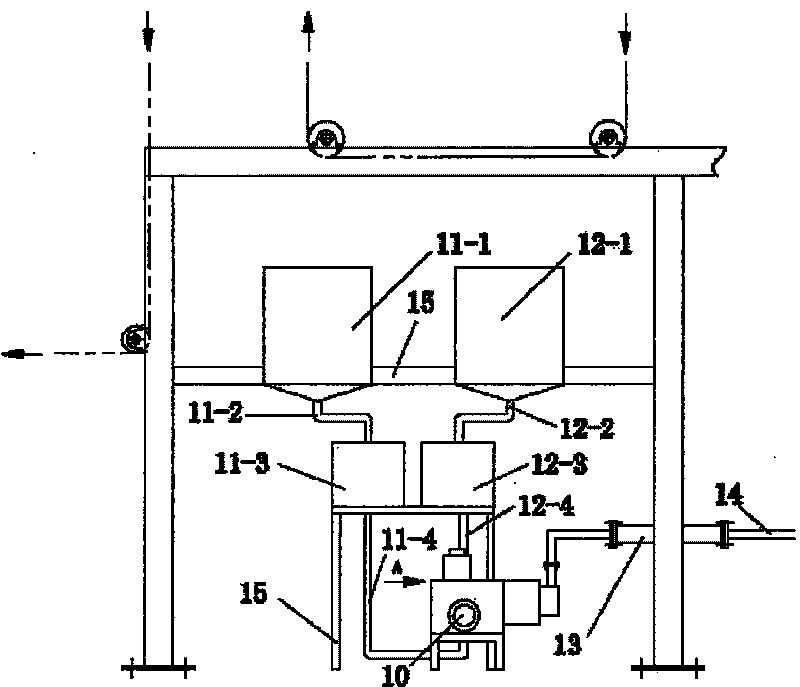

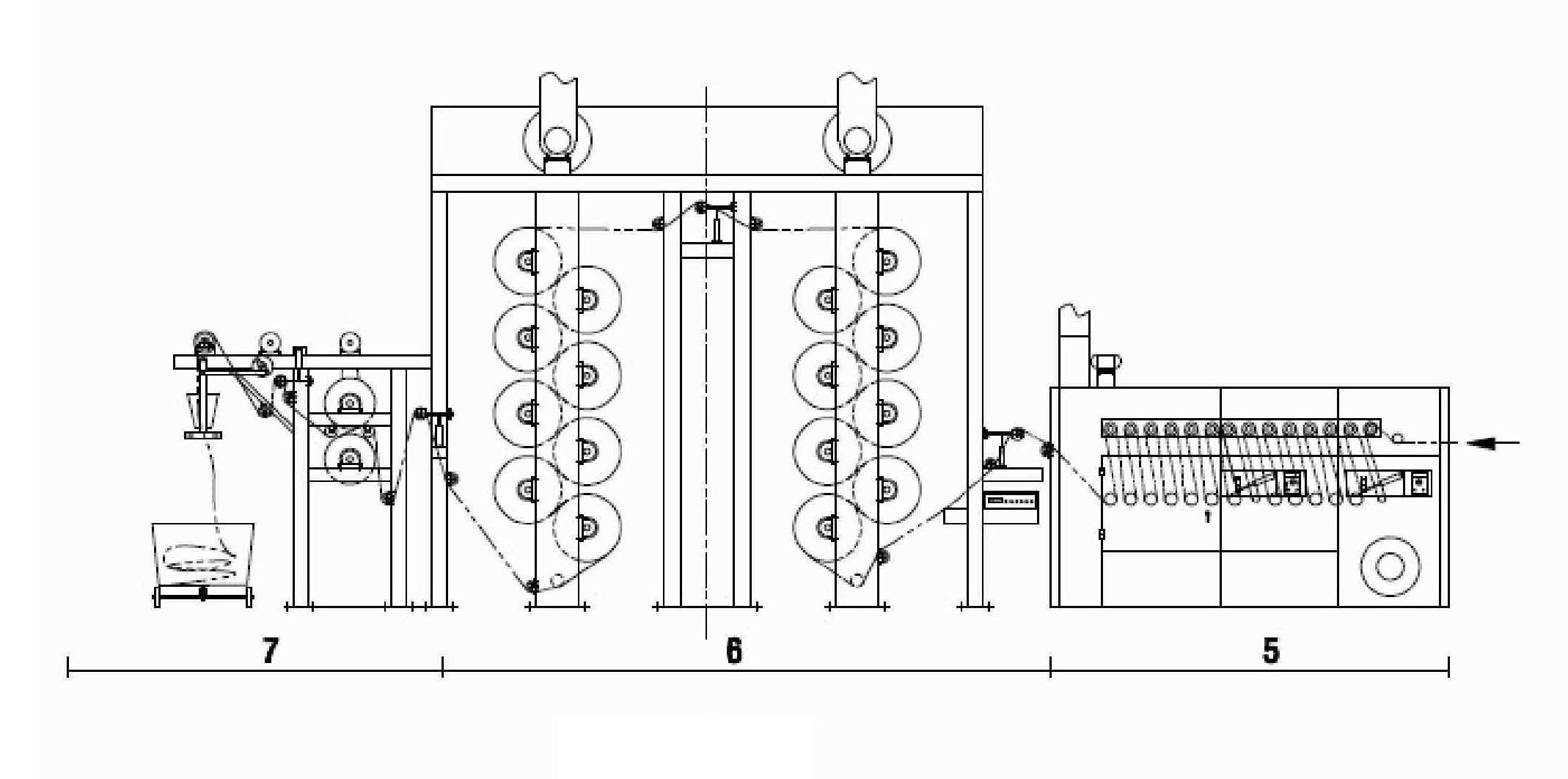

Continuous pigment dyeing pad dyer with infrared pre-baking apparatus

InactiveCN101487177AAvoid damageImprove mobilitySucessive textile treatmentsDrying solid materials with heatEngineeringPre treatment

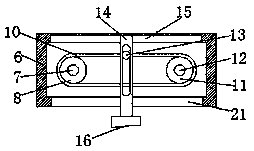

The invention relates to a continuous paint dyeing padding machine with an infrared pre-drying device. The padding machine comprises a fabric inlet pre-processing device, a padding system, a drying system and a fabric outlet processing device which are sequentially arranged. The drying system comprises an infrared pre-drying device and a steam drying device. The infrared pre-drying device comprises two to five pre-dying mechanisms; each pre-drying mechanism comprises a pair of frame parts; and each pair of frame parts is provided with an infrared emitter. The continuous paint dyeing padding machine is characterized in that the front part of each row of infrared emitters is provided with a shielding device; when the padding machine is in use, the shielding device is arranged at a keep-clear position; and when the padding machine is in a shutdown state, the shielding device is arranged at a shielding position. Furthermore, each pair of frame parts can be arranged in a close state or an open state corresponding to the rolling of a first frame. Therefore, the padding machine has protection effect when in use, better dyeing effect and convenient maintenance.

Owner:常州慧杰电气技术有限公司

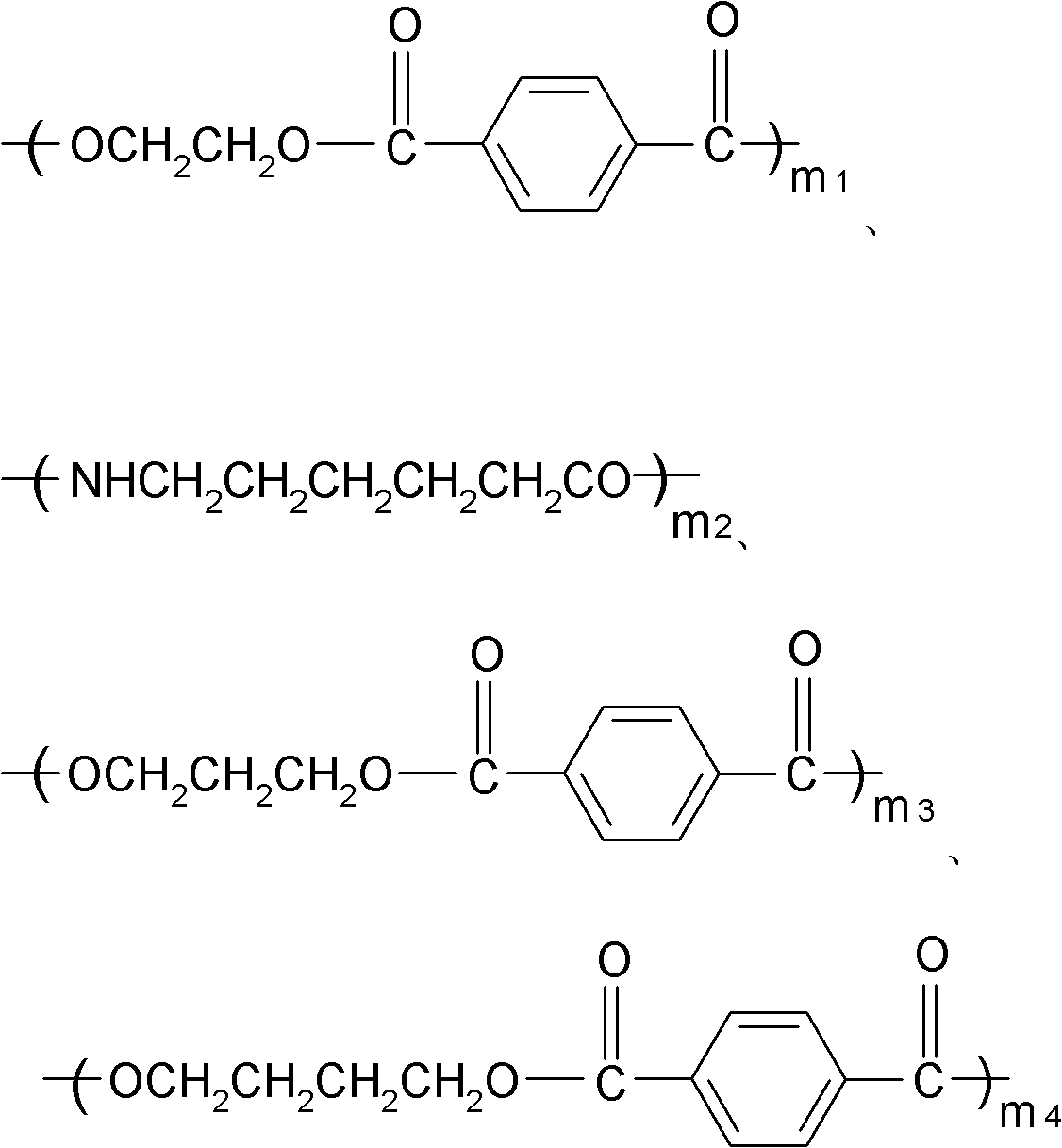

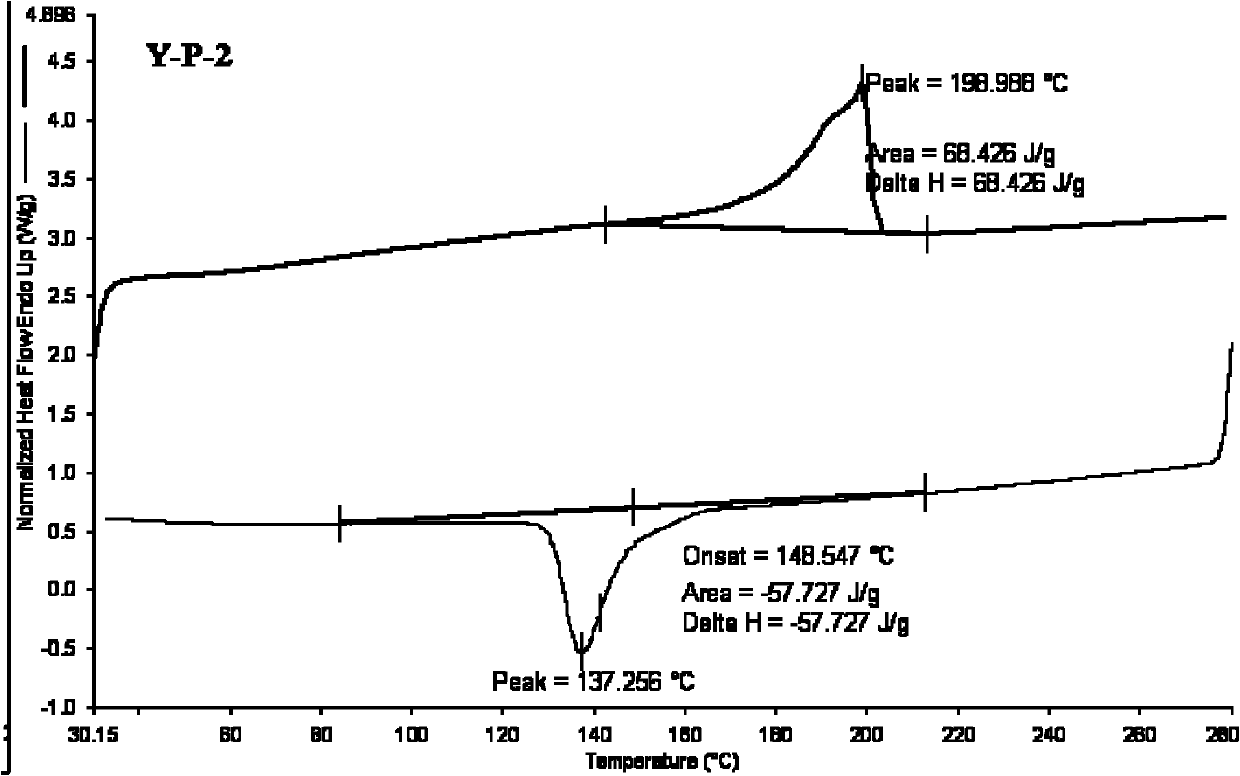

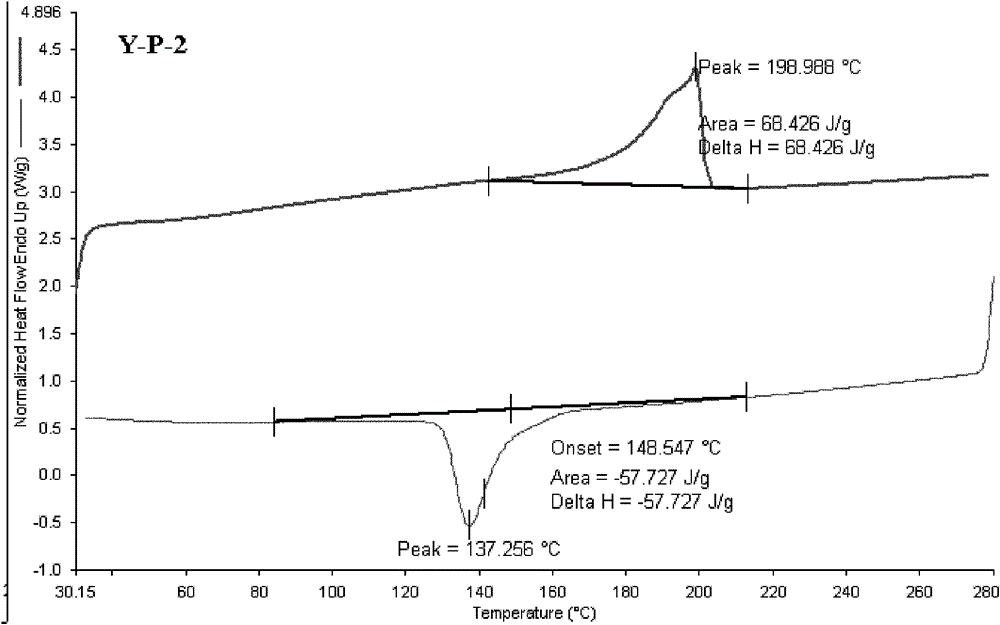

Modified polyester and wool blended fabric and preparation method thereof

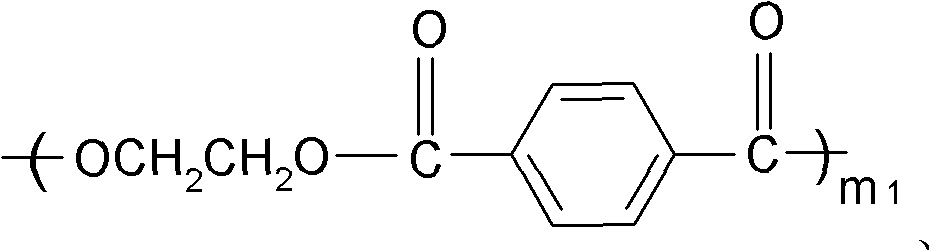

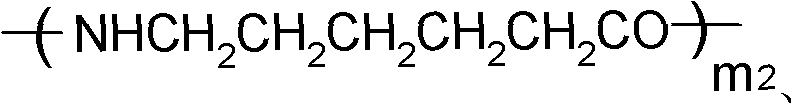

ActiveCN101956278AEvenly distributed sequenceHigh tensile strengthMonocomponent copolyesters artificial filamentDyeing processDisperse dyeYarn

The invention relates to a modified polyester and wool blended fabric and a preparation method thereof. The blended fabric is formed by blending and spinning modified polyester and wool. The modified polyester has the following structural unit, wherein m1 is more than 1 and less than 160; m2 is more than 1 and less than 70; m3 is more than or equal to 0 and less than 20; and m4 is more than or equal to 0 and less than 20. In the blended fabric, the modified polyester accounts for 5 to 80 percent. The blended fabric is formed by weaving one or more modified polyester and wool blended yarns of which the blending ratios are different. In a weaving process, the fabric structure is pre-designed and the blended fabric is subjected to one bath dyeing with an acidic dye and a disperse dye in the environment of which the temperature is less than 100 DEG C and the pH value is between 2 and 6. Both the plain colour effect of the same colour of the whole fabric and the fancy effect similar to a dyed fabric can be realized.

Owner:CHINESE TEXTILE ACAD

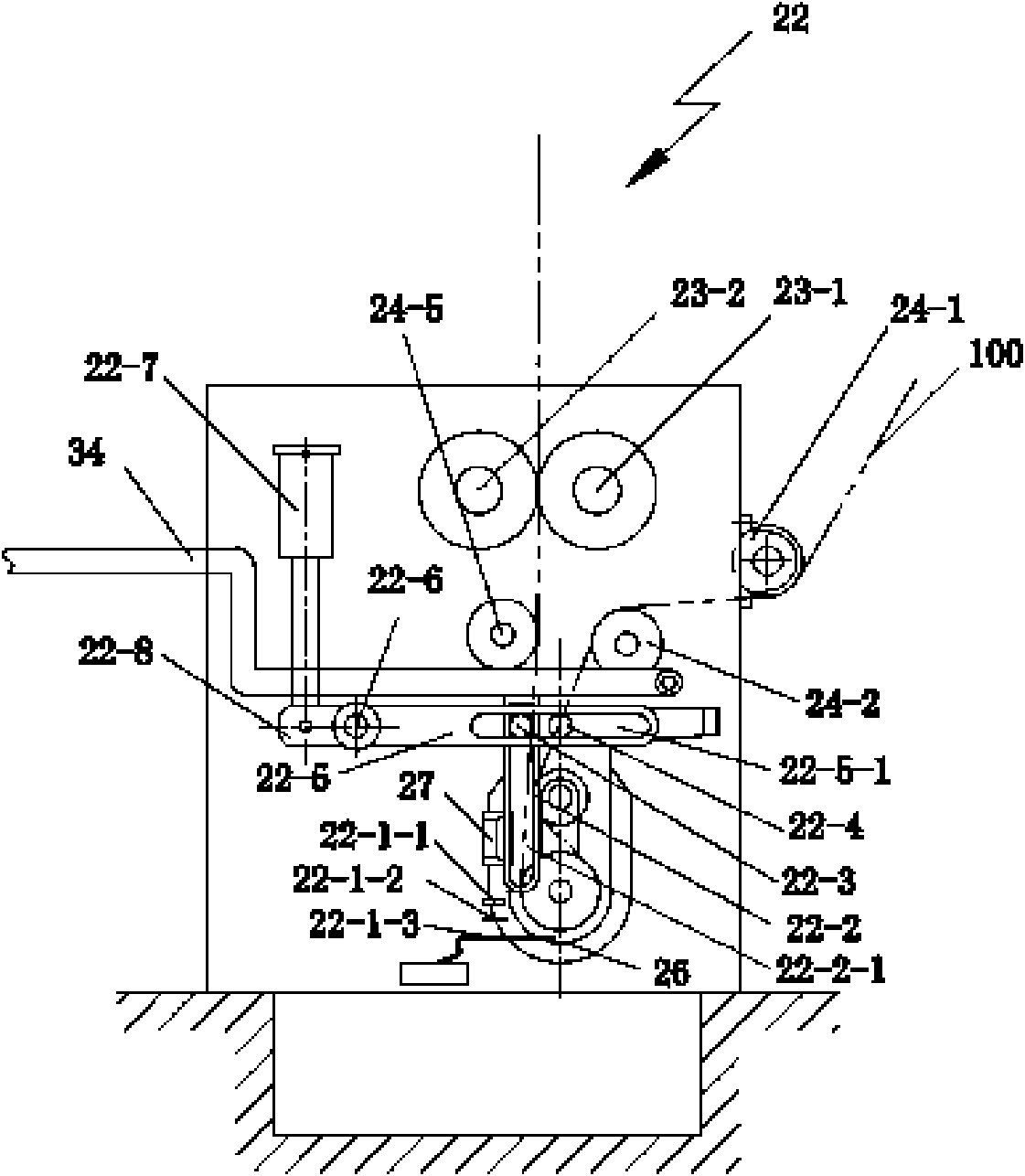

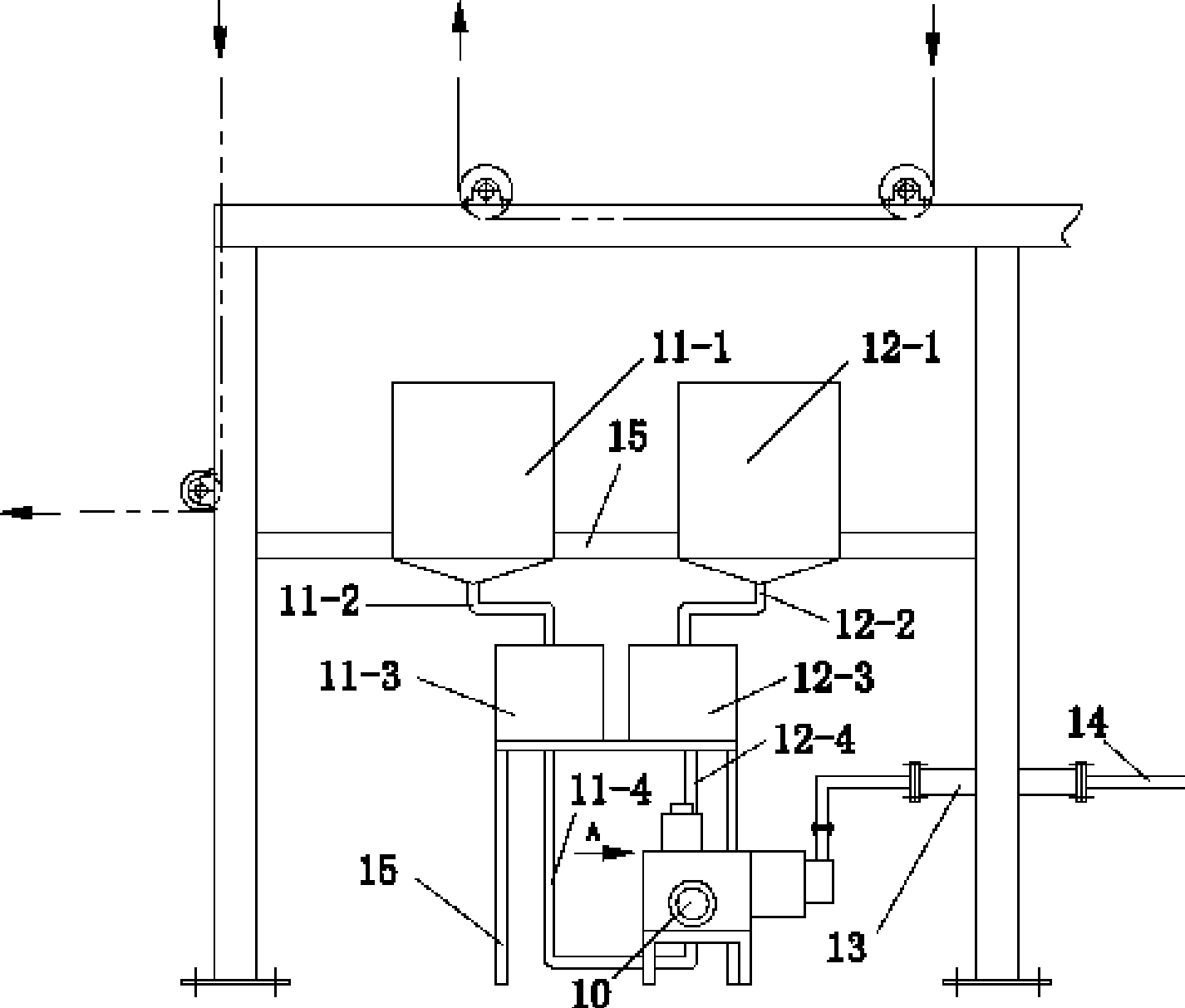

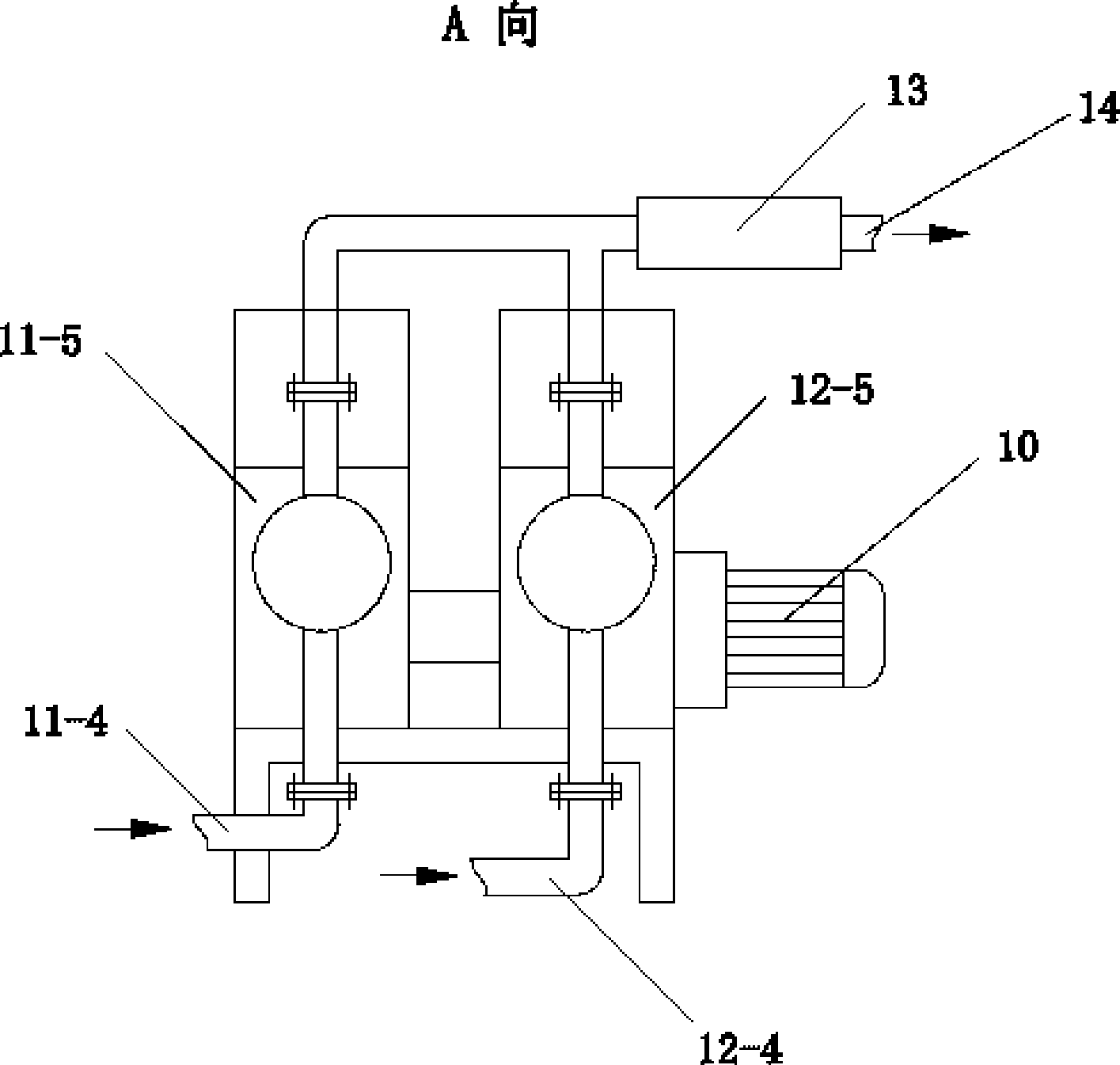

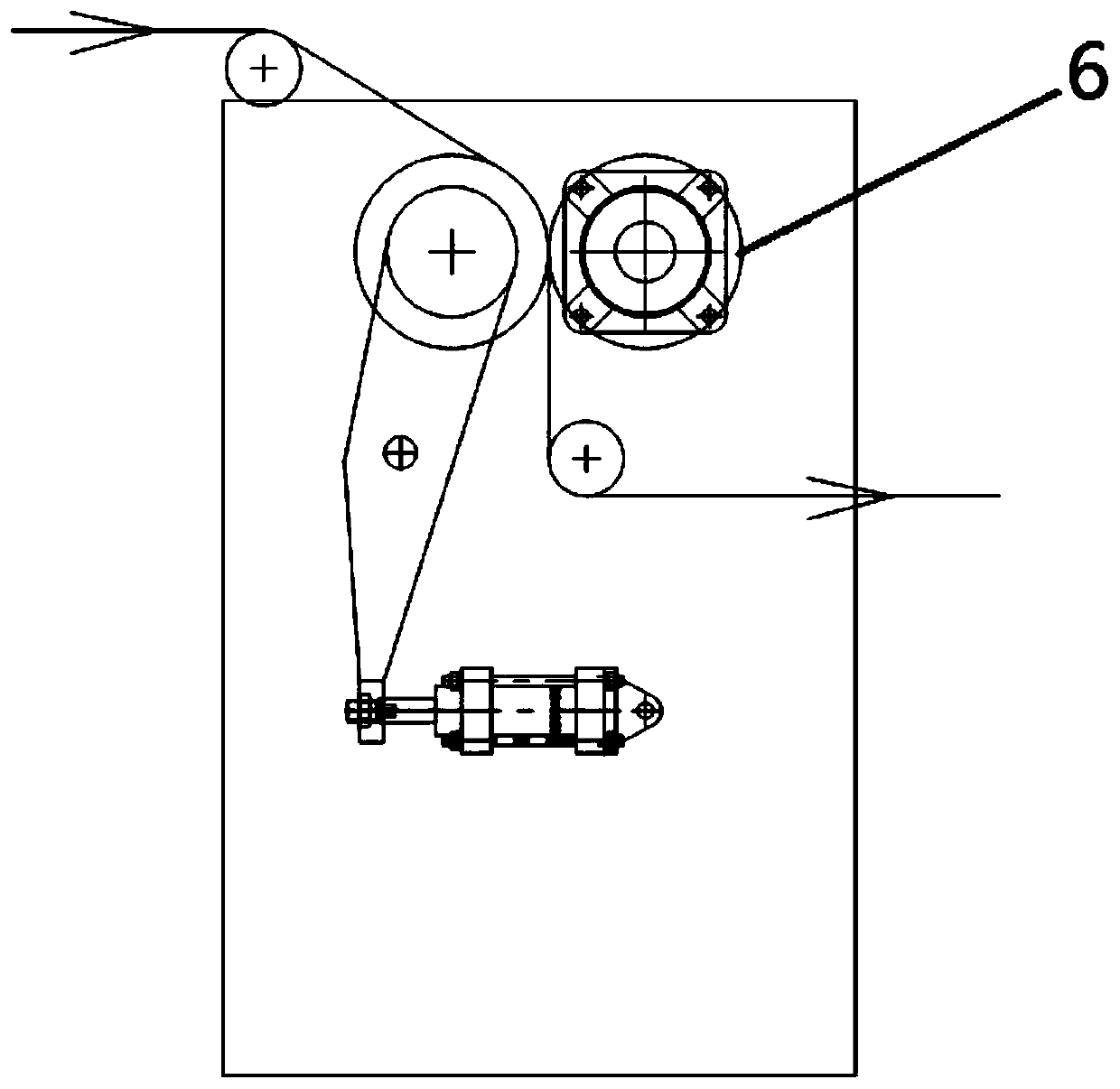

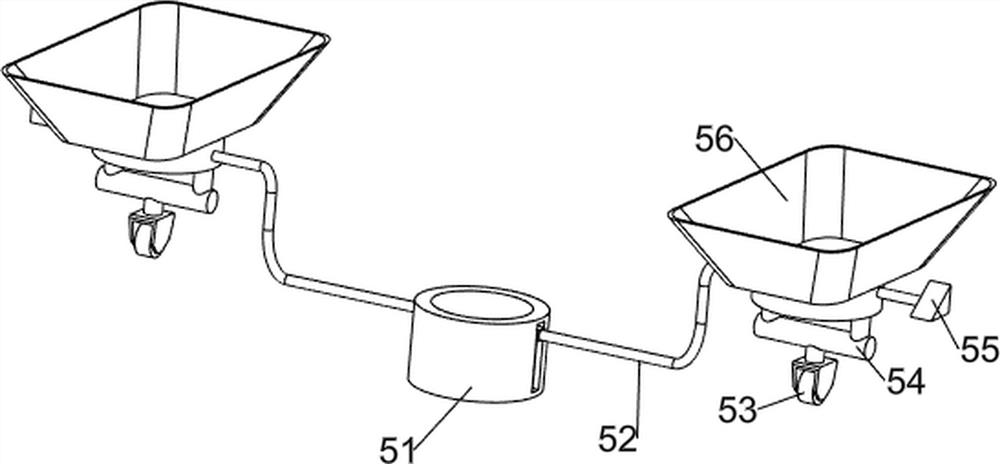

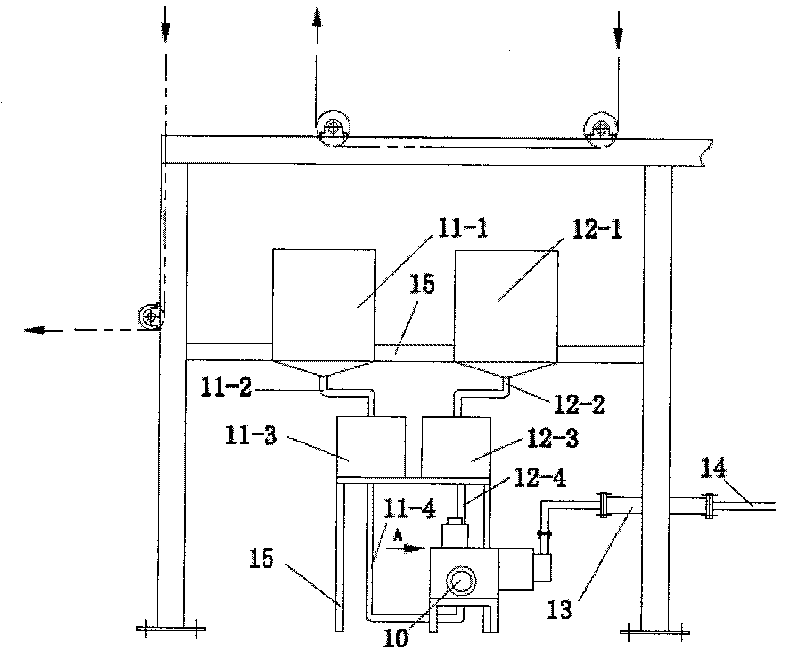

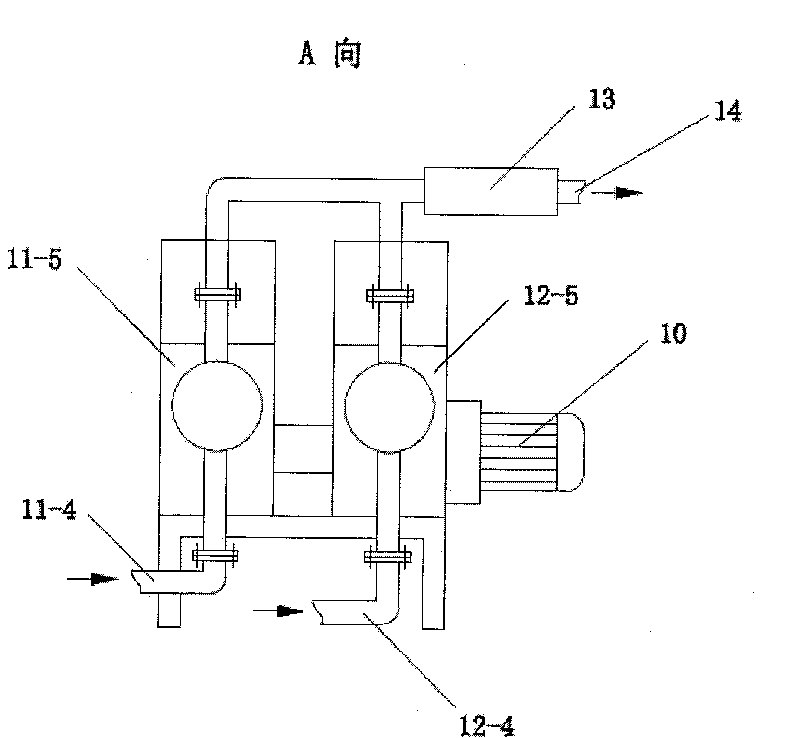

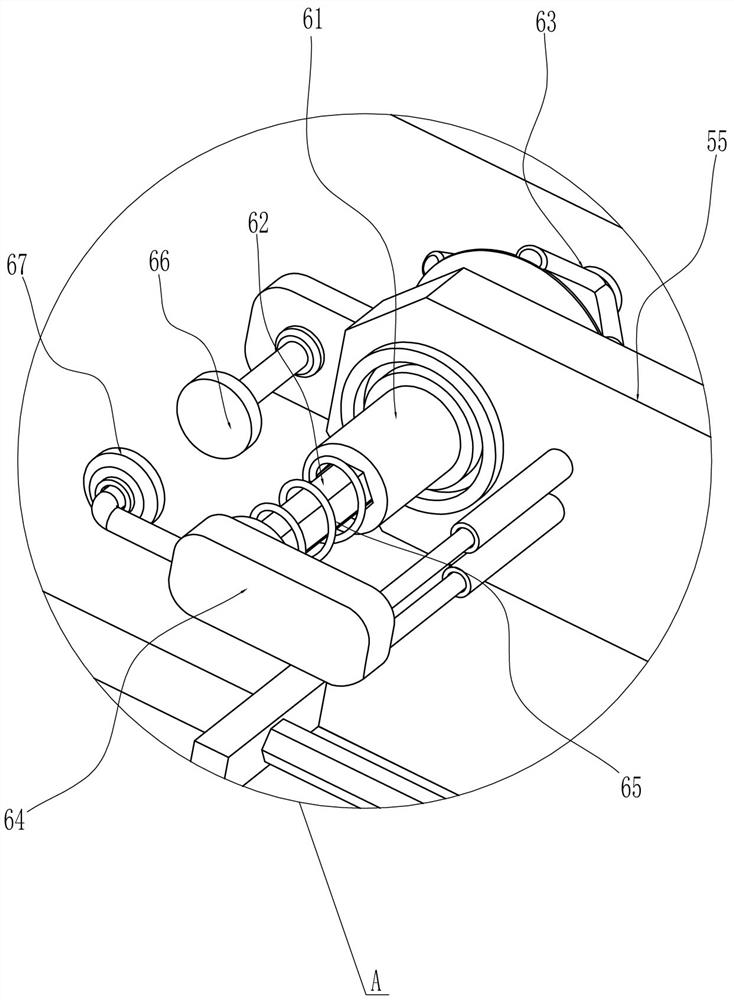

Padding system of continuous pigment dyeing padding mangle

InactiveCN101597846AWell mixedAchieve dyeing effectTextile treatment containersLiquid/gas/vapor removal by squeezing rollersFiberLiquid storage tank

The invention relates to a padding system of a continuous pigment dyeing padding mangle, which comprises a padding device and a proportionally liquid supplying device, wherein the proportionally liquid supplying device comprises a metering pump motor, a two paths of liquid supplying device, a mixer and a liquid inlet pipe; and a liquid storage tank of one path of the liquid supplying device contains a cationic modifier, while a liquid storage tank of the other path of the liquid supplying device contains pigment printing paste. The cationic modifier and the pigment printing paste passes through the corresponding metering pumps in a certain proportion and then are mixed in the mixer to form composite dye liquor, and then, the composite dye liquor flows into a maceration tank constantly along a pipeline; the composite dye liquor soaking fabrics is composite dye liquor which is just mixed; before generating coagulation with the pigment printing paste, the modifier is attached to solid-phase fibers to generate denaturation and the pigment printing paste is also attached to the solid-phase fibers, so the better dyeing effect can be obtained through a latter processing.

Owner:常州市东高染整有限公司

Method of continuous pigment dyeing for fabric

InactiveCN101509184AWell mixedDyeing firmDrying solid materials with heatTextile treatment machine arrangementsSURFACTANT BLENDPigment

The invention relates to a continuous pigment dyeing method for fabrics, in which the fabrics during travelling are subjected to the steeping of a composite dye solution in a steeping tank that is continuously supplemented with the composite dye solution, and then to the rolling of rollers, and the time the fabrics are subjected to the composite dye solution by the fabrics is 2.5-5 seconds. The composite dye solution comprises the components having the following concentrations: 10g / L-50g / L of a pigment paste, 1g / L-8g / L of a cation modifying agent, 3g / L-5g / L of a surfactant and 5g / L-20g / L of a cation bonding agent. The padding fabrics are continuously subjected to an infrared pre-drying apparatus for drying, a hot-air pre-drying tank for drying and a steam drying cylinder apparatus for drying. The inventive method has superior stability of the dyeing effect and is free from agglomeration.

Owner:常州市东高染整有限公司

Continuous pigment dyeing pad dyer with padding system

InactiveCN101487176AWell mixedAchieve dyeing effectSucessive textile treatmentsDrying solid materials with heatFiberPulp and paper industry

The invention belongs to a continuous paint dyeing padding machine with a padding system. According to the successive sequence, the dyeing padding machine is provided with a fabric feeding pre-processing device, a padding system, a drying system and a fabric outlet processing device; the padding system comprises a padding device and a proportional liquid supply device; the proportional liquid supply device comprises a measuring pump motor, two liquid supply devices, a mixer and a liquid inlet pipe; and a liquid storage box of one liquid supply device contains cation modifier and the liquid storage box of the other liquid supply device contains paint color paste. When in use, the cation modifier and the paint color paste pass by a corresponding measuring pump by a certain proportion, are subsequently mixed in the mixer to form composite dye solution, and then flow in a dipping trough continuously along the pipeline; the composite dye solution used for dipping the textile is the just mixed composite dye solution; before the modifier generates cohesion with the paint color paste, the modifier is attached to the solid fiber and generates the modification function; furthermore, the paint color paste is also attached to the solid fiber and better dyeing effect can be obtained after the post-processing.

Owner:常州市东高染整有限公司

Polyester paralleling composite yarn and prepared method thereof

ActiveCN104499091AGood flexibilityGood compatibilityNew-spun product collectionMelt spinning methodsYarnPolyester

The invention relates to a polyester paralleling composite yarn. The polyester paralleling composite yarn is prepared from PBT (polybutylece terephthalate) and modified polyester PET (polyethylene terephthalate) chips through parallel composite spinning, wherein the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fibers is increased by 20-30v / v% when the polyester of the polyester paralleling composite yarn is at 90-130 DEG C, the dying rate of the polyester paralleling composite yarn is higher than that of the common fiber when the polyester paralleling composite yarn adopts disperse red 3B and the like, less surface dyeing is formed after dyeing, and the polyester paralleling composite yarn has wide application prospect in the field of garment materials.

Owner:JIANGSU HENGLI CHEM FIBER

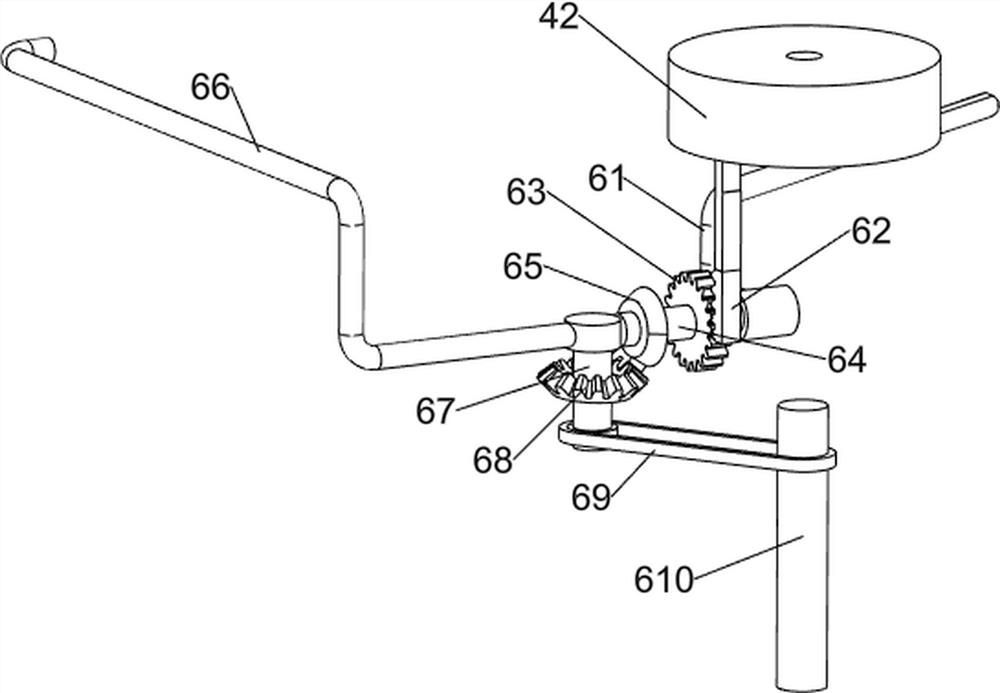

Gradually dyeing novel process for fabric and employed dyeing apparatus

ActiveCN101492866AEmission reductionSave water for dyeingTextile treatment machine partsTextile treatment by spraying/projectingEngineeringDyeing

The invention discloses a fabric gradual color dyeing technique and an employed coloration device thereof. The present gradual color dyeing method can only dye the gradual color of one color at a time and can only dye two colors at utmost, therefore, the yield and the quantity of colors are limited to a certain extent. The invention colors the fabrics by the coloration device, the employed coloration device comprises a plurality of spray coloration apparatuses capable of regulating the concentration of a dyeing liquid, the plurality of spray coloration apparatuses are arrayed in one group or more than two groups, each spray coloration apparatus operates individually to independently regulate the concentration of the dyeing liquid sprayed by each spray coloration apparatus so that the concentration of the dyeing liquid sprayed by each group of the spray coloration apparatuses is regulated to be incremented or decremented in sequence, thus generating, on the fabric, the gradual colors of one or more than two colors at a time.

Owner:ZHEJIANG SILK TECH

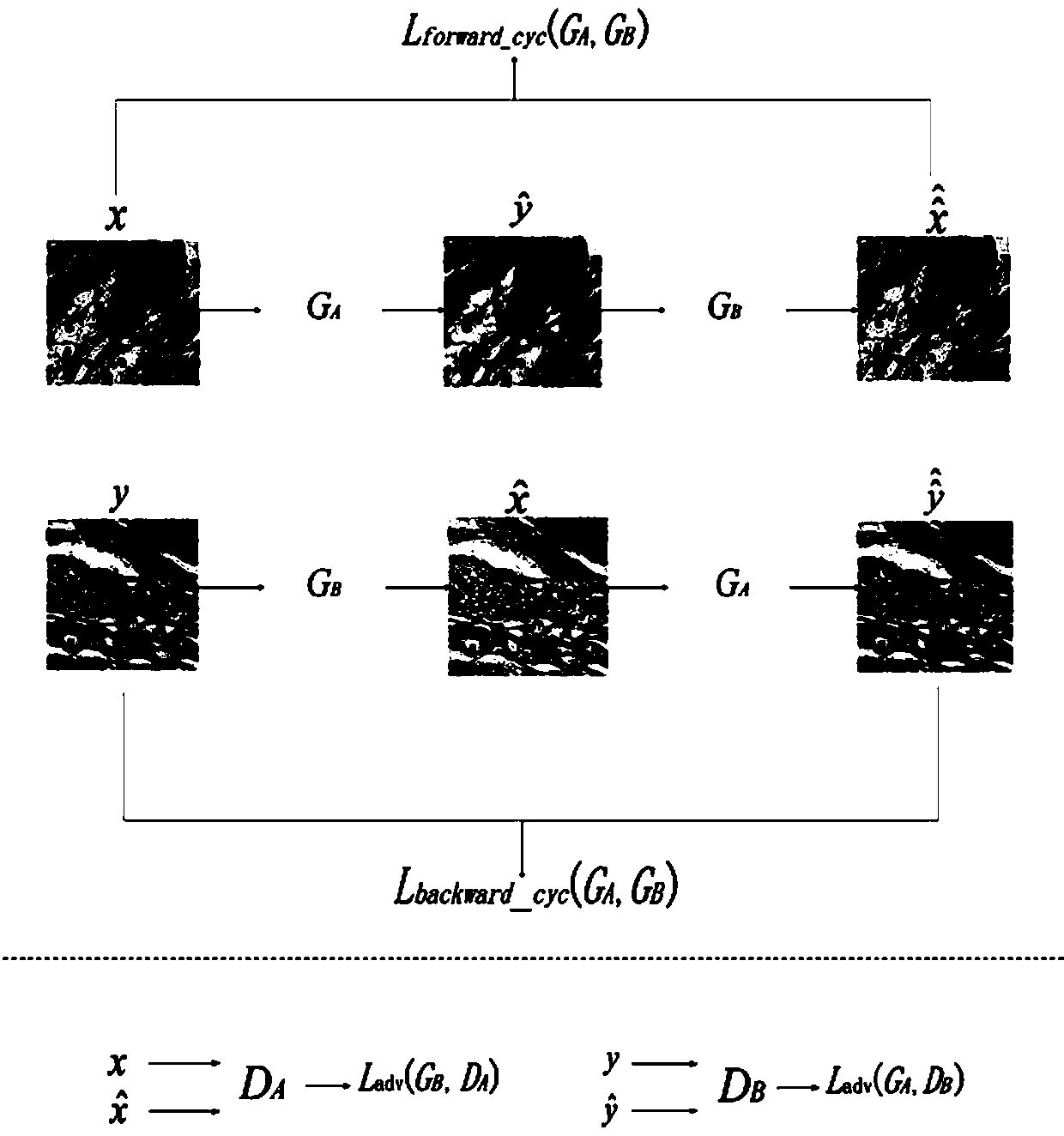

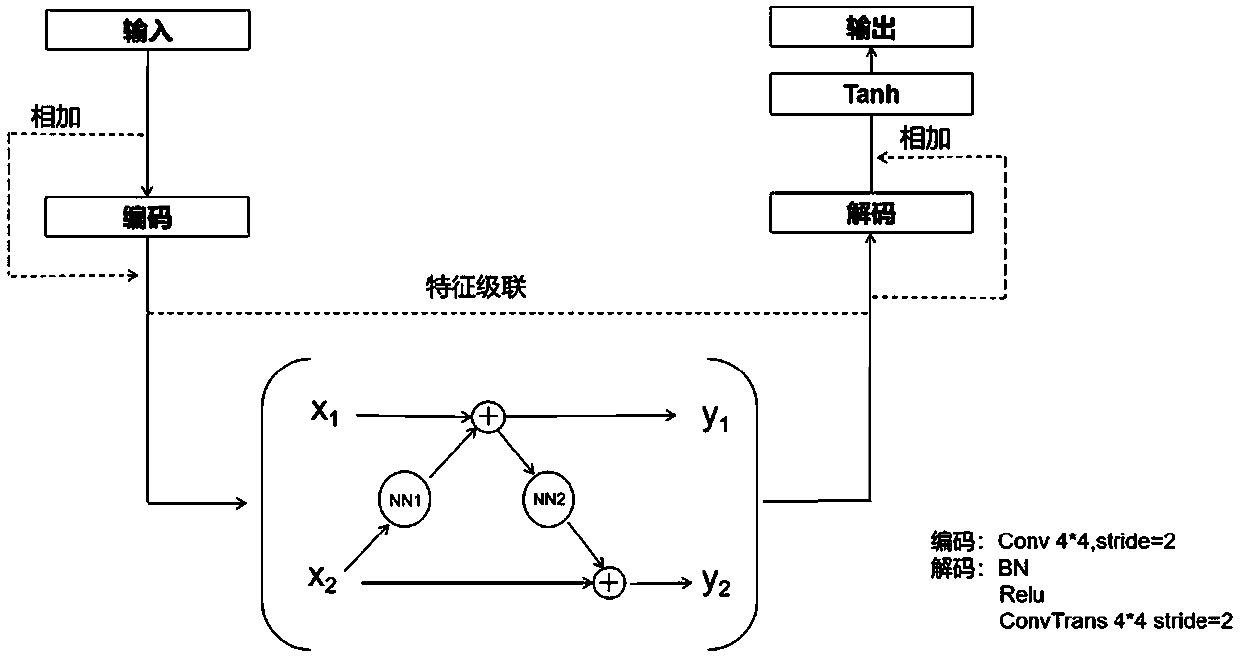

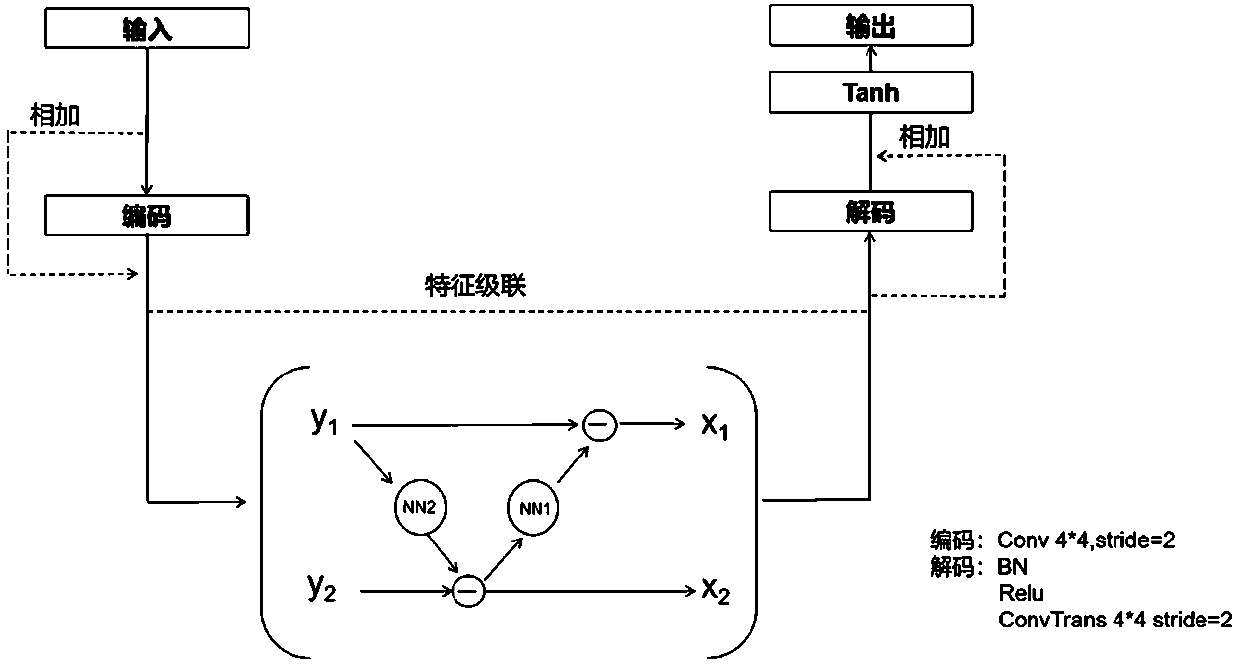

Digital pathological image H&E dyeing restoration method based on strong reversible adversarial network

ActiveCN111539883APromote recoveryPracticalImage enhancementNeural architecturesPattern recognitionData set

The invention relates to a digital pathological image H&E dyeing restoration method based on a strong reversible adversarial network. The method comprises the following steps: training a strong reversible adversarial network comprising two generators and two discriminators; and performing H&E dyeing restoration on the digital pathological image through the trained strong reversible adversarial network. The training process of the strong reversible adversarial network comprises: making image data sets before and after fading, then continuously training a forward process and a reverse process, calculating a total loss function until the total loss function and the quality of the image generated by the generator reach a preset reconstruction effect, stopping training, and obtaining optimal convolution weight parameters and offset parameters of a generator and a discriminator. The method is beneficial to color information restoration of the faded digital pathological image.

Owner:福建帝视科技集团有限公司

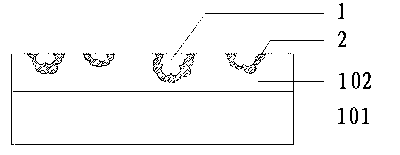

Three-dimensional pore shading decorative ceramic brick and manufacturing method thereof

The invention provides a method of manufacturing a pore decorative ceramic brick. The method comprises the well known processes of: processing powders, stamping and shaping cloth, drying a blank body, sintering the blank body and polishing; the powders comprise a plus material and a backing material; the plus material comprises a pore forming material component; and the pore forming material comprises one or more of hollow organic materials or plant fibers. Preferably, the pore forming material can be dyed by a stain bleeding dyeing agent. During the sintering process, the pore forming material is burnt out so that a pore is formed; and because the pore forming material is dyed, when the blank body is dried and sintered, the stain bleeding dyeing agent disperses around, so that the effect of dyeing inside the pore is achieved. The shading decoration effect of taking the pore as a center and dispersing around is formed at the surface of the brick; and the color is gradually changed. According to the three-dimensional pore, the proper match of the gradually discolored shading taking the pore as the center and the base color of the blank body can bring more abundant decoration effects.

Owner:FOSHAN DONGPENG CERAMIC +2

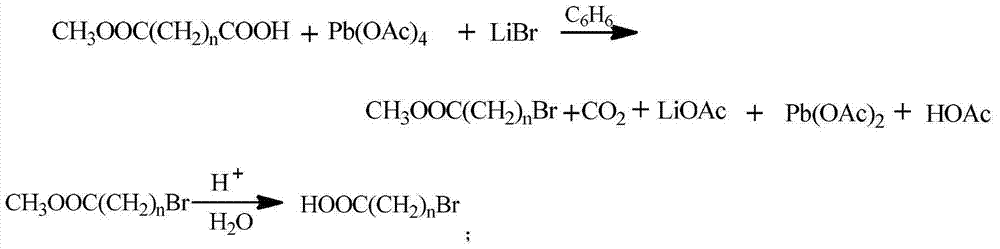

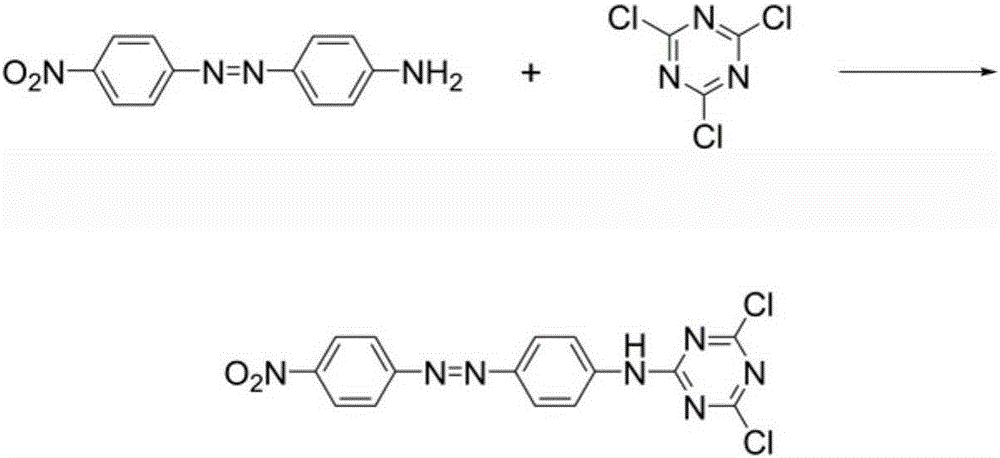

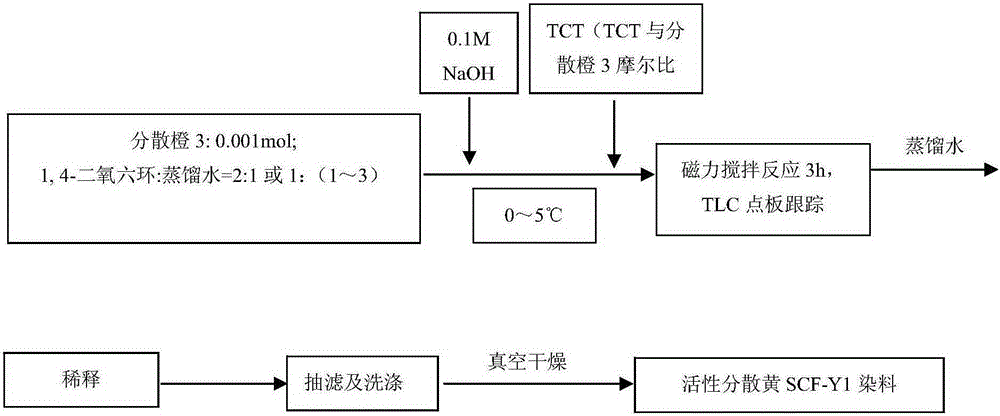

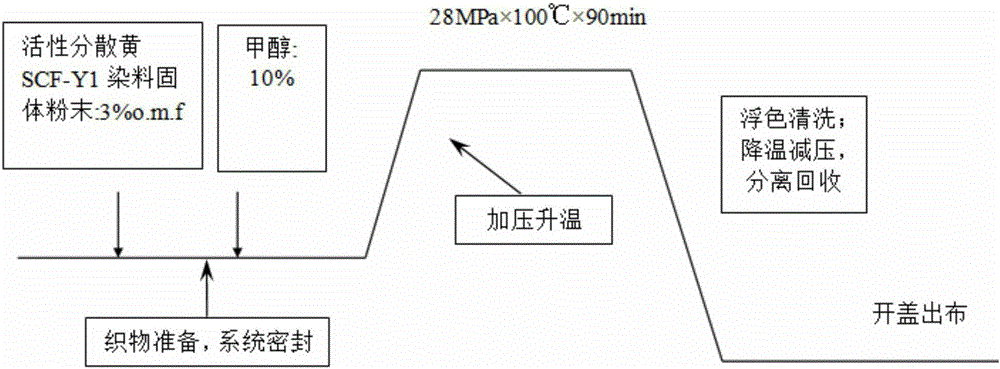

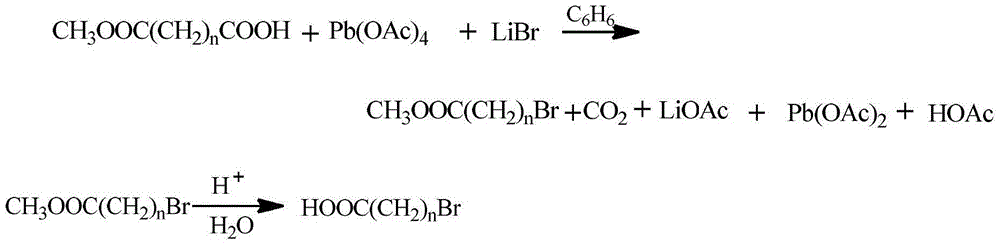

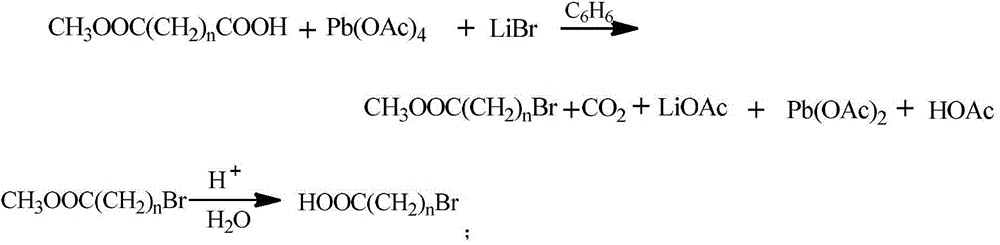

Cotton fiber dye for supercritical CO2 fluid dyeing and dyeing method thereof

InactiveCN106468026AExcellent adsorption and dyeing propertiesAchieve dyeing effectReactive dyesDyeing processCotton fibreLiquid carbon

The invention brings forward a cotton fiber dye for supercritical CO2 fluid dyeing and a dyeing method thereof. the dyeing method comprises the following steps: S1, providing a dyeing system which contains a dye kettle and a dyeing kettle which are communicated with each other; S2, dissolving the cotton fiber dye in a fluid modifier, pouring the cotton fiber dye and the fluid modifier into the dye kettle, and closing the dye kettle; putting fabric into the dyeing kettle, and closing the dyeing kettle; and S3, injecting liquid carbon dioxide into the dyeing system, heating the dyeing system and supercharging, converting liquid carbon dioxide into a supercritical CO2 fluid, and dissolving the cotton fiber dye with the supercritical CO2 fluid; and letting the supercritical CO2 fluid be circulated in the dye kettle and the dyeing kettle so as to finish the dyeing. The cotton fiber dye of the invention has excellent adsorption dyeing properties. In addition, the synthetic method of the cotton fiber dye has simple technological process.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

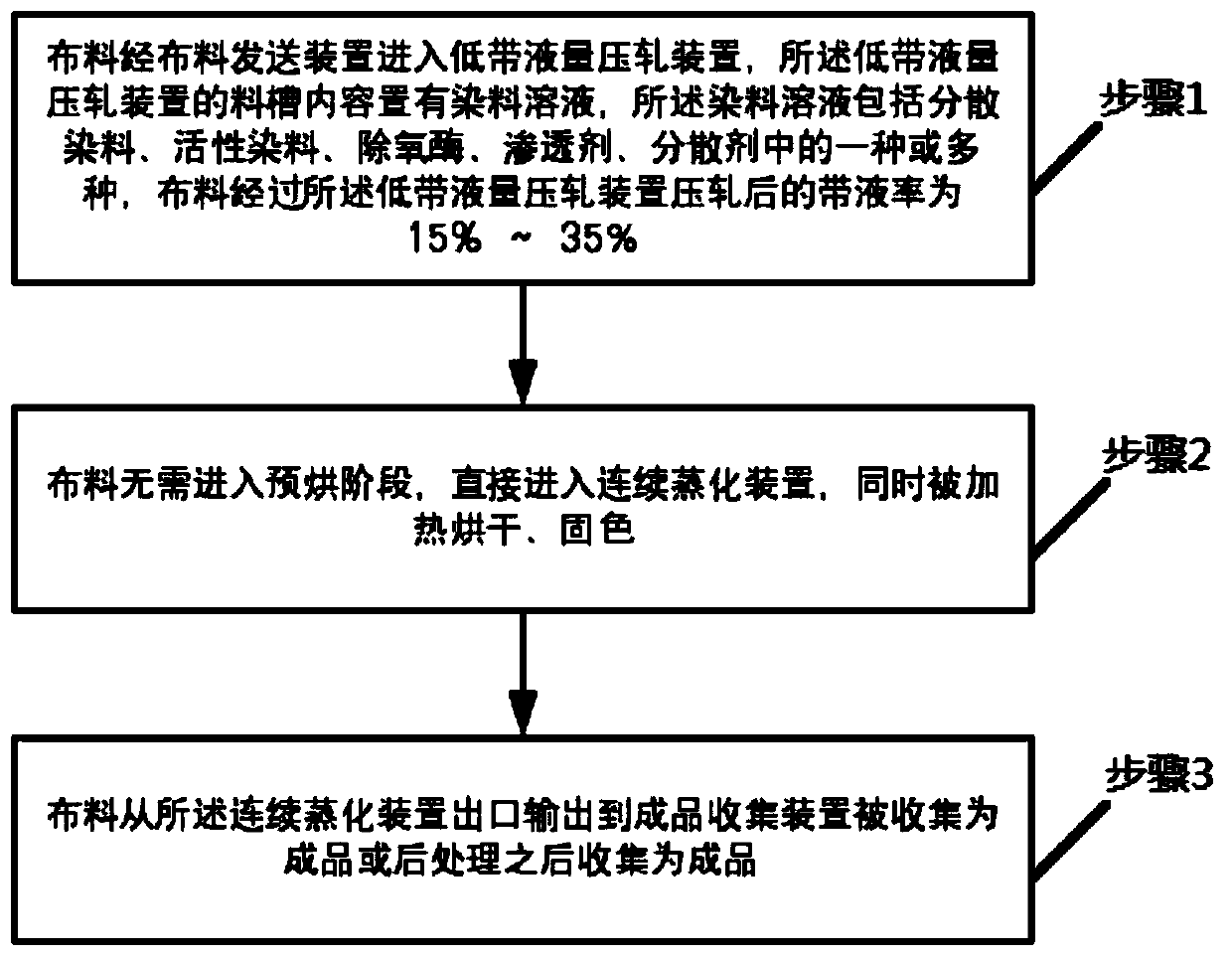

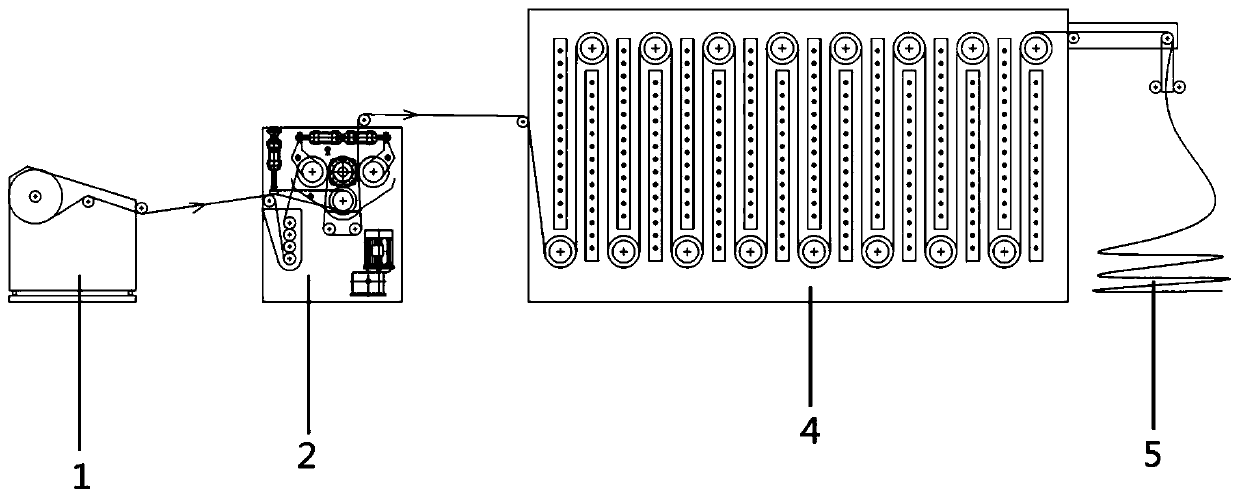

Ultrashort-flow rolling steaming dyeing process and equipment

InactiveCN110258134AAvoid swimming phenomenonReduce dosageHeating/cooling textile fabricsLiquid/gas/vapor removalDisperse dyePulp and paper industry

An embodiment of the invention discloses an ultrashort-flow rolling steaming dyeing process and equipment and aims to solve the technical problem that dye migration occurs easily during high-temperature baking or steaming under the circumstance that cloth high in wet pick up is not pre-dried. The ultrashort-flow rolling steaming dyeing process includes the steps of firstly, cloth enters a low-wet-pick-up rolling device through a cloth feeding device, a dye solution is accommodated in the material tank of the low-wet-pick-up rolling device, the dye solution comprises one or more of disperse dye, reactive dye, deoxidization enzymes, a penetrating agent and a dispersing agent, and the wet pick up of the cloth rolled by the low-wet-pick-up rolling device is 15-35%; secondly, the cloth enters a continuous steaming device and is subjected to heating drying and color fixation; thirdly, the cloth is output from the outlet of the continuously steaming device to a finished-product collecting device and is collected as a finished product or collected as a finished product after post-processing.

Owner:李雅

Polyester elastic yarn and preparation method thereof

ActiveCN104480569AGood flexibilityGood compatibilityOrganic compound preparationFilament/thread formingYarnPolytrimethylene terephthalate

The invention relates to a polyester elastic yarn and a preparation method thereof. The polyester elastic yarn is a double-component parallel composite yarn prepared from PTT (Polytrimethylene Terephthalate) and modified polyester; the elongation at break of the polyester elastic yarn is 30.0+ / -3.0%, and the boiling water shrinkage is 10.0+ / -0.5%; the modified polyester is prepared from polyester and amino fatty acid gylcol ester, wherein the amino fatty acid gylcol ester is dispersed among molecular chains of polyester and is in hydrogen-bond interaction with the molecular chains of polyester, therefore, the relative positions of the amino fatty acid gylcol ester and the molecular chains of polyester can be fixed. According to the polyester elastic yarn, the free volume space among molecular chains in fibers is expanded by 20-30v / v% under a temperature of 90 to 130 DEG C; the dyeing performance of polyester can be improved and the elastic damage degree of composite yarns can be reduced by adopting the polyester elastic yarn; the polyester elastic yarn is suitable for preparing elastic fibers and elastic decorative products.

Owner:JIANGSU HENGLI CHEM FIBER

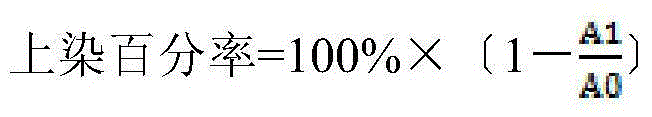

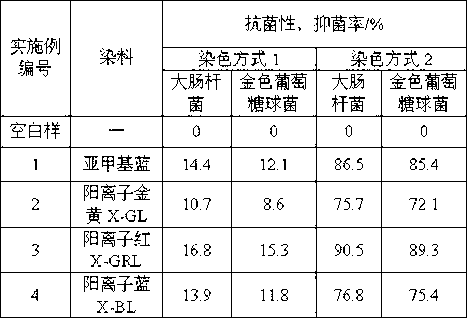

Natural retarding agent for dyeing of cationic dye and using method of natural retarding agent

InactiveCN103321064AConsistent product qualityAntibacterial and Antistatic Antibacterial or AntistaticDyeing processDyeingBenzalkonium chloride solution

The invention discloses a natural retarding agent for dyeing of cationic dye. The natural retarding agent is at least one of chitosan and derivatives thereof, wherein the concentration of the chitosan or the derivatives thereof is 0.1-4g / L. According to the retarding agent, natural chitosan or derivatives thereof, such as carboxymethyl chitosan and hydroxypropyl chitosan with different molecular weights are adopted for dyeing of cationic dye, and the problem that 1227 contains benzalkonium chloride and CTAB (cetyltrimethyl ammonium bromide) has strong fishy smell when a conventional cationic dye is used for dyeing are solved; and the prepared product has the quality consistent with that of a product prepared by adopting a conventional process, and has a certain antibacterial and anti-static performance. The technical scheme disclosed by the invention is simple in process and convenient to operate, does not have special requirement on cationic dye and equipment, and can be applied to large-scale production by utilizing conventional dyeing equipment.

Owner:HENAN INST OF ENG

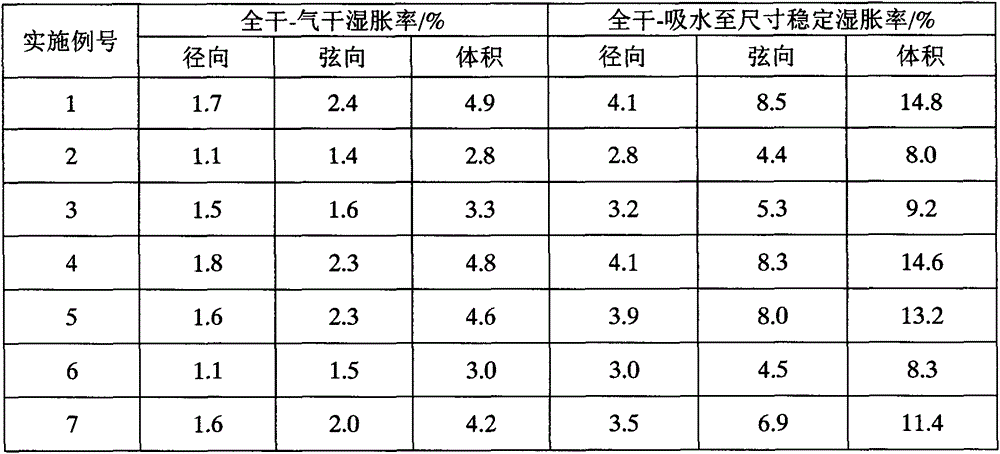

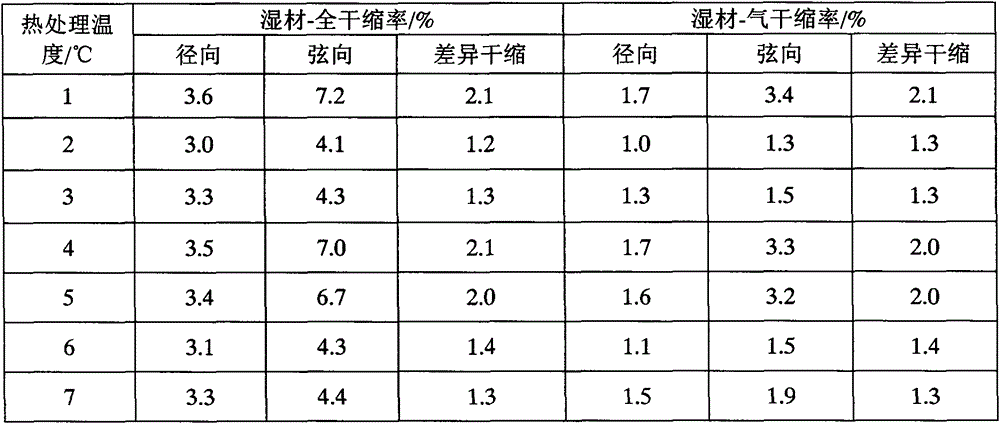

Burnishing and modifying treatment method for maple wood

ActiveCN106493819AFull color and beautifulGood anti-mold and anti-corrosion effectWood treatment detailsTemperature treatmentCarbon dioxide

The invention provides a burnishing and modifying treatment method for maple wood, and belongs to the field of wood dyeing for wood modification. The burnishing and modifying treatment method for the maple wood comprises the following three steps of boiling treatment, supercritical treatment and high-temperature heat-treatment burnishing treatment. During the boiling treatment through water vapor, the temperature is required to below 105 DEG C, and the pressure is required to be proper. During supercritical treatment, the pressure is required to be equal to or higher than 20 MPa, the temperature is required to be over 50 DEG C, and the supercritical treatment time is required to be equal to or longer than 5 min. The temperature for high-temperature heat-treatment burnishing treatment is required to be determined according to the maple wood color required in application. According to the burnishing and modifying treatment method for the maple wood, the water vapor and carbon dioxide are used as media for drying and blanching of the maple wood and burnishing and modifying through high-temperature treatment, so that the maple wood dyeing effect is achieved, and environmental friendliness and safety are guaranteed. The maple wood burnished through the method is good in mold-proof effect and anti-corrosion effect, resistant to deformation, safe and nontoxic, and can be used for preparing wooden tableware, wooden toys for children and other products.

Owner:ZHEJIANG FORESTRY ACAD +1

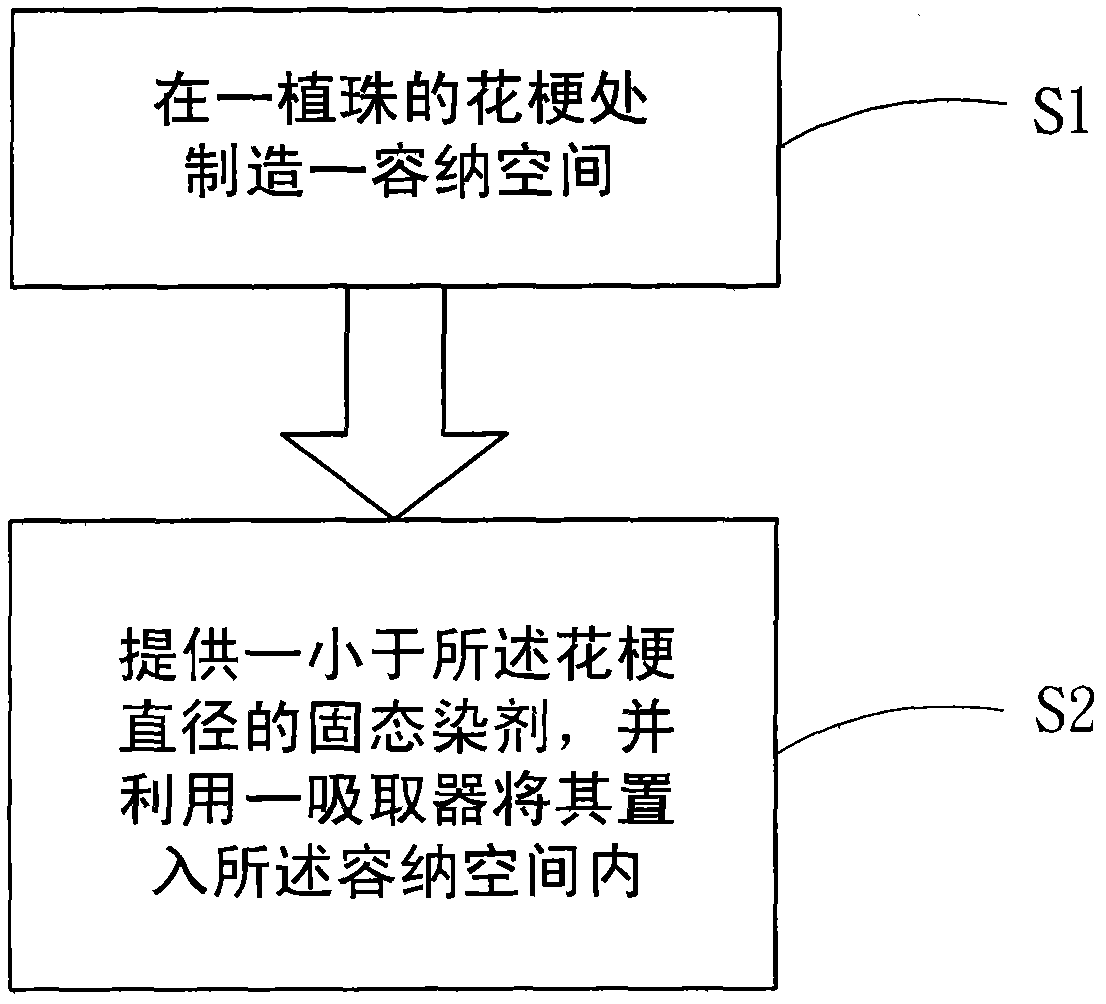

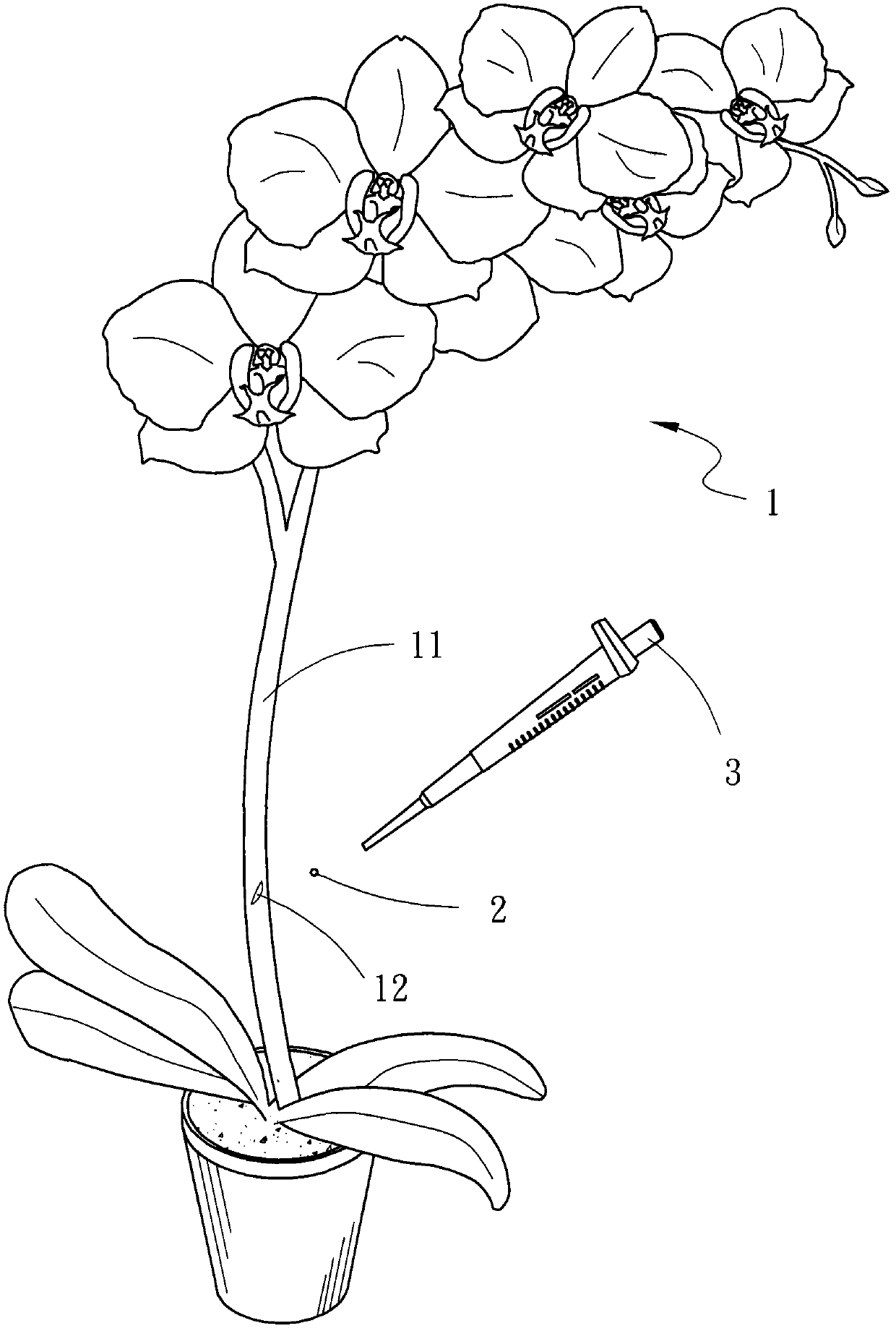

Method for changing flower color of orchid

The invention discloses a method for changing the flower color of orchid. The method comprises the following steps of forming an accommodation space at a pedicel of a plant, providing a solid-state dye of which the diameter is smaller than that of the pedicel, placing the solid-state dye in the accommodation space by utilizing a sucker, and supplying water to the plant before or after the solid-state dye is placed in the accommodation space to facilitate the dissolution and adsorption of the solid-state dye. Therefore, the colors of petals of the plant can be quickly and uniformly changed to be rich and bright, and diversity and a convenient dyeing effect are further achieved.

Owner:TAIWAN SUGAR CORP

Nitrate dyeing process for transition color furs

InactiveCN107956161AIncrease profitAchieve dyeing effectTanning treatmentPre-tanning chemical treatmentSodium carbonateOXALIC ACID DIHYDRATE

The invention discloses a nitrate dyeing process for transition color furs which relates to a fur dyeing process. The nitrate dyeing process for transition color furs is mainly invented for solving the current problem that transition colors dyed on furs are not natural and attractive. The nitrate dyeing process for transition color furs is carried out according to the following steps: fur washing:degreasing agent, sodium carbonate and ammonia are added into water, and a fur is immersed for 2 hours; mordanting: FeSO4 is added into water, and the fur is immersed for 8 to 16 hours; bleaching: bleaching agent is added into water, and the fur is immersed for 6 to 8 hours; deferrization: oxalic acid is added into water, and deferrization time is 3 to 6 hours; reduction bleaching: 2g to 5g of sodium hydrosulfite is added per liter of water, and processing time is 3 to 8 hours; tanning: aluminum retanning is adopted for the whitened fur, chromium retanning is adopted for the fur to be dyed, and after retanning, fatliquoring and drying are carried out; the dyeing method includes dip dyeing, brush dyeing and template dyeing; and dehydration, air-drying, TP oil application and drying are carried out. The advantage is that a transition color which is gradually lightened is dyed on the whole fur.

Owner:灯塔市兄弟皮毛硝染厂

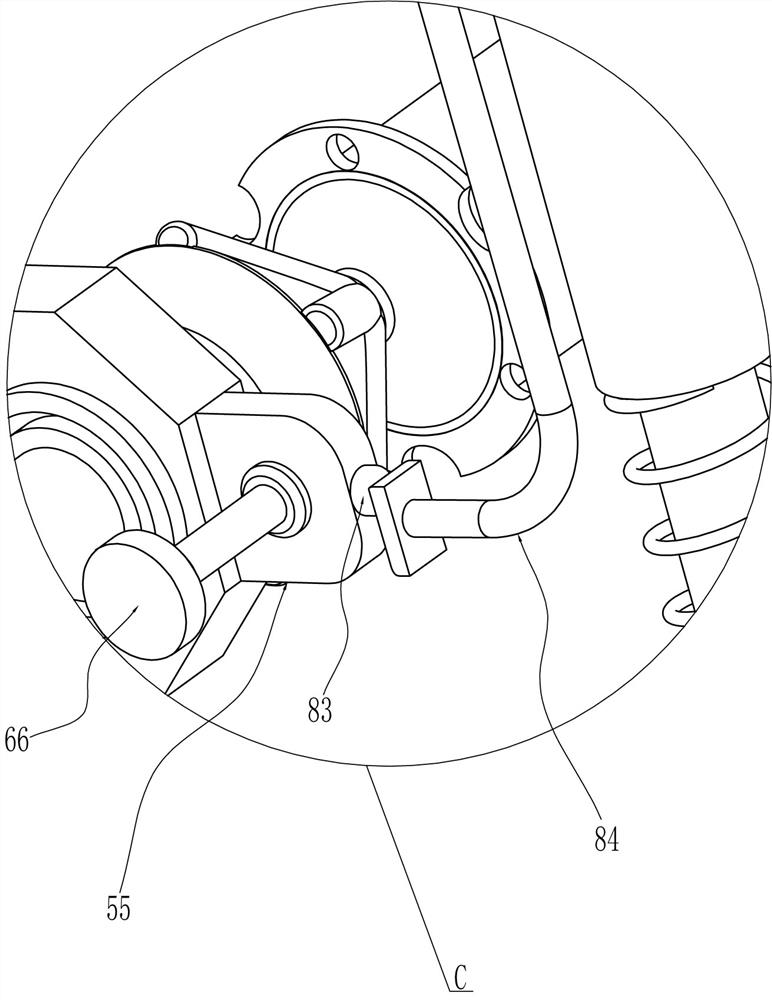

Continuous rolling type airflow dyeing machine applied to clothing production

ActiveCN105177897ASimple structureStrong targetingLiquid/gas/vapor article treatmentContinuous rollingAutomation

The invention discloses a continuous rolling type airflow dyeing machine applied to clothing production. The continuous rolling type airflow dyeing machine comprises a rack and a rack table top. A drying chamber and an airflow control chamber are formed in the middle of the rack. A heating device is arranged at the right side of the dyeing chamber. A dyeing work table is arranged in the dyeing chamber and provided with a rolling and dyeing device. The rolling and dyeing device comprises an upper rolling and dyeing device and a lower rolling and dyeing device. The upper rolling and dyeing device is connected with the rolling and dyeing transmission device. A rolling and dyeing adjustment device is connected below the lower rolling and dyeing device and collected with an adjustment drive device. A control box and an airflow atomizing device are arranged in the airflow control chamber. The airflow atomizing device is connected with an airflow nozzle assembly located above the dyeing chamber. The machine is simple in structure, scientific, convenient, and high in pertinence and automation degree, and well solves the problem of dyeing cloth and fabric.

Owner:苏州盛泽科技创业园发展有限公司

Continuous pigment dyeing pad dyer

InactiveCN101487175BOptimize layoutGuaranteed uptimeSucessive textile treatmentsDrying solid materials with heatEngineeringHot blast

The invention relates to a continuous paint dyeing padding machine. The padding machine comprises a device which brushes hair and collects dusts for the textile, a traction binding vehicle which can obstruct the tensile force of the textile, a padding device, an infrared pre-baking device, a hot-blast pre-baking device, a steam drying device and a fabric outlet disposing device, and all devices are sequentially arranged. All components of the dyeing padding machine are reasonably configured; and when in use, the energy resource is saved, the process is simple and the dyeing effect is good.

Owner:常州市东高染整有限公司

A kind of polyester side-by-side composite yarn and preparation method thereof

ActiveCN104499091BGood flexibilityGood compatibilityNew-spun product collectionMelt spinning methodsYarnPolyethylene terephthalate

The invention relates to a polyester paralleling composite yarn. The polyester paralleling composite yarn is prepared from PBT (polybutylece terephthalate) and modified polyester PET (polyethylene terephthalate) chips through parallel composite spinning, wherein the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fibers is increased by 20-30v / v% when the polyester of the polyester paralleling composite yarn is at 90-130 DEG C, the dying rate of the polyester paralleling composite yarn is higher than that of the common fiber when the polyester paralleling composite yarn adopts disperse red 3B and the like, less surface dyeing is formed after dyeing, and the polyester paralleling composite yarn has wide application prospect in the field of garment materials.

Owner:JIANGSU HENGLI CHEM FIBER

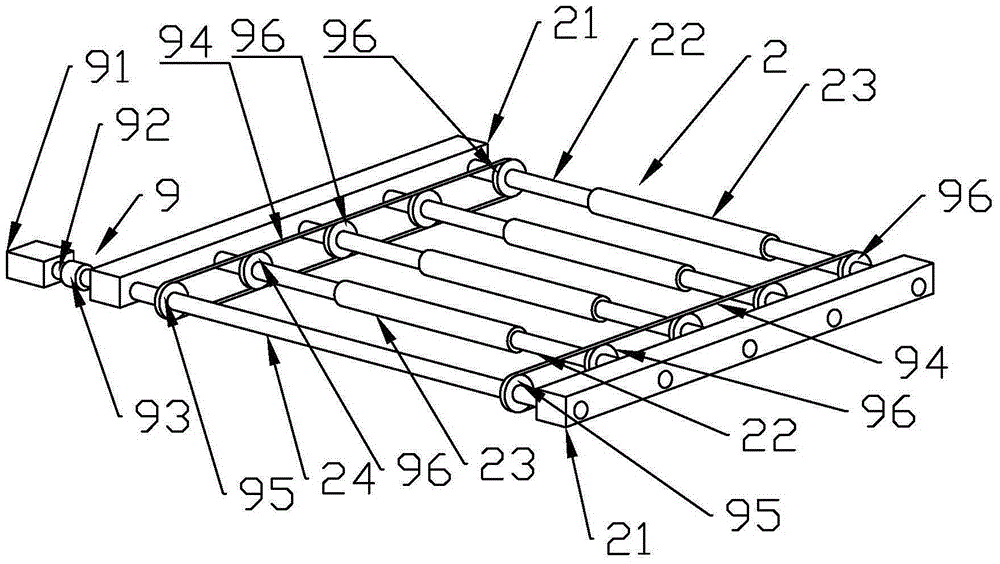

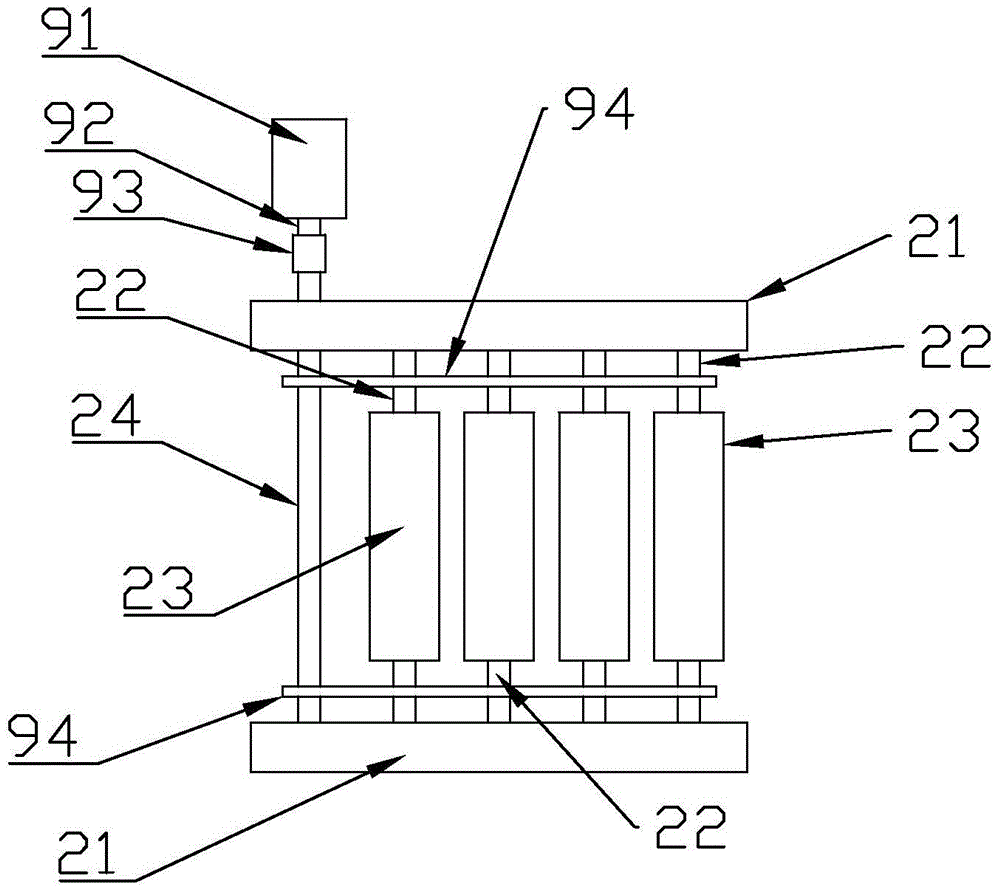

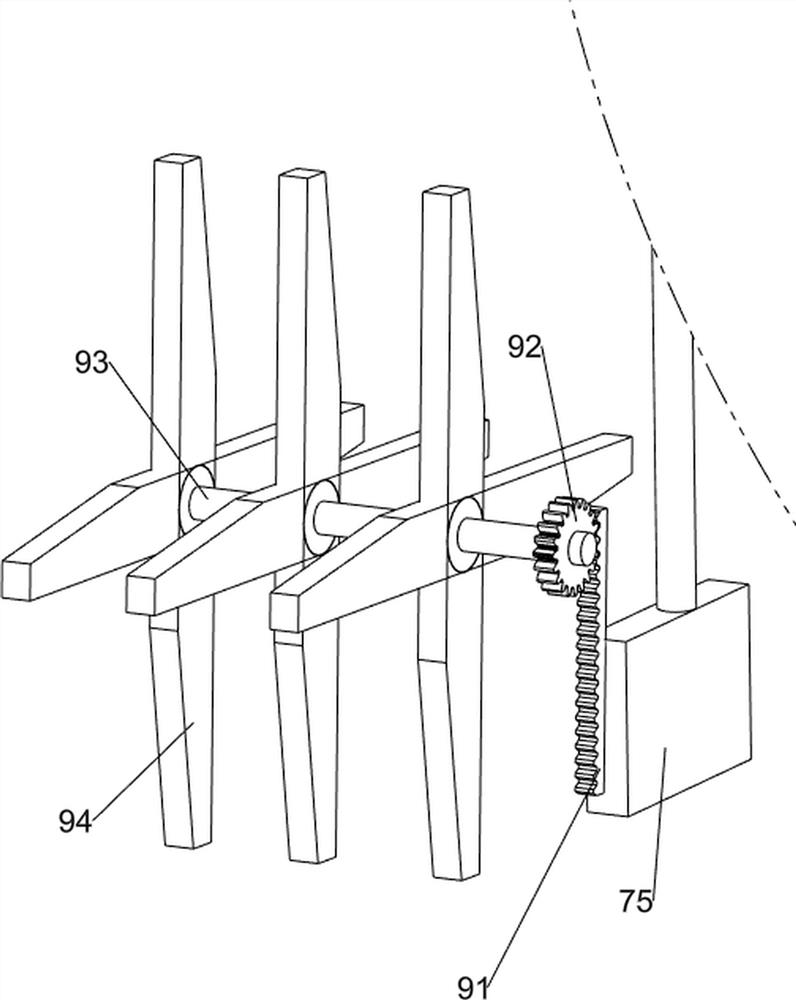

Dyeing device for cloth processing

InactiveCN113430744AAchieve effectAchieve dyeing effectTextile treatment machine arrangementsTextile treatment carriersEngineeringMechanical engineering

The invention relates to a dyeing device, in particular to a dyeing device for cloth processing. The dyeing device for cloth processing is relatively good in dyeing effect, convenient to operate and capable of conducting dyeing treatment on multiple pieces of cloth. The dyeing device for cloth processing comprises a bottom plate, a first supporting frame, an air cylinder, a material supporting mechanism, a dyeing mechanism and a loading frame, wherein the first supporting frame is arranged on the bottom plate; the air cylinder is installed on the upper portion of the first supporting frame; the material supporting mechanism is arranged on a telescopic rod of the air cylinder; the dyeing mechanism is arranged on the bottom plate; and the loading frame is arranged on the dyeing mechanism. By arranging the material supporting mechanism, the material supporting mechanism is matched with the air cylinder, people place the cloth on the material supporting mechanism, the air cylinder operates to drive the material supporting mechanism to operate, the cloth can be conveyed into the loading frame, and therefore the material supporting effect is achieved.

Owner:周庆余

Dyeing method of colorful echinopsis tubiflora

The invention relates to a dyeing method of colorful echinopsis tubiflora. The dyeing method comprises the following steps of: mixing plant-pigment stock solutions with different proportions, injecting the mixed plant-pigment stock solution into the epidermis and the root part of the echinopsis tubiflora by a syringe. The dyeing method has the advantages that the pigment stock solution prepared by utilizing natural plant dyes such as butterflybush flower, henna, tulip petals, peristrophe roxburghiana, dandelion, safflower and hematoxylon does not contain any chemical substances, so that the influence on the growth of the echinopsis tubiflora can be avoided while the echinopsis tubiflora is dyed; the plant-pigment stock solution is respectively injected into the root part and the epidermis of the echinopsis tubiflora, so that the plant-pigment stock solution can be better permeated into the internal tissues of the echinopsis tubiflora; by long-time continuous injection, the plant-pigment stock solution and the grown tissues of the echinopsis tubiflora are fused togehter.

Owner:邱泽文

Modified polyester and wool blended fabric and preparation method thereof

ActiveCN101956278BProcess environmental protectionSoft touchMonocomponent copolyesters artificial filamentDyeing processDisperse dyeYarn

The invention relates to a modified polyester and wool blended fabric and a preparation method thereof. The blended fabric is formed by blending and spinning modified polyester and wool. The modified polyester has the following structural unit, wherein m1 is more than 1 and less than 160; m2 is more than 1 and less than 70; m3 is more than or equal to 0 and less than 20; and m4 is more than or equal to 0 and less than 20. In the blended fabric, the modified polyester accounts for 5 to 80 percent. The blended fabric is formed by weaving one or more modified polyester and wool blended yarns of which the blending ratios are different. In a weaving process, the fabric structure is pre-designed and the blended fabric is subjected to one bath dyeing with an acidic dye and a disperse dye in the environment of which the temperature is less than 100 DEG C and the pH value is between 2 and 6. Both the plain colour effect of the same colour of the whole fabric and the fancy effect similar to a dyed fabric can be realized.

Owner:CHINESE TEXTILE ACAD

Cable sheath material dyeing device

InactiveCN108654942AImprove dyeing effectSolve the problem of poor dyeing effectLiquid surface applicatorsCoatingsDrive wheelElectric machinery

The invention discloses a cable sheath material dyeing device. The cable sheath material dyeing device comprises a machine body; the left side of the machine body is fixedly connected with an unreeling device and a dyeing device sequentially from left to right through a supporting plate; the right side of the machine body is fixedly connected with a reeling device through a supporting plate; one side of an inner cavity of the machine body is welded with a heating device; a box body is embedded at the top of the machine body; and the left side of the back side of an inner cavity of the box bodyis fixedly connected with a motor through a fixing piece. Through cooperation of the unreeling device, the dyeing device, the reeling device, the heating device, the motor, a driving wheel, a belt, adriven wheel, a rotating rod, a fixed shaft, an annular groove plate, a sliding groove, a connecting plate, an air outlet spray head and an air inlet, the effect of dyeing a cable sheath is achieved,so that the advantage of good effect of dyeing the cable sheath is achieved, the quality of a cable product is improved, the post processing of the cable is guaranteed and the cable can be differentiated by installation personnel.

Owner:何盼

Pericarpium juglandis hair dye as well as preparation method and application method thereof

InactiveCN109330950AAchieve dyeing effectDark colorCosmetic preparationsHair cosmeticsHair dyesAntioxidant

The invention provides a pericarpium juglandis hair dye. The pericarpium juglandis hair dye contains an agent A and an agent B, wherein the agent A is mainly prepared from pericarpium juglandis, a surfactant, ethanol amine, a thickening agent, L-cysteine and a plant penetrant; the agent B is prepared from a surfactant, an antioxidant, a thickening agent, ferrite and pericarpium juglandis juice. The invention further provides a preparation method and an application method of the pericarpium juglandis hair dye. The pericarpium juglandis juice is adopted as the main raw material, plant pigment and the plant penetrant are applied, and the pericarpium juglandis hair dye is safe, non-irritant and uniform in dyeing, has stable performance, high dyeing power and long dye retention time and is suitable for all kinds of people for long-term hair dyeing.

Owner:LULIANG UNIV

Method of continuous pigment dyeing for fabric

InactiveCN101509184BWell mixedDyeing firmDrying solid materials with heatTextile treatment machine arrangementsSURFACTANT BLENDPigment

The invention relates to a continuous pigment dyeing method for fabrics, in which the fabrics during travelling are subjected to the steeping of a composite dye solution in a steeping tank that is continuously supplemented with the composite dye solution, and then to the rolling of rollers, and the time the fabrics are subjected to the composite dye solution by the fabrics is 2.5-5 seconds. The composite dye solution comprises the components having the following concentrations: 10g / L-50g / L of a pigment paste, 1g / L-8g / L of a cation modifying agent, 3g / L-5g / L of a surfactant and 5g / L-20g / L of acation bonding agent. The padding fabrics are continuously subjected to an infrared pre-drying apparatus for drying, a hot-air pre-drying tank for drying and a steam drying cylinder apparatus for drying. The inventive method has superior stability of the dyeing effect and is free from agglomeration.

Owner:常州市东高染整有限公司

Wool garment dyed and washed garment and its manufacturing process

ActiveCN106901414BSmall shrinkageSmall sizeDyeing processShrinking resistant fibresManufacturing technologyShrinkage rate

The invention discloses dyed and washed clothing of a wool garment and a manufacturing technology of the dyed and washed clothing. The technology comprises the steps of firstly carrying out ozone non-shrink treatment on white wool fabric to obtain washable wool fabric of which the shrinkage rate is greatly reduced when the dyed and washed clothing of the wool garment is manufactured; tailoring the wool fabric, increasing the shrinkage rate while tailoring and sewing the wool garment; and finally dyeing and washing the wool garment. In the process of manufacturing the dyed and washed clothing of the wool garment, the shrinkage rate is improved in advance to ensure accurate size of the dyed and washed wool clothing; and the wool garment is firstly manufactured and then the whole wool garment is subjected to dyeing and washing procedures to achieve a unified dyeing effect. Therefore, the manufacturing technology is simple, the manufactured wool garment is capable of keeping the wearing comfort requirement of an original wool garment, the wool garment is washable, easy to care and good in dyeing effect, and meets the unrestrained fast-pace individualized requirements of modern people.

Owner:SHANDONG NANSHAN TEXTILE GARMENT +1

An automatic painting device for steel pipes

ActiveCN111570189BAchieve dyeing effectSave human effortLiquid surface applicatorsCoatingsLacquerIndustrial engineering

The invention relates to a painting device, in particular to an automatic painting device for steel pipes. The technical problem to be solved by the present invention is to provide an automatic painting device for steel pipes that does not require frequent manual placement and removal of steel pipes and can save manpower during operation. In order to solve the above-mentioned technical problems, the present invention provides such an automatic painting device for steel pipes, which includes: a base, which is connected to the top side of the base, and an arc-shaped baffle is connected to the discharge ramp; a liquid storage frame, which is connected to On the other side of the top of the base; the driving assembly is arranged on the base. The invention can put the steel pipe into the paint bucket through the cooperative operation of the driving component and the clamping component, and then rotate the steel pipe to complete the dyeing, so that the effect of dyeing the steel pipe can be achieved.

Owner:DEXIN STEEL PIPE CHINA

Continuous pigment dyeing pad dyer with infrared pre-baking apparatus

InactiveCN101487177BAvoid damageImprove mobilitySucessive textile treatmentsDrying solid materials with heatEngineeringPre treatment

The invention relates to a continuous paint dyeing padding machine with an infrared pre-drying device. The padding machine comprises a fabric inlet pre-processing device, a padding system, a drying system and a fabric outlet processing device which are sequentially arranged. The drying system comprises an infrared pre-drying device and a steam drying device. The infrared pre-drying device comprises two to five pre-dying mechanisms; each pre-drying mechanism comprises a pair of frame parts; and each pair of frame parts is provided with an infrared emitter. The continuous paint dyeing padding machine is characterized in that the front part of each row of infrared emitters is provided with a shielding device; when the padding machine is in use, the shielding device is arranged at a keep-clear position; and when the padding machine is in a shutdown state, the shielding device is arranged at a shielding position. Furthermore, each pair of frame parts can be arranged in a close state or an open state corresponding to the rolling of a first frame. Therefore, the padding machine has protection effect when in use, better dyeing effect and convenient maintenance.

Owner:常州慧杰电气技术有限公司

Staining liquid capable of rapidly changing color and preparation method of staining liquid

InactiveCN113119257AConsistent colorAchieve dyeing effectWood treatment detailsReed/straw treatmentFiberPolymer science

The invention relates to a staining liquid capable of rapidly changing color and a preparation method thereof. The staining liquid comprises the following components: 50% of metal complex dye with a concentration of 30%, 30% of an emulsifier, 5% of an accelerant (cyanided tallow amine polyoxyethylene ether), 5% of a penetrant (dimethyl sulfoxide) and 10% of ethanol. The staining liquid has the beneficial effects that the staining agent has the effect of being directly soaked without heating and pressurizing; meanwhile, the composite dyeing liquid can be recycled, is good in transparency, good in light resistance and uniform in dyeing effect, retains good wood texture feeling, is fixed to wood wool fibers, has no adverse effect on subsequent processes (such as high-temperature long-time boiling and dry gluing) after dyeing, does not change color or fade after being dried at high temperature, and has good color fastness. The dyed recombined wood wool does not affect subsequent processing such as coating and gluing, so that the multifunctional modernization requirements of wood processing are met, the utilization value of fast-growing willow (bamboo) wood is comprehensively improved, and the staining liquid is widely applied to the fields of high-grade furniture, building materials, high-grade floors, wood carvings, car decoration plates and the like.

Owner:强舒瑜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com