Gradually dyeing novel process for fabric and employed dyeing apparatus

A new process and fabric technology, applied in the field of fabric dyeing, to achieve the effect of reducing pollution, reducing emissions, and reducing raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the fabric is 02 crepe de chine, the door width is 114cm, the moving mode of the coloring device is adopted, the color is a two-color progressive color of light red and blue in the middle of both sides, and a plurality of liquid spray colorers 16 installed on the coloring device 14 are divided into two groups, The deepest concentration is dyeing mother liquor: diluent = 1:0 (that is, the concentration of dyeing mother liquor), and the shallowest concentration is dyeing mother liquor: diluent = 1:19 (that is, 1 / 20 of the concentration of dyeing mother liquor), the process is as follows:

[0023] Stretched silk—coloring (the moving speed of the coloring device is 10 m / min)—heating and drying or natural drying—steaming in a garden barrel steamer (steam pressure 0.8kg / cm 2 , 30 minutes) - rope washing, color fixation - stenter drying - finished product.

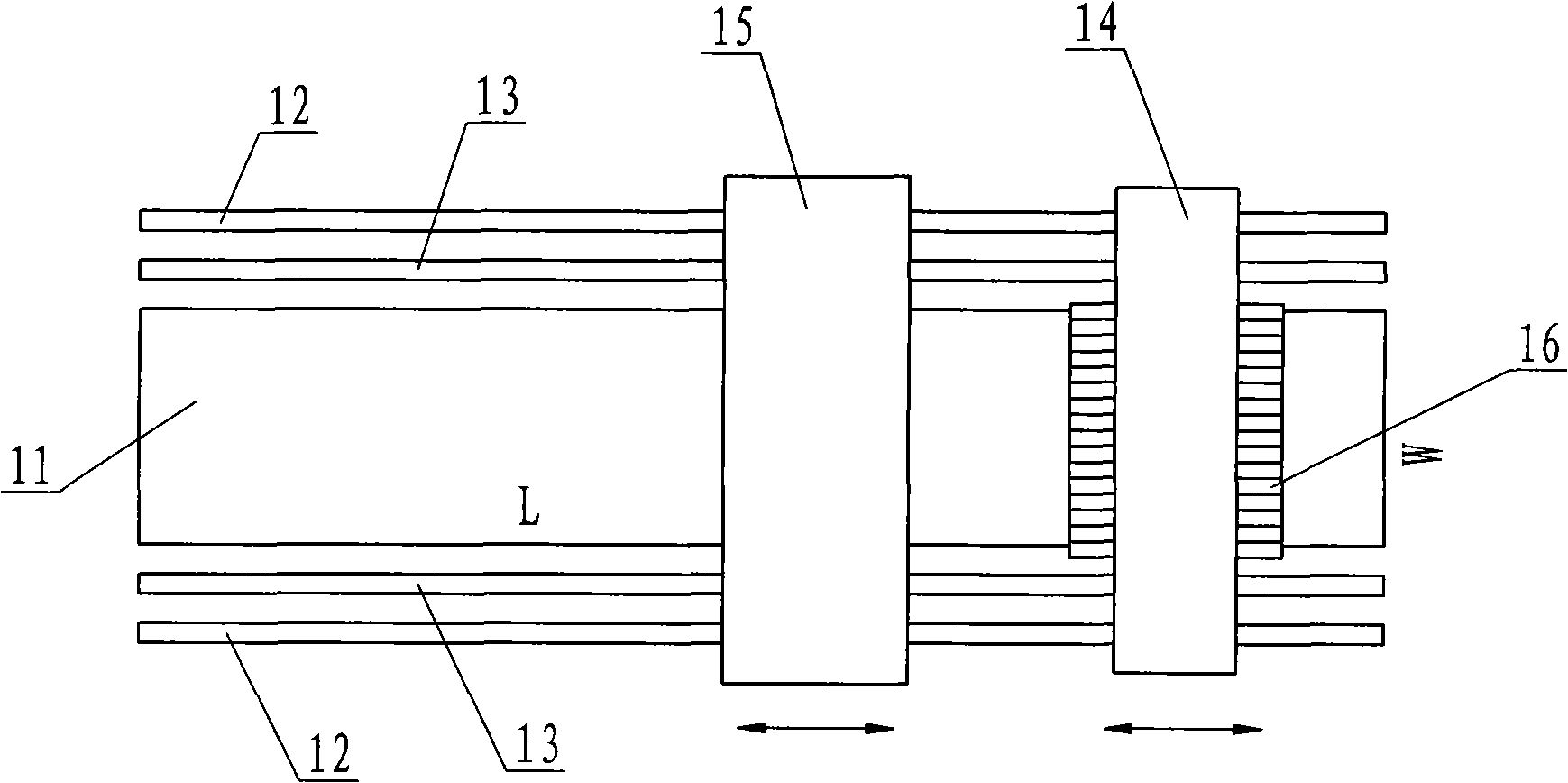

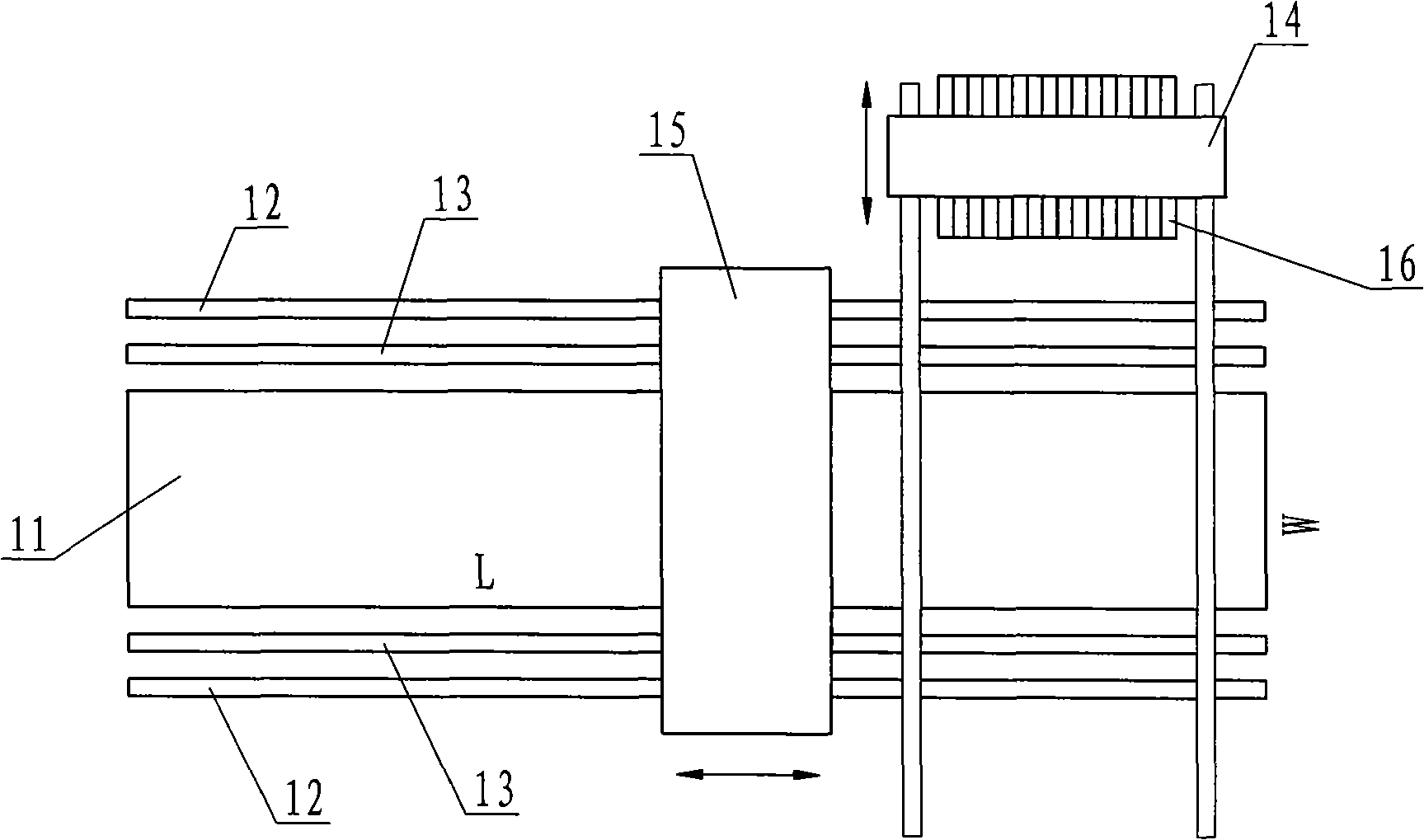

[0024] Stretch the fabric 11 on the stretcher frame 13 with track 12, the coloring device 14 moves along t...

Embodiment 2

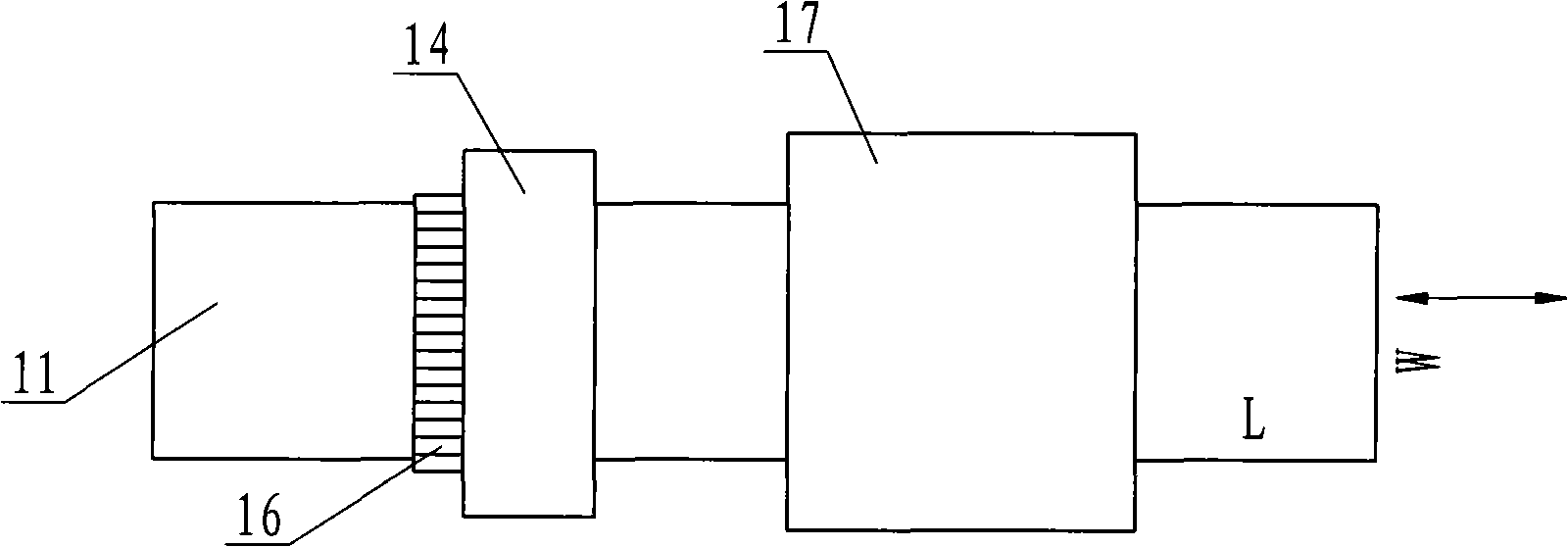

[0025] Embodiment 2: the fabric is 16 electric power spinning, the door width is 114cm, the fabric is moved, the equipment is a hot air stenter, the color is green monochromatic progressive color, and a plurality of liquid spray colorers 16 installed on the coloring device 14 are one Group, the deepest concentration is the dyeing mother liquor: diluent = 1:0 (that is, the concentration of the dyeing mother liquor), the lightest concentration is the dyeing mother liquor: diluent = 1:24 (that is, 1 / 25 of the concentration of the dyeing mother liquor), the process as follows:

[0026] Fabric rolling - coloring, drying (vehicle speed 15 m / min, oven temperature 120°C) - steaming (continuous steamer, temperature 102°C, time 30 minutes) - open width washing (open width washing machine or Jig dyeing machine washing), color fixation - woolen blanket machine drying - finished product.

[0027] The coloring device 14 is fixed, and the coloring device 14 colors the fabric when the fabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com