Ultrashort-flow rolling steaming dyeing process and equipment

A process method and technology of dyeing equipment, which are applied in the field of ultra-short process pad dyeing process methods and equipment, can solve problems such as dye migration, and achieve the effects of reducing dye consumption, saving labor, and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

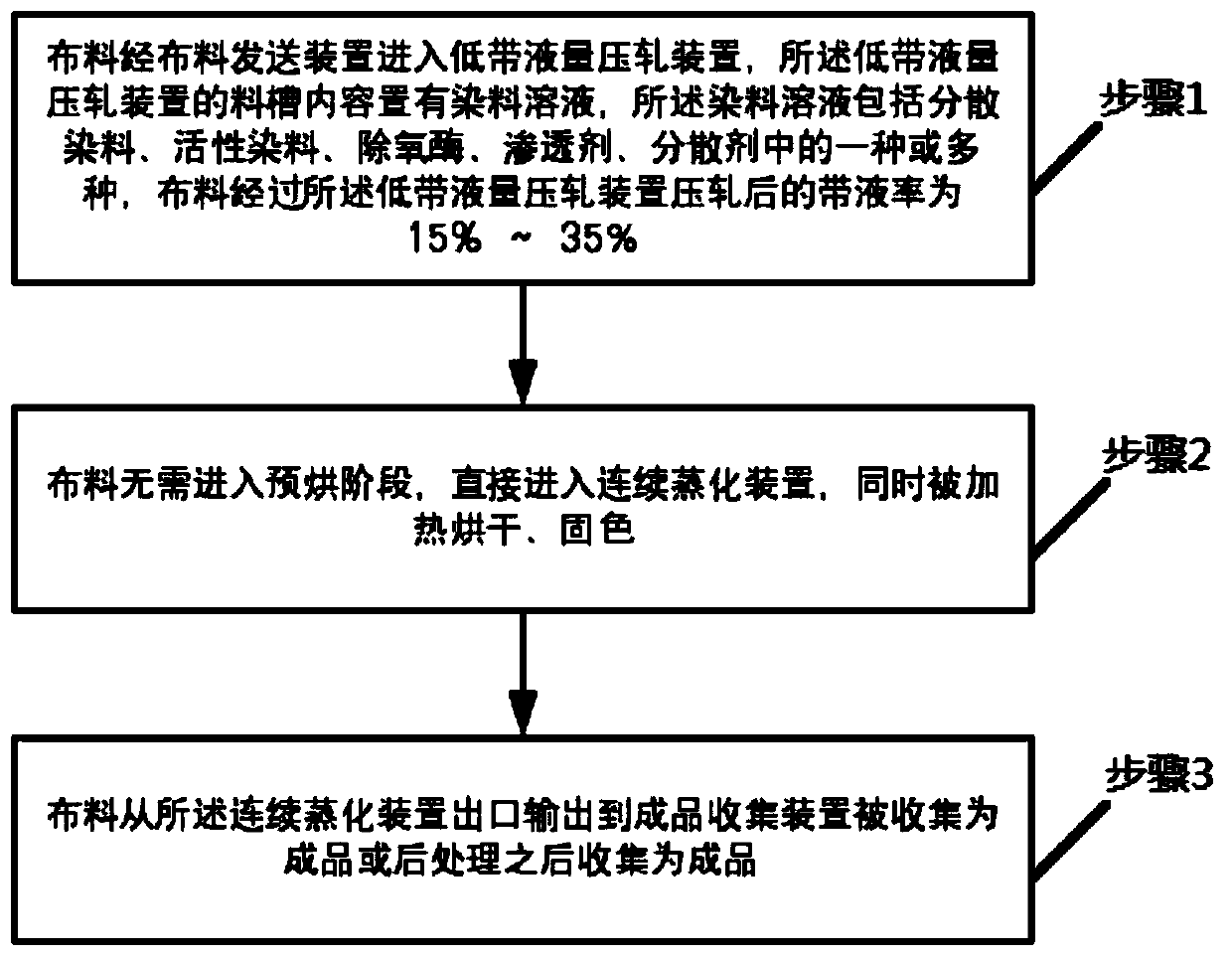

[0054] see figure 1 , an ultra-short flow pad-steam dyeing process method provided in this embodiment includes:

[0055] Step 1, the cloth enters the low-carrying liquid rolling device 2 through the cloth sending device 1, and a dye solution is placed in the trough of the low-carrying liquid rolling device 2, and the dye solution includes disperse dyes, reactive dyes, One or more of oxygen enzyme, penetrating agent, and dispersant, and the entrainment rate of the cloth after being rolled by the low-entrainment rolling device 2 is 15% to 35%;

[0056] Step 2, the cloth enters the continuous steaming device 4, and is heated and dried at the same time to fix the color;

[0057] Step 3, the cloth is output from the outlet of the continuous steaming device 4 to the finished product collection device 5 to be collected as a finished product or collected as a finished product after post-processing.

[0058] What needs to be explained is that the ultra-short-flow pad-steam dyeing pro...

Embodiment 2

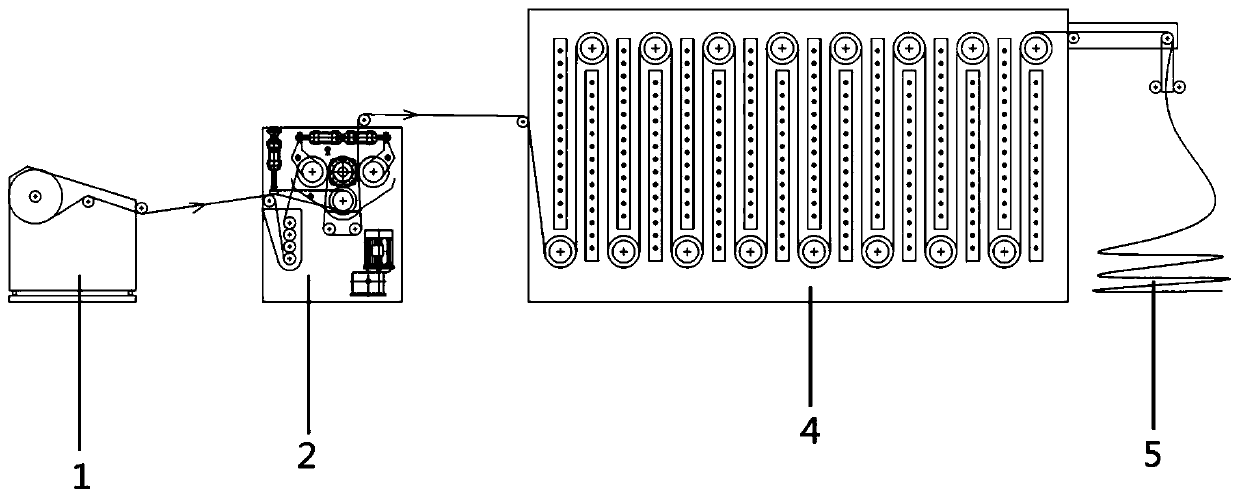

[0173] This embodiment provides a continuous dyeing equipment for quantitatively applying auxiliary agents, including at least:

[0174] Cloth sending device 1, low liquid volume rolling device 2, continuous steaming device 4, finished product collecting device 5 or / and post-processing device;

[0175] The low liquid volume rolling device 2 is a quantitative coating rolling device; the continuous steaming device 4 is a continuous steaming device 4 composed of one or more heating wheels 21, or is formed by a tenter setting machine or a heating steamer. A continuous steaming device 4 composed of a steaming oven.

[0176] Further, a second rolling device 3 is also provided between the low-volume rolling device 2 and the continuous steaming device 4;

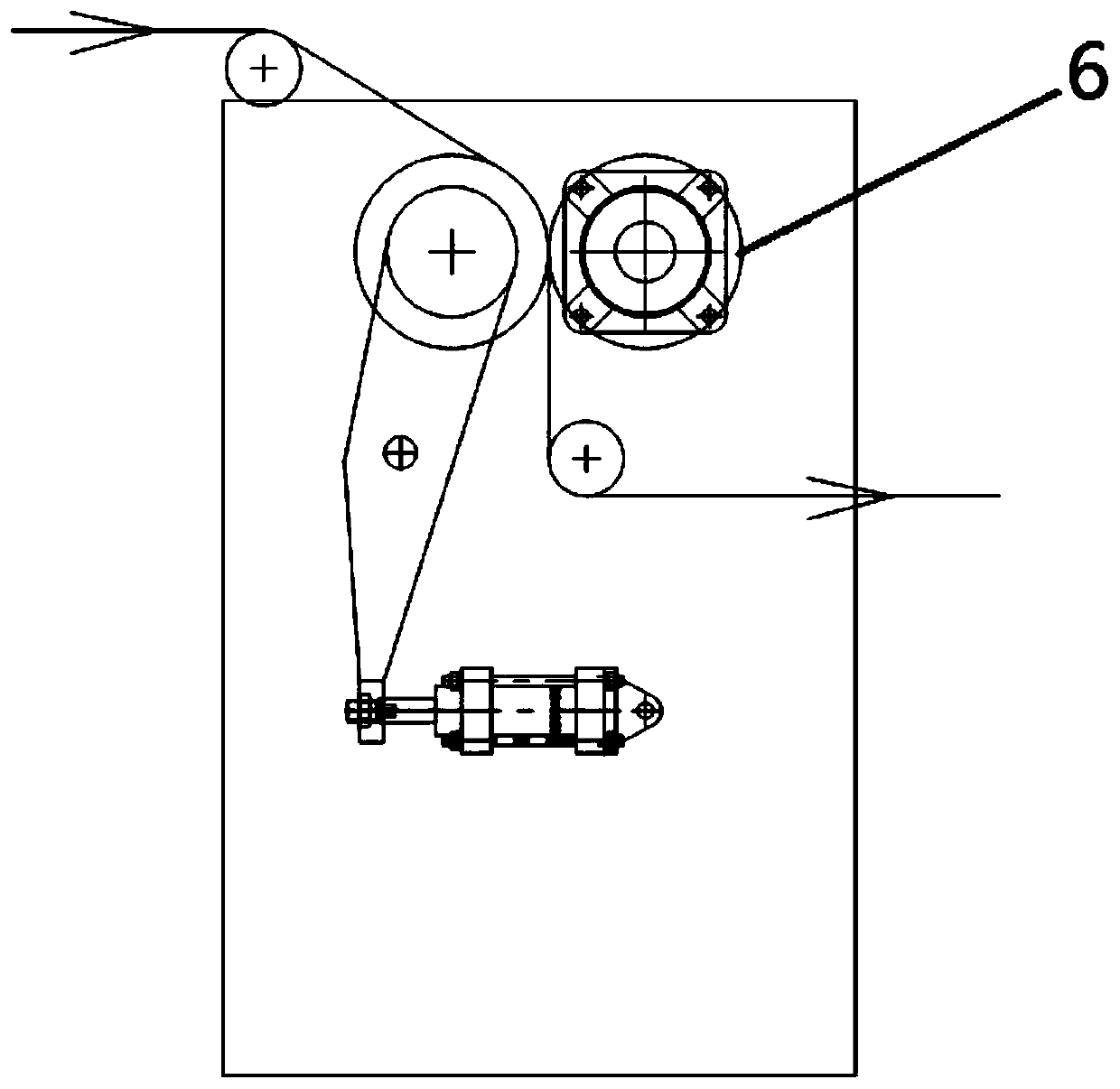

[0177] The second rolling device 3 is a quantitative coating rolling device, and the quantitative coating rolling device is a single-sided, double-sided rotary screen printing and rolling device, or a single-sided, Double-sided co...

Embodiment 3

[0250] This embodiment provides a kind of ultra-short process pad steam dyeing equipment, comprising:

[0251] Frame, cloth sending device 1 for sending cloth, cloth guide wheel device, low liquid volume rolling device 2, second rolling device 3, continuous steaming device 4 and finished product collecting device 5; The volume rolling device 2 and the second rolling device 3 are rolling devices continuously arranged on the same stand, and the rolling device at least includes the first roll 10, the Two rolls 11, the third roll 12, and the fourth roll 13, the first roll 10 and the second roll 11 form the low-band liquid rolling device 2, the second roll 11 and the third roll The roll 12 or the third roll 12 and the fourth roll 13 form the second rolling device 3, and the second rolling device 3 is the quantitative coating rolling device of the present invention; the first The bottom of the roll 10 is provided with a trough for accommodating liquid dyes or functional coatings, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com