An automatic painting device for steel pipes

An automatic, steel pipe technology, applied to the surface coating liquid device, transportation and packaging, conveyor objects, etc., can solve the problem of manpower consumption, and achieve the effect of simple operation and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

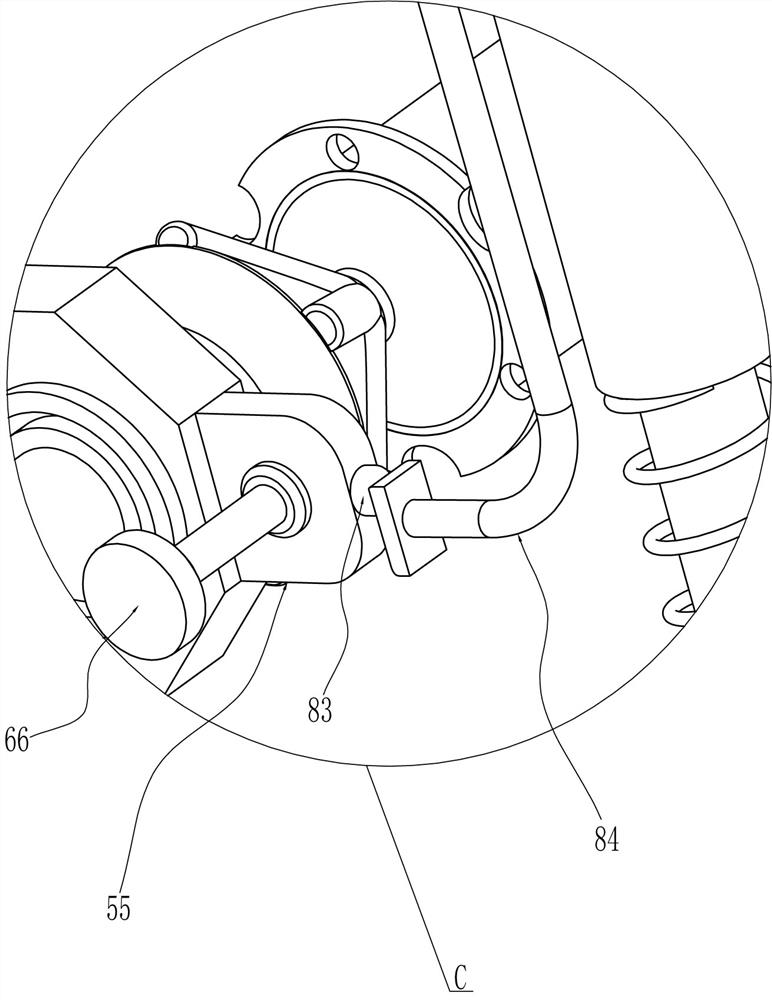

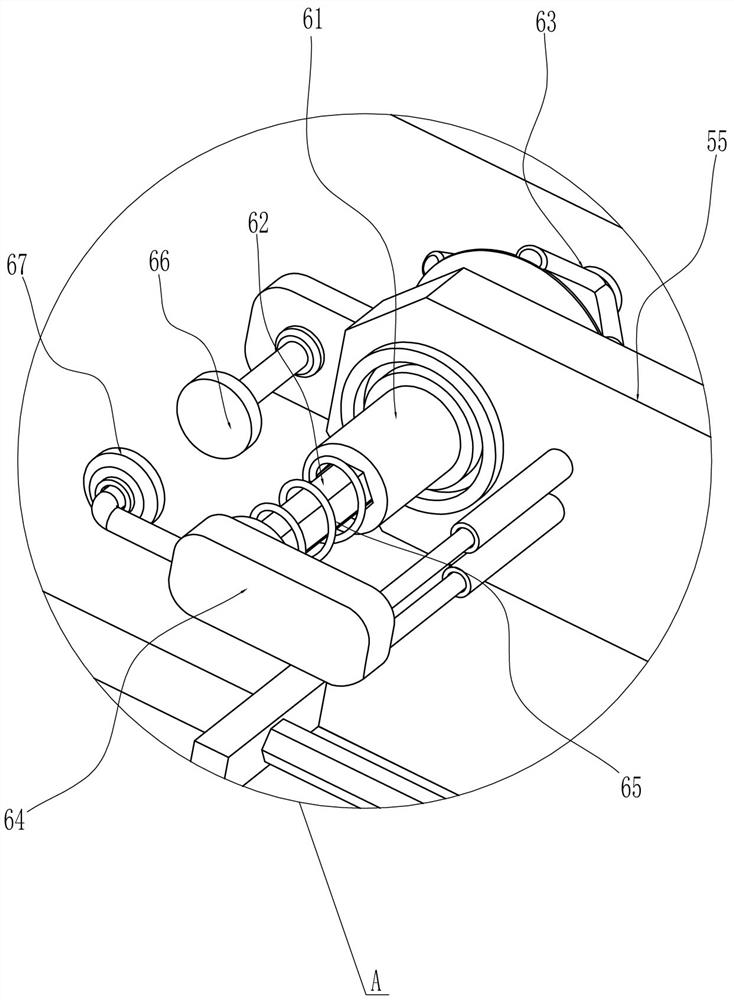

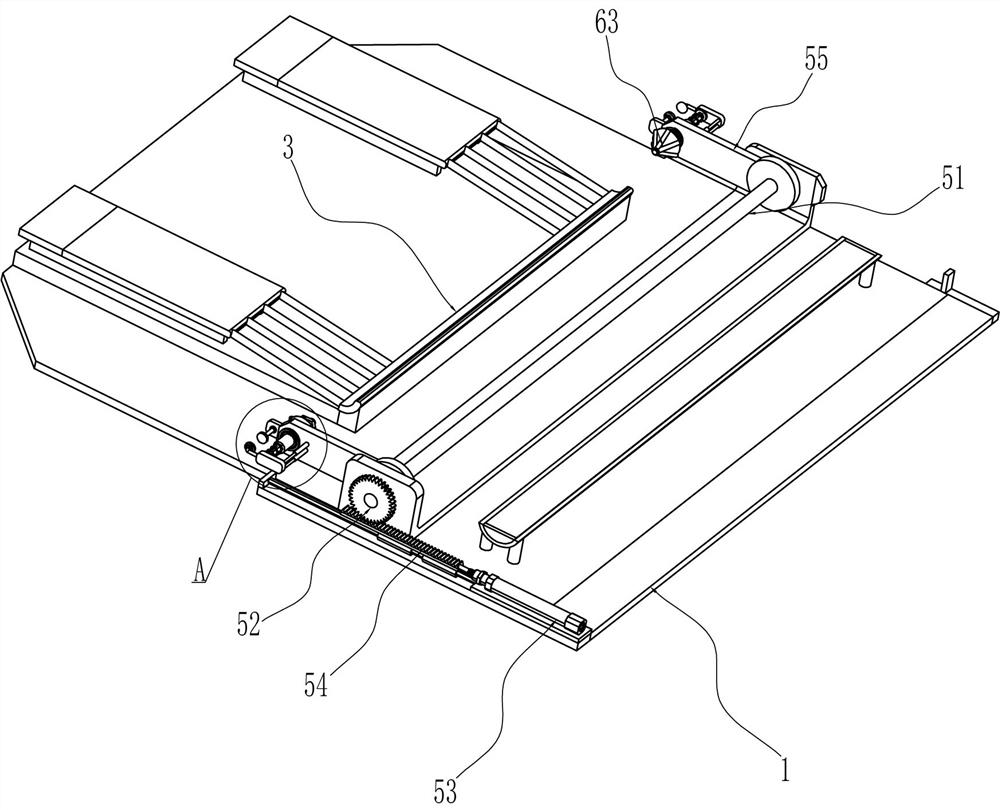

[0028] A steel pipe automatic painting device, such as Figure 1-3 As shown, it includes a base 1, a discharge ramp 2, an arc-shaped baffle 3 and a liquid storage frame 4. The rear side of the top of the base 1 is connected to a discharge ramp 2, and the front side of the discharge ramp 2 is connected to an arc-shaped stop. The plate 3 is connected to the liquid storage frame 4 on the front side of the top of the base 1, and also includes a driving assembly 5 and a clamping assembly 6. The base 1 is provided with the driving assembly 5, and the driving assembly 5 is provided with the clamping assembly 6.

[0029] The driving assembly 5 includes a first rotating shaft 51, a driving gear 52, a cylinder 53, a driving rack 54 and a mounting plate 55. The top of the base 1 on the rear side of the liquid storage frame 4 is rotatably connected to the first rotating shaft 51, and the left end of the first rotating shaft 51 A driving gear 52 is connected, a cylinder 53 is installed on ...

Embodiment 2

[0033] On the basis of Example 1, such as Figure 4-5 As shown, a rotating assembly 7 is also included, and the rotating assembly 7 includes a sector gear 71, a transmission gear 72, a transmission rack 73, a return spring 74, a second rotating shaft 75, a one-way clutch 76, a first cylindrical gear 77 and a second Cylindrical gear 78, sector gear 71 is connected to the right end of the first rotating shaft 51, transmission gear 72 is connected on the inner rhombic casing 61 on the right side, and transmission rack 73 is slidingly connected to the right side of the top of base 1, transmission gear 72 will be connected with transmission The gear rack 73 is meshed, and the transmission rack 73 is connected with the back spring 74 between the base 1. The right side of the base 1 is rotatably connected with the second rotating shaft 75, and the second rotating shaft 75 is connected with a one-way clutch 76. On the one-way clutch 76 A first cylindrical gear 77 is connected, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com