Continuous pigment dyeing pad dyer with infrared pre-baking apparatus

A paint dyeing and infrared technology, which is applied in the continuous processing of textile materials, drying machines, dyeing methods, etc., can solve the problems of large steam activity space, fabric damage, and large external heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

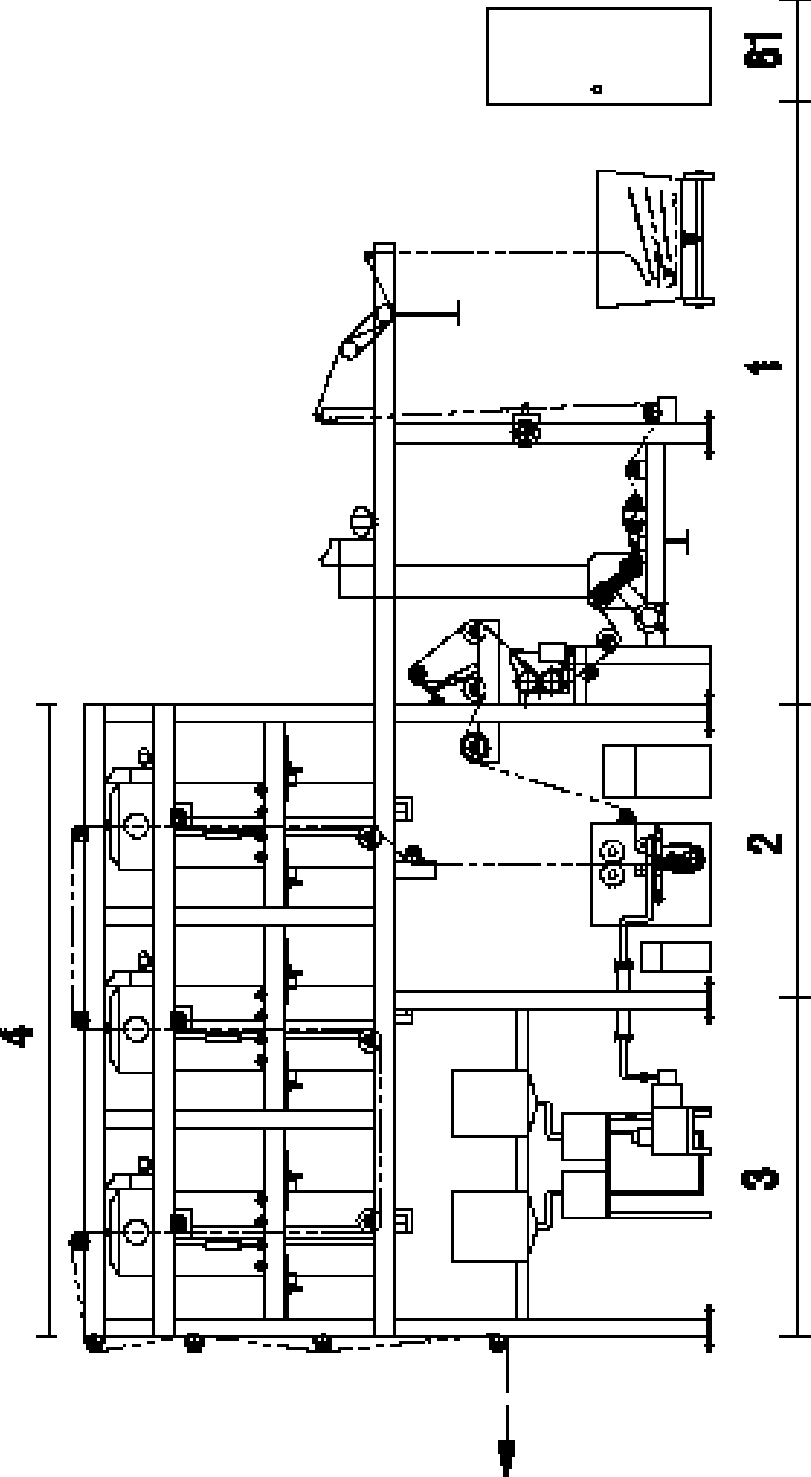

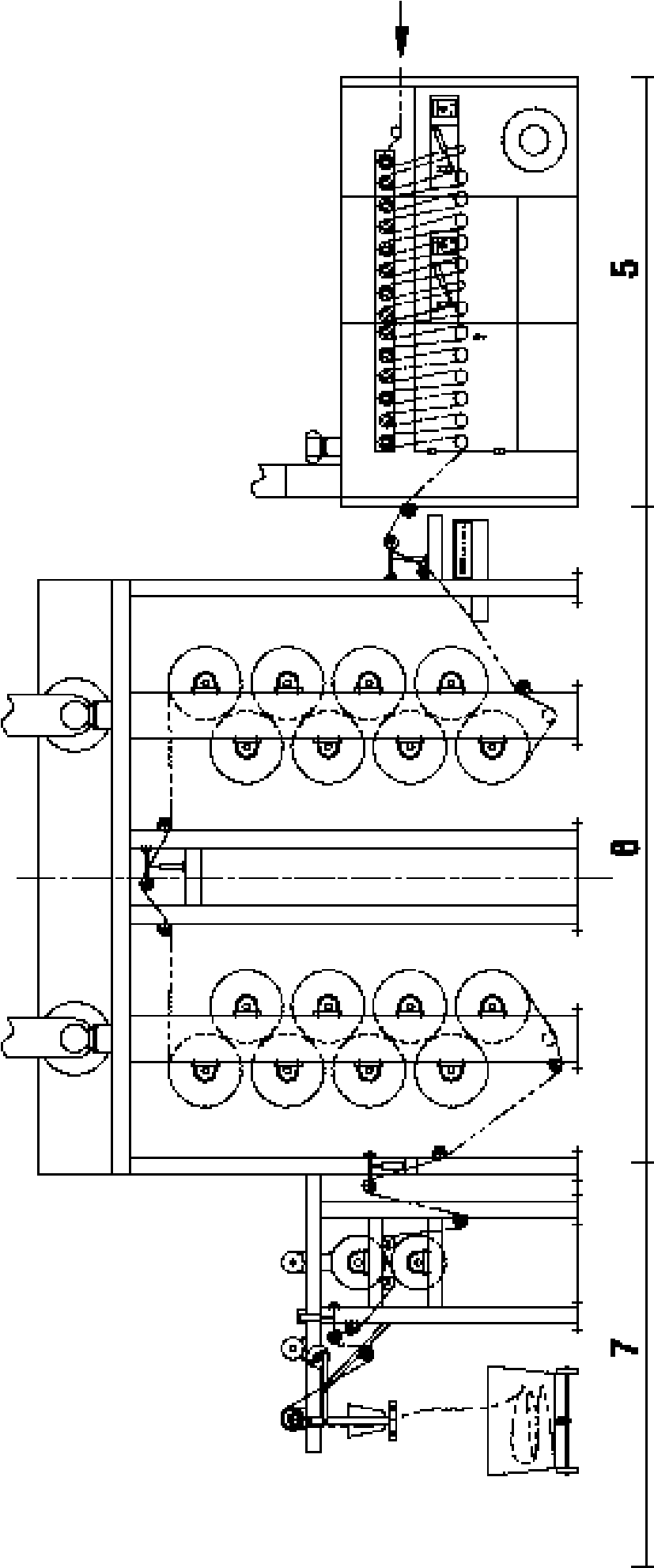

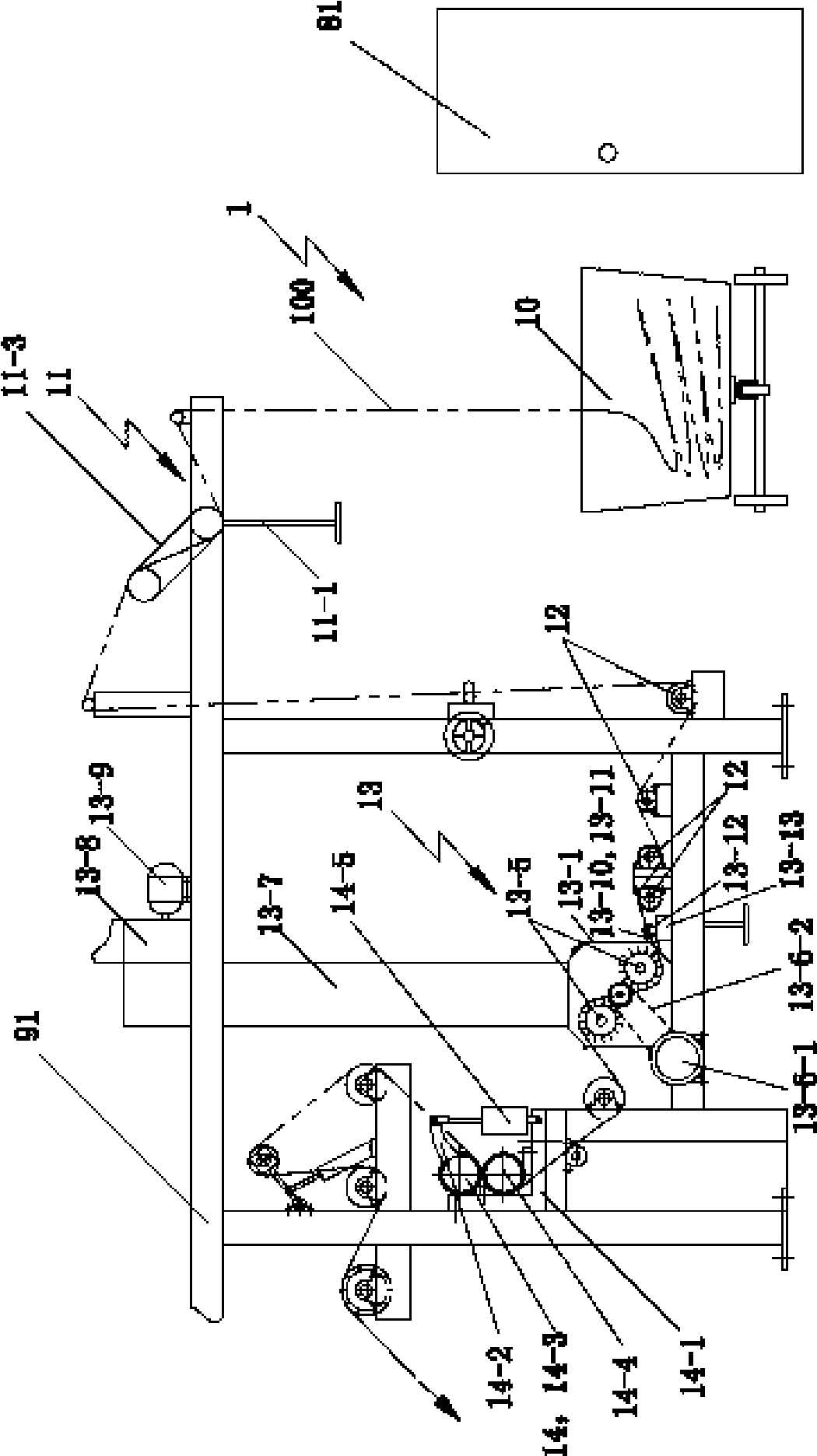

[0182] Seefigure 1 and figure 2 , the continuous paint dyeing and padding machine of the present embodiment comprises a cloth feeding pretreatment device 1, a padding system, a drying system and a cloth discharging processing device 7 arranged sequentially according to the process sequence; it also includes a main compressed air valve, an electric control box 81. The first rack 91 and the second rack 92. The drying system includes an infrared pre-drying device 4 , a hot air pre-drying device 5 and a steam drying device 6 arranged in sequence. Both the cloth feeding pretreatment device 1 and the infrared pre-drying device 4 are installed on the first frame 91 , and the steam drying device 6 and the cloth output processing device 7 are installed on the second frame 92 .

[0183] The electric control box 81 includes a programmable controller, a man-machine dialogue device, various switching circuits and various frequency converters. Both the programmable controller and the hum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com