Method of continuous pigment dyeing for fabric

A paint dyeing and continuous technology, applied in the dyeing field, can solve the problems of poor stability, inability to industrialize, difficult dyeing, etc., and achieve the effect of stable dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

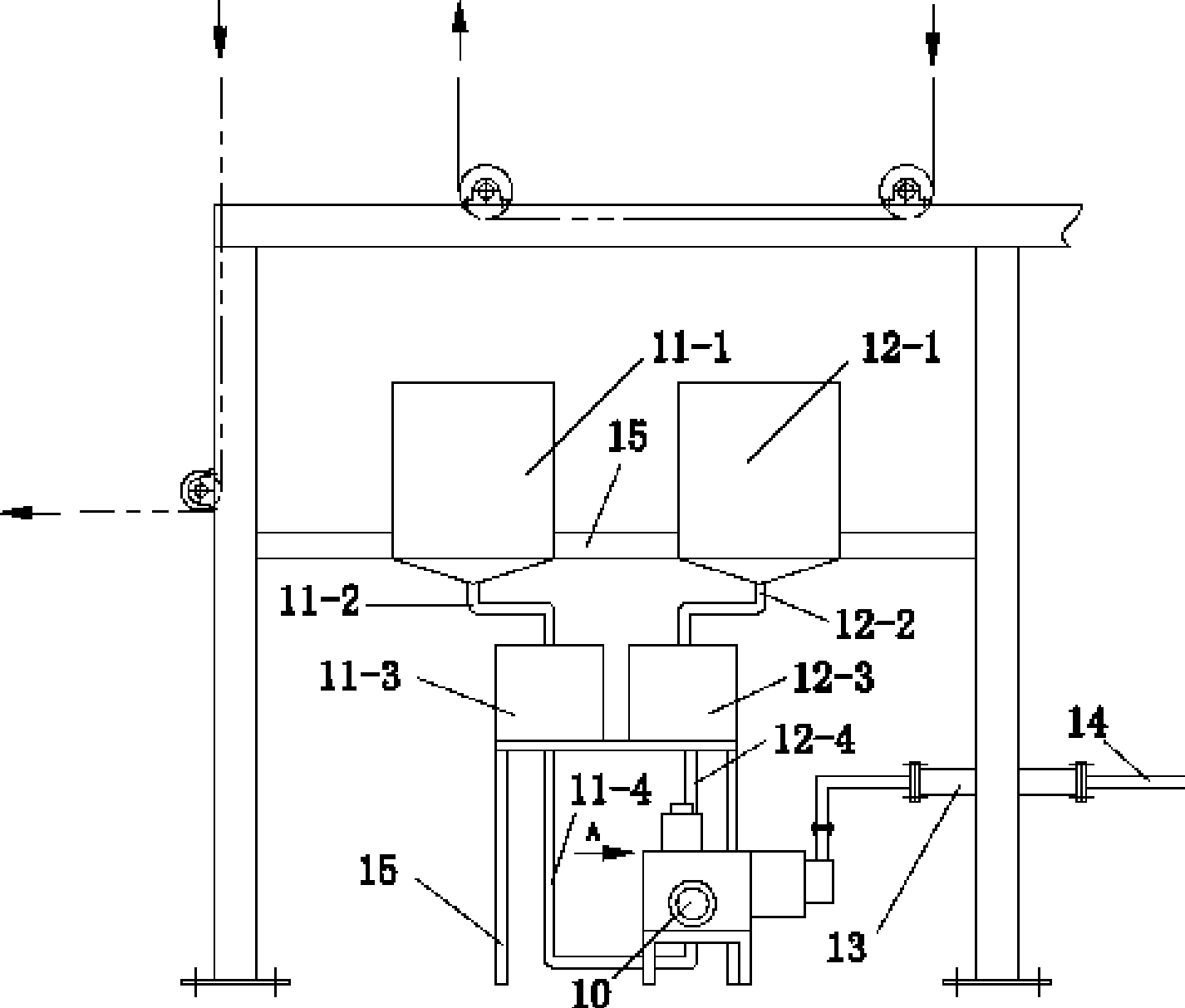

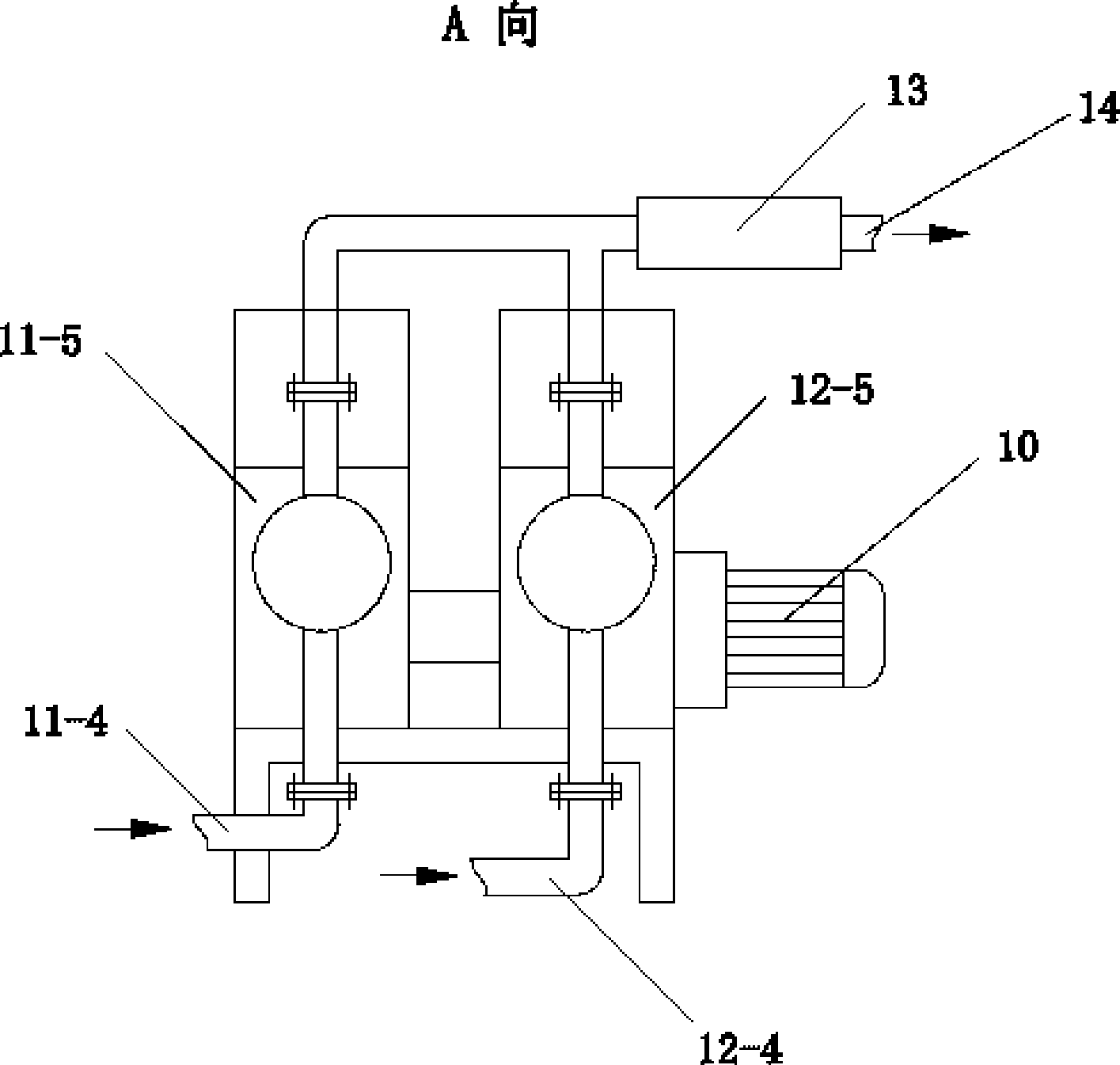

[0023] See figure 1 and figure 2 , the two-way liquid supply device of the proportional liquid supply device 1 is a first-way liquid supply device and a second-way liquid supply device. The first liquid supply device includes a first liquid storage tank 11-1, a first connecting pipe 11-2, a first liquid level tank 11-3, a first liquid supply pipe 11-4 and a first metering pump 11 connected in sequence -5; The second liquid supply device includes a second liquid storage tank 12-1, a second connecting pipe 12-2, a second liquid level tank 12-3, a second liquid supply pipe 12-4 and a second liquid supply pipe connected in sequence. Two metering pumps 12-5. The proportional liquid supply device 1 also includes a metering pump motor 10 , a mixer 13 , a liquid inlet pipe 14 and a liquid supply frame 15 . Mixer 13 is a three-way steel container.

[0024] Both the first liquid storage tank 11 - 1 and the second liquid storage tank 12 - 1 are fixedly installed on the liquid supply...

Embodiment 2~ Embodiment 5

[0033] Each embodiment is basically the same as Embodiment 1, and the differences are shown in Table 1.

[0034] Example 1 Example 2 Example 3 Example 4 Example 5 Paint color paste 30g / L 41g / L 17g / L 21g / L 22g / L cationic modifier 5g / L 5g / L 2g / L 8g / L 3g / L Surfactant 4g / L 5g / L 3g / L 5g / L 4g / L cationic binder 12g / L 18g / L 8g / L 5g / L 10g / L Infrared pre-baking temperature 70℃ 65℃ 60℃ 75℃ 80℃ Infrared pre-baking time 25 seconds 25 seconds 30 seconds 20 seconds 18 seconds Hot air pre-drying temperature 100℃ 95℃ 90℃ 105℃ 110℃ Hot air pre-drying time 40 seconds 40 seconds 45 seconds 35 seconds 30 seconds Steam drying temperature 140℃ 135℃ 130℃ 145℃ 150℃ steam drying time 60 seconds 65 seconds 70 seconds 55 seconds 50 seconds

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com