Modified polyester and wool blended fabric and preparation method thereof

A technology for modifying polyester and blended fabrics, used in textiles, fabrics, textiles and papermaking, etc., can solve the problems of large batch requirements, unfavorable energy saving and emission reduction, long dyeing process, etc. The effect of high strength and high tensile elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Example 1: Fabric Product One

[0094] Yarn: Warp - Modified Polyester / Wool 50 / 5020 S

[0095] Weft - Wool 20 S

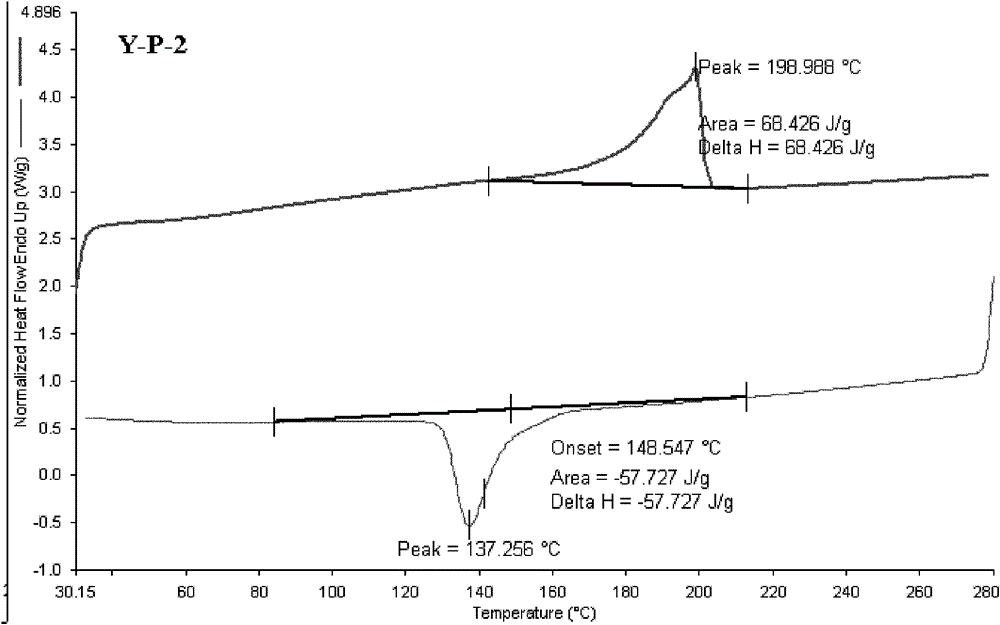

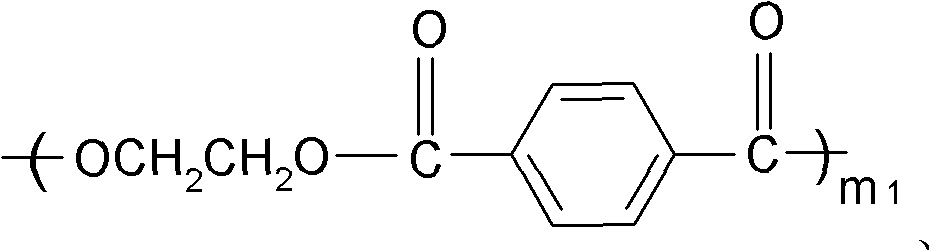

[0096] The structural formula of the modified polyester has the following structural units:

[0097]

[0098] where 101 2 3 4 <5.

[0099] Fabric structure: basic organization——A: four pieces of warp surface broken twill; B: four pieces of weft surface broken twill dobby weaving, A and B tissue form a rectangular lattice distribution on the fabric.

[0100] Process flow: Prepared according to the preparation method of blended fabrics commonly used in this field, the process flow includes warping - sizing - drawing and reeding - weaving - gray cloth - dyeing and finishing - finished product

[0101] The woven fabric is dyed using four schemes to obtain different fabric effects.

[0102] Dyeing scheme (1): Dyeing with acid dyes only

[0103] Dyeing process:

[0104] Ellinier black AM-R2.0%, leveling agent 0.5g / L,

[0105] Glacial acetic acid ...

Embodiment 2

[0127] Example 2: Fabric Product Two

[0128] Combination of fabric raw materials: warp yarn - modified polyester 20 S

[0129] Weft - Wool 20 S

[0130] The structural formula of the modified polyester has the following structural units:

[0131]

[0132] where 101 2 <70.

[0133] The organizational structure is the same as that of fabric products.

[0134] Process flow: Prepared according to the preparation method of blended fabrics commonly used in this field, the process flow includes warping - sizing - drawing and reeding - weaving - gray cloth - dyeing and finishing - finished product

[0135] Dyeing scheme (1): only one kind of fiber is dyed

[0136] Dyeing process: disperse black ATT 2.3%, leveling agent 0.4g / L

[0137] Glacial acetic acid + sodium acetate to adjust pH to 5.0

[0138] Dye at 40°C, heat up to boiling at 2°C / min, and keep warm for 30 minutes.

[0139] Fabric effect: the warp yarn is dyed black, and the weft yarn is not dyed whit...

Embodiment 3

[0147] Example 3: Fabric Product Three

[0148] Combination of raw materials: warp yarn: armor yarn - modified polyester 32 S

[0149] B yarn - wool 32 S

[0150] Acrylic yarn - modified polyester / wool 50 / 5032S

[0151] Warp arrangement - A 2 C 72 B 10 C 72

[0152] Weft yarn - modified polyester / wool 50 / 5032 S

[0153] The structural formula of the modified polyester has the following structural units:

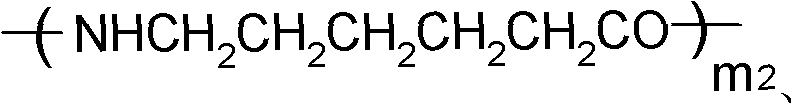

[0154]

[0155]

[0156] where 101 2 4 <5.

[0157] Fabric structure: plain weave

[0158] Process flow: Prepared according to the preparation method of blended fabrics commonly used in this field, the process flow includes warping - sizing - drawing and reeding - weaving - gray cloth - dyeing and finishing - finished product

[0159] Dyeing scheme (1): Dyeing with disperse dyes only

[0160] Acid black ATT 1.8%, leveling agent 0.5g / L

[0161] Glacial acetic acid + sodium acetate to adjust pH to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com