Cotton fiber dye for supercritical CO2 fluid dyeing and dyeing method thereof

A dyeing method and supercritical technology, applied in the field of dyes, can solve the problems of increasing the complexity of the dyeing process and increasing the production cost, and achieve the effects of excellent adsorption and dyeing characteristics, simple process and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The synthetic method of this cotton fiber dyestuff comprises the following steps:

[0041] Step 1, using cyanuric chloride (TCT) as the active group, and putting the dye matrix and the active group into a single or mixed solvent to completely dissolve it, thereby obtaining a reaction system;

[0042] Step 2, placing the reaction system in an ice bath at 0°C to 5°C, and then adding cyanuric chloride solution and an acid scavenger dropwise to the reaction system until the condensation reaction of the reaction system ends;

[0043] Step 3, diluting the reaction system after the condensation reaction, washing, filtering and drying to obtain the cotton fiber dye.

[0044] In the above synthesis method, the dye matrix can be 1,4-diaminoanthraquinone, disperse orange 3 or disperse blue 35. When the dye parent is 1,4-diaminoanthraquinone, the cotton fiber dye is red, which is recorded as reactive disperse red SCF-R1; when the dye parent is disperse orange 3, the cotton fiber d...

no. 1 example

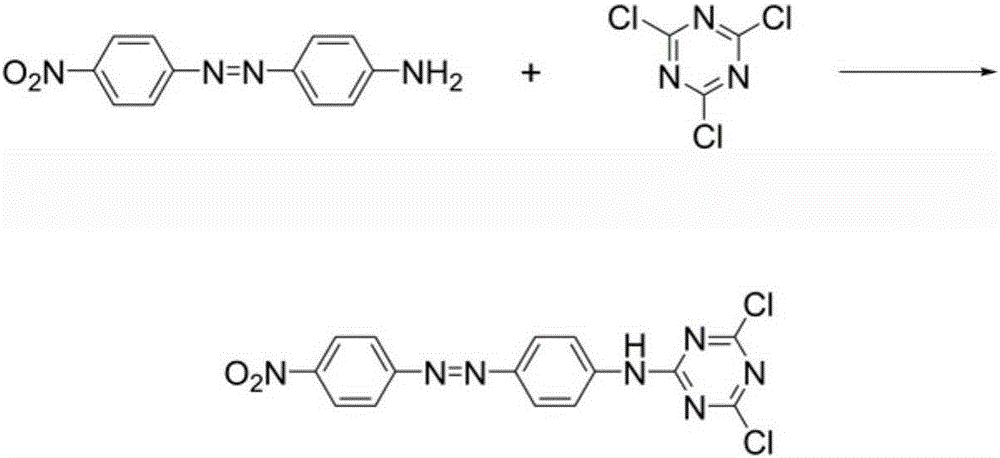

[0056] This embodiment provides a kind of synthetic method of yellow cotton fiber dye.

[0057] Specifically, refer to figure 1 , figure 1 It is the synthetic route of yellow cotton fiber dye, and it can be seen that the present embodiment adopts Disperse Orange 3 and cyanuric chloride as raw materials, so that a Cl on the cyanuric chloride replaces a H on the amino group of Disperse Orange 3, thereby synthesizing Produces yellow cotton fiber dye.

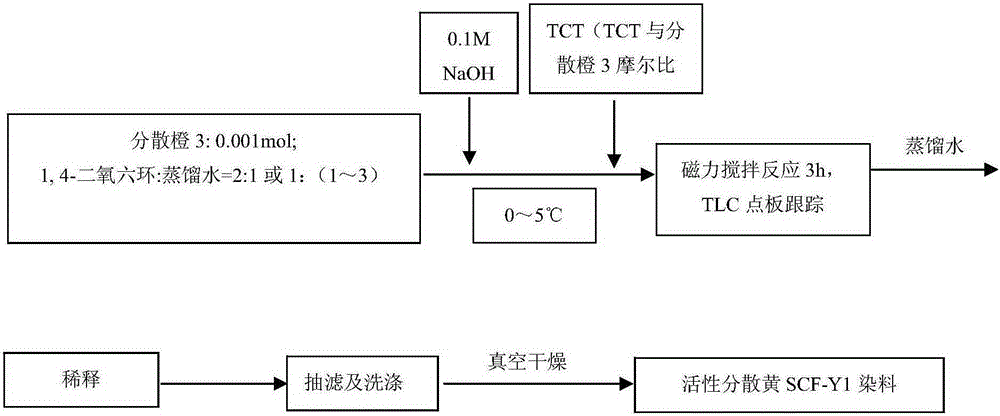

[0058] refer to figure 2 , figure 2 show figure 1 Process flow diagram of the yellow cotton fiber dye shown.

[0059] The synthetic method of yellow cotton fiber dyestuff comprises:

[0060] Step 1, using disperse orange 3 as the dye matrix, and putting the dye matrix into a mixed solvent of dioxane and water to completely dissolve it, thereby obtaining a reaction system;

[0061] In the mixed solvent of dioxane and water, the mass ratio of 1,4-dioxane to distilled water is 2:1 or 1:(1~3);

[0062] Further, Disperse Orang...

no. 2 example

[0080] This embodiment provides a kind of synthetic method of blue cotton fiber dye.

[0081] Specifically, refer to Figure 8 , Figure 8 For the synthetic route of blue cotton fiber dye, it can be seen that the present embodiment adopts disperse blue 35 and cyanuric chloride as raw materials, so that a Cl on cyanuric chloride replaces a H on the hydroxyl group of disperse blue 35, thereby Crafts blue cotton fiber dye.

[0082] refer to Figure 9 , Figure 9 show Figure 8 The process flow chart of blue cotton fiber dyeing is shown.

[0083] The synthetic method of blue cotton fiber dyestuff comprises:

[0084] Step 1. Use disperse blue 35 as the dye matrix, and put the dye matrix into a mixed solvent of tetrahydrofuran and water to completely dissolve it, thereby obtaining a reaction system;

[0085]In the mixed solvent of tetrahydrofuran and water, the mass ratio of tetrahydrofuran and distilled water is 3:1;

[0086] Further, disperse blue 35 adopts 0.001mol; here,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com