Padding system of continuous pigment dyeing padding mangle

A paint dyeing and pad dyeing machine technology, applied in the direction of dyeing method, textile material processing, fabric elongation, etc., can solve the problems of dispersion, insufficient compactness and reasonableness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

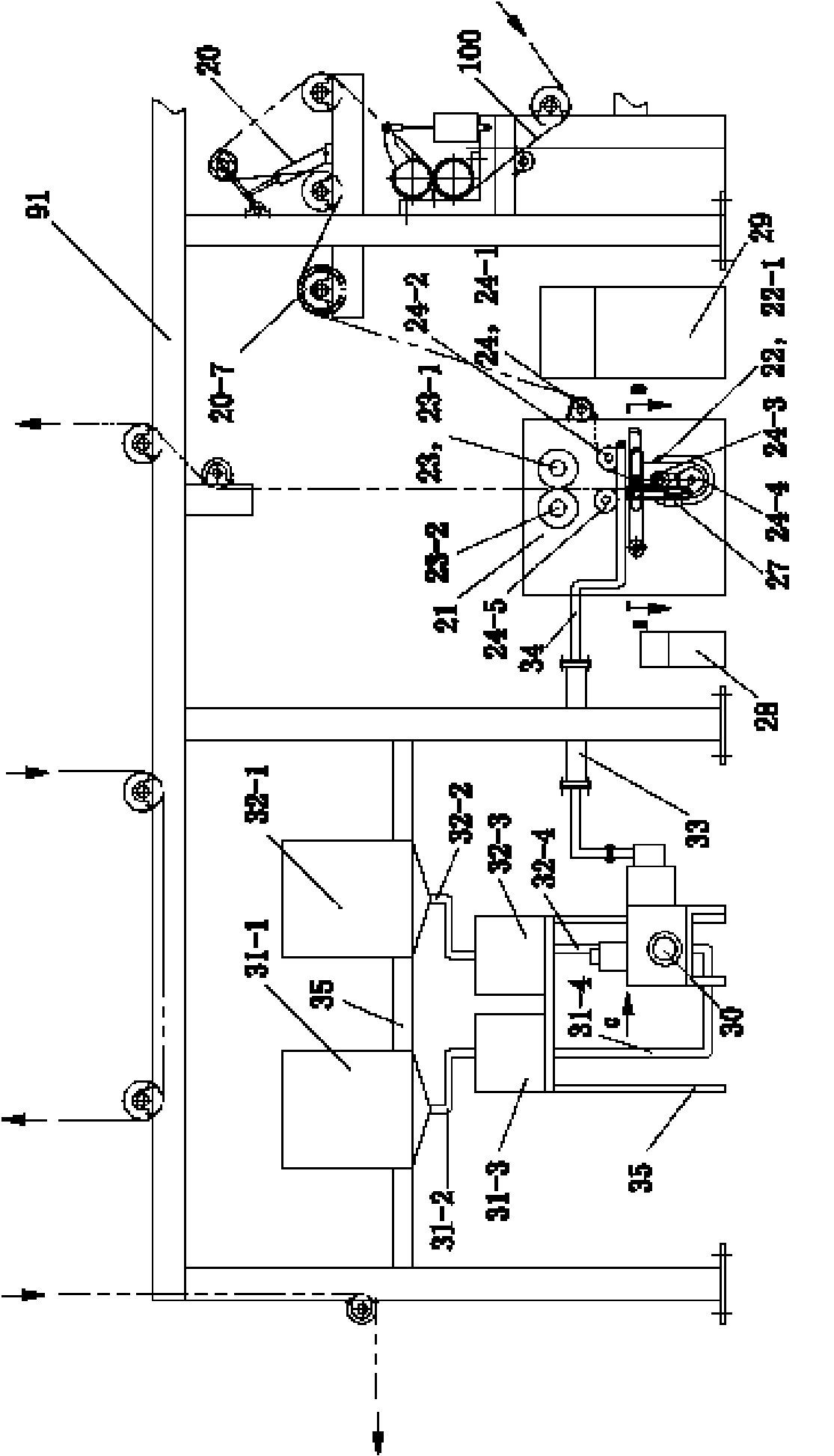

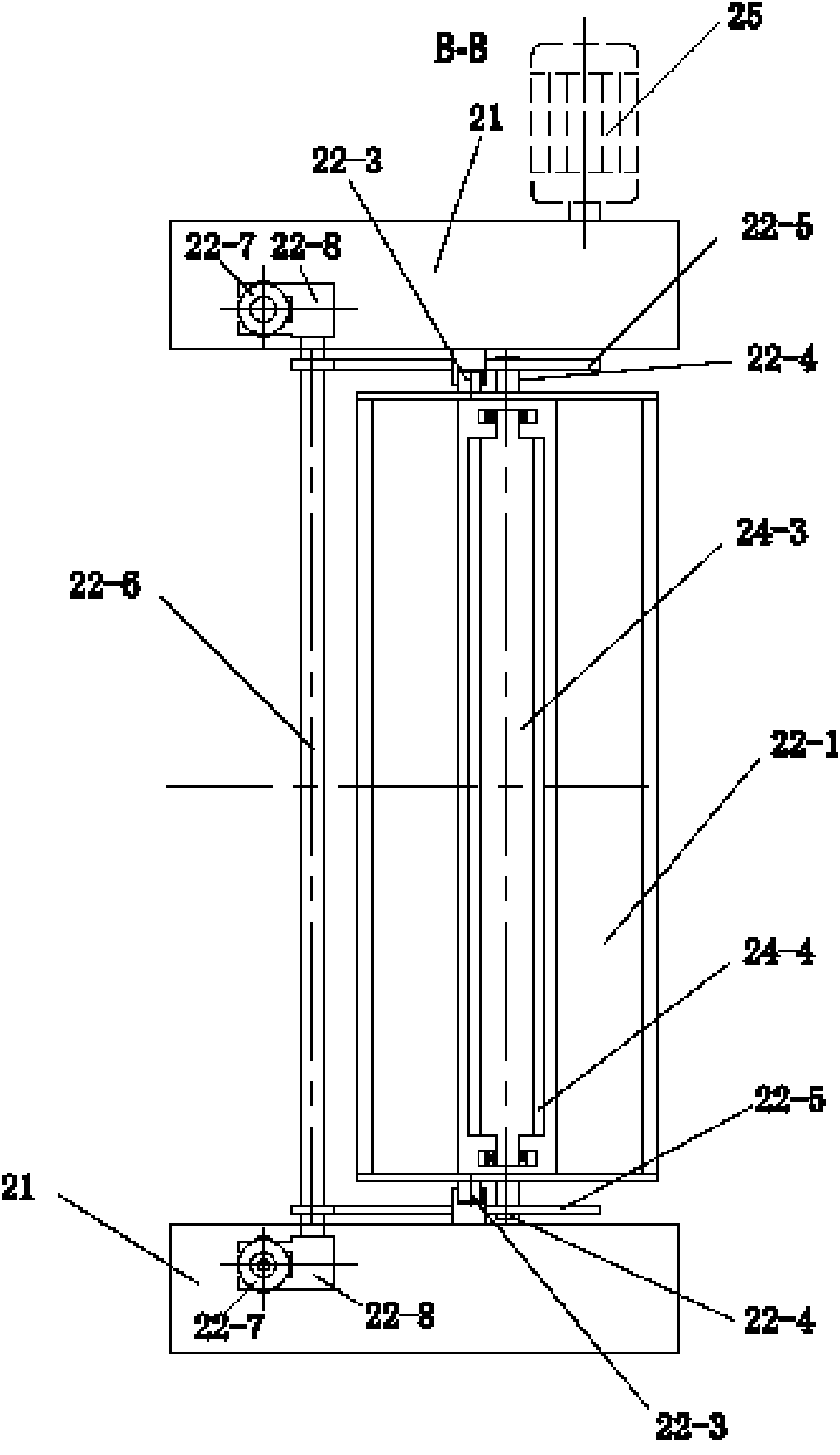

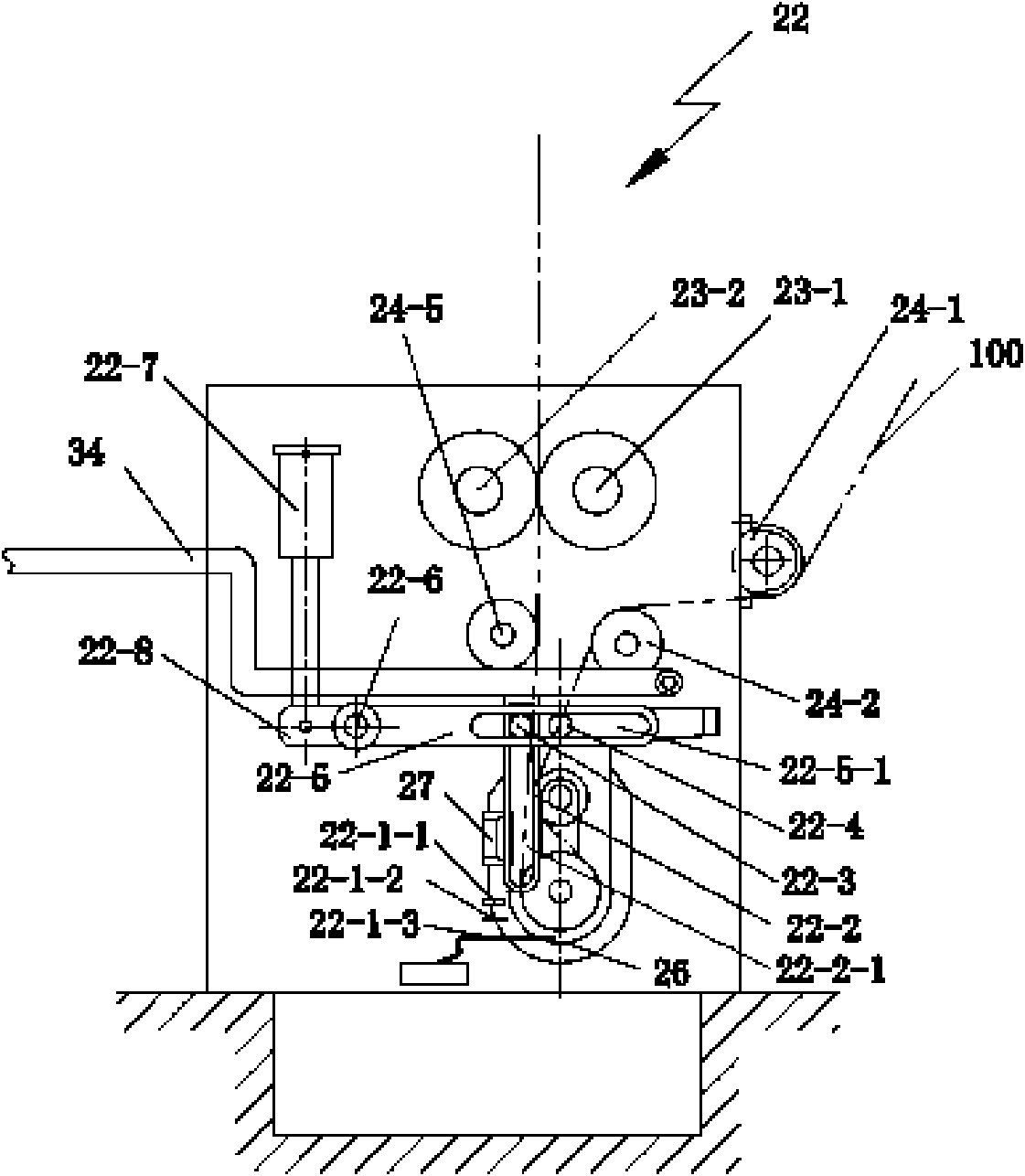

[0050] See figure 1 , The padding system of this embodiment includes a first stand 91, a padding device 2, a proportional liquid supply device 3, a cooling water pump, a main compressed air valve and an electric control box. The padding device 2 includes a first tension adjustment mechanism 20 , an open-width drum 20 - 7 , a uniform rolling car, a uniform rolling car control box 29 and an ultrasonic generator 28 . The proportional liquid supply device 3 includes a two-way liquid supply device.

[0051] The electric control box includes a programmable controller, a switch circuit and 2 frequency converters. The detection signal input end of the programmable controller includes the dipping tank temperature signal input end, the dipping tank liquid level signal input end and the first angle signal input end; the control signal output end of the programmable controller includes a switch circuit control signal Output terminal and 2 frequency conversion control signal output termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com